Non-leakage balance oil cylinder in power failure

A balanced oil cylinder and no leakage technology, which is applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of small balance force, slow slide of ram, in-situ change of machine tool ram, etc., and achieve reliable Sustained pressure compensation, the effect of making up for oil pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

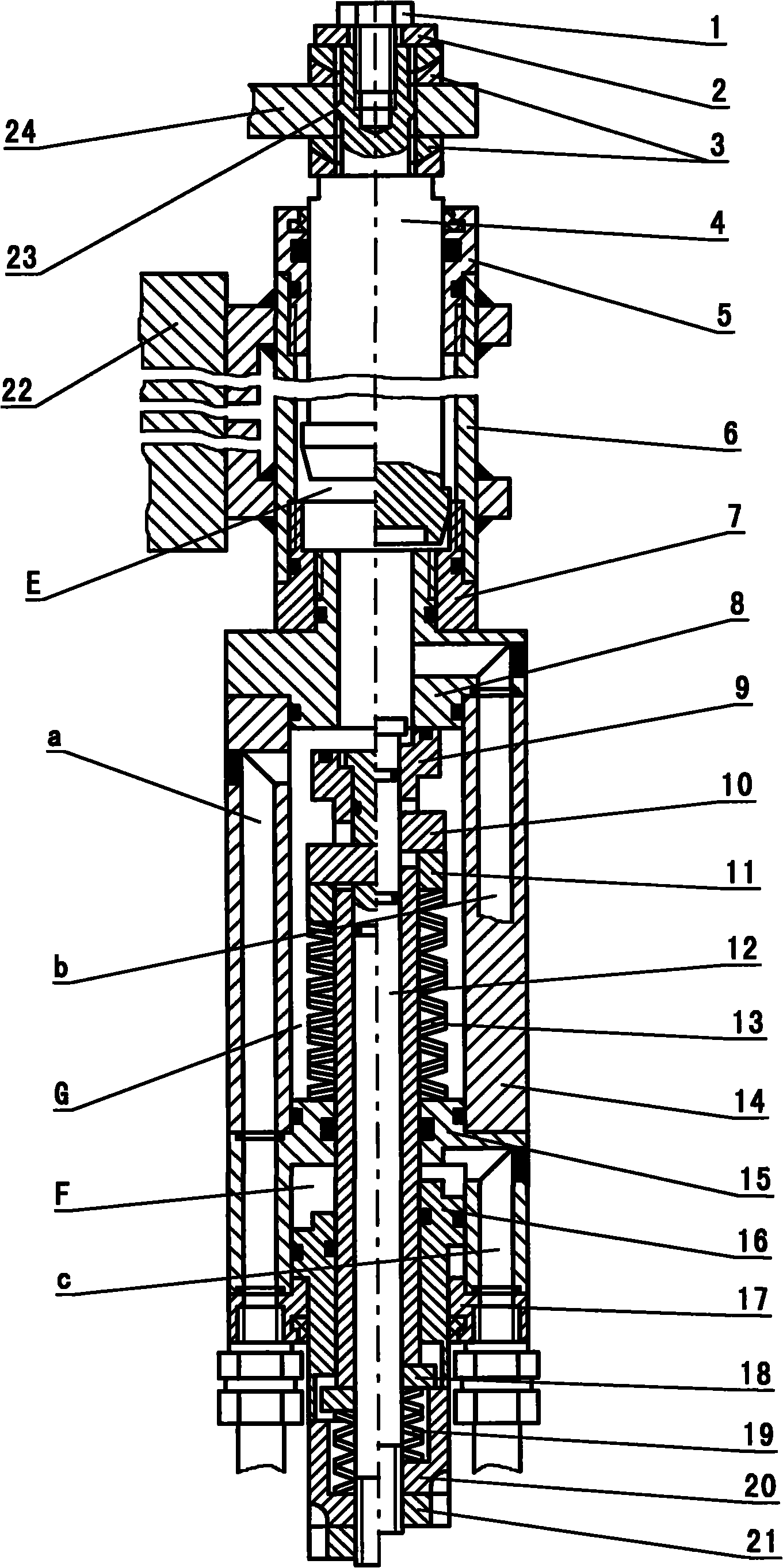

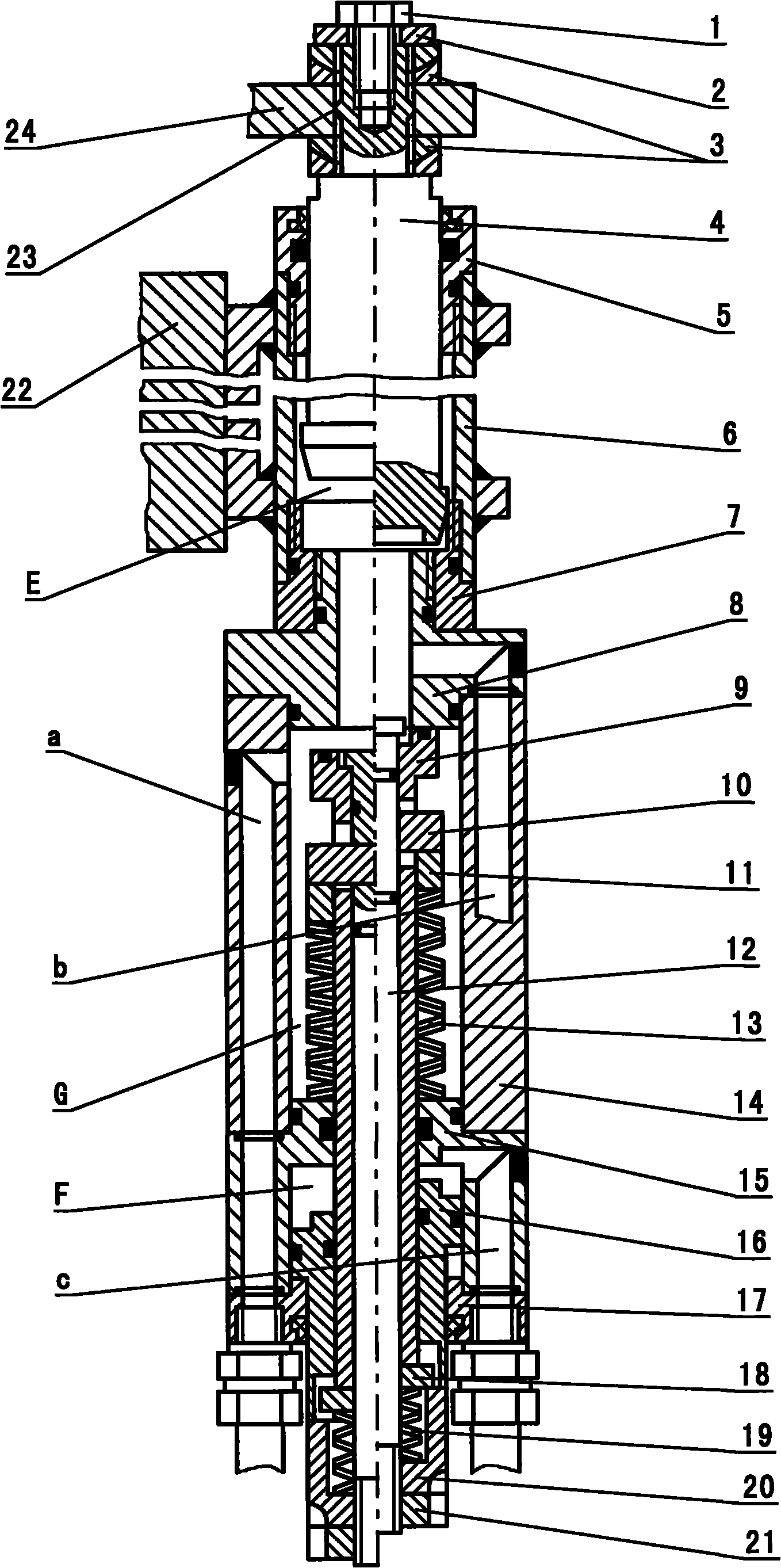

[0023] The invention consists of a balance oil cylinder and a compensation device.

[0024] The balance cylinder includes cylinder barrel 6, piston rod 4, cylinder front and rear end covers 5, 7. The cylinder tube 6 is connected and fixed with the machine tool slide 22, the piston rod 4 is connected with the machine tool ram connecting plate 24, and the two ends of the cylinder tube 6 are respectively connected to the front and rear covers 5, 7 of the balancing cylinder through threads. The piston rod 4 and the machine ram connecting plate 24 are fixedly connected by a bolt 1 at the shaft end of the piston rod 4, a retaining ring 2 and two spherical washers 3. The end shaft of the piston rod 4 has a matching small ring surface 23. The two sides of the machine ram connecting plate 24 are connected together by two sets of spherical washers 3. The matching small ring surface 23 of the small shaft on the piston rod 4 is connected to the machine tool. The pores of the ram connecting ...

Embodiment 2

[0035] This embodiment is a simplification of the compensation device in the first embodiment above, and the pressure compensation mechanism in the compensation device is eliminated. That is, the push block 10, the push ring 11, the retaining ring 18 and the small spring 19 are eliminated, and the plug rod 9 and the push rod 12 are made into a whole. The large spring 13 is extended and directly hits the plug at the front end of the plug rod 9, and the limit sleeve 20 can be shortened or eliminated, which can reduce the number of parts, simplify the structure, reduce costs, and improve reliability. It is used in occasions that do not require high jump control under the ram.

[0036] The compensation device of this embodiment is composed of a compensation cylinder 15, a piston 16, a push rod 12, a large spring 13, a middle cylinder 14 and a nut 21. The push rod 12 is placed in the cavity where the middle cylinder 14 and the compensation cylinder 15 are connected. In the body; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com