Drive unit and method for single-phase switch type magnetic resistance motor

A technology of reluctance motor and driving method, which is applied in the field of motors, and can solve the problems of not being able to stop, not being able to use the stop magnet, and failure to start next time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the present invention will be described in more detail with reference to the drawings.

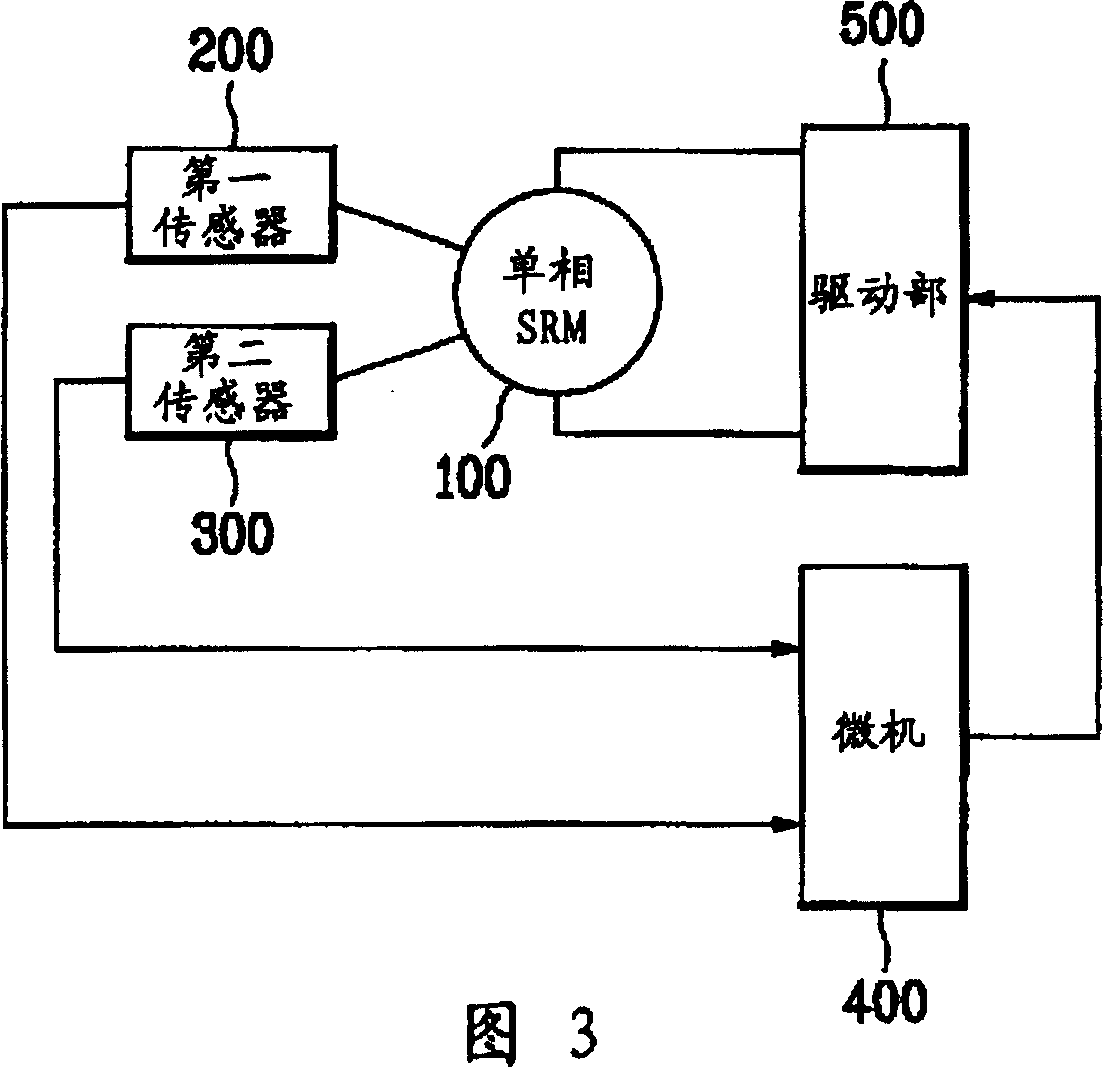

[0030] Fig. 3 is a block diagram showing the structure of a single-phase SRM drive device according to the present invention, Figure 4 It is a flowchart showing the single-phase SRM driving method related to the present invention, Figure 5 It is a waveform diagram explaining the single-phase SRM driving method according to the present invention.

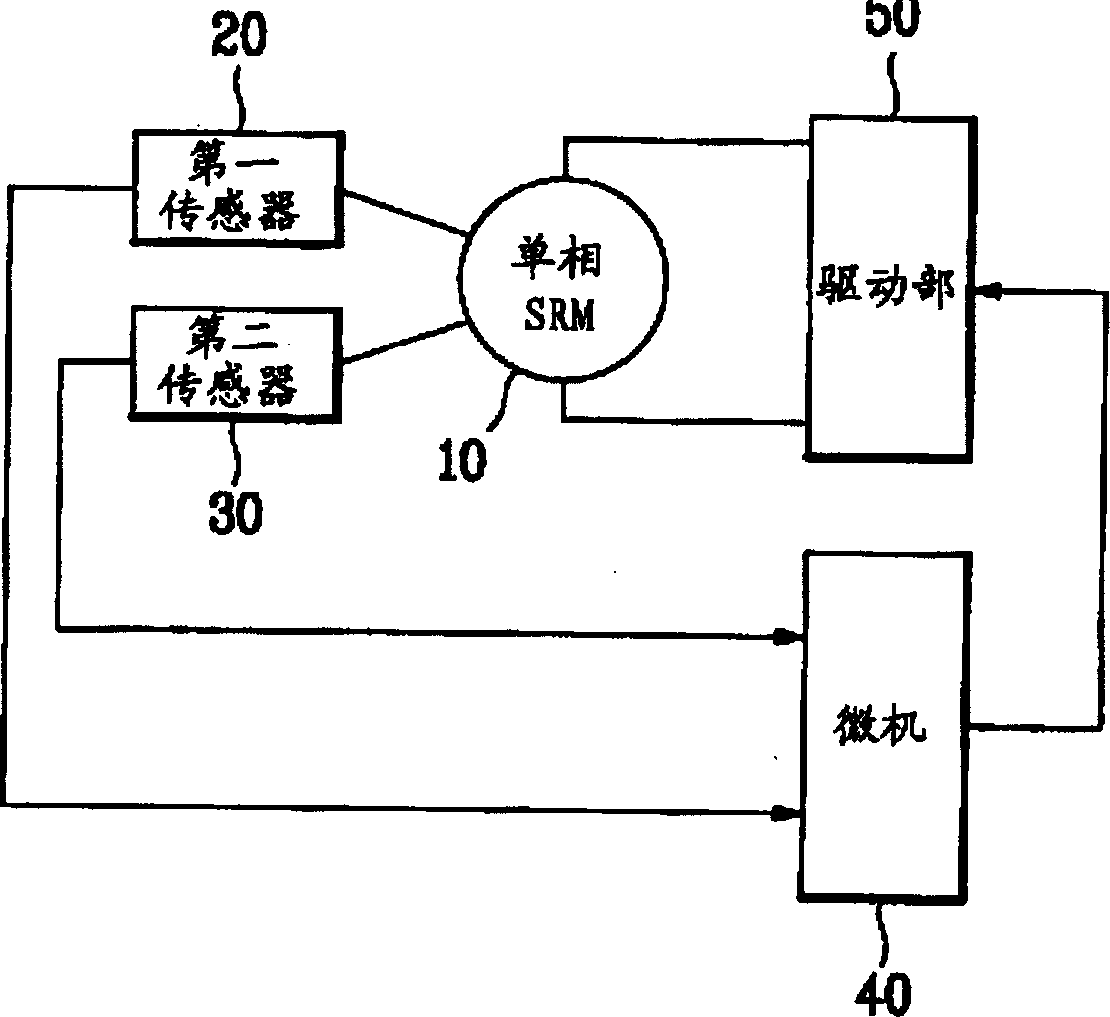

[0031] As shown in FIG. 3, the structure of the single-phase SRM drive device according to the present invention includes: a single-phase SRM 100; a first sensor 200 for detecting the rotation speed of the single-phase SRM 100 and the rotor position for low-speed driving; The second sensor 300 for the position of the rotor for driving; judges whether the rotor is in the correct position based on the output of the first sensor 200 and the second sensor 300 and the rotation speed of the single-phase SRM, and if it is judged to be n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com