Manganese dry battery

A technology of manganese dry battery and negative electrode, which is applied in the field of manganese dry battery and can solve problems such as electrolyte leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

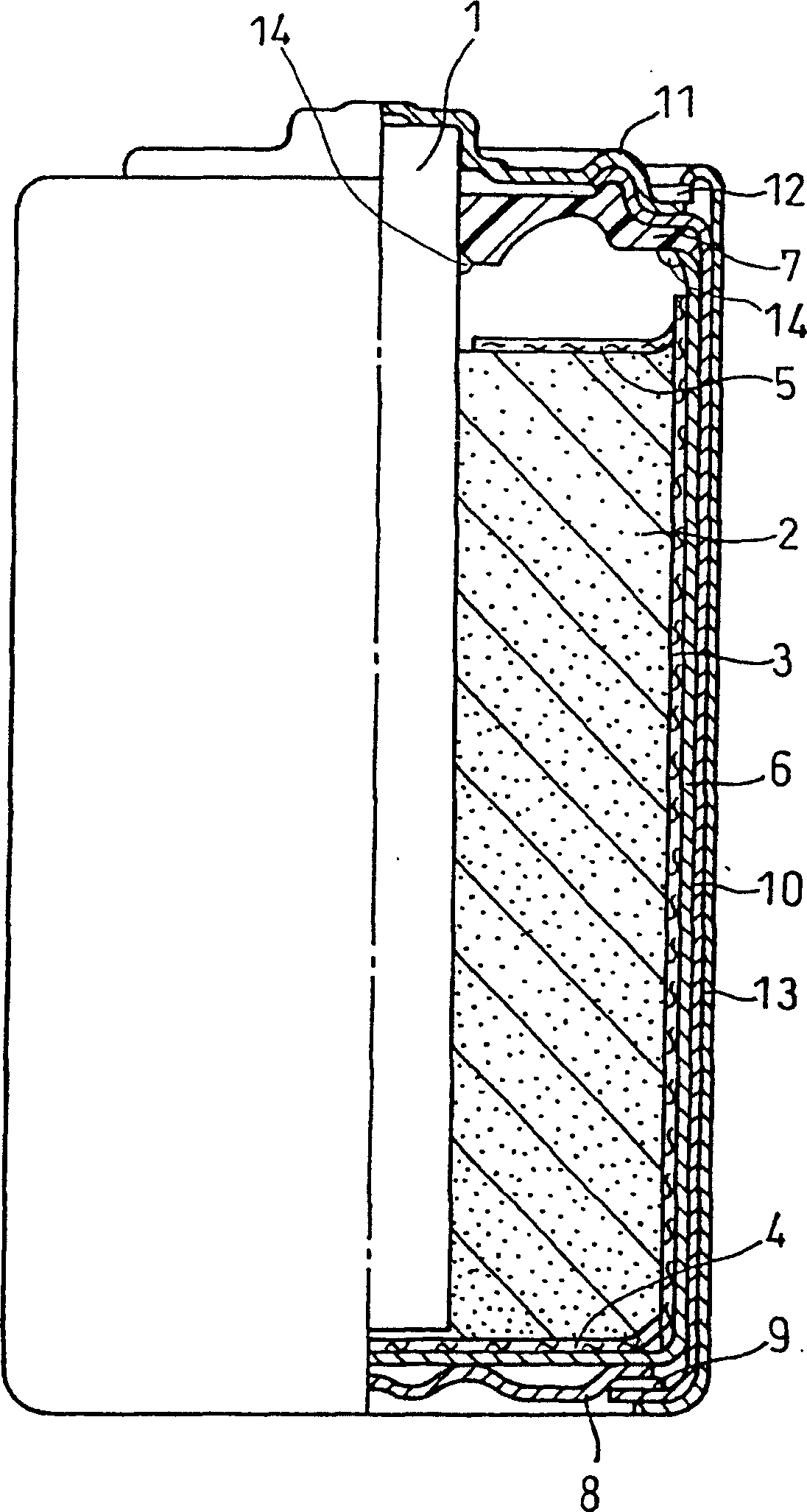

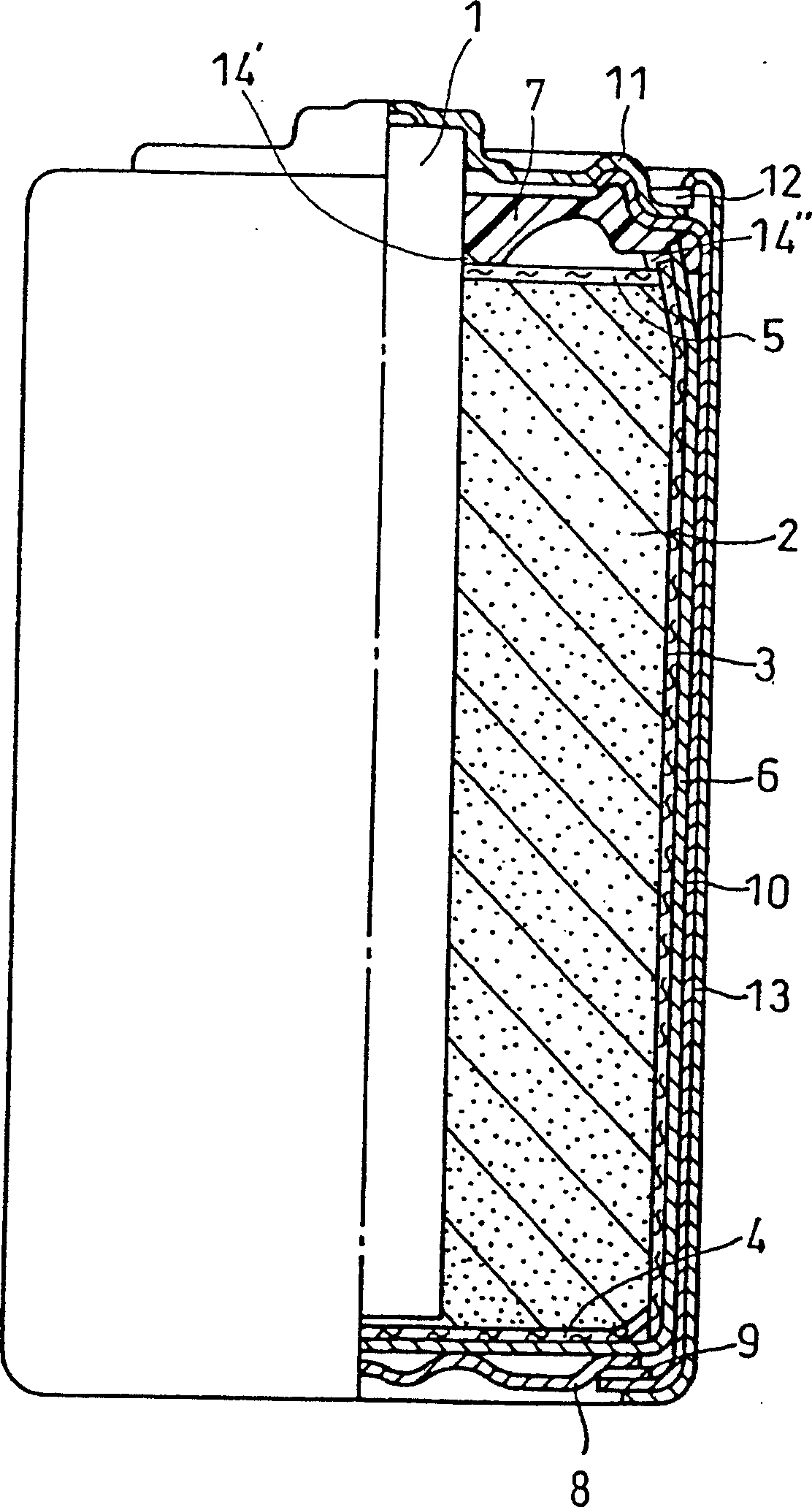

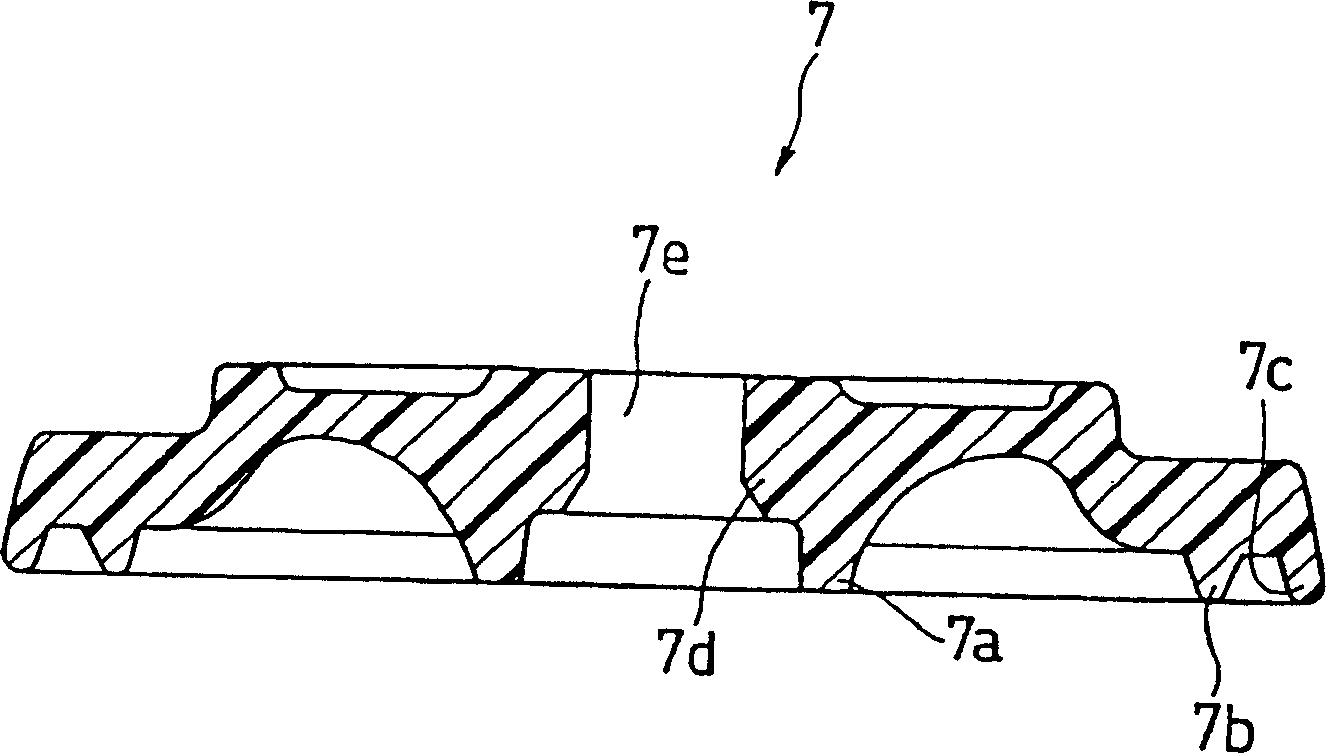

[0034] In this embodiment, the system has Figure 4 The manganese dry battery of the present invention of the structure shown. First of all, it is made of polyethylene by injection molding with image 3 The sealing body 7 of the structure shown.

[0035]Next, a base paper 4 made of kraft paper is placed on the bottom of the negative zinc shell 6, and then a separator 3 made by coating a paste with a starch with good liquid retention properties on the kraft paper is placed on the inner side. Then, a positive electrode mixture 2 composed of a mixture of manganese dioxide, a conductive agent, and an electrolyte is inserted inside the separator 3. The upper surface of the positive electrode mixture 2 is covered with a protective plate 5 made of kraft paper with a hole for inserting the positive electrode carbon rod 1 in the center.

[0036] On the other hand, the positive electrode carbon rod 1 is inserted into the sealing body 7 and the sealant pitch is applied to the groove 7f formed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap