Rosin dissolving method

A technology of turpentine and dissolving pot, which is applied in the field of rosin processing, can solve the problems of large amount of waste water, water vapor consumption, and high energy consumption in production, and achieve the effects of reducing personnel operations, simplifying the processing process, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

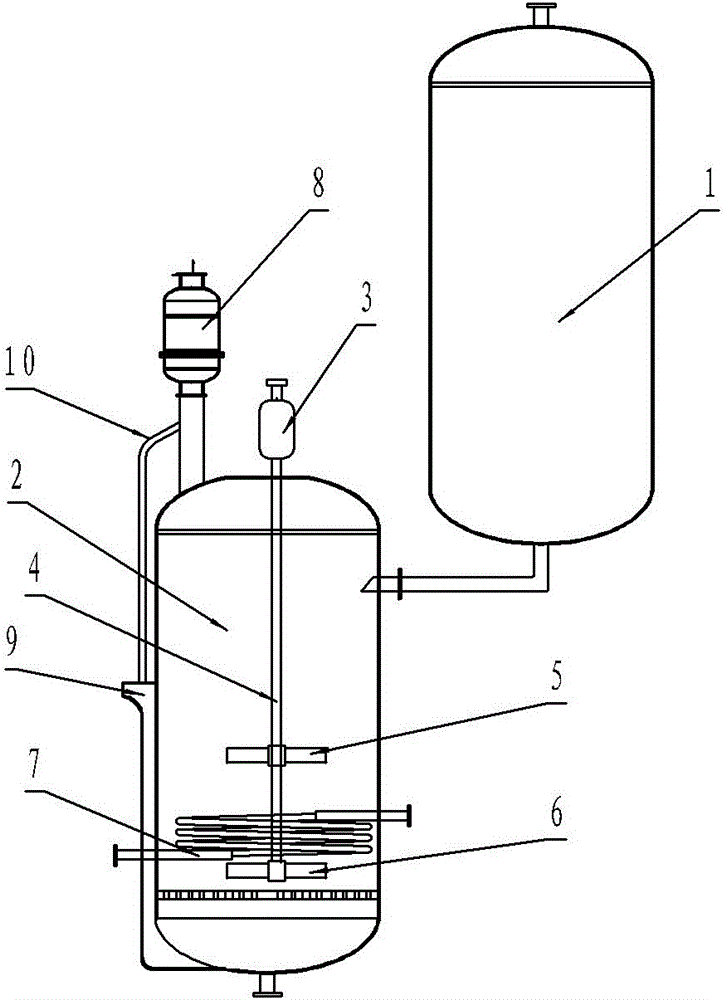

[0014] figure 1 The structural representation of the equipment that the dissolving method of shown turpentine adopts, wherein, dissolving pot 2 is provided with agitator, and this agitator includes the motor 3 that is installed on the top of dissolving pot 2 and the stirring shaft 4 that connects motor 3 output ends, stirs The other end of the shaft 4 extends into the dissolving pot 2; the lower part of the stirring shaft 4 is equipped with a paddle-type double blade 5, and the bottom end is connected with a turbine blade 6; the heating coil 7 is arranged on the paddle-type double blade around the stirring shaft 4 Between 5 and the turbine blade 6, the two ends of the heating coil 7 extend out of the dissolving pot 2 respectively.

[0015] The present embodiment provides necessary equipment for the dissolving of turpentine, especially the bottom of stirring shaft 4 is equipped with paddle type double blade 5, and the bottom end is connected with the structure that turbine blad...

Embodiment 2

[0017] The dissolving scheme of present embodiment rosin comprises the following specific steps:

[0018] Put the rosin into the preheating pot 1, preheat it to 70°C, then send it into the dissolving pot 2, start the motor 3 on the stirring device, and feed 350°C steam into the coil heater 7 to make the rosin Heating to 110°C, and then under this temperature condition, the pine resin is continuously stirred, sheared, broken and dissolved at a stirring speed of 80 rpm;

[0019] Wherein, the above-mentioned dissolving pot 2 is provided with a stirring device, and the stirring device includes a motor 3 installed on the top of the dissolving pot 2 and a stirring shaft 4 connected to the output end of the motor 3, and the other end of the stirring shaft 4 stretches into the dissolving pot 2; The bottom of 4 is equipped with paddle type double blade 5, and the bottom end is connected with turbine type blade 6; Heating coil 7 is arranged between paddle type double blade 5 and turbine...

Embodiment 3

[0022] The structure of the equipment adopted in the dissolving method of present embodiment rosin is as embodiment 2;

[0023] The method includes the following specific steps:

[0024] Put the turpentine into the preheating pot 1, preheat it to 70°C, and then send it into the dissolving pot 2, start the motor 3 on the stirring device, and feed 380°C heat conduction oil into the coil heater 7 to make the rosin Heating to 115°C, then at this temperature, the pine resin is stirred, sheared, broken, and dissolved at a stirring speed of 95 rpm.

[0025] Compared with the currently commonly used rosin dissolving method, every ton of rosin dissolved in this embodiment can reduce the discharge of waste water by about 1,000 kg, save 465,750 kcal of heat energy, and reduce production costs by about 160 yuan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com