Superthin-wall aluminium-alloy high-speed pressure casting method

An aluminum alloy and ultra-thin-wall technology, applied in the field of aluminum alloy with copper addition, can solve the problems of insufficient material rigidity, deformation, and inability to meet the needs of 3C products, and achieve the best tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

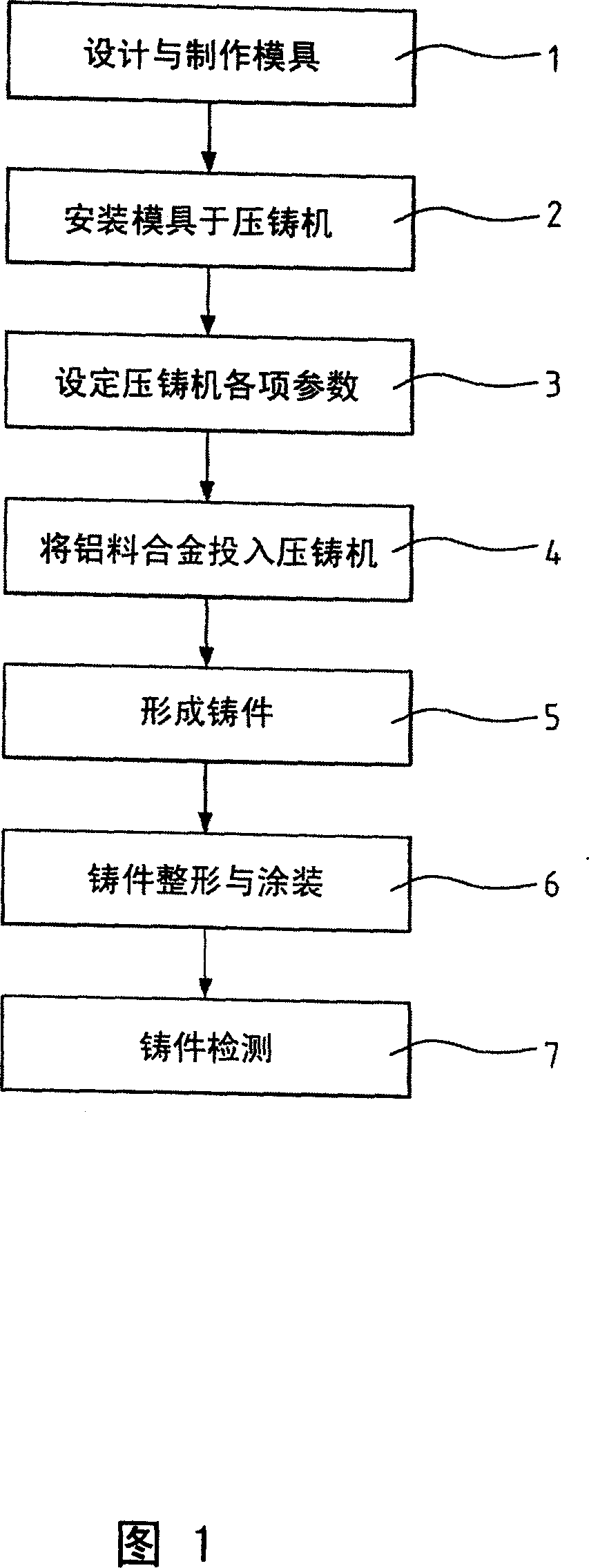

[0021] A preferred feasible embodiment is now described in detail in conjunction with the accompanying drawings as follows:

[0022] Please refer to the figure, which is a schematic flow chart of the die-casting method of the present invention.

[0023] In the implementation of the present invention, as in step 1, a target casing is first selected, and a preliminary plan is determined according to empirical rules. Use the three-dimensional casting computer simulation software ProCAST to carry out the three-dimensional mold flow and heat transfer computer simulation. Before the computer simulation, it is necessary to use the I-DEARS3D software to establish the casting plan of the casing, and then make the mold according to the computer simulation results, and then carry out Step 2: Make a mold according to the computer simulation results, and install the mold on the machine platform. The machine platform uses a CT-250 vertical high-pressure casting machine (or melting forging m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com