A method to improve the starting performance of permanent magnet synchronous motor without position sensor control

A permanent magnet synchronous motor and starting performance technology, applied in the direction of motor generator control, electronic commutation motor control, starting device, etc., can solve the problems of short execution time, complicated implementation process, and easy starting failure, etc., and achieve improvement Effect of starting characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

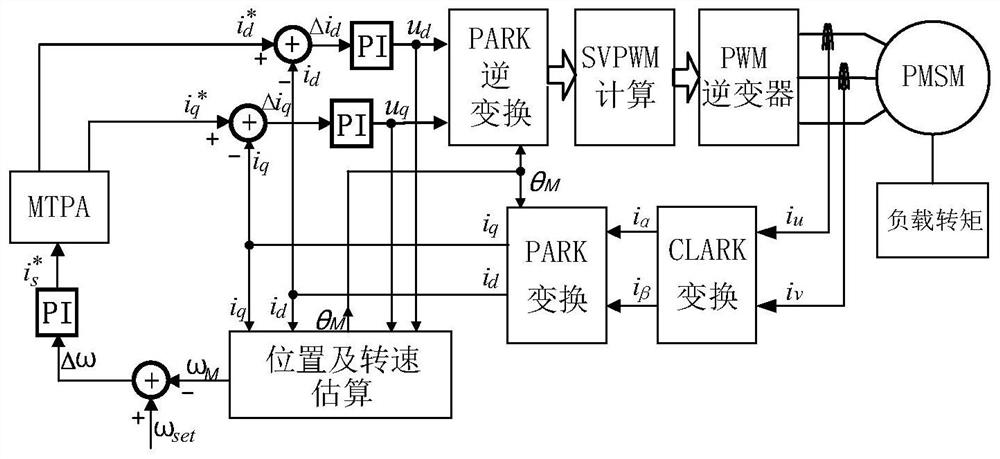

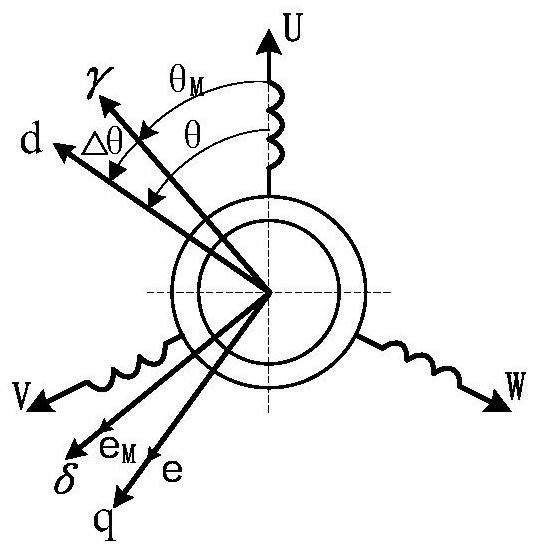

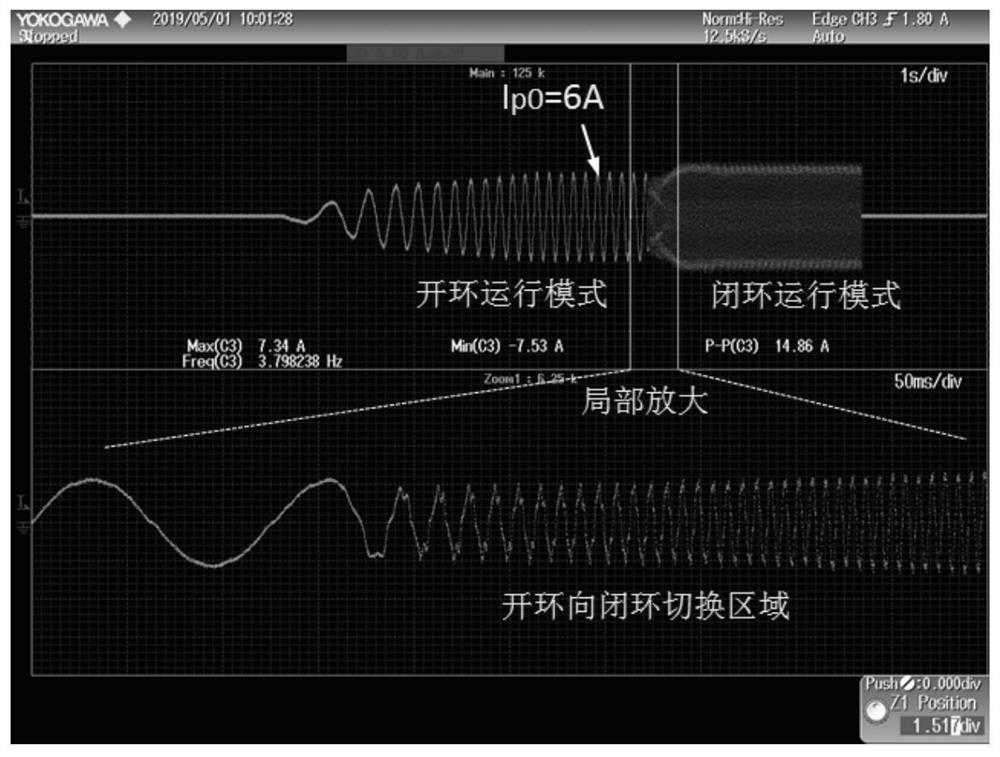

[0020] Such as Figure 1 to Figure 4 As shown, the present invention discloses a method for improving the starting performance of a permanent magnet synchronous motor without position sensor control, comprising the following steps:

[0021] Step 1, set the peak value of the motor winding phase current I p0 and the open-loop operating frequency ω 0 , the three-phase sine wave current is generated in the motor winding to form an active rotating magnetic field. At this time, the permanent magnet synchronous motor works in the open-loop synchronous operation mode;

[0022] Wherein, the three-phase sine wave current generated in the permanent magnet synchronous motor winding is expressed as:

[0023]

[0024] In the above formula, I U ,I V ,I W are the three-phase sine wave currents of the motor windings, I p0 is the set motor winding phase current peak value, f 0 Is the open-loop operating frequency, and t is the time parameter.

[0025] Step 2, establishing the equatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com