Guiding device for a flotation machine

A guiding device and flotation machine technology, applied in the field of flotation machines, can solve the problems of reducing the total efficiency and output of gas dispersion devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

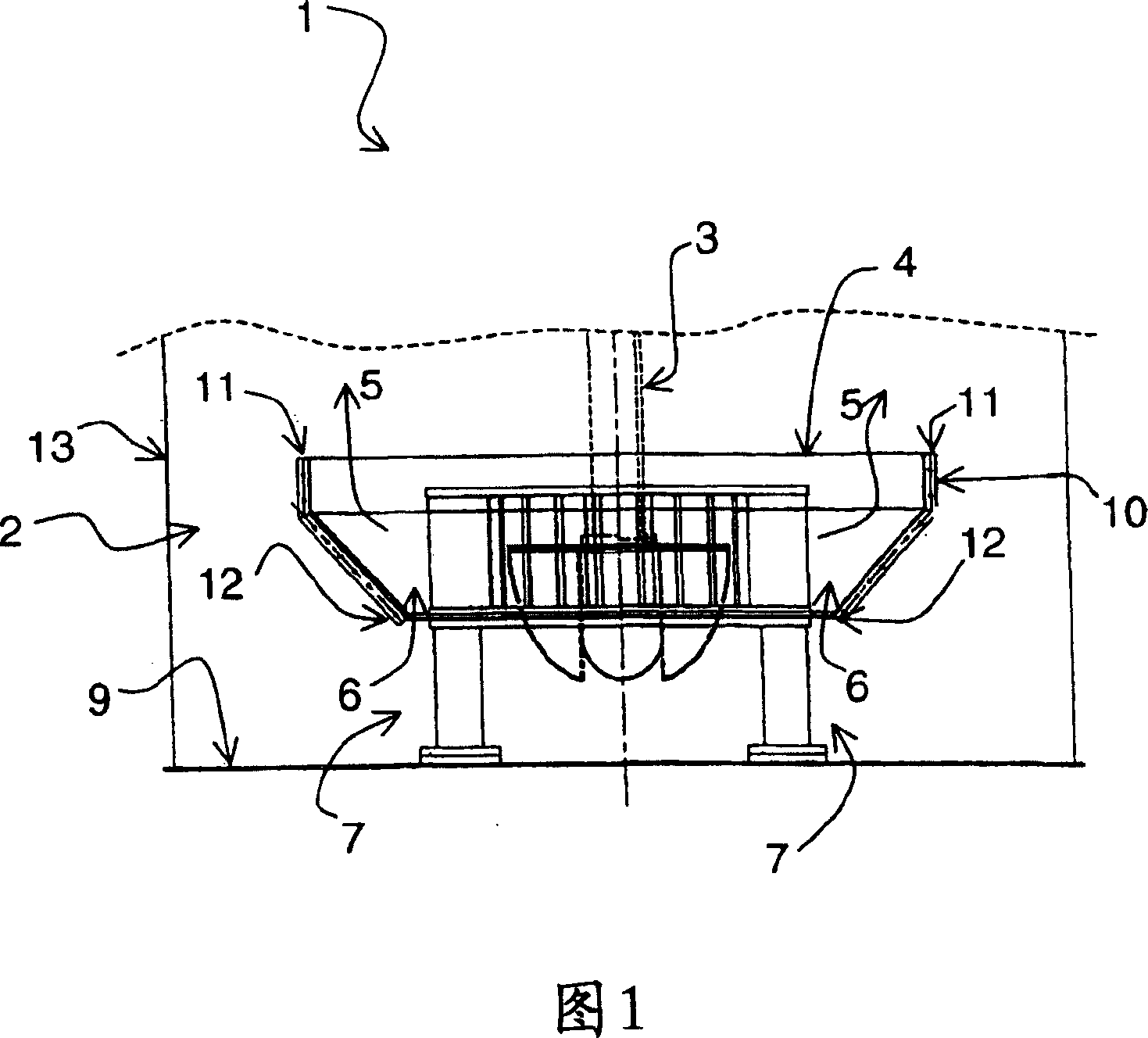

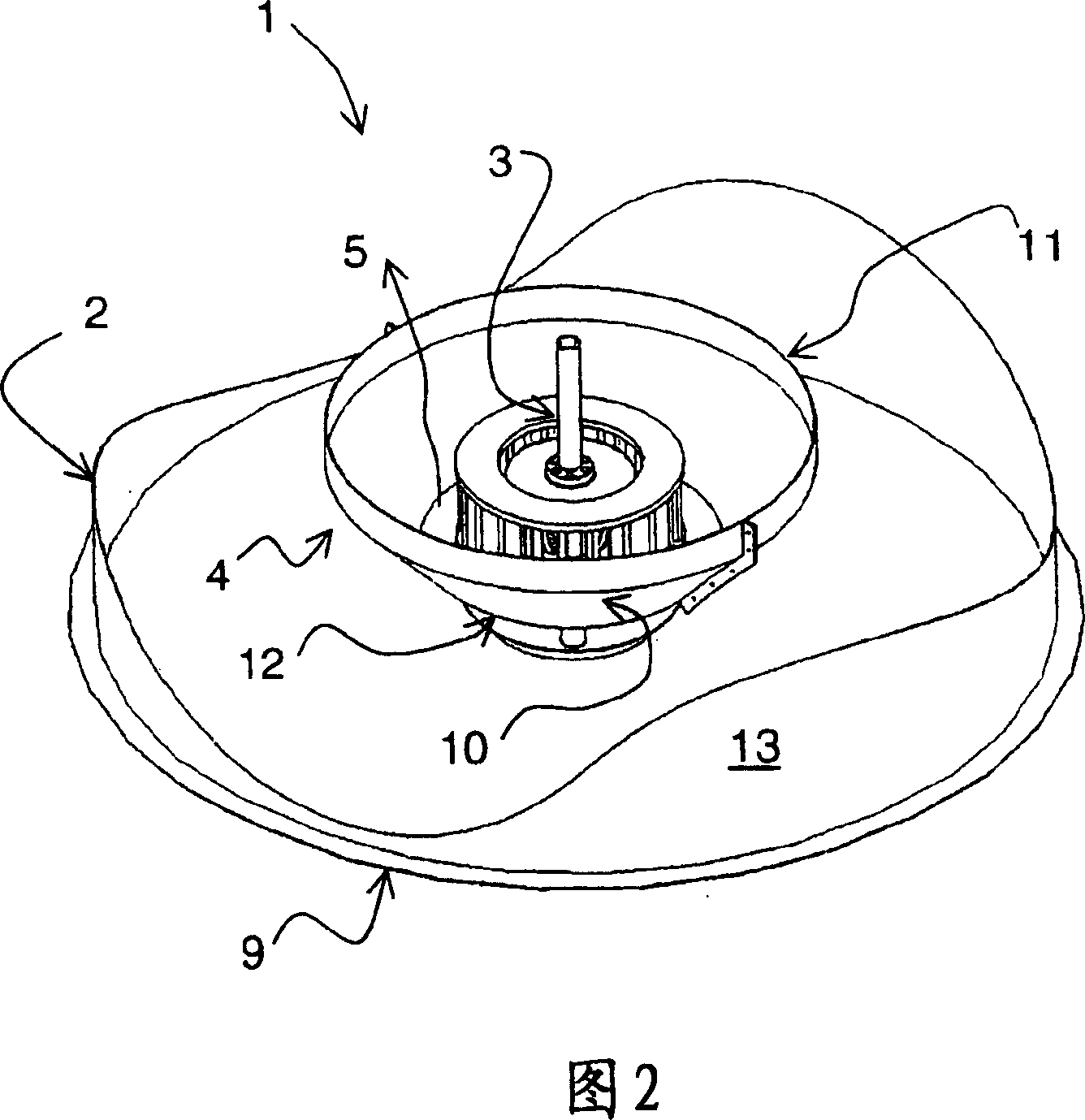

[0013] As shown in Figure 1, a flotation machine 1 includes at least one flotation cell 2, a gas dispersion device 3, a device for removing foam from the flotation cell and a device for removing tailings from the flotation cell, flotation The tank has a device for feeding the slurry into the tank; the gas dispersion device 3 is used to feed gas 5 into the slurry and generate foam. According to the invention, at least one guiding device 4 is installed close to the gas dispersing device 3 in order to lead the dispersed gas away from the gas dispersing device, preventing recirculation of the flotation gas into the suction zone 7 of the gas dispersing device 3 . The guiding device 4 is installed close to the gas dispersing device so that it guides the gas 5 away from the gas dispersing device. According to this example, the guiding means are conical and comprise a wall element 10 extending substantially symmetrically around the entire gas dispersing means 3 in the direction upward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com