Hand tool capable of disassembling and changing cutting edge

A technology of hand tools and blades, which is applied in the field of hand tools, can solve the problems of no shearing effect, inconvenient use, low usage rate, etc., and achieve good practicability and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

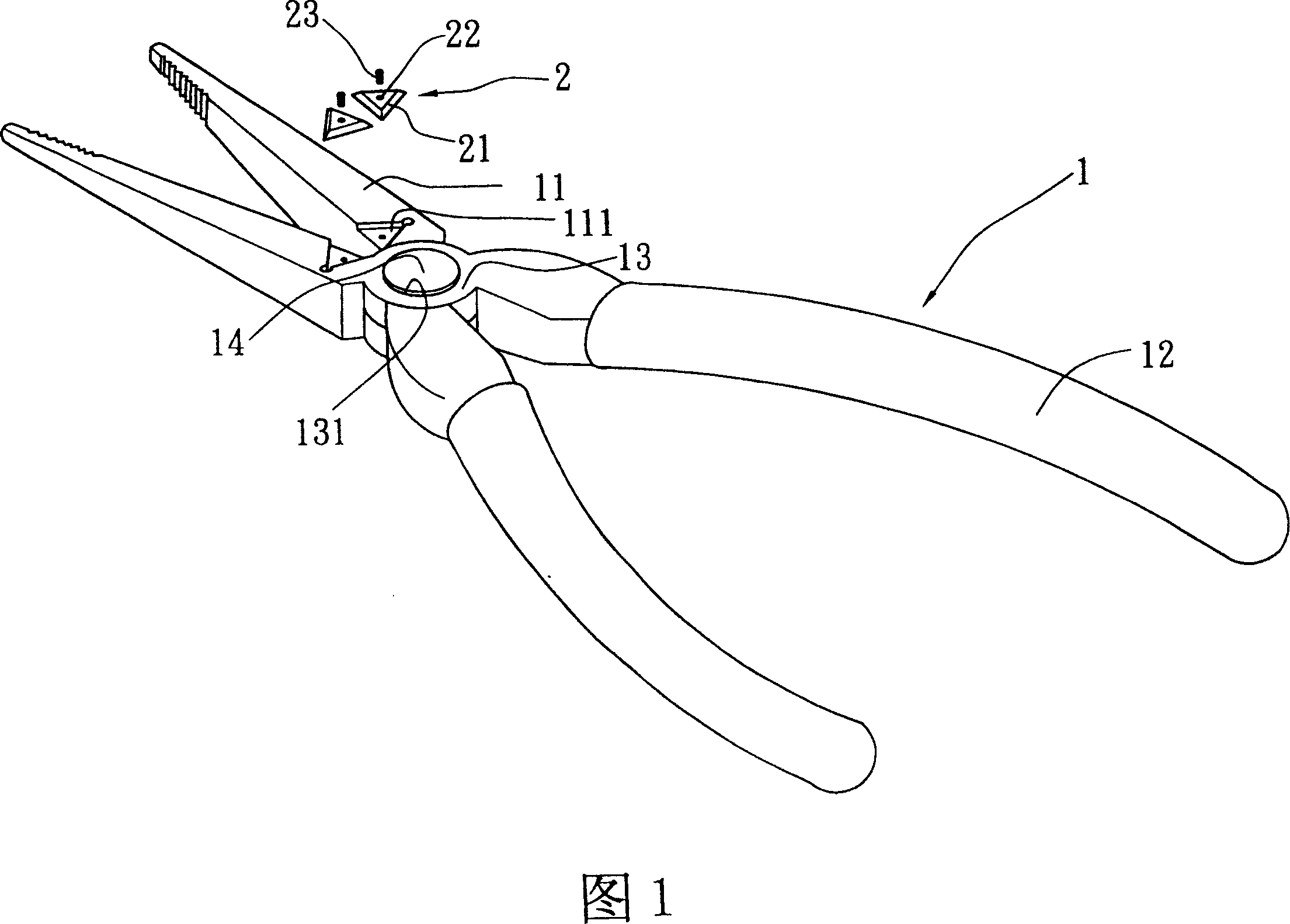

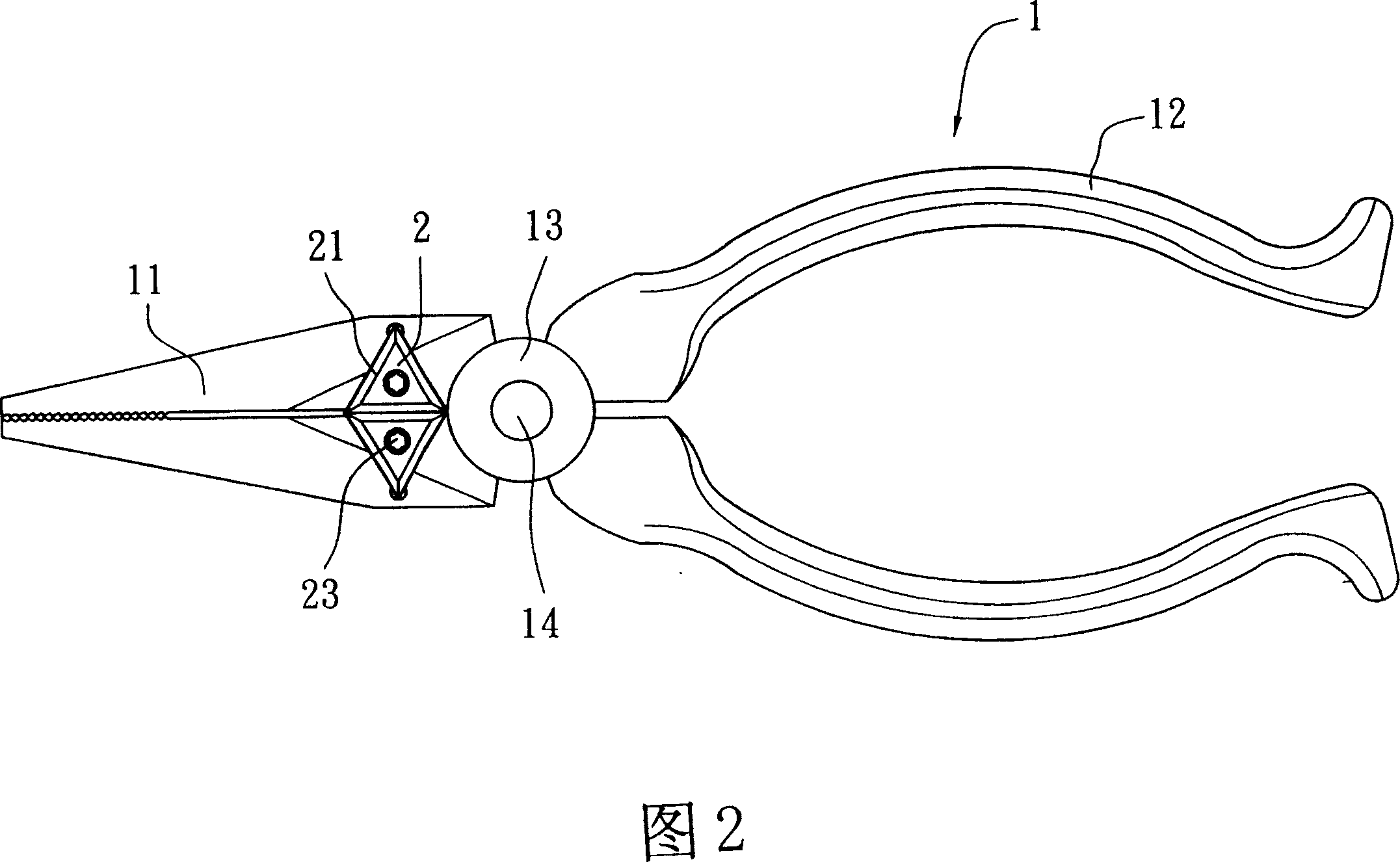

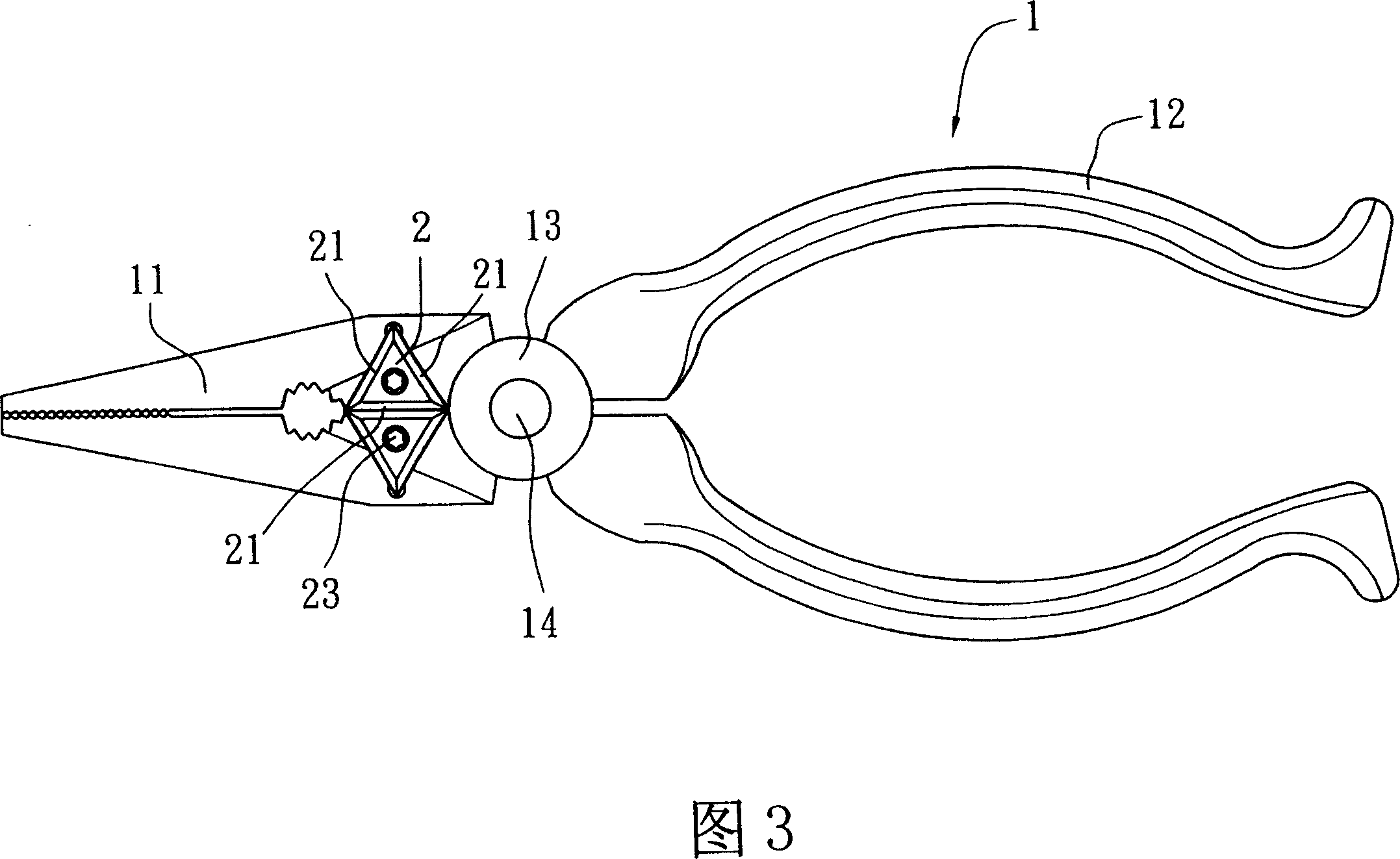

[0037] Please refer to Fig. 1 to Fig. 15, the hand tool of the embodiment of the present invention is a needle-nose pliers as an example, as shown in Fig. 1, the hand tool includes: two handles 1, the two handles 1 are pivotally connected to each other , one end of each handle 1 has an action part 11 for clamping objects, and the other end of each handle 1 has a grip part 12 for holding, and each handle 1 has a pivot joint A pivoting portion 13, each pivoting portion 13 has a pivoting hole 131 in the middle of each pivoting portion 13, for a shaft rod 14 to penetrate and pivot, so that the two handles 1 are pivoted to each other, so that the grip of the two handles 1 Part 13 drives the two action parts 11 to open and close for clamping workpieces. An accommodating groove 111 is respectively provided on the opposite inner side of each action part 11 near the pivot joint part 13 . The blade portion 2 has at least one shearing section 21 and a fastening hole 22, and a fastening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com