Chassis test bench for cars

A technology for test benches and small cars, which is applied in vehicle testing, vehicle components, machine/structural components testing, etc. It can solve problems such as unbearable for enterprises, large investment, and large equipment volume, and achieves wide application range and high detection content. The effect of multiple, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

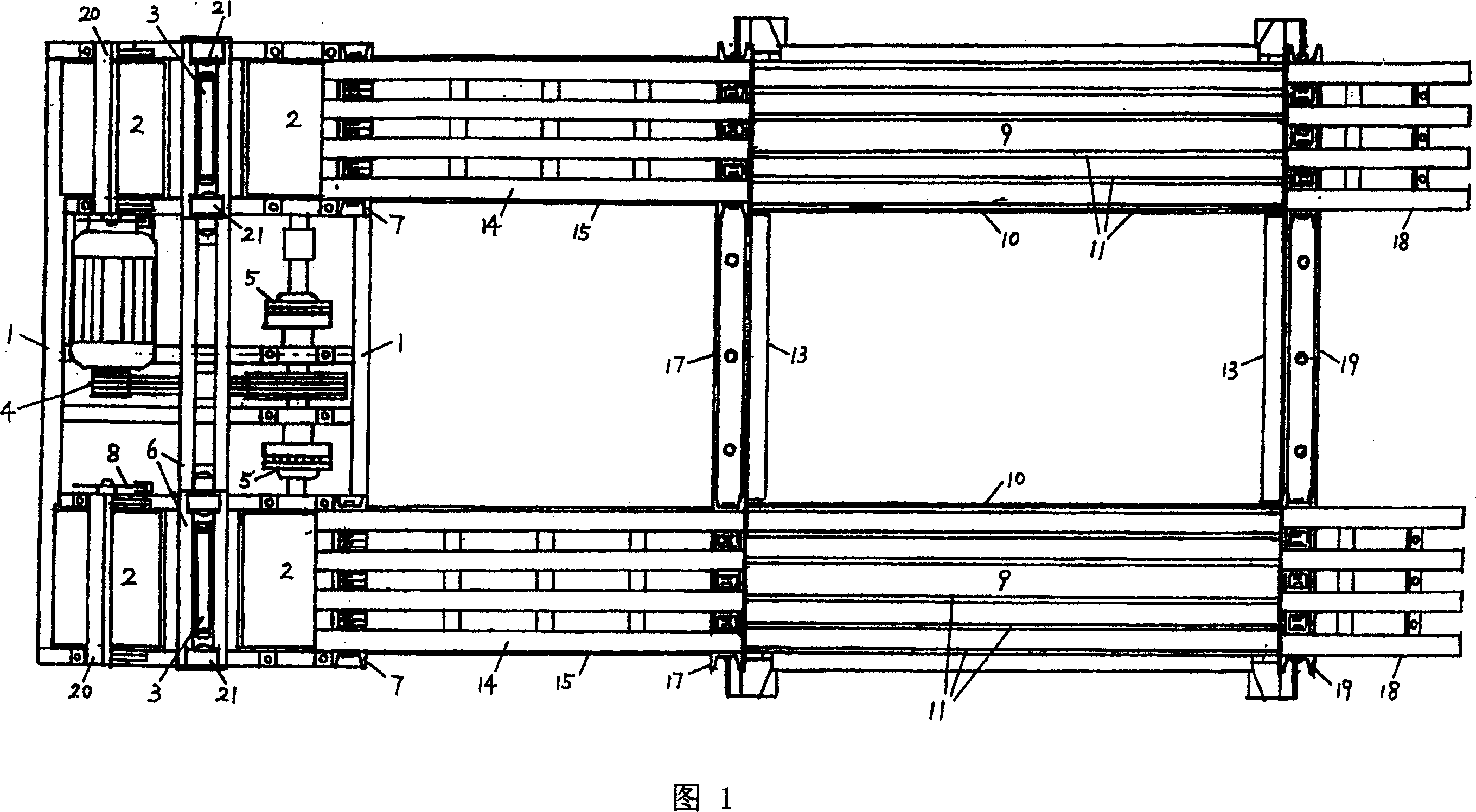

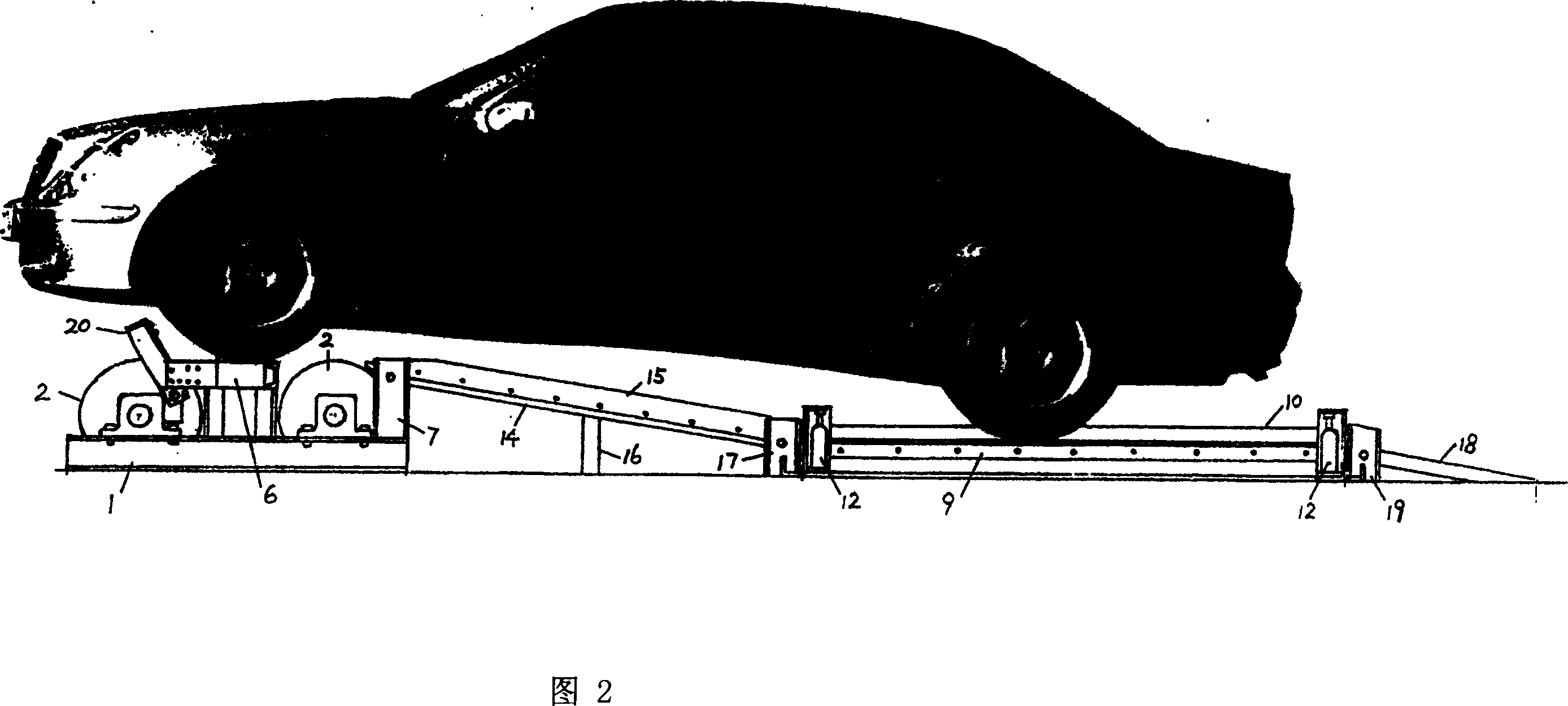

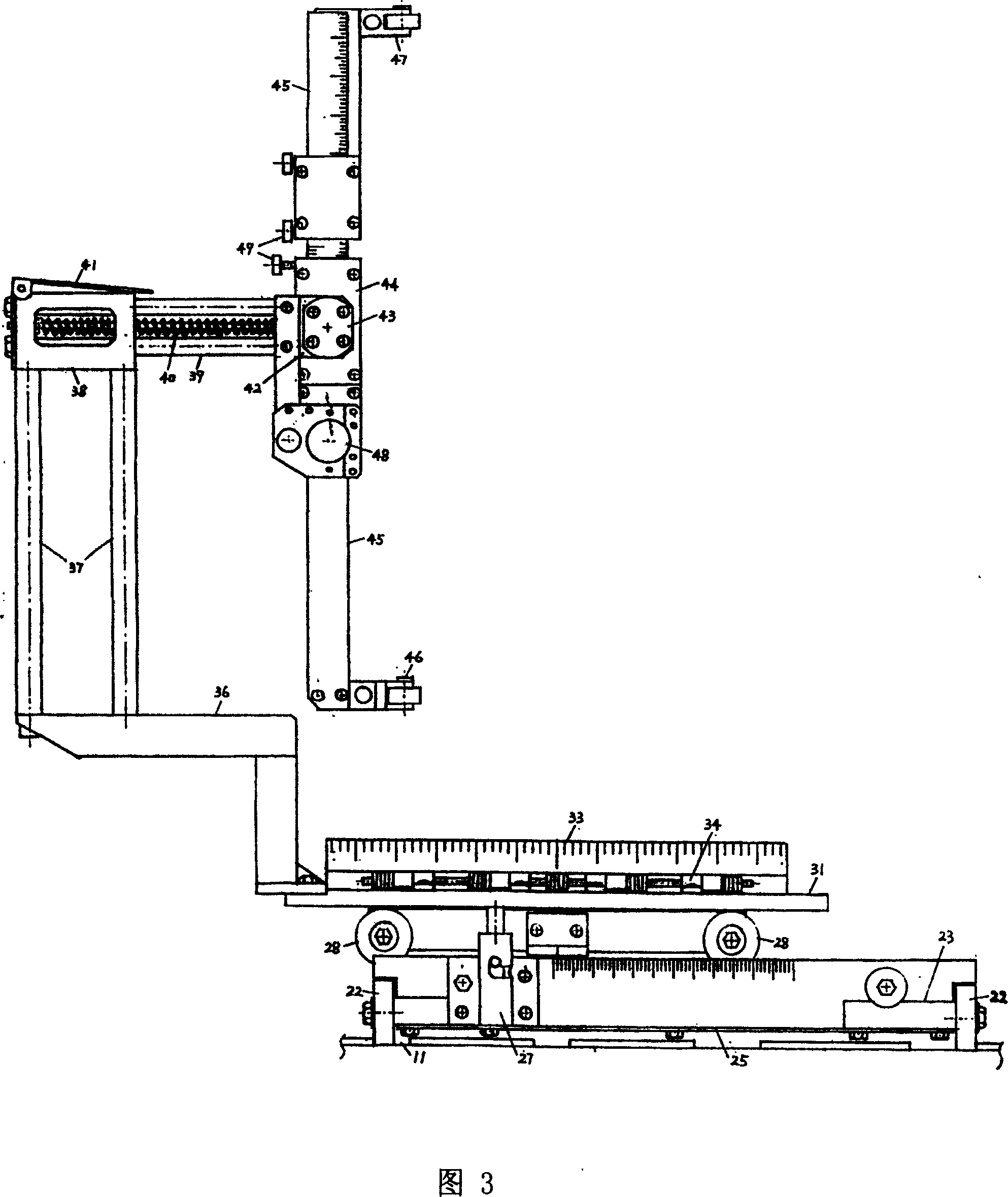

[0018] The invention is composed of a braking platform, a lifting platform, a connecting bridge, an approach bridge, a detection disc, a computer and a console. Among them, the brake platform and the lifting platform are the main mechanical structures, which are connected in series by the connecting bridge and allow the wheels to pass through. The approach bridge is just a slope for the car to go up and down the lifting platform, as shown in Figure 1 and Figure 2.

[0019] 1. Braking table. The main bench for braking and sliding tests can also load and position the wheels of the non-detection axis when detecting the steering. It consists of the base 1, the roller group 2, the third roller 3, the motor and pulley 4, the clutch 5, Riser 6, rear axle seat 7 etc. are formed.

[0020] 1.1. Base 1. The four-shaped base welded by channel steel is the basis for carrying and connecting all parts on the brake platform.

[0021] 1.2. Roller group 2. It consists of four independent ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com