Sporting shoes outer sole

A technology for shoe outsoles and sports shoes, applied in the field of shoe outsoles, can solve the problems of hard contact between feet and the ground, reduced stability, discomfort, etc., and achieve the effect of avoiding leverage and reducing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

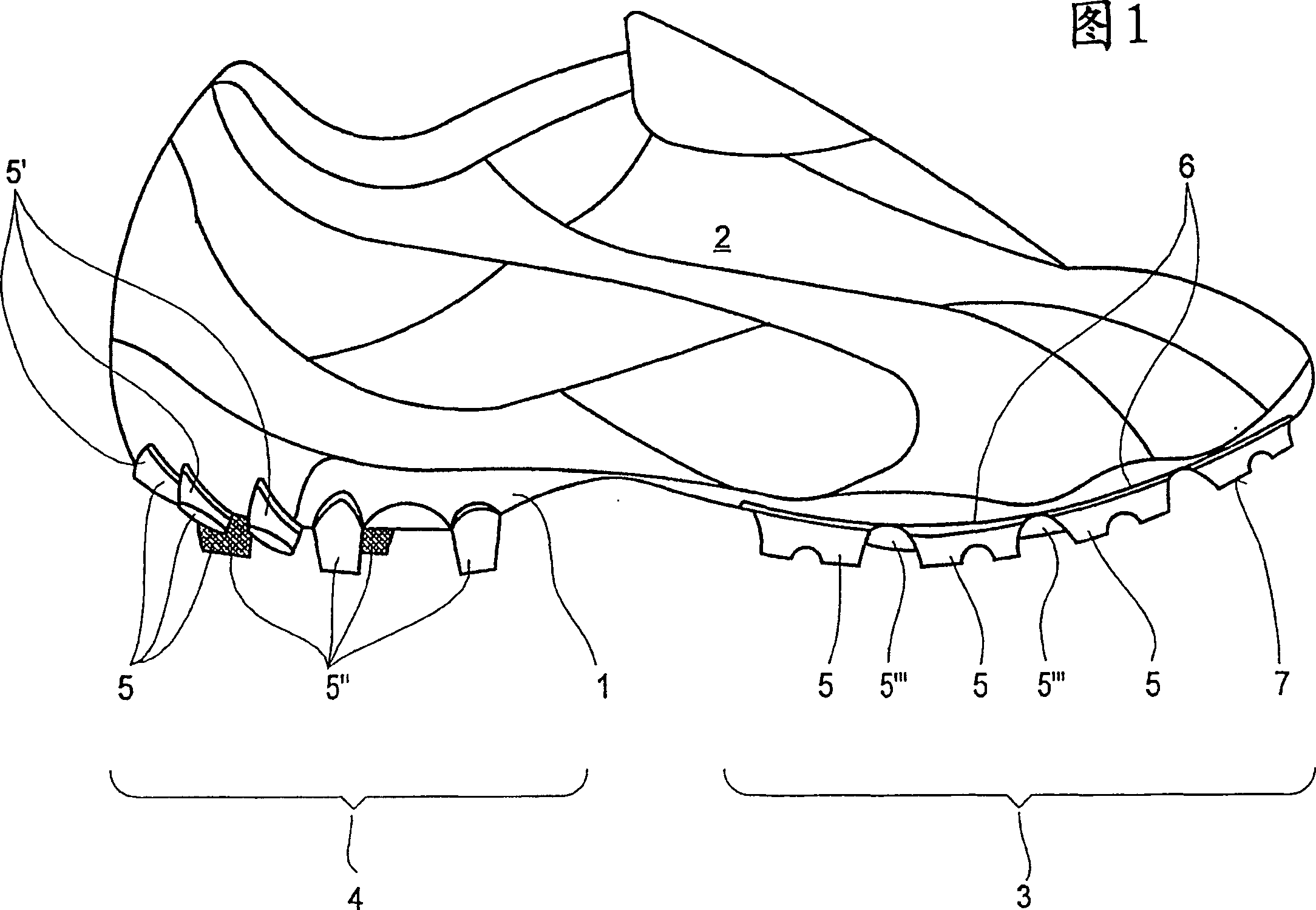

[0025] FIG. 1 shows a sneaker 2 for the left foot in side view. It has an outsole 1 on the underside of which a plurality of studs 5, 5', 5", 5'' are arranged. These studs 5 to 5'' are used when the outsole 1 is injection-molded Co-injection molding process injection molding is formed on the outsole 1 of the shoe.

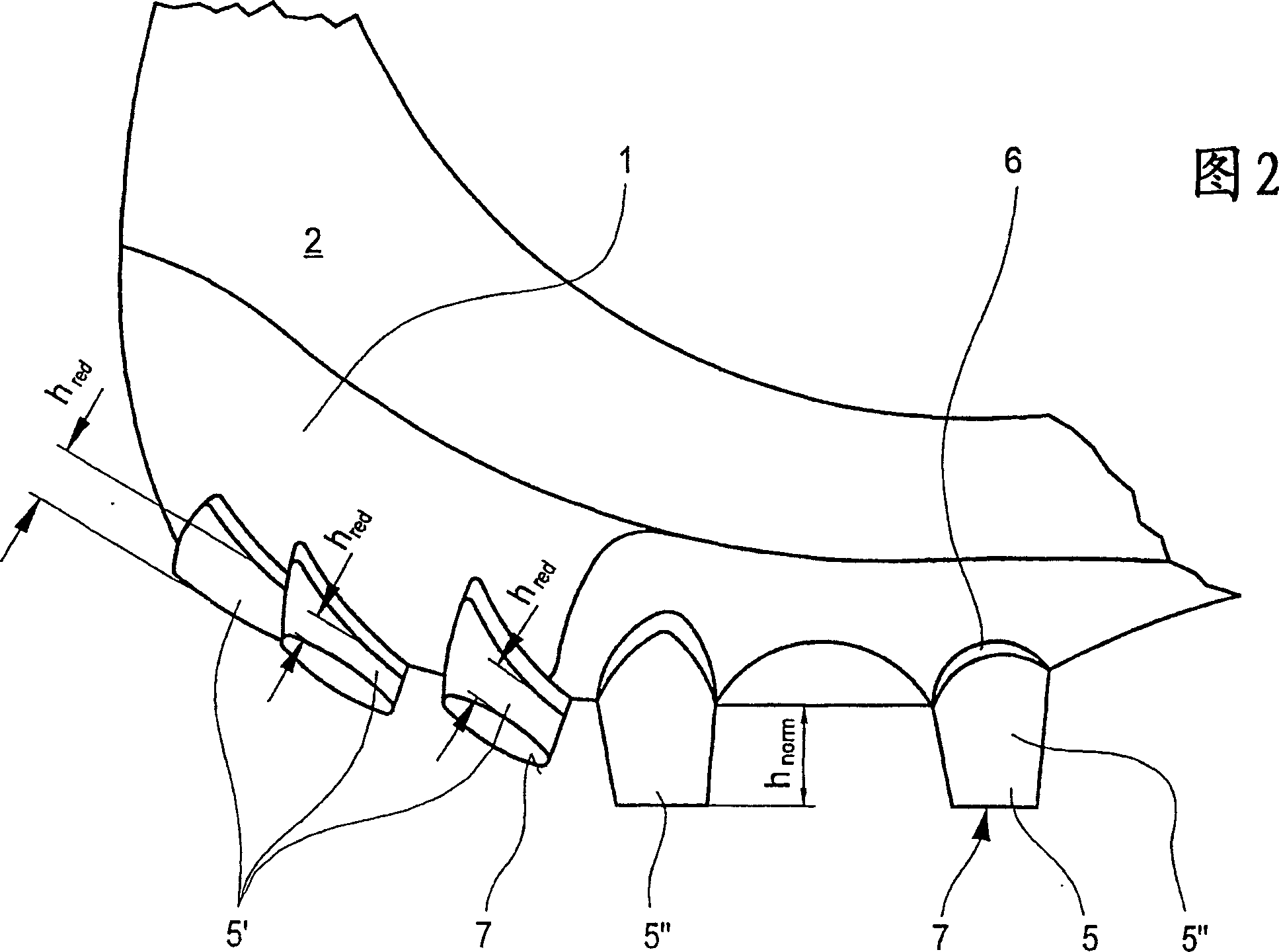

[0026] The studs 5, 5', 5", 5'' or parts thereof are arranged in the front sole region 3 and the heel region 4 of the outsole 1. They have a base 6 from which they face the studs Touching the ground 7 is conically tapered.

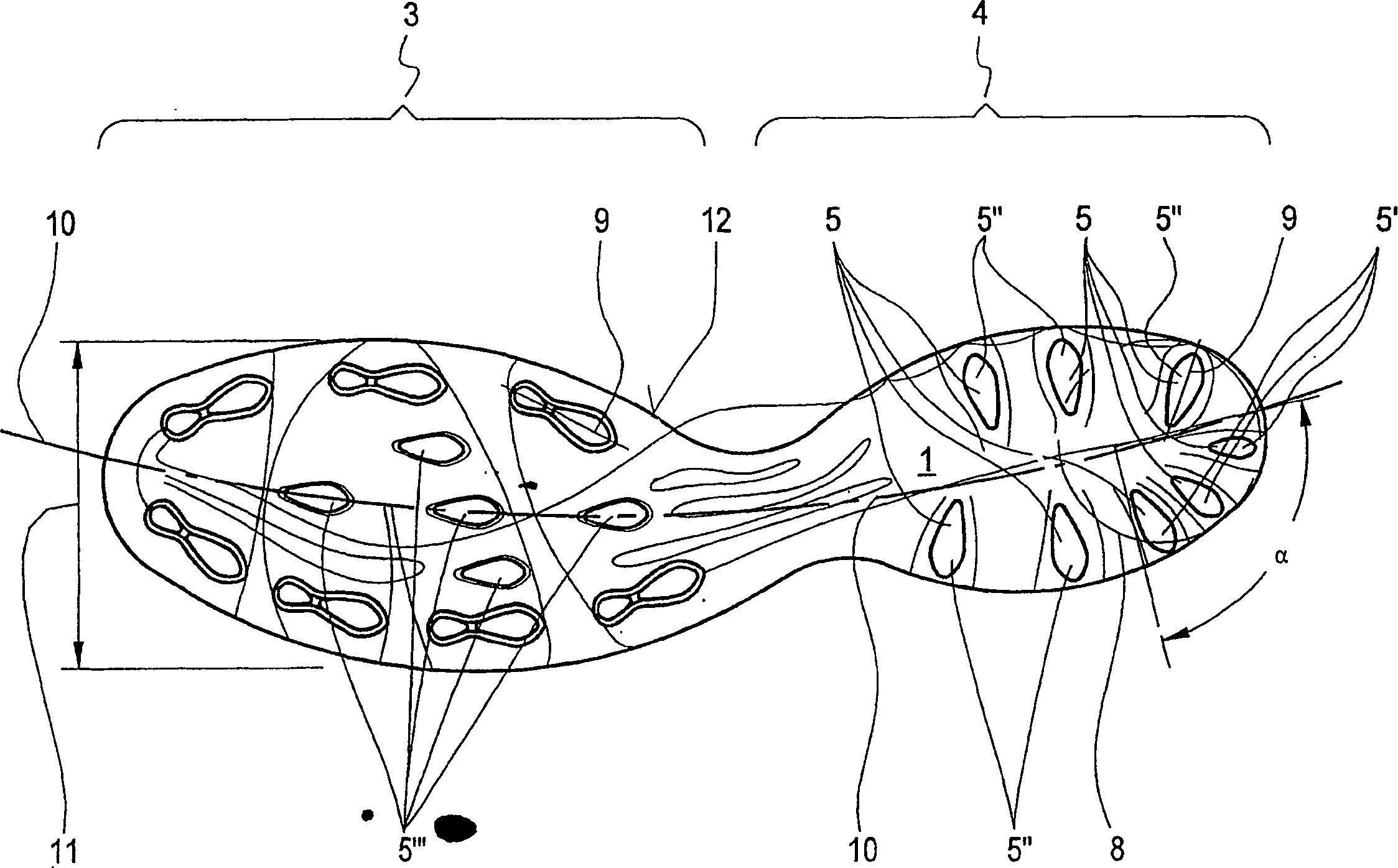

[0027] In cross-section, like the stud base 6, the studs 5, 5', 5", 5'' have an elongated shape, preferably an elliptical or roughly elliptical shape, such as image 3 shown. In the front sole region 3 , the studs 5 are arranged along a sole edge region 12 , the longitudinal axis 9 of which extends in the direction of this sole edge region 12 . In contrast, in the heel region 4 the studs 5 are arranged in the sole edge region 12 such that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com