Concentric double-pipe hoisting jack

A vertical drive and casing string technology, applied in earthwork drilling, wellbore/well components, logic circuits, etc., can solve problems such as difficult installation and complicated devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

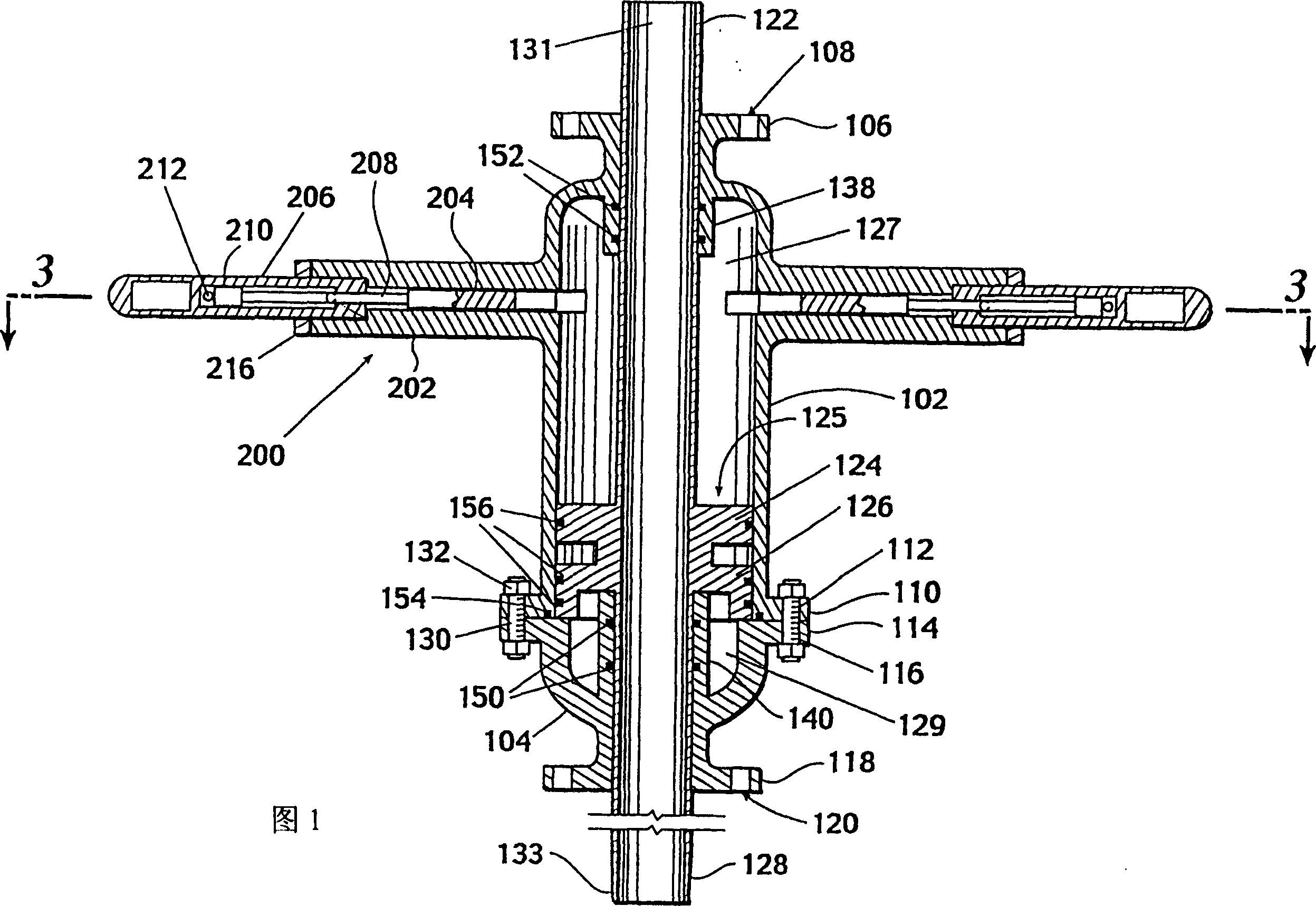

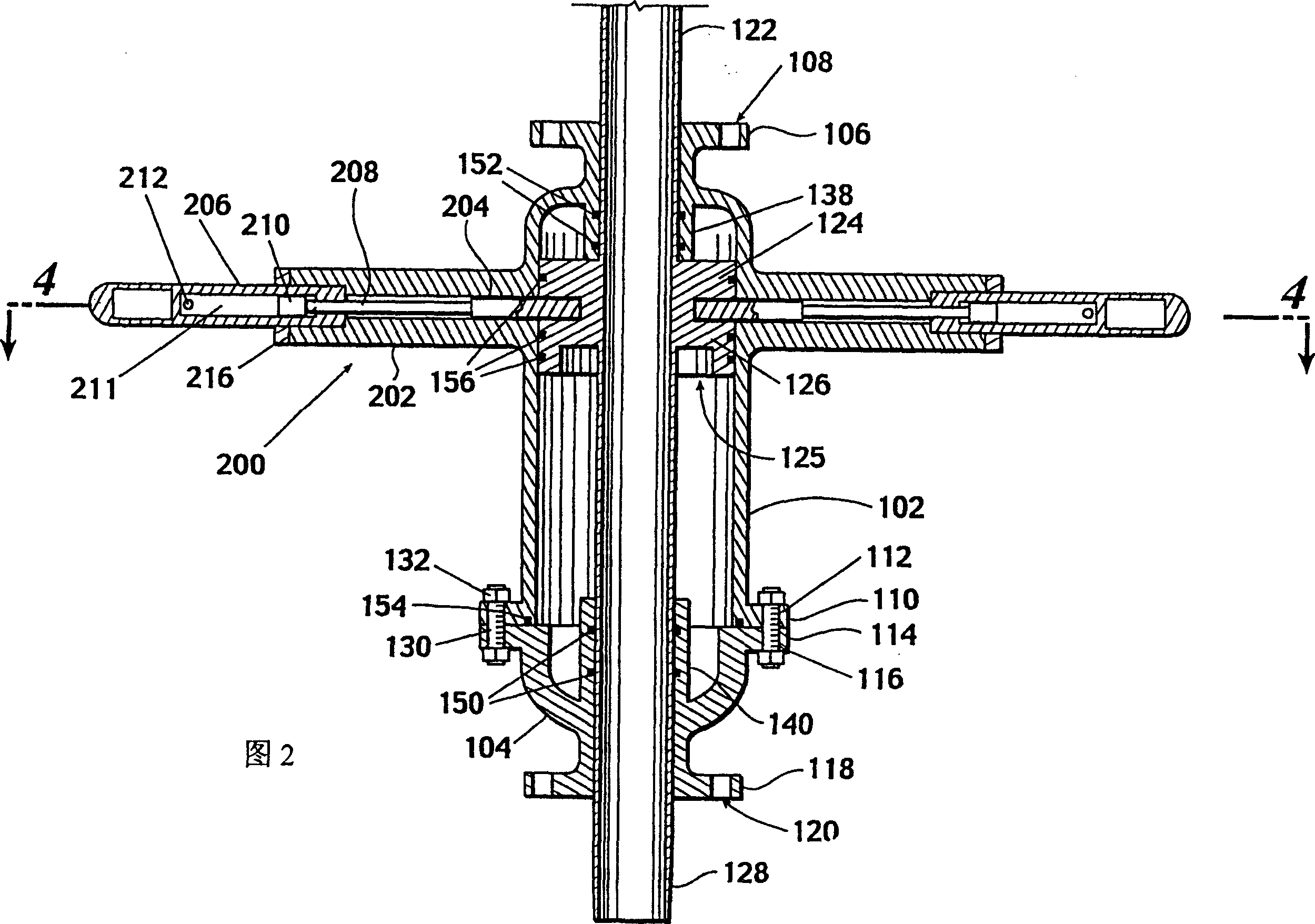

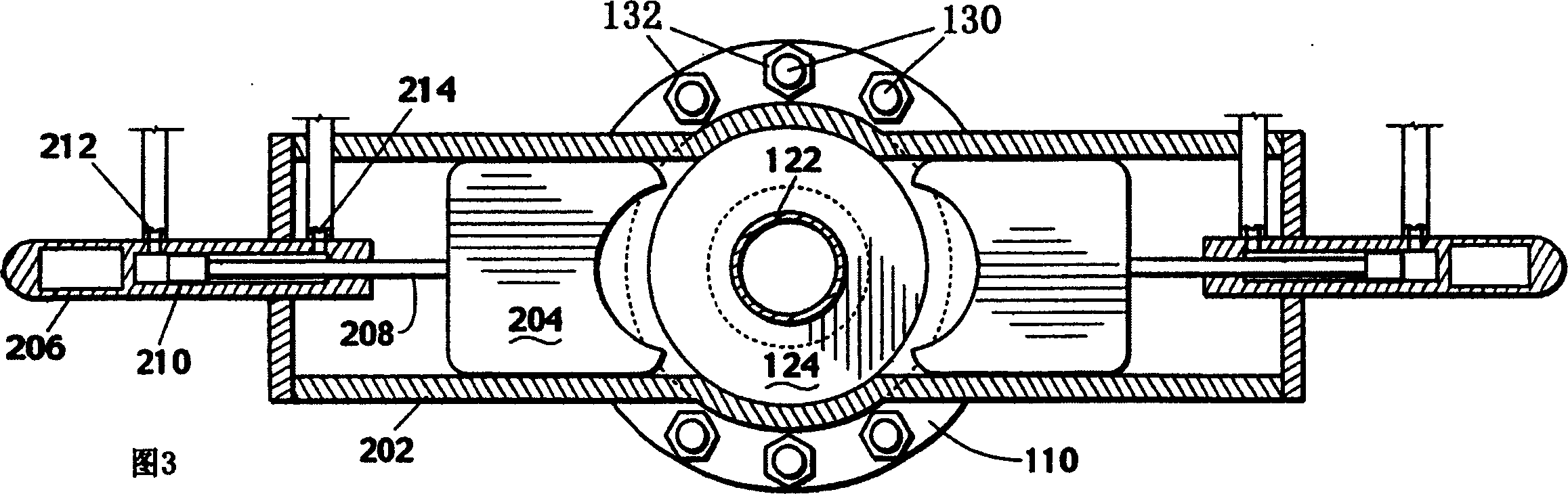

[0015] As shown in FIG. 1 , the CCJ 100 includes an upper housing 102 , a lower housing 104 , and a piston assembly 125 . The upper casing 102 has a top flange 106 for detachable coupling with a cross member for connection between blowout preventers, such as cross member 12 (see FIG. 8 ) for connection between blowout preventers. Bolts 130 (not shown) pass through the top flange bolt holes 108 and nuts (not shown) are used to secure the top flange 106 to the spool member 12 for inter-BOP connections. By passing the bolts 130 through the main flange bolt holes 112 of the upper casing and the main flange bolt holes 116 of the lower casing and fixing the bolts with nuts 132, the main flange 110 of the upper casing is connected to the lower casing. The main flange 114 is engaged, and the upper housing 102 is connected to the lower housing 104 . The main seal 154 is installed between the main flange 110 of the upper housing and the main flange 114 of the lower housing to prevent f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com