Patents

Literature

218results about "Dissolving methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

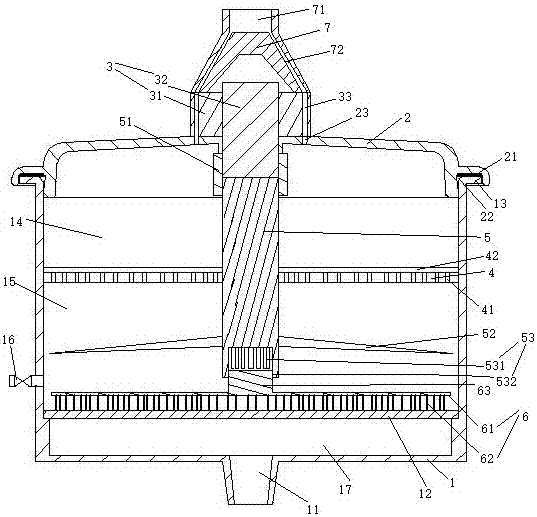

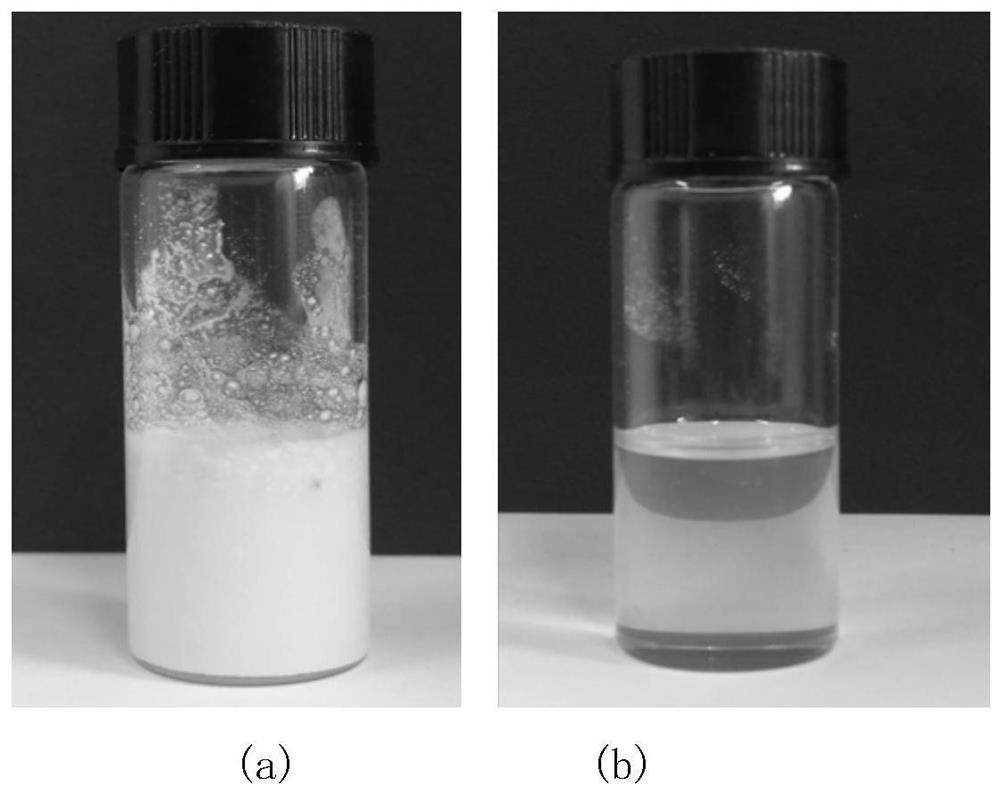

Preparation device of supersaturated hydrogen solution and preparation method thereof

InactiveCN106000136AHigh concentration of gas massExcellent gas concentrationTransportation and packagingMixing methodsMicro nanoHydrogen

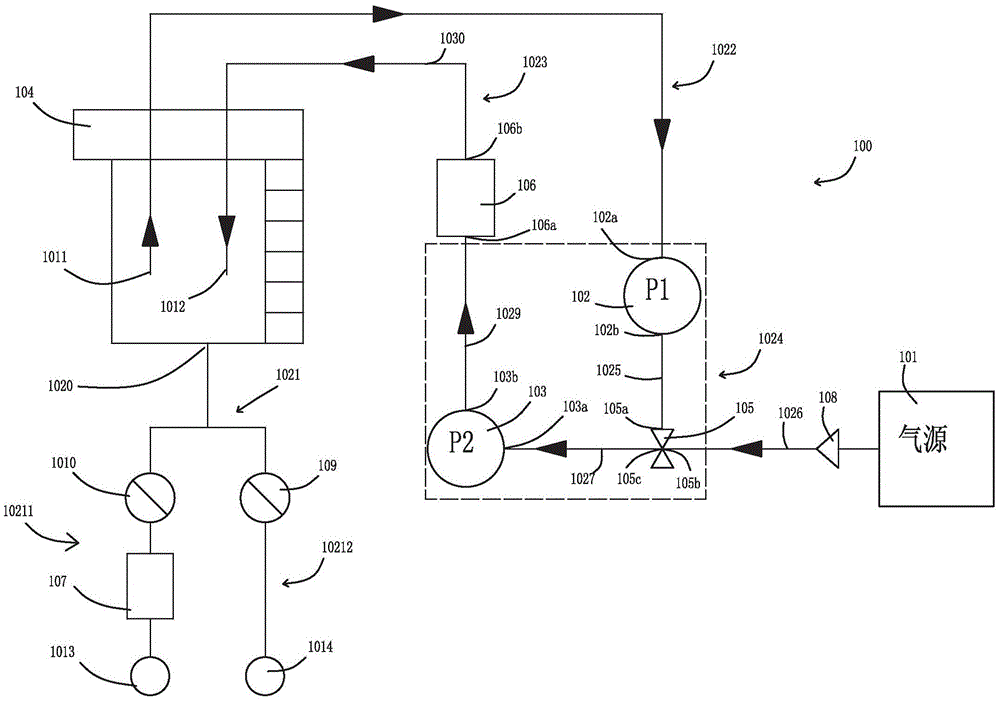

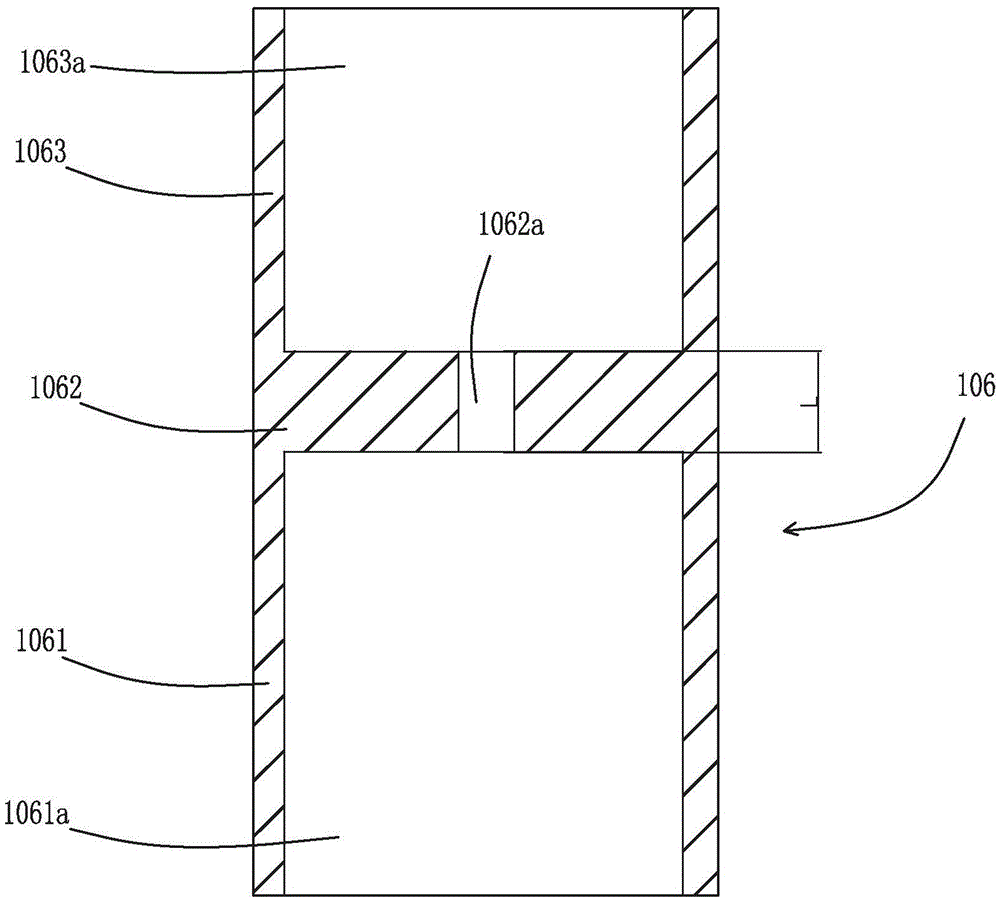

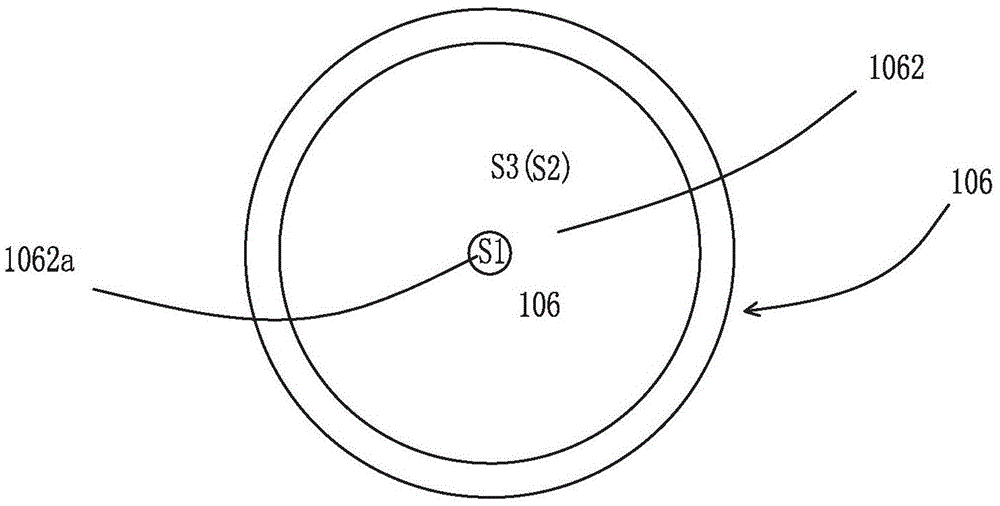

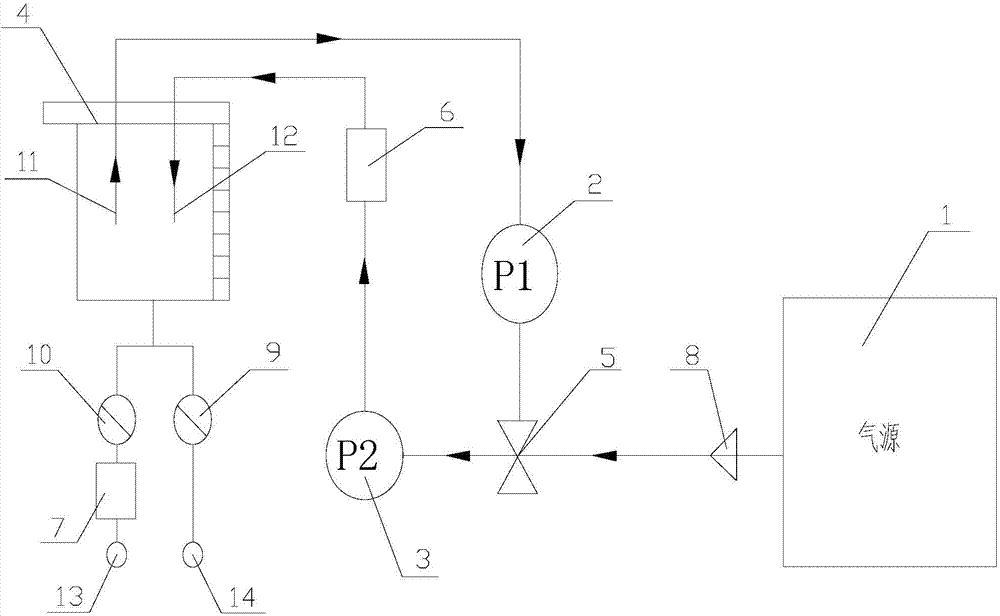

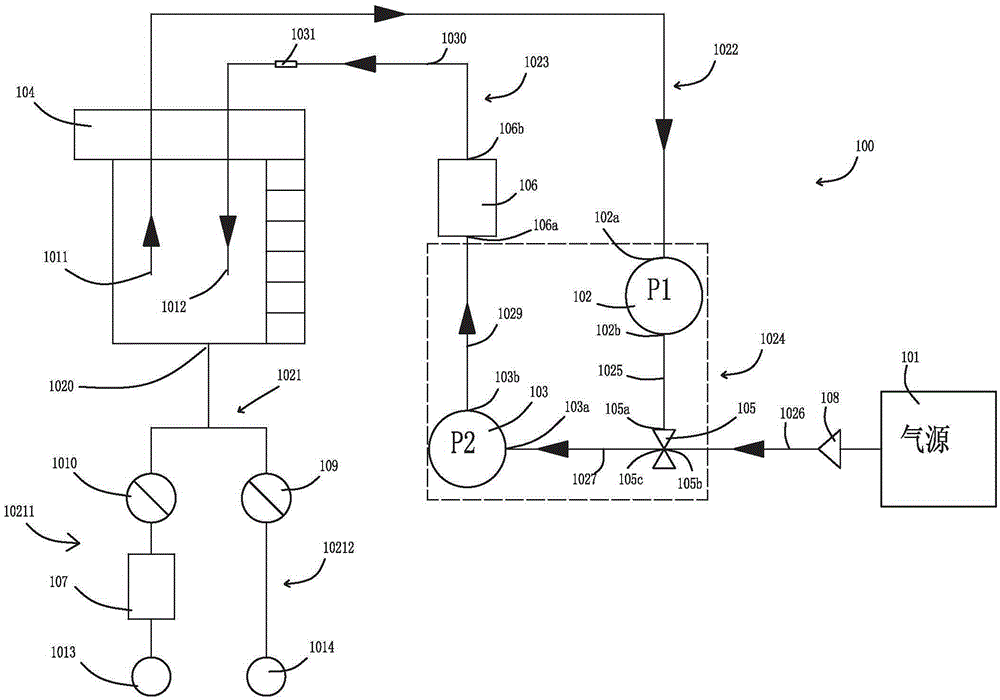

The invention discloses a preparation device of a supersaturated hydrogen solution and a preparation method thereof. The preparation device of the supersaturated gas solution comprises a gas generator, a gas-liquid mixer and a water tank. The gas generator generates an air source. The gas-liquid mixer is connected to the gas generator. The gas-liquid mixer and the water tank are connected by a gas-liquid mixer water absorption flow branch and a gas-liquid mixer drainage flow branch respectively. And the gas-liquid mixer water absorption flow branch and the gas-liquid mixer drainage flow branch form a gas-liquid mixed flow loop. According to the invention, gas in the form of micro-nano scale diameter bubbles is fully mixed with water, a gas-liquid mixture cyclically operates through the gas-liquid mixed flow loop to form a supersaturated gas solution in the water tank rapidly within a predetermined time, and the gas mass concentration of the supersaturated gas solution is significantly higher than the mass concentration of gas prepared by a conventional method, both the prepared gas mass concentration and the preparation time are superior to the prior art, and the preparation efficiency is high.

Owner:SHANGHAI NANOBUBBLE TECH

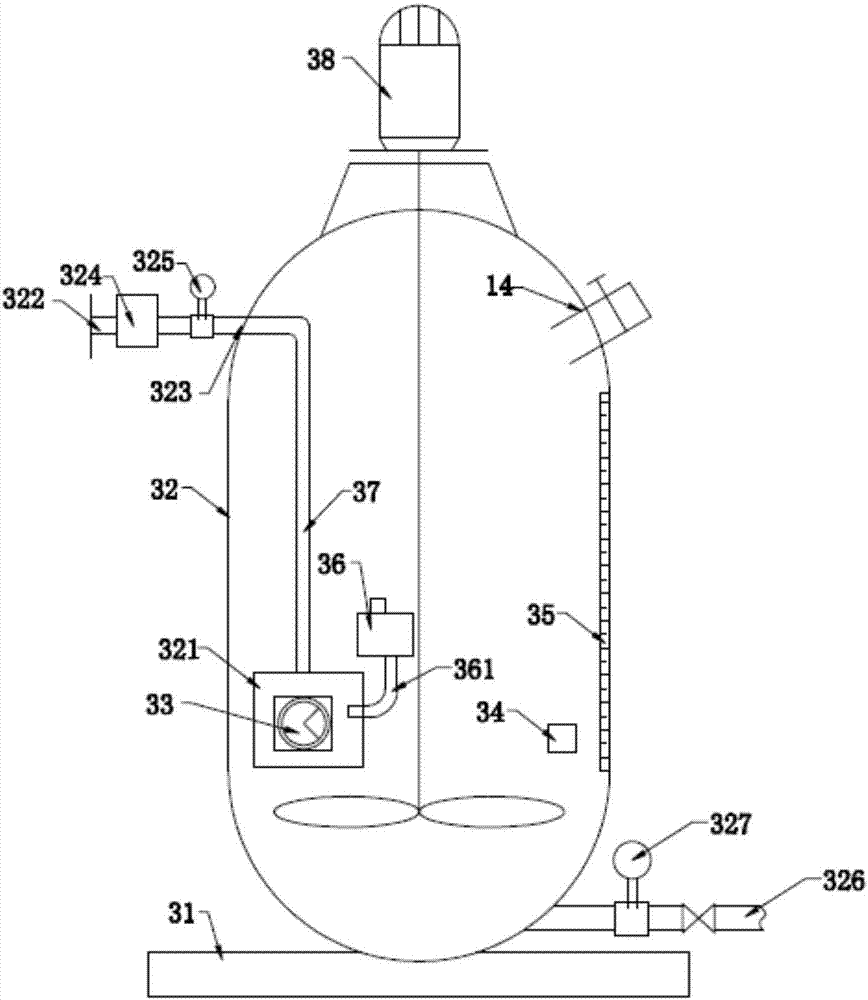

Preparation device and preparation method for over-saturated hydrogen solution

InactiveCN104707494AGood technical effectExcellent preparation timeMixing methodsTransportation and packagingHydrogen concentrationDrainage flow

The invention discloses a preparation device and a preparation method for an over-saturated hydrogen solution. The preparation device comprises a hydrogen generator, a gas-liquid mixer and a water tank, wherein the hydrogen generator is used for generating a hydrogen source; the gas-liquid mixer is connected with the hydrogen generator; a gas-liquid mixer water absorption flowing branch path and a gas-liquid mixer water drainage flowing branch path are respectively connected between the gas-liquid mixer and the water tank; a gas-liquid mixing flowing loop is formed by the gas-liquid mixer water absorption flowing branch path and a gas-liquid mixer water drainage flowing branch path. By adoption of a method for fully mixing gas with water in a micronano-level diameter gas bubbles; gas-liquid mixed fluid cyclically runs in the gas-liquid mixing flowing loop to quickly form the over-saturated hydrogen solution within two minutes in the water tank, and the mass concentration of hydrogen of the hydrogen solution is not smaller than 2.5ppm; either the prepared hydrogen concentration or the preparation time is higher than that in the prior art, and the preparation efficiency is high.

Owner:SHANGHAI NANOBUBBLE TECH

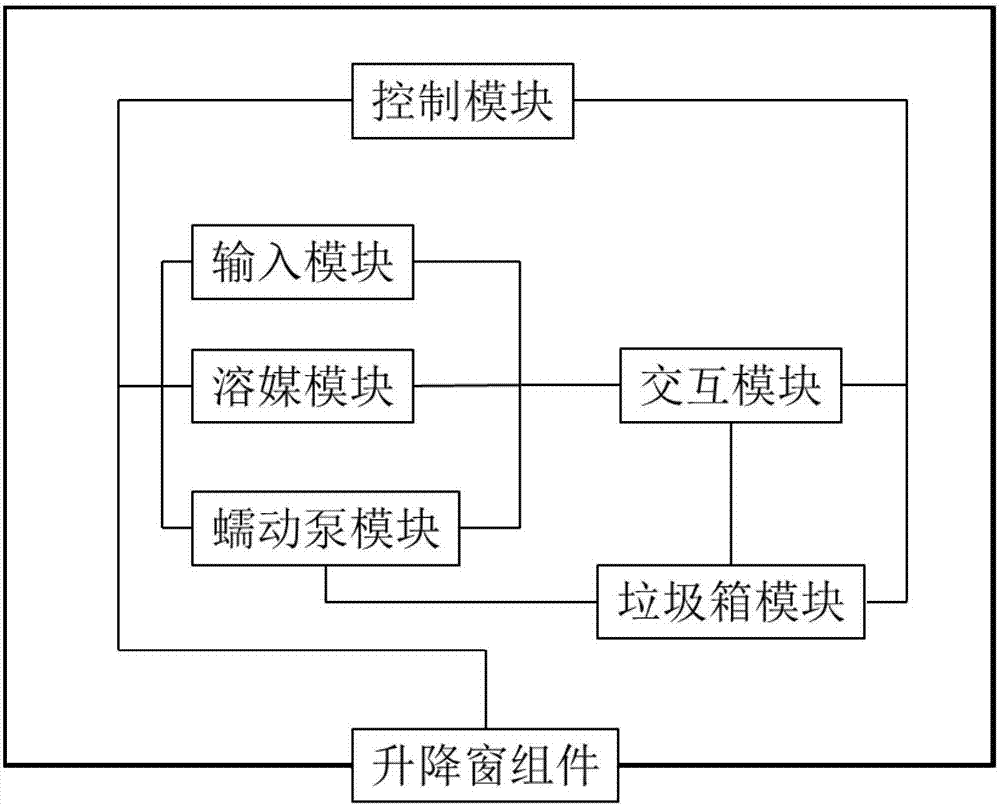

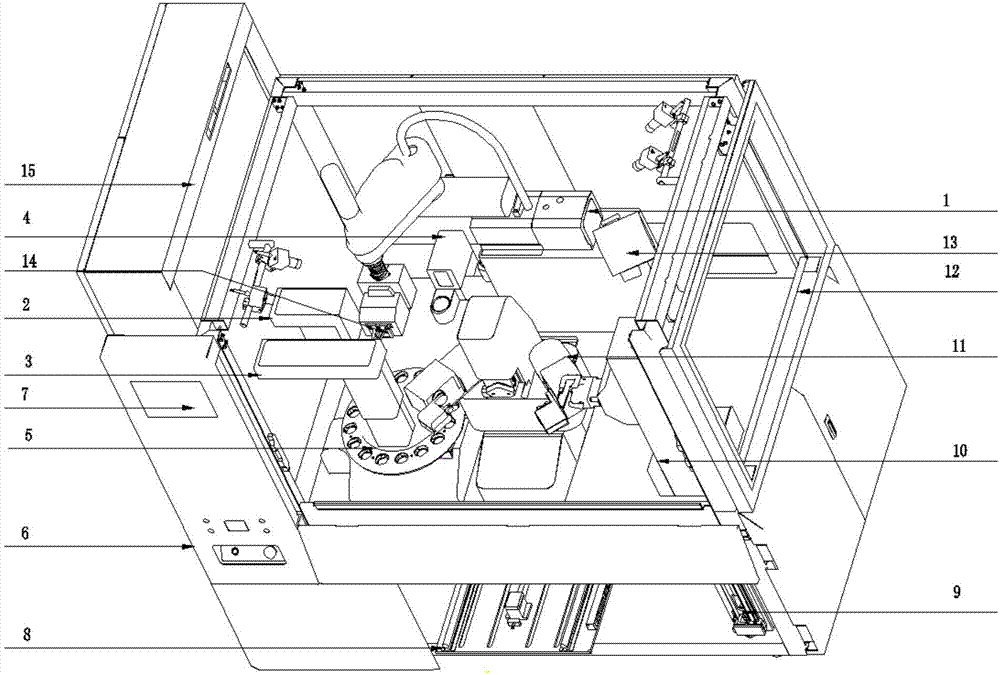

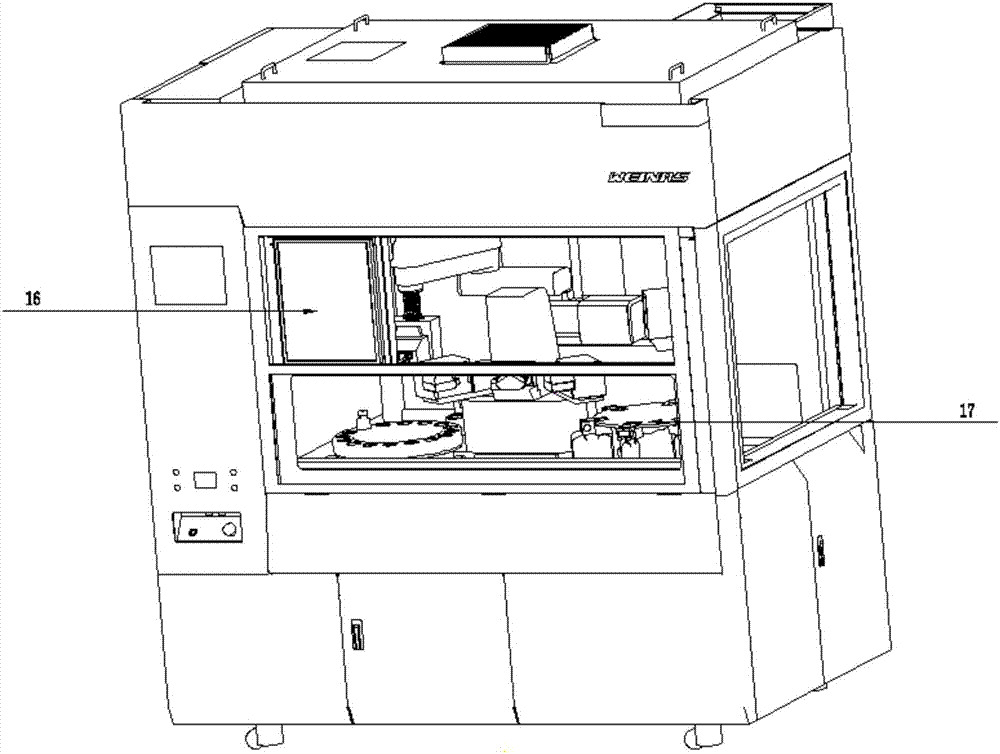

Automatic medicine dispensing device

InactiveCN107149886ARealize automatic liquid injectionSafe handlingShaking/oscillating/vibrating mixersDissolving systemsPeristaltic pumpPenicillin

The invention discloses an automatic medicine dispensing device, which comprises a control module, an input module, an interaction module, a solvent module, a peristaltic pump module, a waste bin module and a lifting window component, wherein the input module, the interaction module, the solvent module and the peristaltic pump module are arranged in a medicine dispensing cavity located in the upper part of the automatic medicine dispensing device; the waste bin module and the lifting window component are arranged in a supporting cavity located below the medicine dispensing cavity. Through the automatic medicine dispensing cavity provided by the invention, the liquid injection on a penicillin bottle, the dissolution of a medication in the penicillin bottle and the suction of a liquid medicine can be automatically realized; after the medicine dispensation is completed, waste medicine bottle and needling instrument are discarded into the waste bin; therefore, the whole medicine dispensing process is automatically completed with high efficiency; meanwhile, the pollution of the liquid medicine, which is easily brought during manual operation, can be avoided; the safety is improved; a medical worker is also prevented from injuries from edge tools of the medication and the broken medicine bottle or a needle head and the like during the medicine dispensation.

Owner:SHENZHEN CITY WEIBANG TECH

Preparation device of gas solution and method for improving solubility of gas in liquid

InactiveCN106000137AIncreased gas storageTransportation and packagingMixing methodsSolubilityEngineering

The invention discloses a preparation device of a gas solution and a method for improving the solubility of gas in liquid. The preparation device comprises a gas-liquid mixing apparatus, which is used for mixing gas and liquid to form a gas-liquid mixture. The gas-liquid mixing device is provided with a water outlet for discharging the gas-liquid mixture, and the water outlet is connected to a connecting pipeline. The connecting pipeline is provided with a variable diameter pipe, which includes multiple segments of pipe bodies, wherein at least two pipe bodies have different inner diameters, and the gas-liquid mixture from the gas-liquid mixing apparatus flows through the variable diameter pipe. The gas solution prepared by the preparation device provided by the invention has obviously improved gas solubility than that of gas solutions prepared by conventional preparation apparatuses.

Owner:SHANGHAI NANOBUBBLE TECH

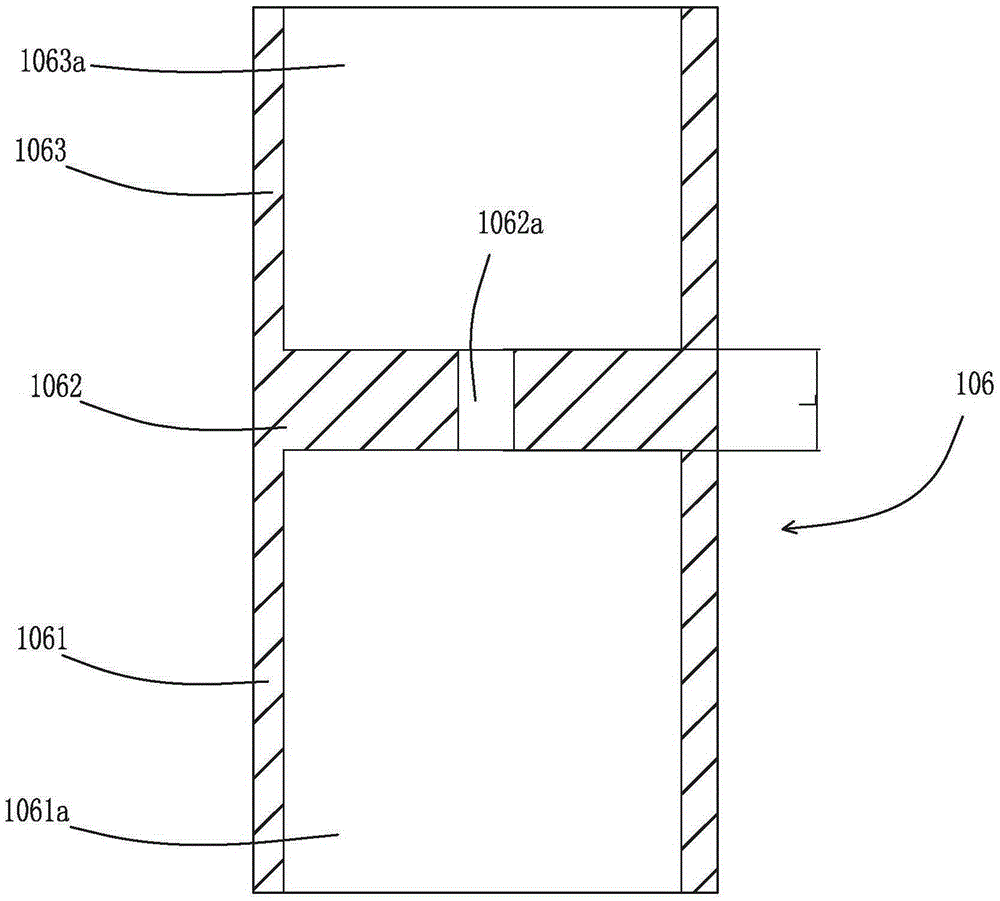

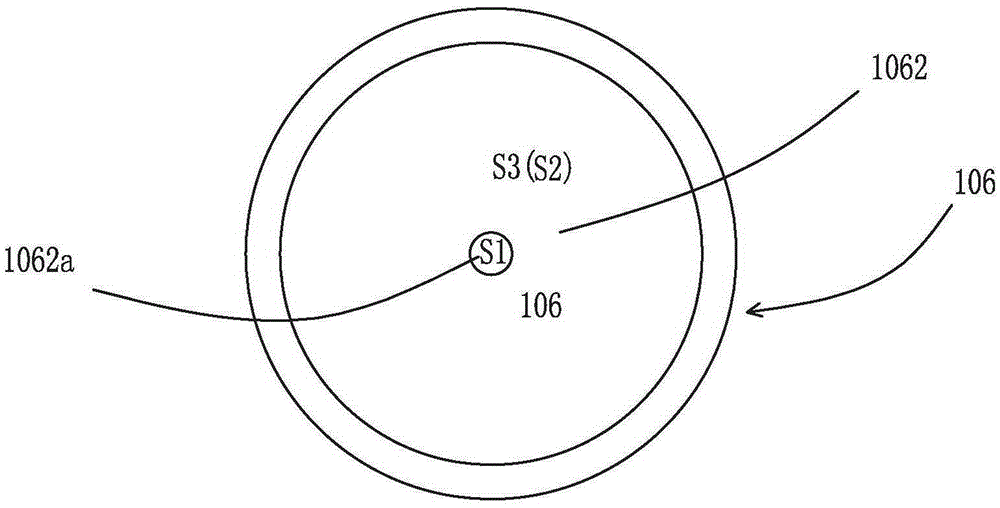

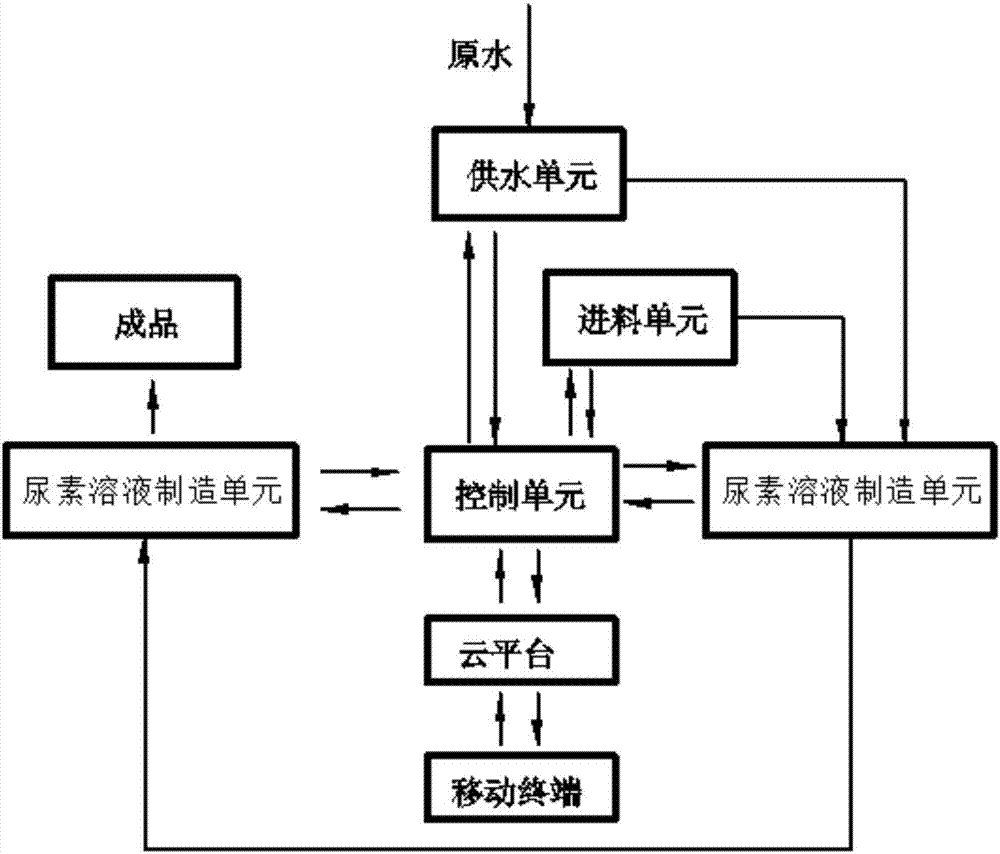

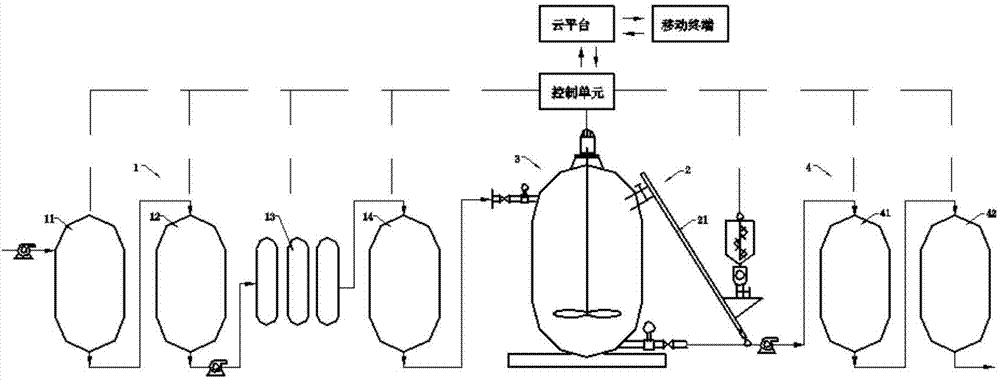

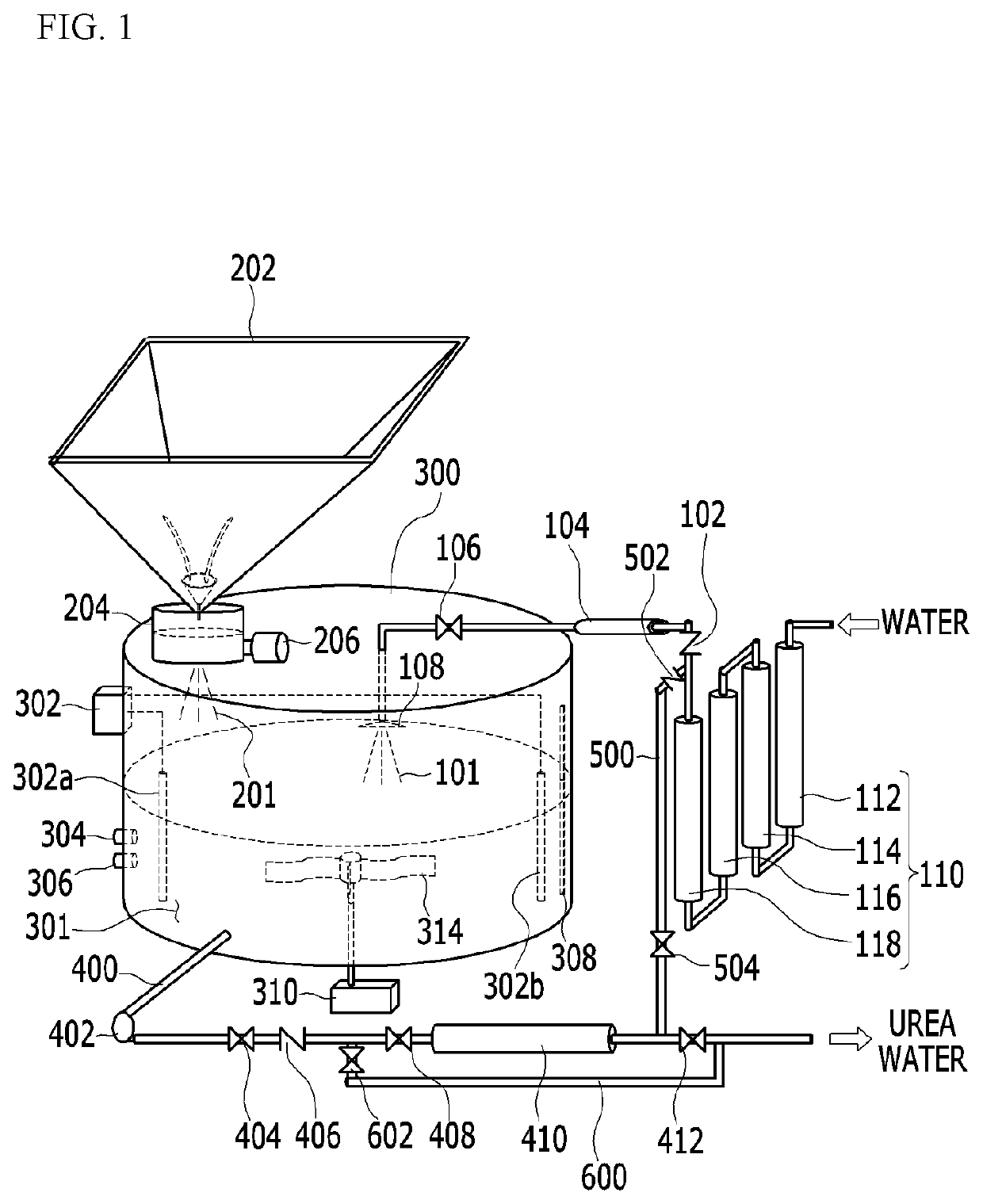

Manufacturing method and manufacturing system of urea solution for vehicle

ActiveCN107324554ATimely reminderTimely processingTransportation and packagingRotary stirring mixersSolubilityAutomatic control

The invention discloses a manufacturing method and a manufacturing system of a urea solution for a vehicle. The manufacturing method comprises the following steps: S1, manufacture of high-purity water, S2, preparation of the urea solution for the vehicle, and S3, filtration and purification of the urea solution for the vehicle; in the manufacturing process, quality controlling and data monitoring are conducted in real time through a control unit and each data collecting sensor, and data are transmitted to a mobile terminal through a cloud platform. The manufacturing system comprises a control unit, the cloud platform and the mobile terminal, and further comprises a water supply unit and a feeding unit as well as a urea solution manufacturing unit and a filtration and purification unit; the control unit is used for control of the whole system, data collection, data analysis and automatic control. In conclusion, according to the manufacturing method and manufacturing system of the urea solution for the vehicle, which are disclosed by the invention, the urea solution for the vehicle, which has qualified urea solubility, can be automatically manufactured; the manual operation strength and frequency are reduced; the manufacture of the urea solution for the vehicle is automatically completed; the mobile terminal can be supervised and looked over in real time through the cloud platform.

Owner:SHANDONG NEW BLUE ENVIRONMENTAL PROTECTION TECH CO LTD

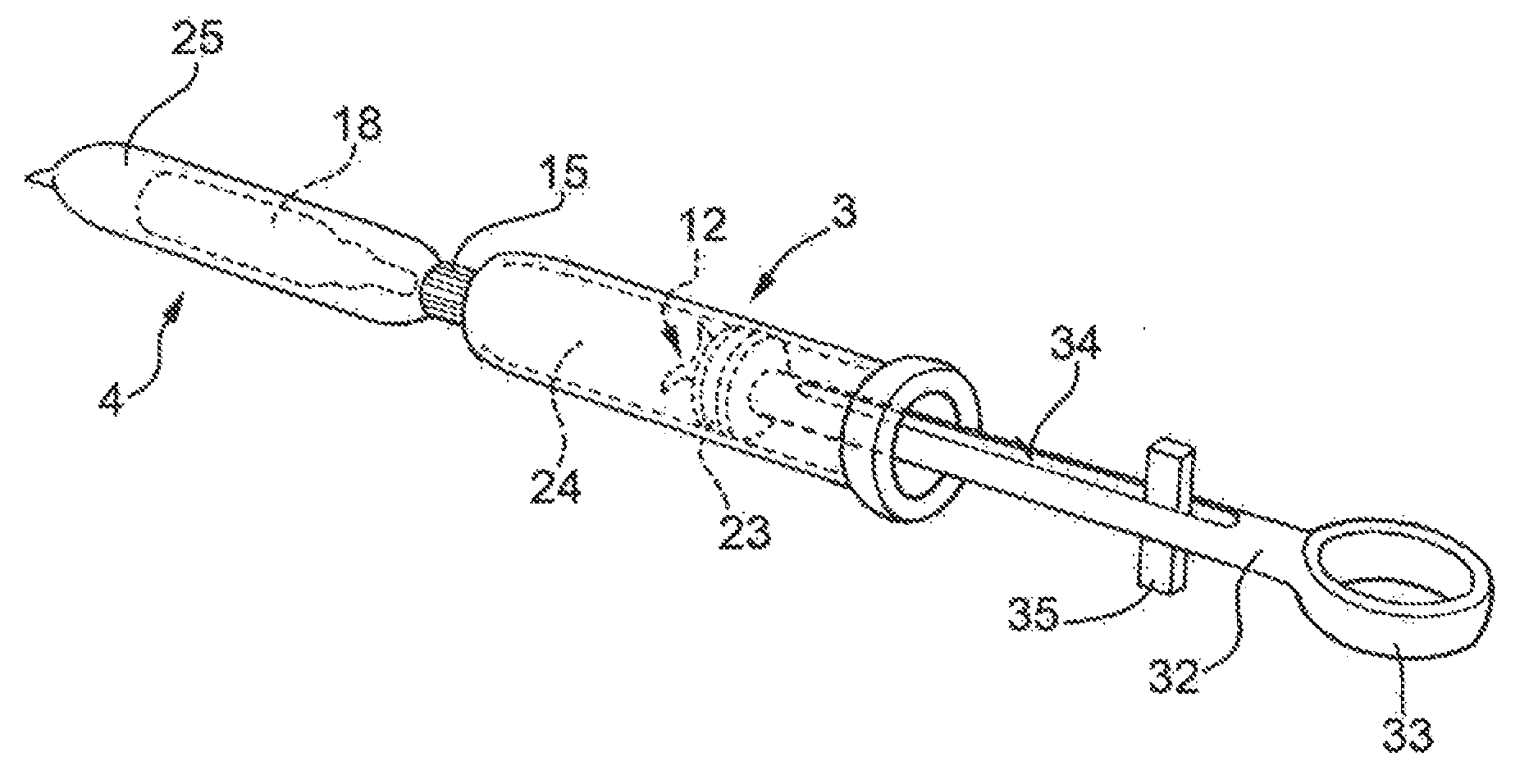

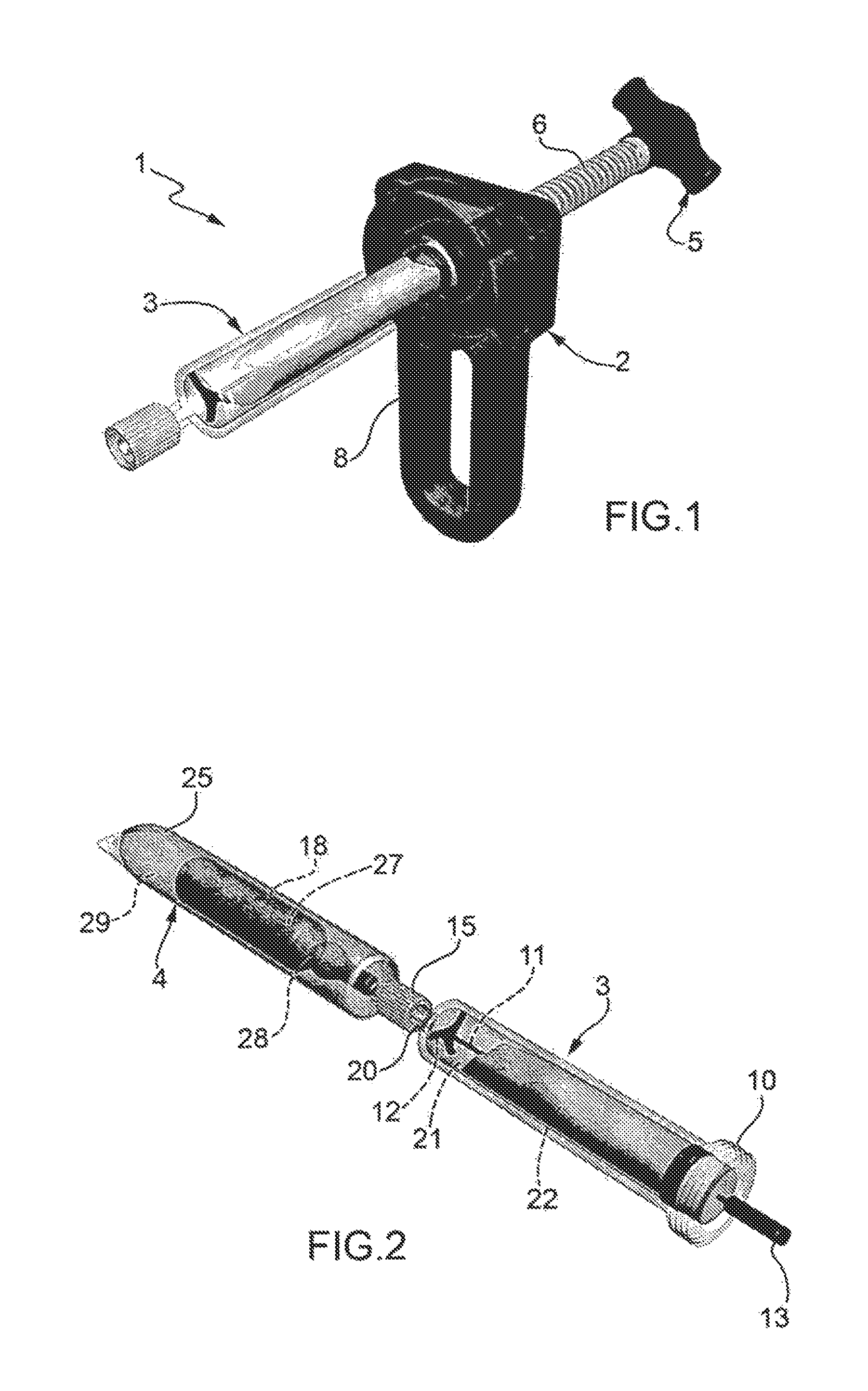

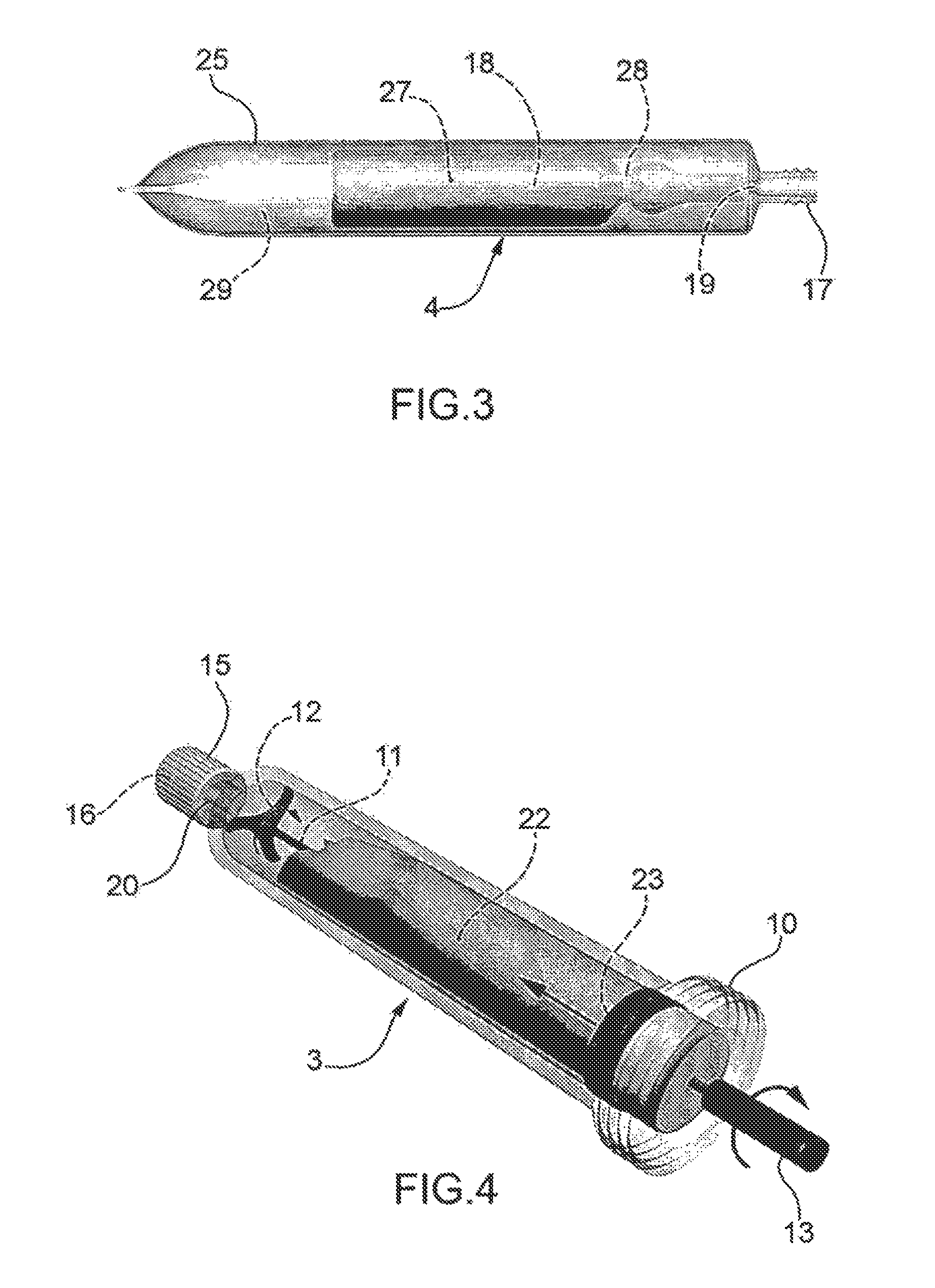

Mixer for biphasic compounds

ActiveUS9016925B2Efficient use ofDirect contact guaranteeShaking/oscillating/vibrating mixersFlow mixersEngineeringSolid phases

Mixer for biphasic compounds, including a chamber for containing a solid phase and a cartridge containing a phial of a liquid phase, said chamber and said cartridge being able to communicate through respective channels, wherein said cartridge includes an external casing made in a deformable material and said phial is of the breakable type.

Owner:TECRES SPA

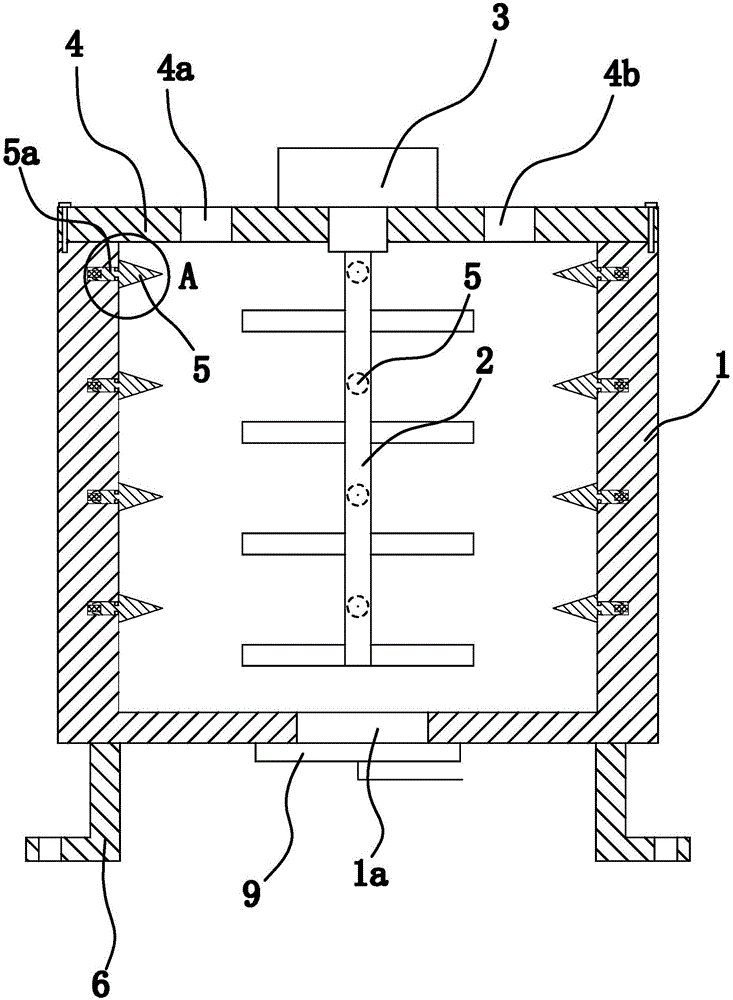

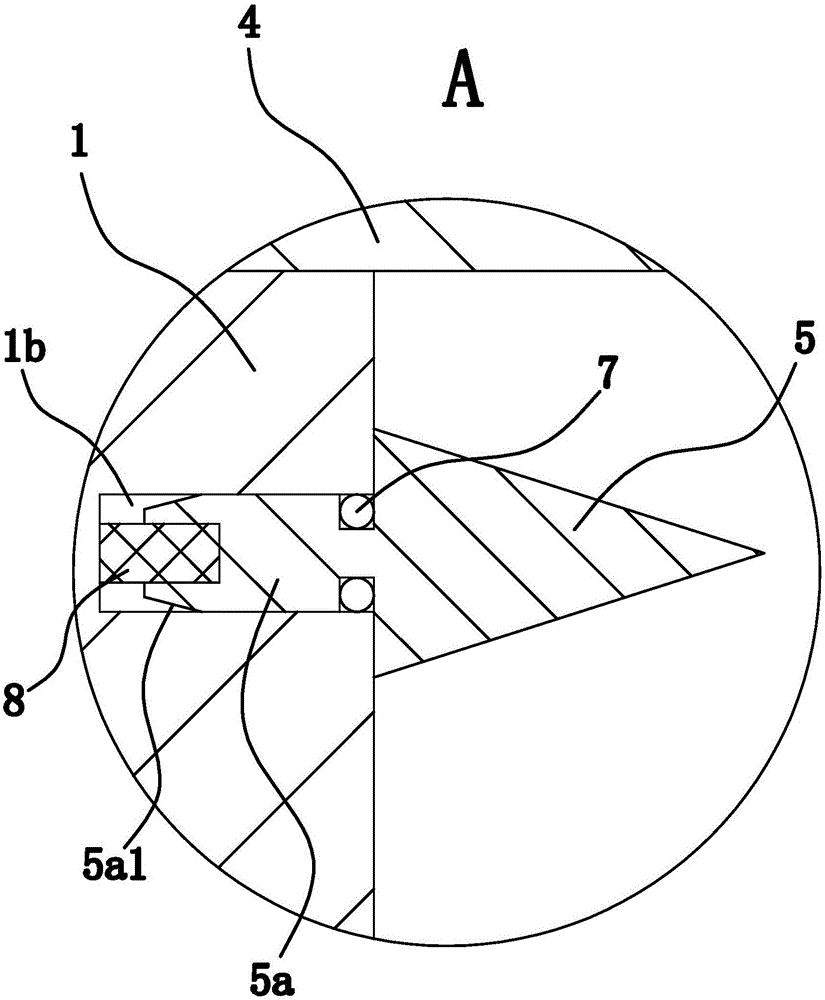

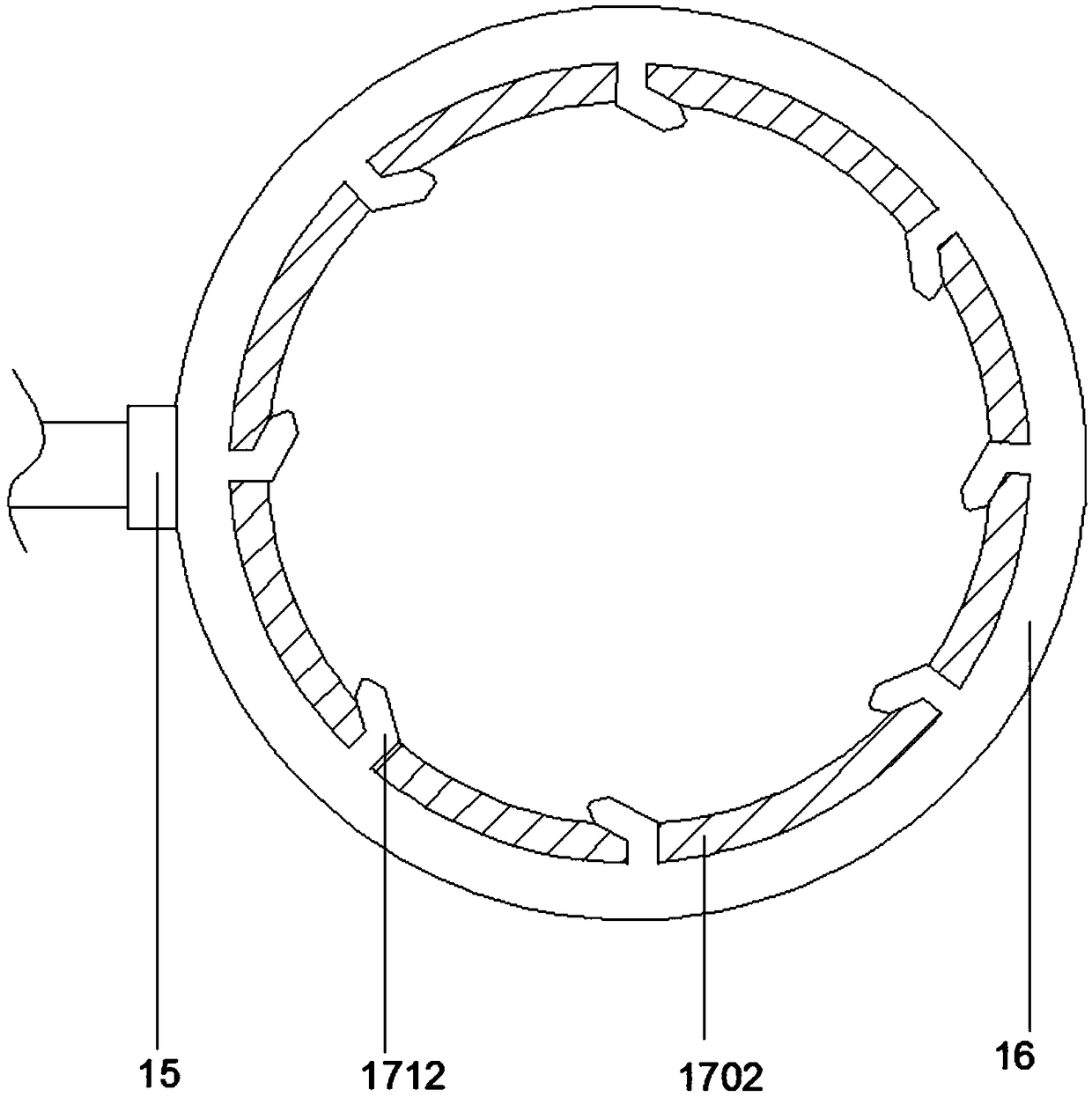

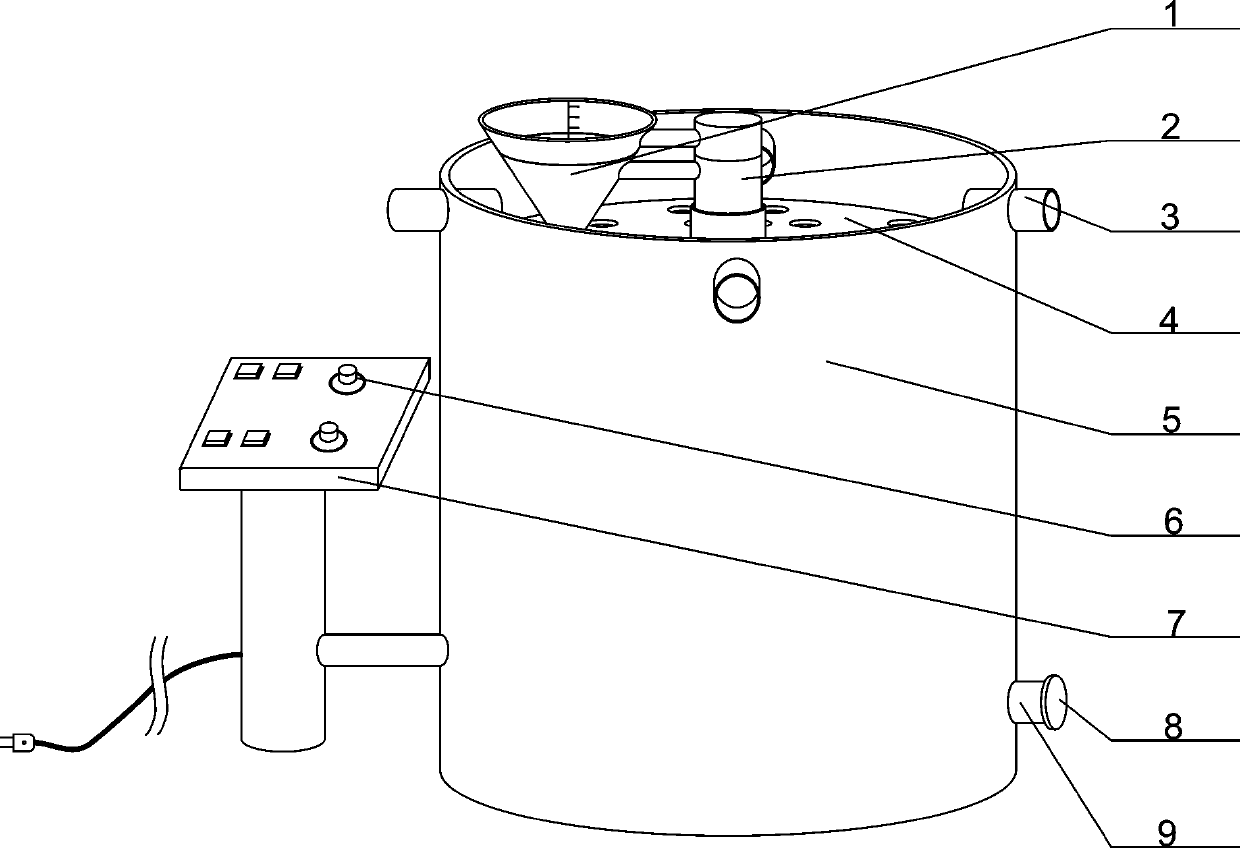

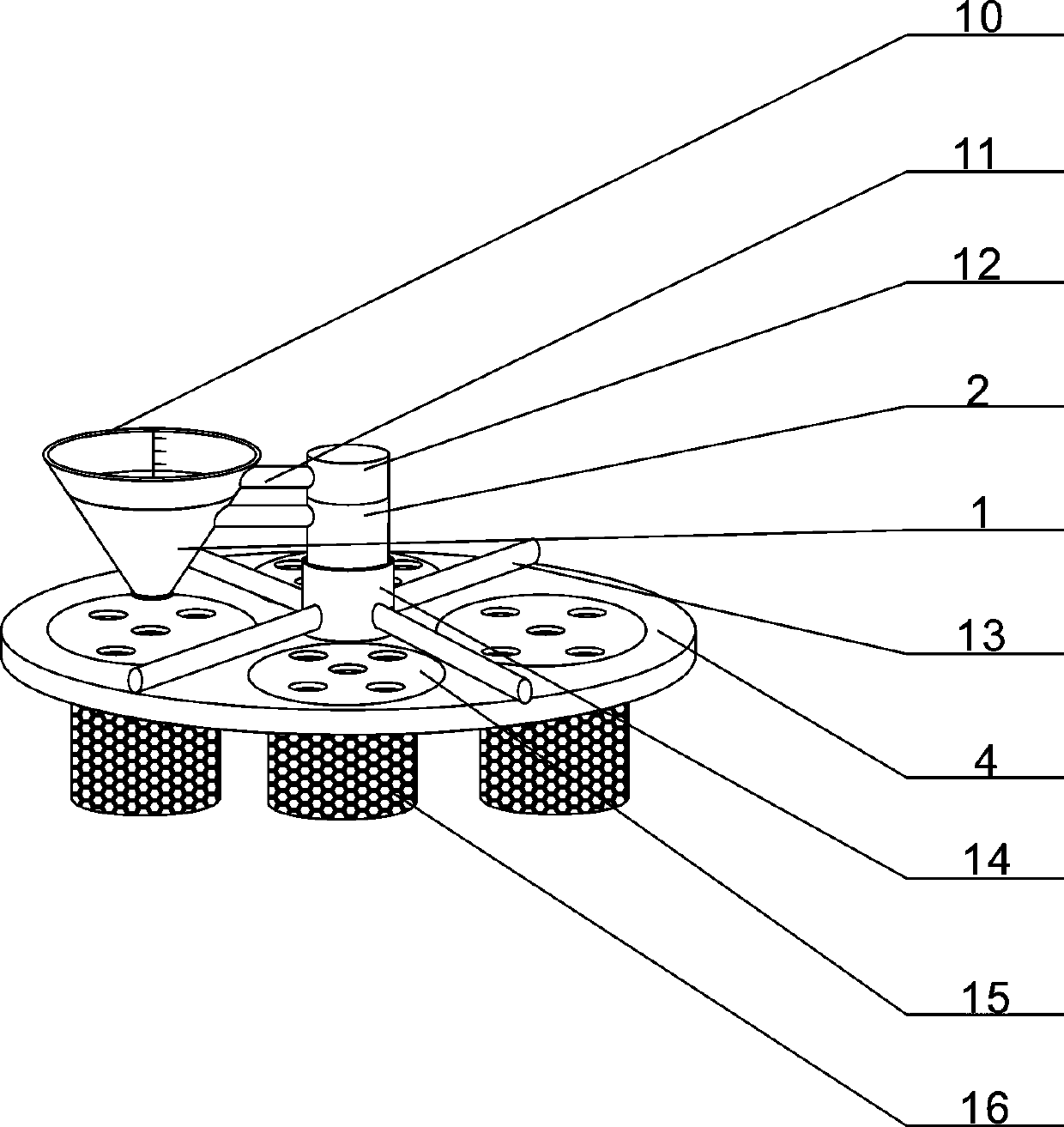

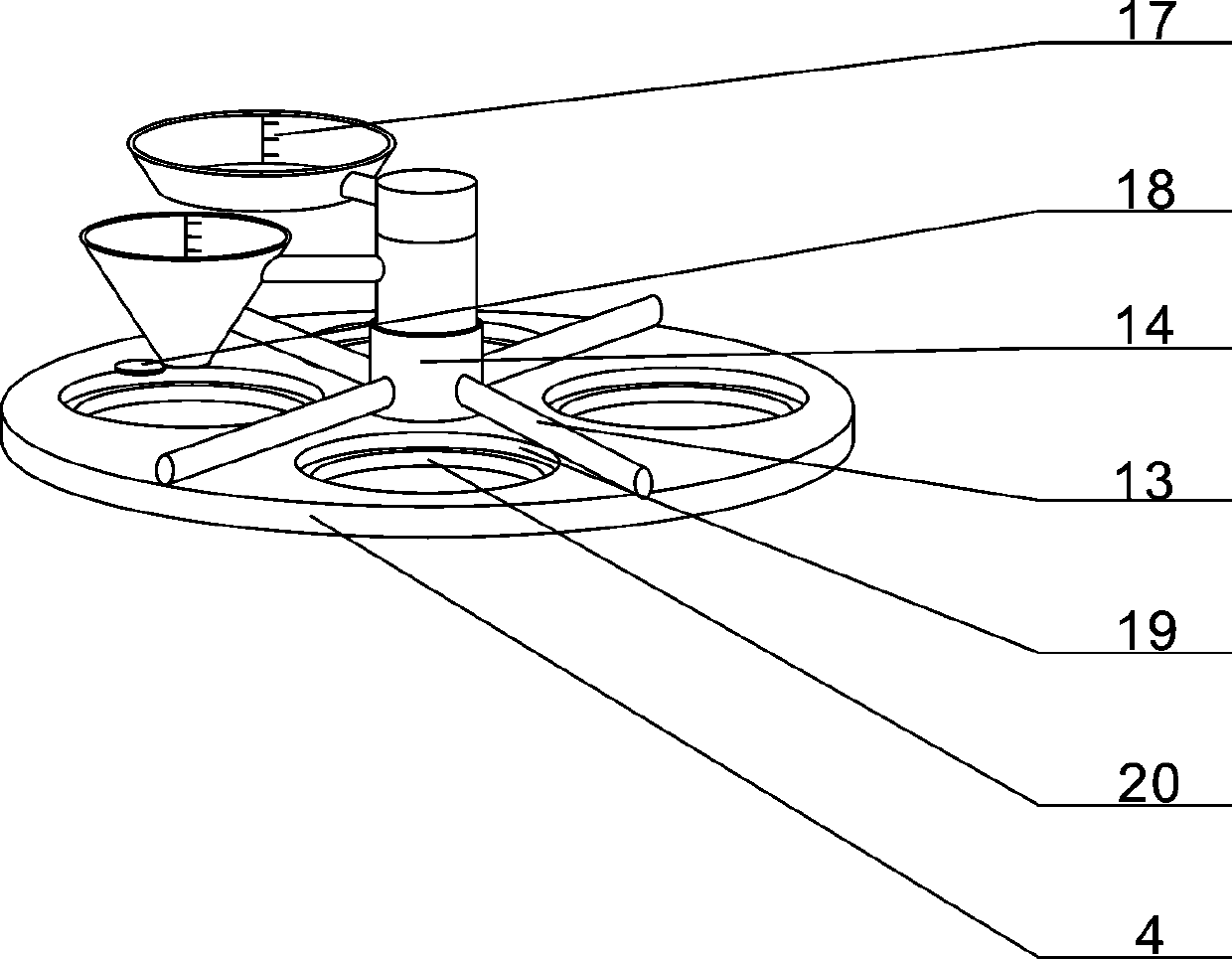

Dissolving device for sewage treating agent

InactiveCN105727776AFast and fully soluble inIncrease profitRotary stirring mixersTransportation and packagingElectric machineryEngineering

The invention provides a dissolving device for a sewage treating agent, which belongs to the technical field of water treatment and can be used for solving the problem that existing sewage treating agents cannot be adequately dissolved. The dissolving device comprises a stirring cylinder, wherein a water outlet is formed in the bottom of the stirring cylinder, stirring blades are arranged in the stirring cylinder, a limiting ring is fixed at the top of the stirring cylinder, and a motor capable of driving the stirring blades to rotate is arranged on the limiting ring; a plurality of solid cone-shaped cone heads are arranged in the stirring cylinder, cylindrical connecting parts are arranged on the bottom walls of the cone heads, connecting holes are formed in the inner side wall of the stirring cylinder, the number of the connecting holes is same as that of the connecting parts, and the positions of the connecting holes corresponds to the connecting parts one by one, the connecting parts are inserted into the connecting holes, sealing rings are arranged between the connecting parts and the inner walls of the connecting holes, positioning grooves are formed in the end surfaces of the connecting parts, magnetic pillars are inserted and fixed in the positioning grooves, the outer ends of the magnetic pillars stretch out of the positioning grooves, and the outer end surfaces of the magnetic pillars cling to the bottom walls of the connecting holes; and the stirring cylinder is made of stainless steel materials. The dissolving device has the advantage of being capable of adequately dissolving the sewage treating agent.

Owner:叶君芝

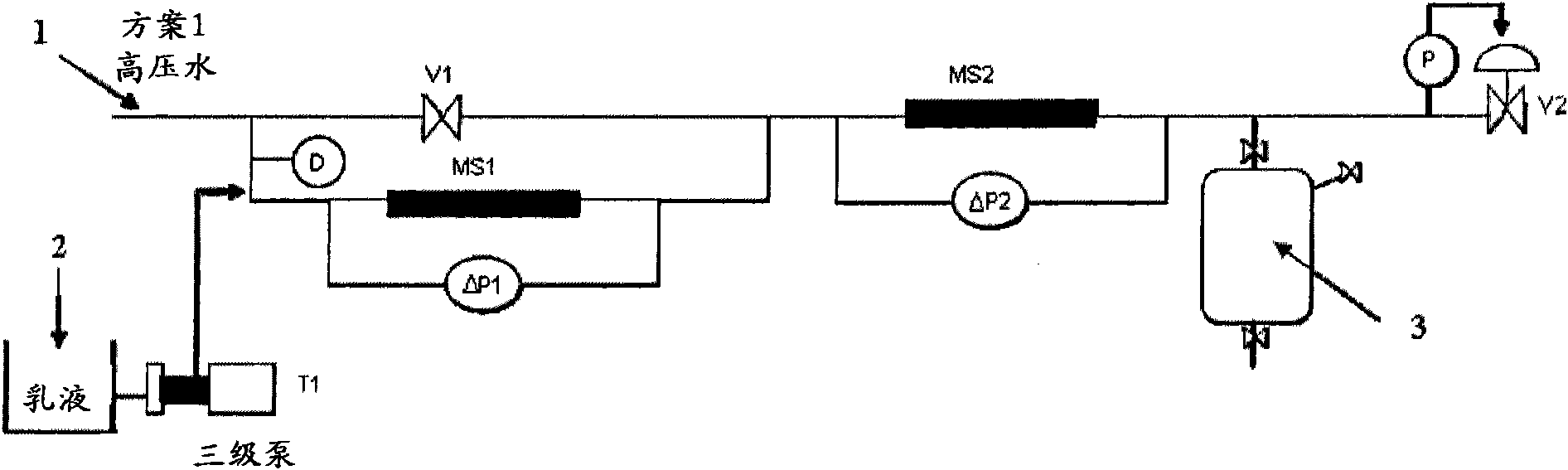

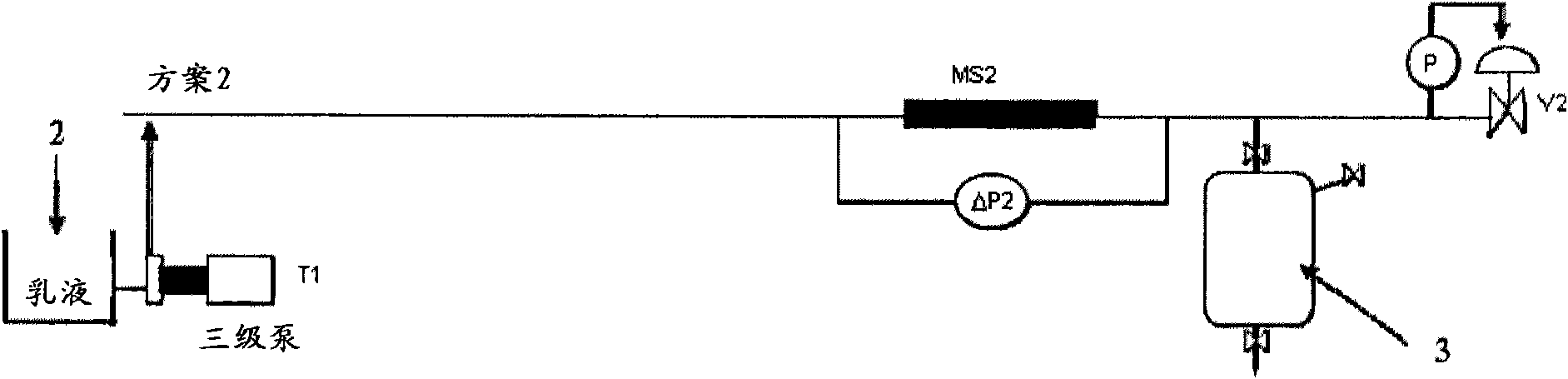

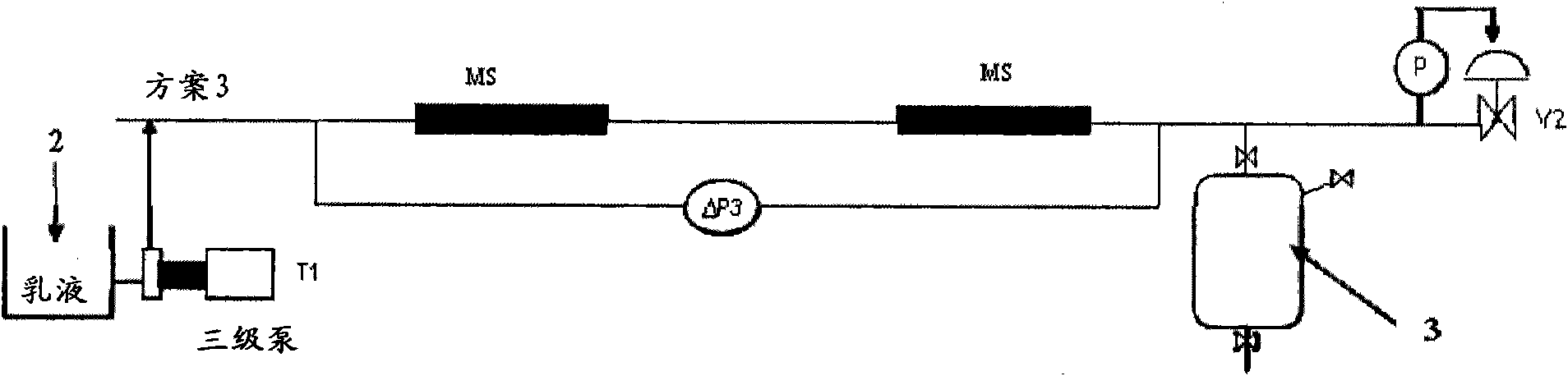

Method of continuous dissolution of polyacrylamide emulsions for enhanced oil recovery (eor)

ActiveCN101994502AFix stability issuesSpeed up the processTransportation and packagingFluid removalEmulsionPolymer science

Enhanced oil recovery method consisting in continuously dissolving, in the injection water, a stable invert emulsion of acrylamide (co)polymer containing at least one inverting agent, and a water soluble polymer, whereby: - in a first step, the emulsion is prediluted in a first static mixer to a (co)polymer concentration of at least 5 g / l, the difference of pressure between the mixer outlet and inlet being at least 2 bar, - in a second step, the suspension from the first mixer is diluted in a second static mixer to a concentration corresponding to the injection concentration of the water in the well of between 500 and 3000 ppm, the difference of pressure between the mixer outlet and inlet being at least 1 bar.

Owner:S P C M SA

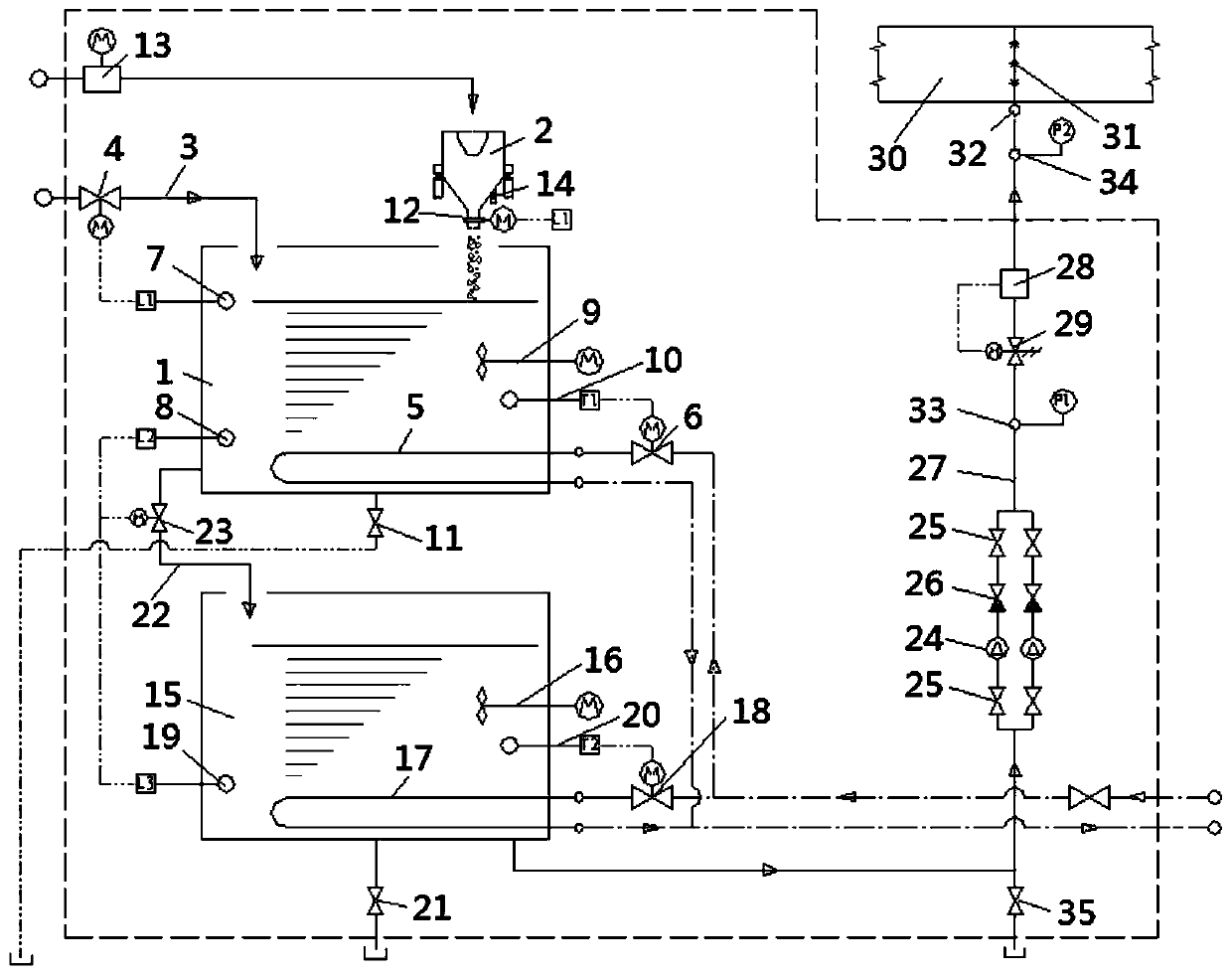

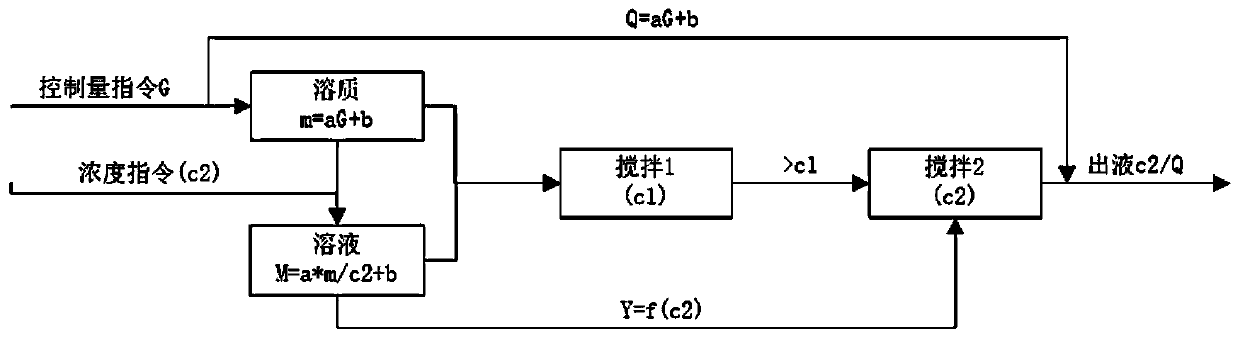

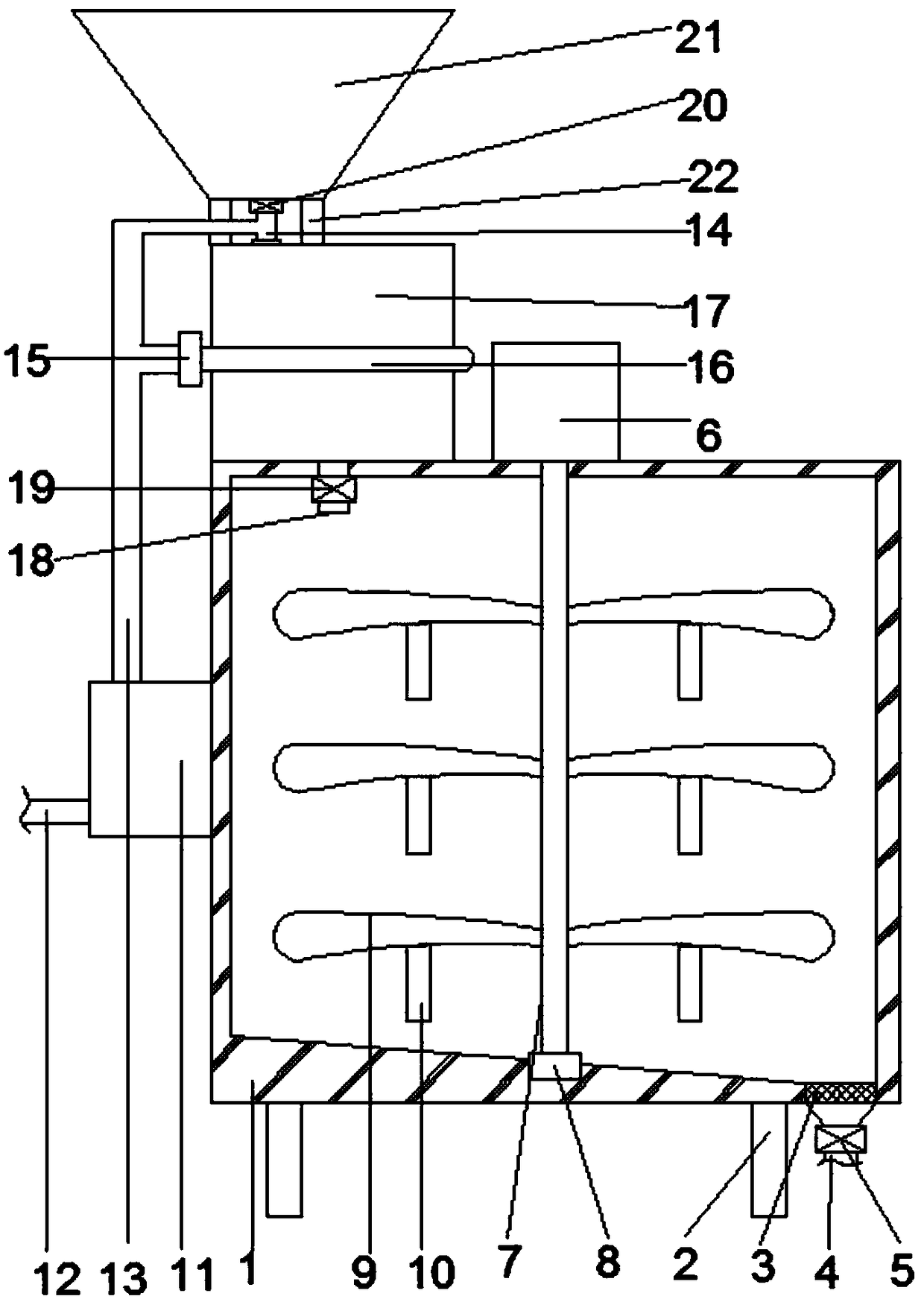

Preparation and conveying system for constant-concentration solution

InactiveCN110314563AFormulated continuously and efficientlyFormulated efficiently and sustainablyDissolving systemsTransportation and packagingSolubilityHigh concentration

The invention discloses a preparation and conveying system for a constant-concentration solution. The system is adopted for preparation of an alkaline solution or alkaline salt solution used for removing SO3 components in boiler flue gas, the high concentration and basically-constant concentration of the solution can be ensured, the requirements of solute variety changes, control over the solutiontemperature range, adjustment for the spraying amount of the solution and the like can be met, and the system comprises a preparation and conveying controller, a constant-concentration solution preparation device, a solution storage device and a solution conveying device. In the constant-concentration solution preparation device, a first liquid level sensor is used for detecting the liquid levelof a first solution in a preparation tube, a solvent control unit is used for controlling a solvent addition device to add a solvent into the preparation tube according to the liquid level of the first solution, and a solute control unit is used for controlling a solute addition device to add a solute into the preparation tube in an amount control mode according to the addition amount of solvent every time by the solvent addition device and the solute solubility corresponding to the temperature of the first solution, so that the constant concentration of the solution is maintained. The systemhas the technical advantage that the constant concentration, the constant temperature and efficient and sustainable preparation are achieved.

Owner:SHANGHAI ORIENTAL MARITIME ENG TECH CO LTD

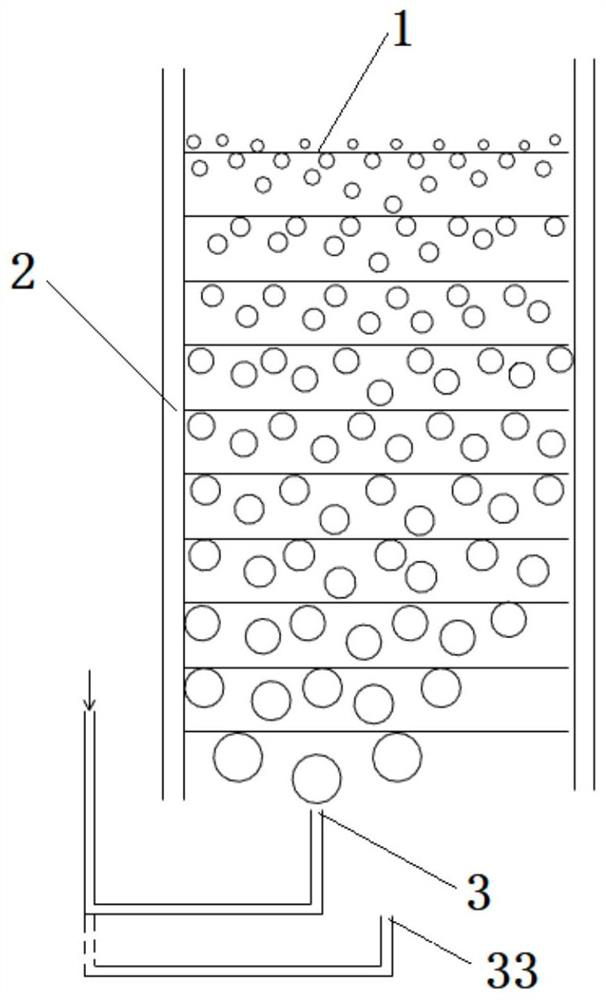

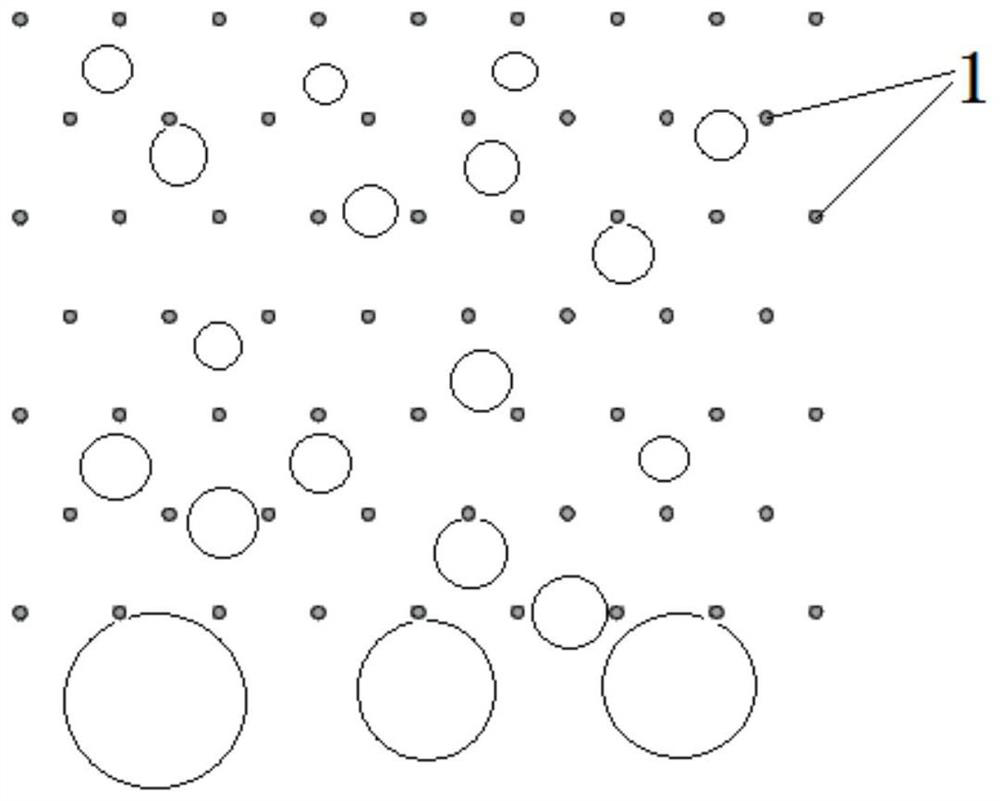

Bubble cutting device

PendingCN112957934AImprove dissolution efficiencyImprove practicalityMixing methodsTransportation and packagingEngineeringMechanical engineering

The invention discloses a bubble cutting device. Multiple layers of bubble cutters 1 are arranged in the rising process of bubbles, and each bubble cutter can be an elastic monofilament with one end fixed and the other end suspended. When the bubbles are cut, if sundries are hung on the monofilaments 1, the monofilaments can be bent upwards under the washing of gas-liquid flow 4, sundries can be hardly attached and are washed away, and the long-time efficient operation of equipment is facilitated.

Owner:GUANGZHOU ENERQUID TECH CO LTD

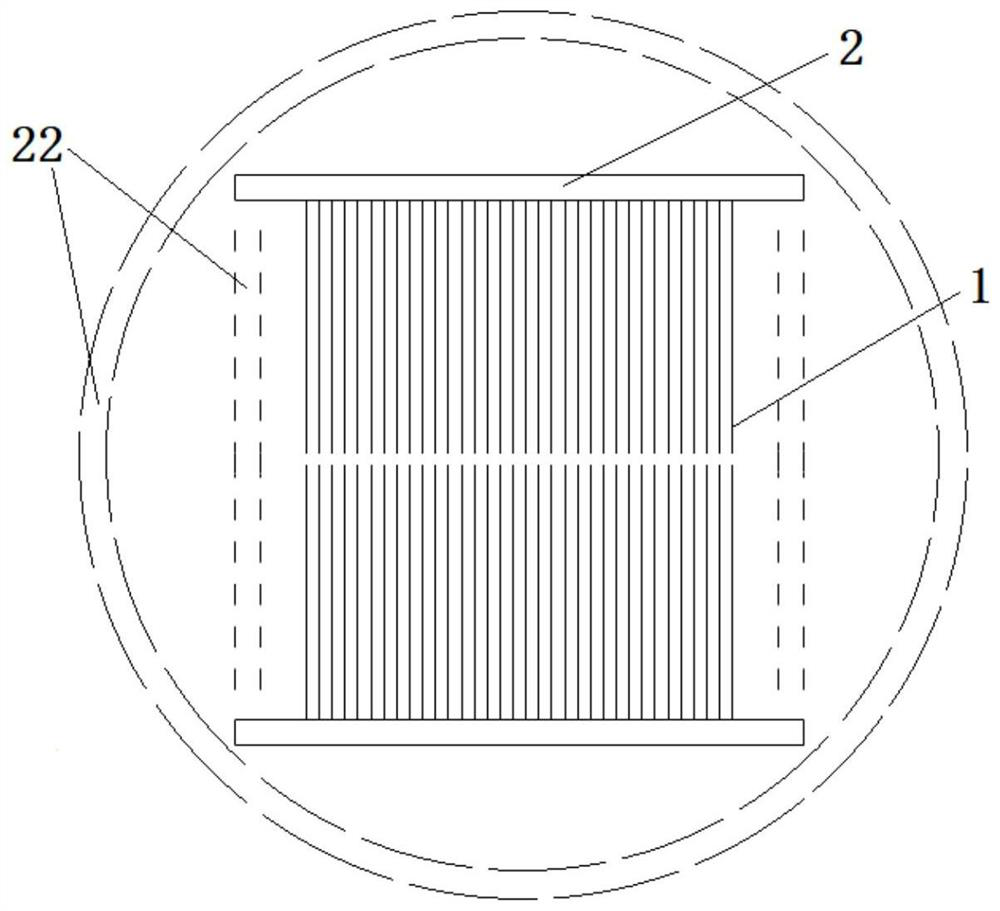

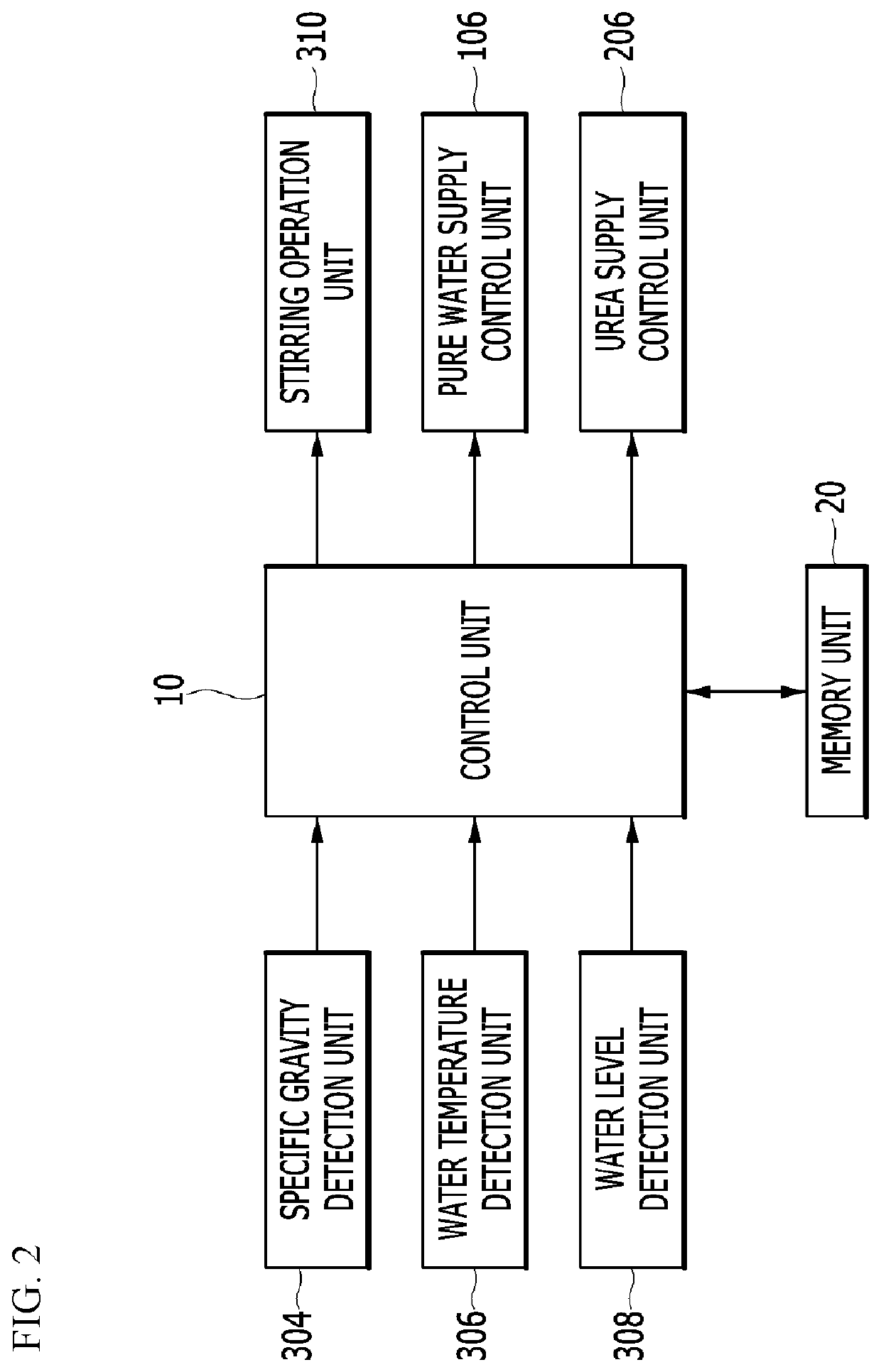

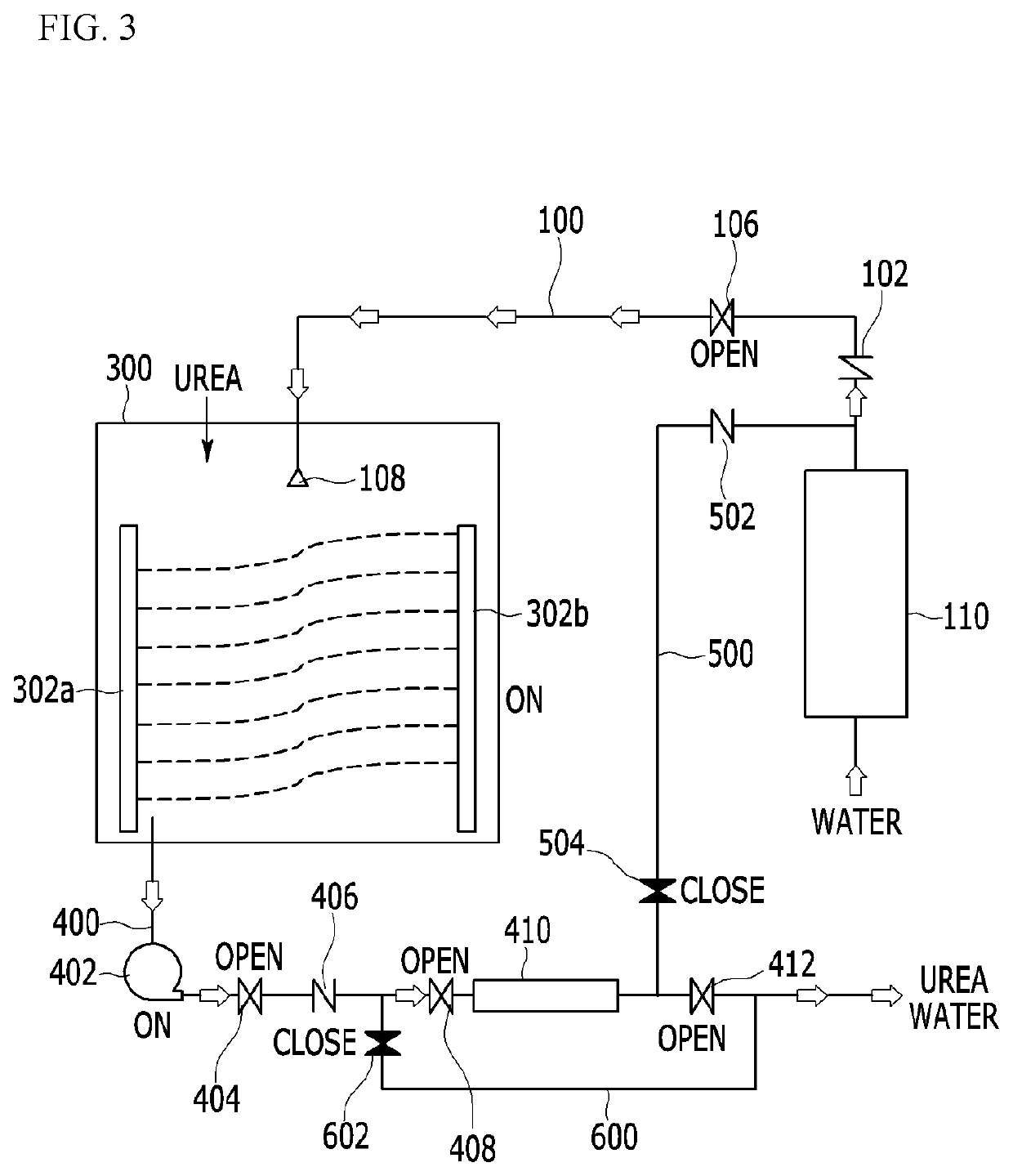

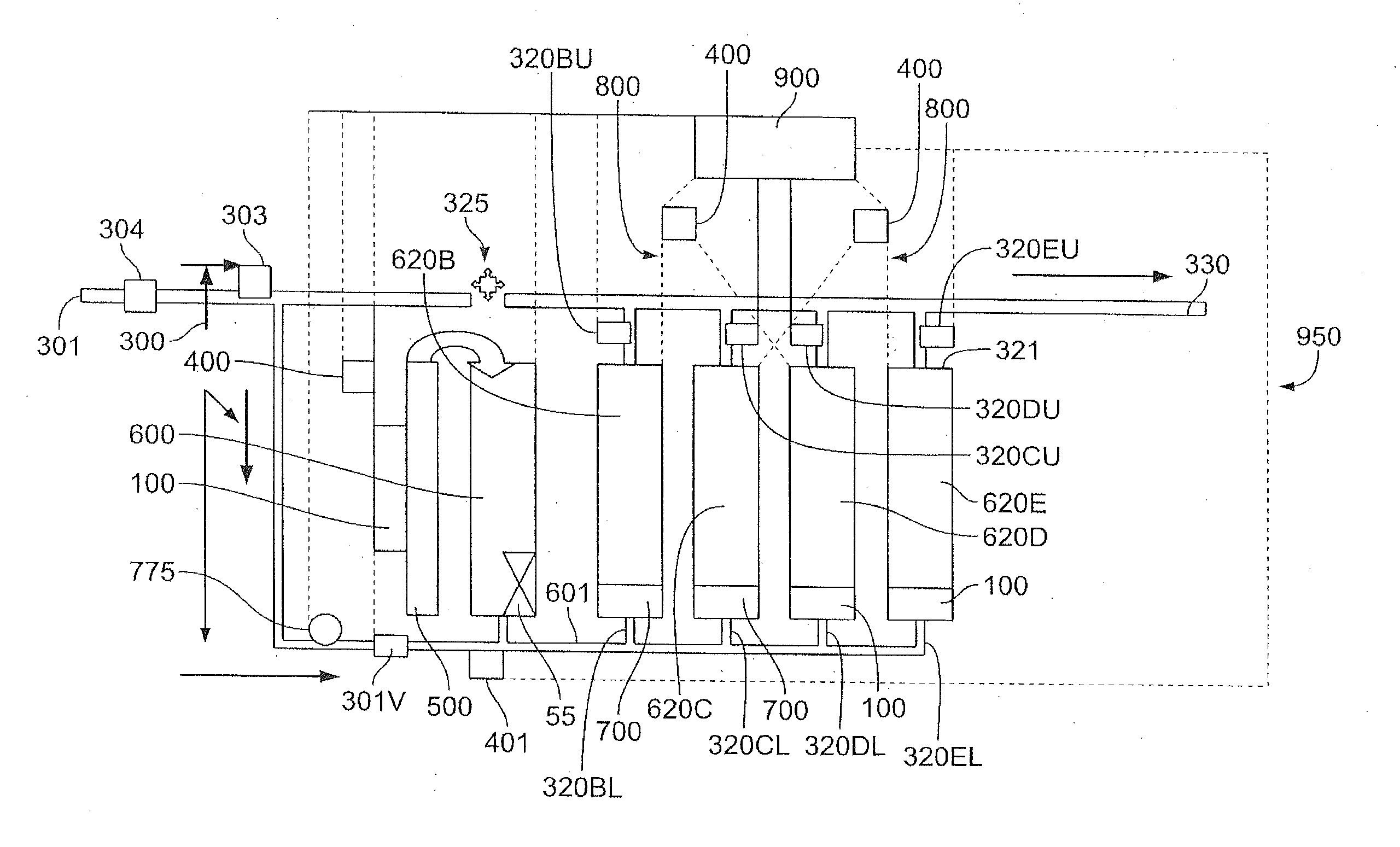

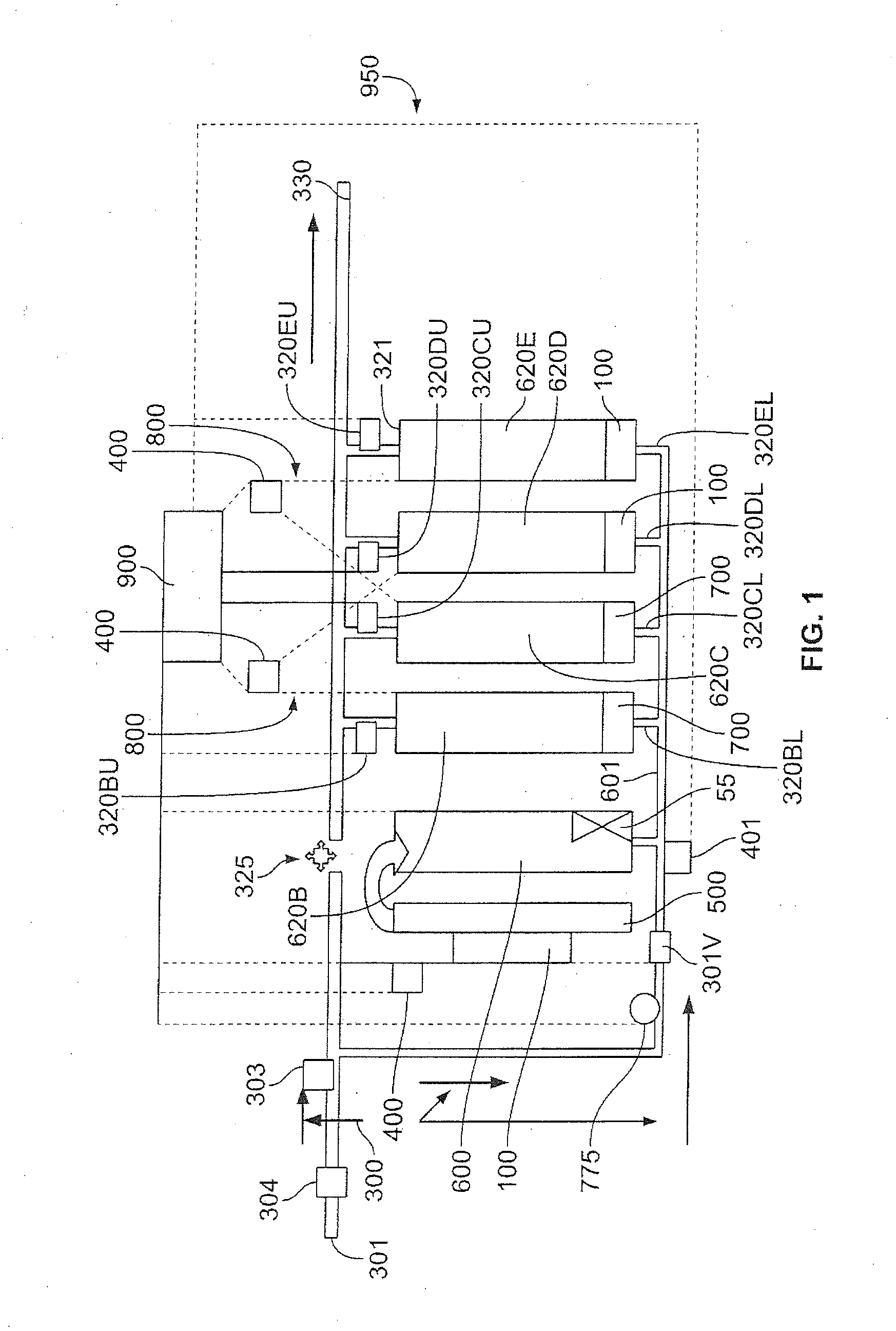

Urea water manufacturing device and thereof method

PendingUS20200270204A1Shorten the timeHigh purityUrea derivatives preparationShaking/oscillating/vibrating mixersControl cellProcess engineering

An exemplary embodiment of the present invention provides a urea water manufacturing device which can reduce the time for producing urea water by forming a vibrating atmosphere using an ultrasonic wave generator when stirring urea and pure water supplied inside a stirring tank, and can produce urea water with high purity by real-time feedback control of specific gravity of urea water, and a method thereof. The urea water manufacturing device according to an exemplary embodiment of the present invention includes a pure water supply unit, a urea supply unit, a stirring unit, a specific gravity detection unit, a control unit, and a urea water discharge unit.

Owner:SEO JAEKWANG

Efficient activating and dissolving method of rhodium powder

PendingCN111304457ADoes not affect protectionImprove protectionTransportation and packagingMixer accessoriesMetallurgyPhysical chemistry

The invention discloses an efficient activating and dissolving method of rhodium powder. The rhodium powder and a hydrochloric acid solution are mixed in a certain ratio, the mixed solution is put ina reactor, a certain amount of activator gold powder is introduced, temperature is controlled at 60-112 DEG C, Cl2 is introduced and subjected to a reaction for 1-3 h, Cl2 is recycled in a dissolvingprocess, heat preservation is performed at a certain temperature for 10-90 min after Cl2 introduction is ended, the mixed solution is cooled to normal temperature and then is filtered, and a chlororhodic acid solution with purity higher than 99.95% and Rh content higher than 15% is obtained. The dissolution rate of rhodium is higher than 96%, Cl2 is recycled in the dissolving process, and the method has the characteristics that environmental protection property is good, the technological process is short, dissolving efficiency and dissolution rate are high, no new impurities are introduced basically, the obtained chlororhodic acid solution has high Rh content and high purity and the production cost is low.

Owner:康纳新型材料(杭州)有限公司

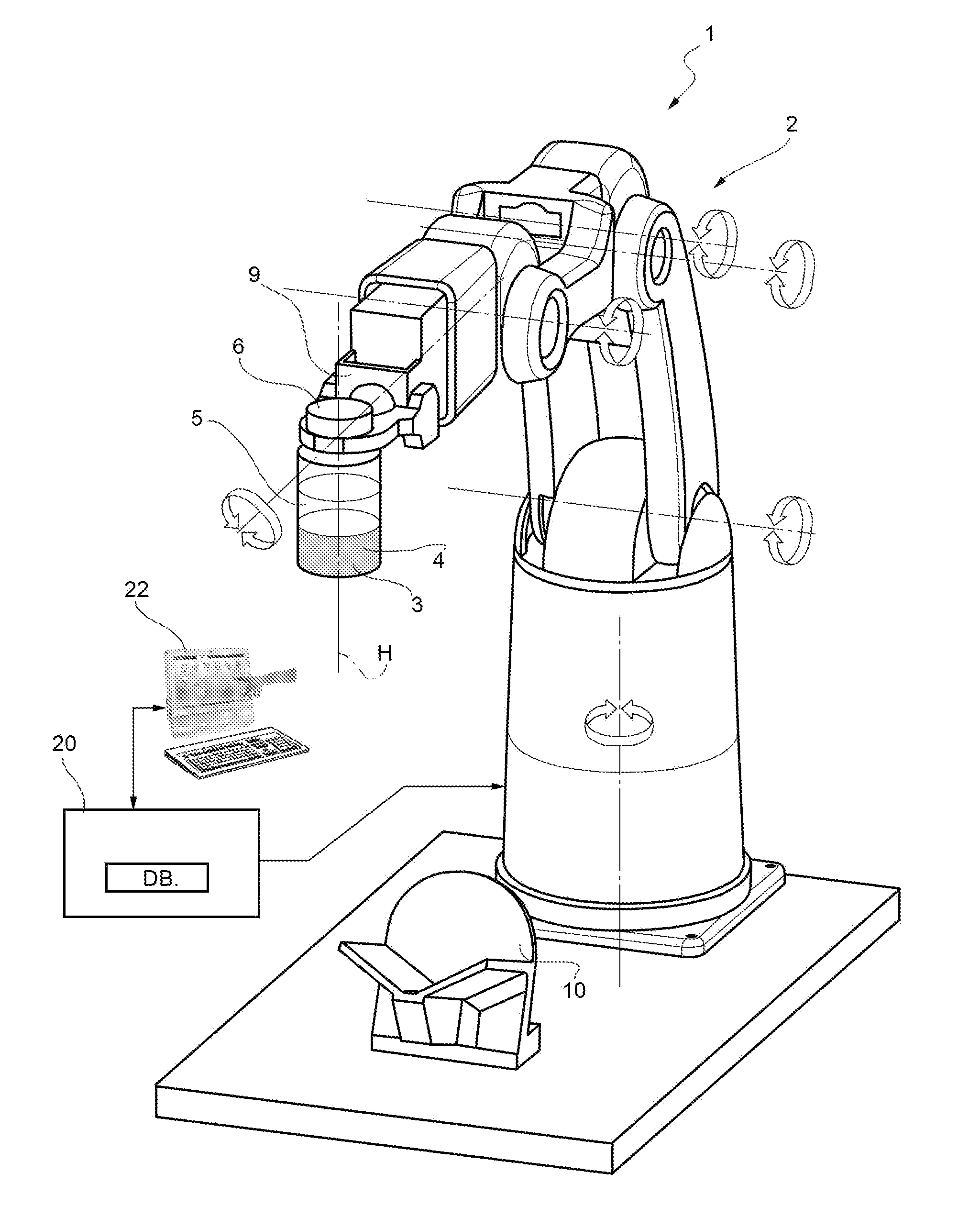

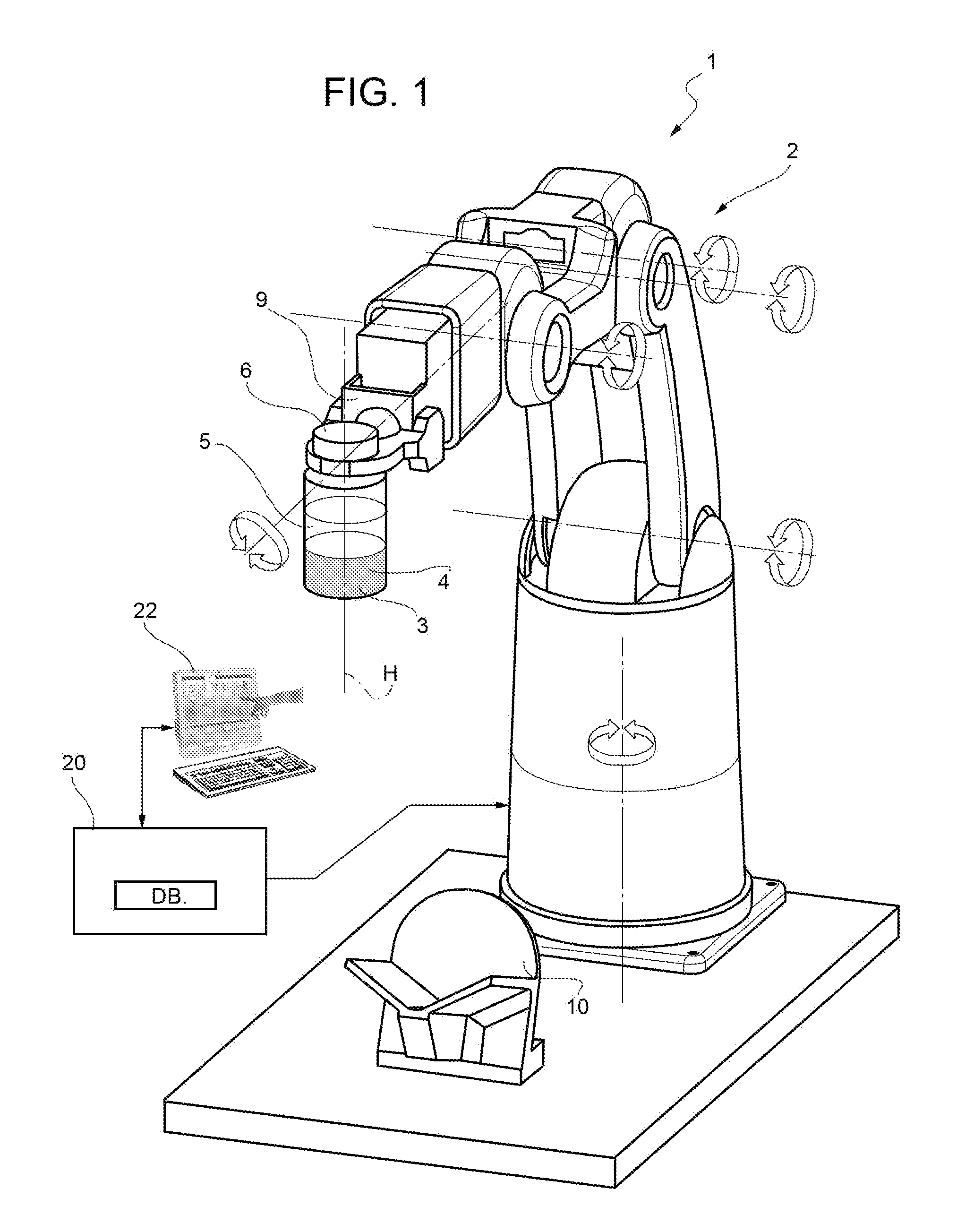

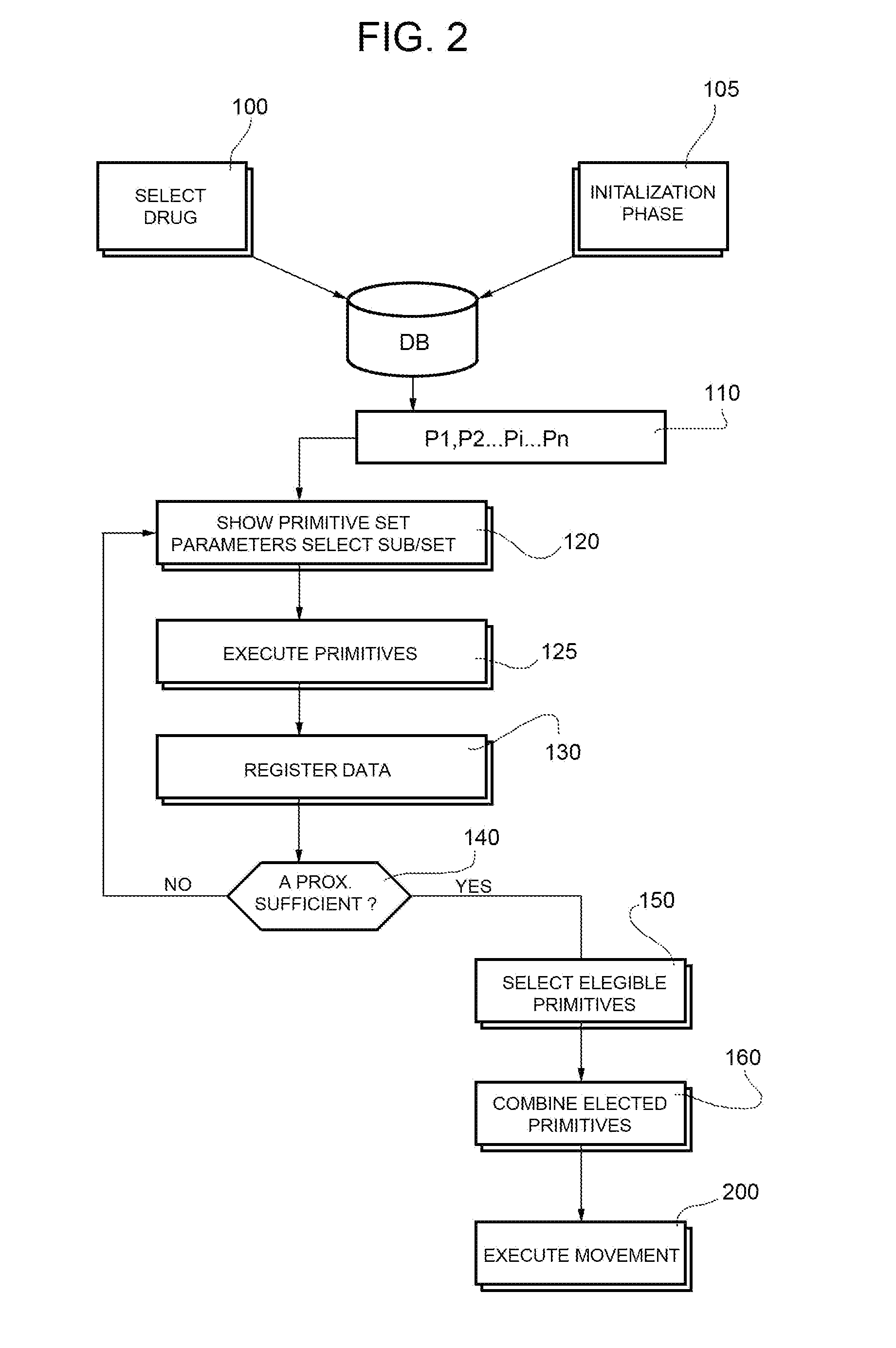

Method For Powdered Drug Reconstitution

ActiveUS20140358272A1Programme controlShaking/oscillating/vibrating mixersRobot controlHuman–computer interaction

Method of robot control is disclosed that includes the steps of: providing a user interface for introducing data indicative of a drug to be subjected to a reconstitution process; accessing an internal data base for outputting, for a selected drug, a list of primitive movements P1, P2, . . . Pi, . . . Pn to be used in the reconstructing process; operating the robot for executing sequentially the primitives and moving a container according to the instructions of the primitives; measuring, during the movement of the container under robot action, physical positions in the space and dynamic parameters of the container creating a list of registered data; comparing the measured positions in the space and the dynamic parameter with the corresponding ones of the primitive movements for selecting a list of eligible primitives if a sufficient approximation level is reached; elaborating selected eligible primitives together to generate instructions for the robot allowing a complex movement encompassing the simple movements; and using the robot for shaking the container according to the complex movement.

Owner:OMNICELL

Method for uniforming solution and solution tank

PendingCN105771709AQuick mixSave consumption costFlow mixersTransportation and packagingEngineeringDistributor

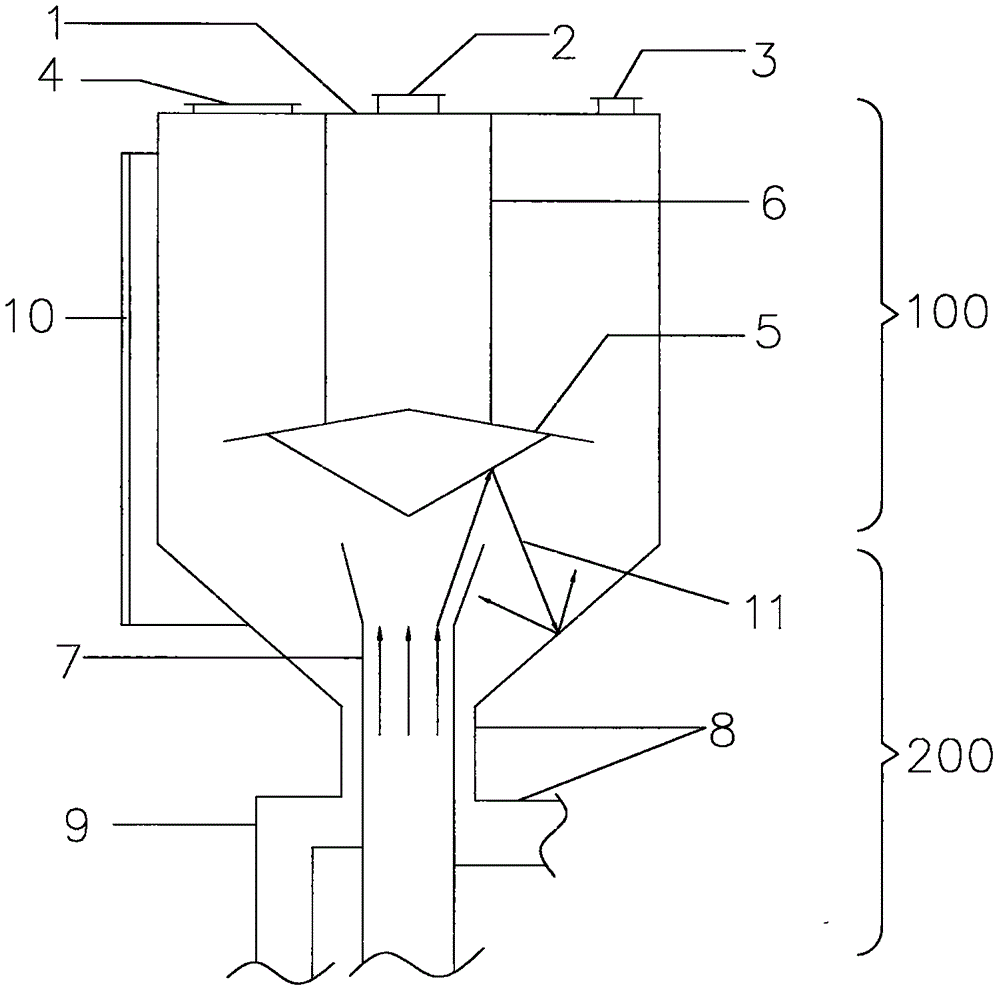

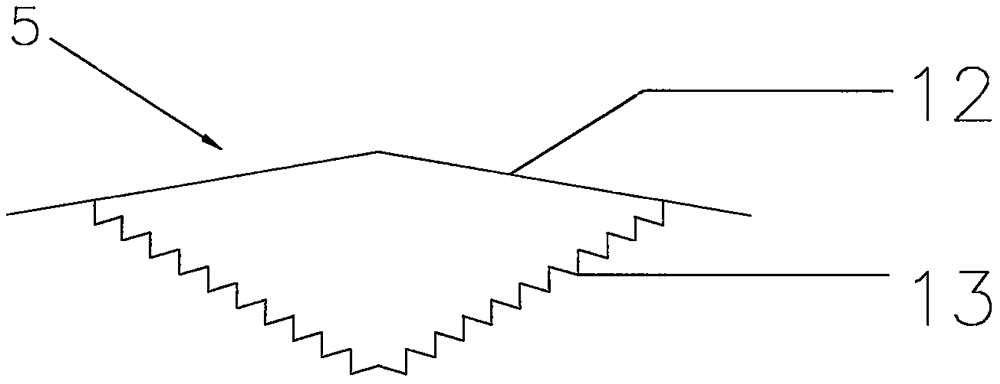

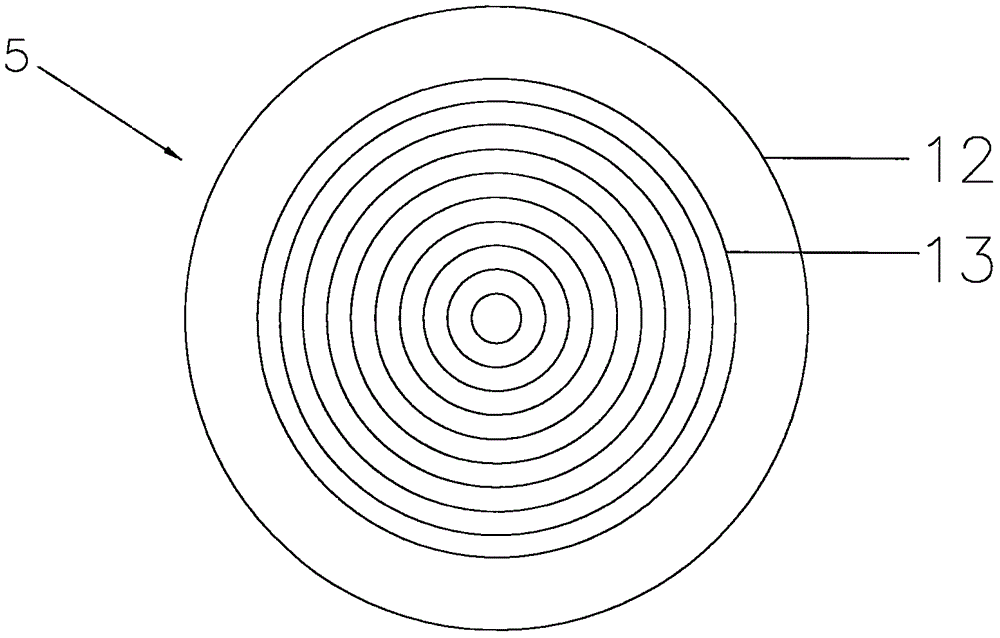

The invention discloses a method for uniforming a solution and a solution tank.The method mainly comprises the steps that the solution strikes a liquid baffling device arranged in a vessel to enable the solution to baffle to strike the bottom of the container, so that a vertical vortex is formed in the vessel, the solution mutually collides and agitates to cause strong turbulent flow, and then rapid mixing is achieved.The solution tank is mainly composed of an upper columnar shell part (100) and a lower conical shell part (200), a baffled liquid distributor (5) is arranged in the solution tank and formed by buckling two bamboo-hat-shaped devices (12 and 13), and the lower bamboo-hat-shaped device (13) is fixed to the inner side of the fan face of the lower bamboo-hat-shaped device (12) along the edge; the lower portion of the conical shell part (200) is provided with a liquid outlet pipe (8), and a circulating liquid inlet pipe (7) which extends to the position under the baffled liquid distributor (5) and is concentric with the liquid outlet pipe (8) is arranged in the liquid outlet pipe (8).

Owner:JINCHANG DASHUNHE ELECTRIC INSTR MAINTENANCE CO LTD

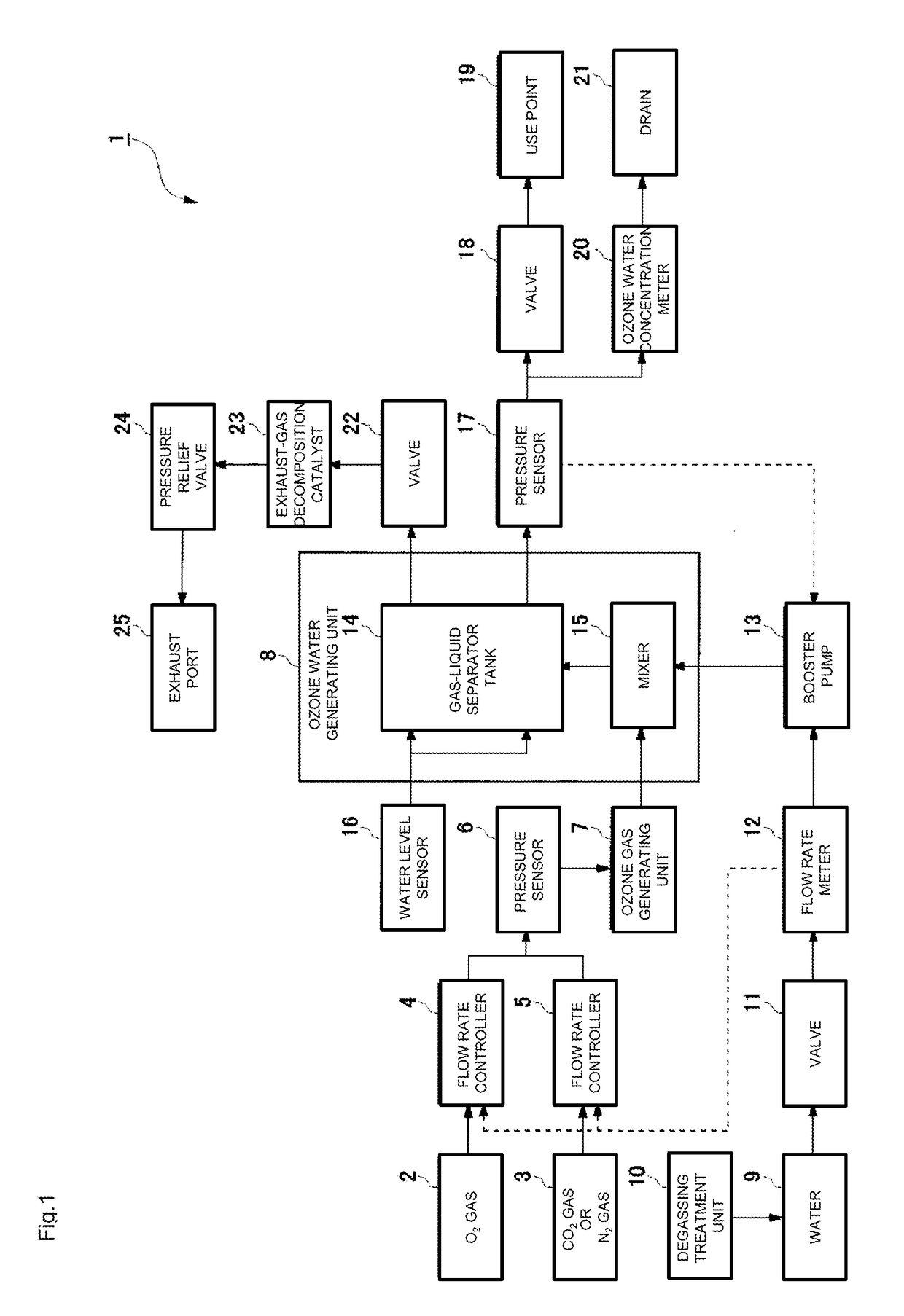

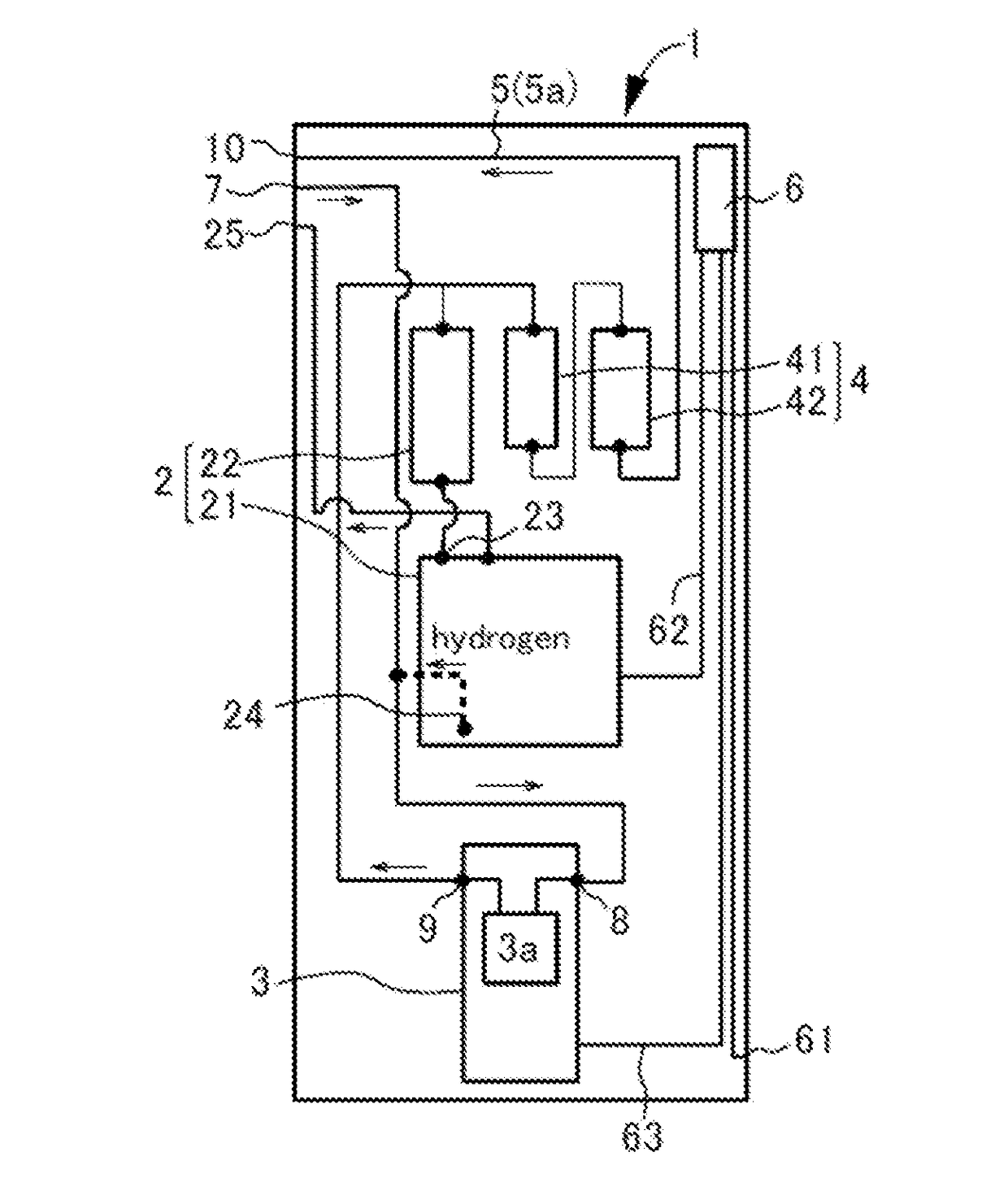

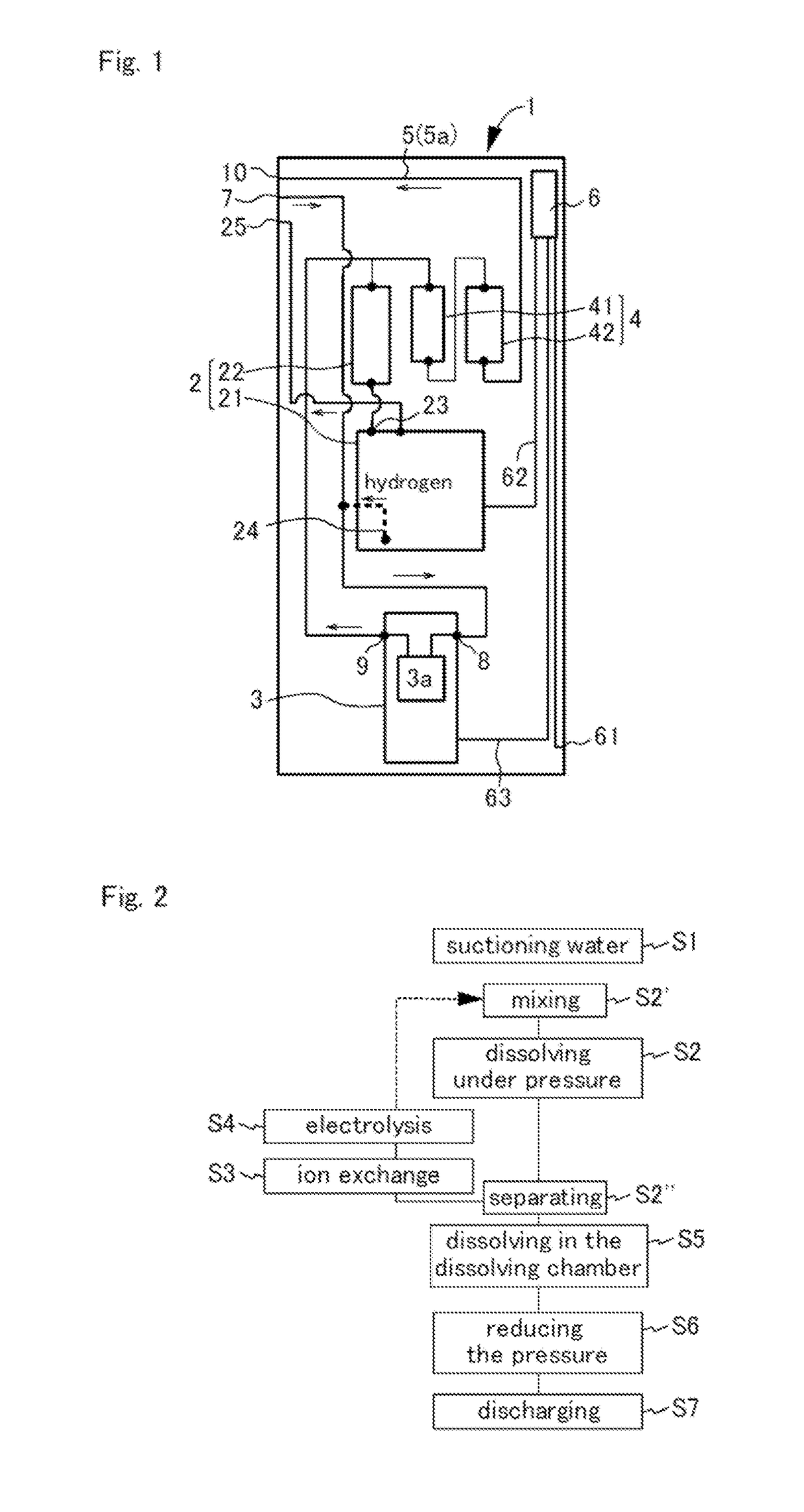

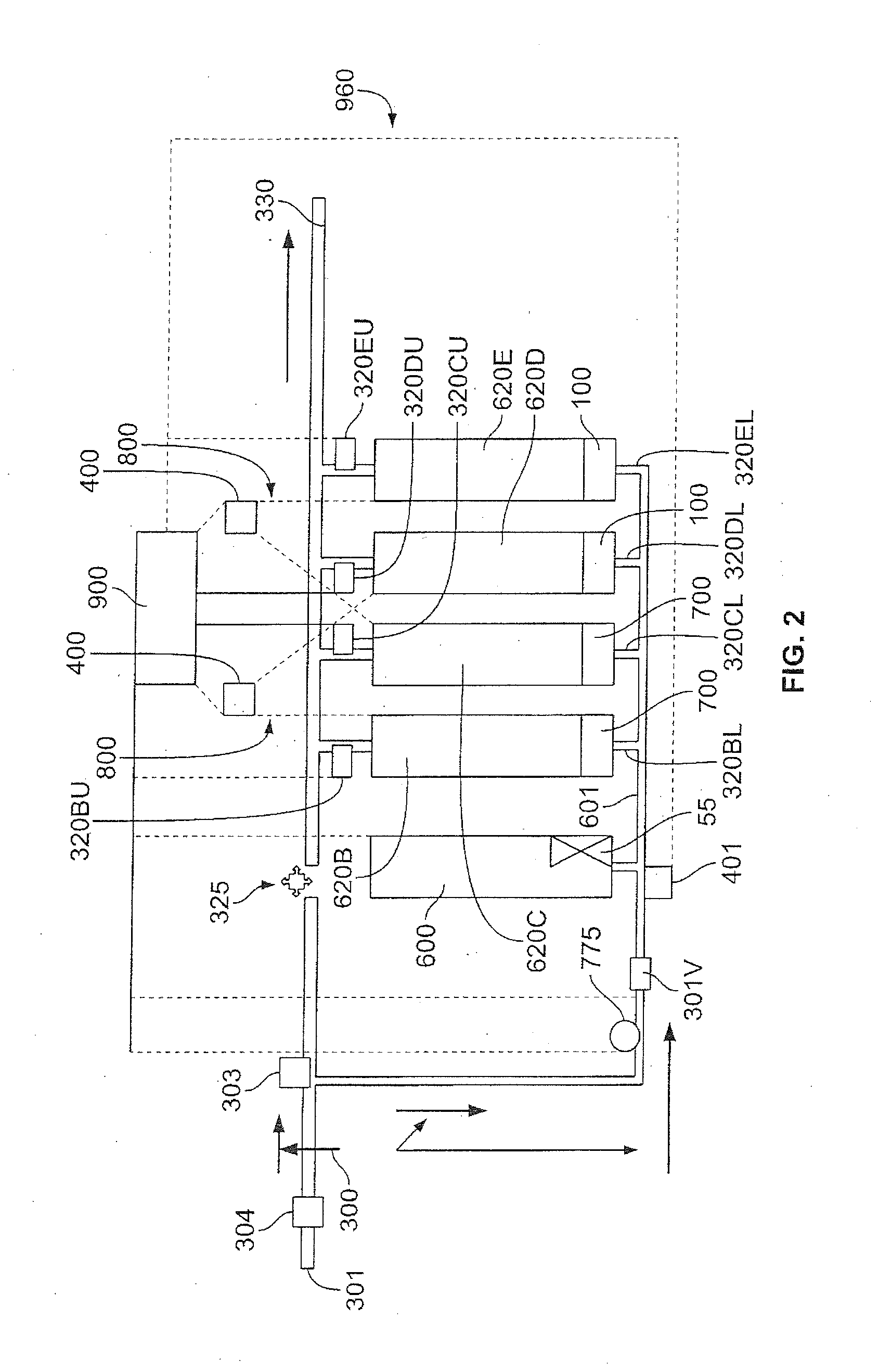

Gas-dissolved water production device and production method

InactiveUS20170282132A1Increase temperatureFlow mixersTransportation and packagingWater productionProduct gas

An ozone water production device (1) includes: flow rate controllers (4, 5) that each control a flow rate of gas which is a raw material; a flow rate meter (12) that measures a flow rate of water which is a raw material; a booster pump (13) that controls pressure of the water; an ozone water generating unit (8) that generates ozone water by mixing ozone gas and the water; and a pressure sensor (17) that measures pressure of the ozone water which is to be supplied to a use point (19). The booster pump (13) controls the pressure of the water such that the pressure of the ozone water measured by the pressure sensor (17) is constant. The flow rate controllers (4, 5) each control the flow rate of the gas in accordance with the flow rate of the water measured by the flow rate meter (12).

Owner:EBARA CORP

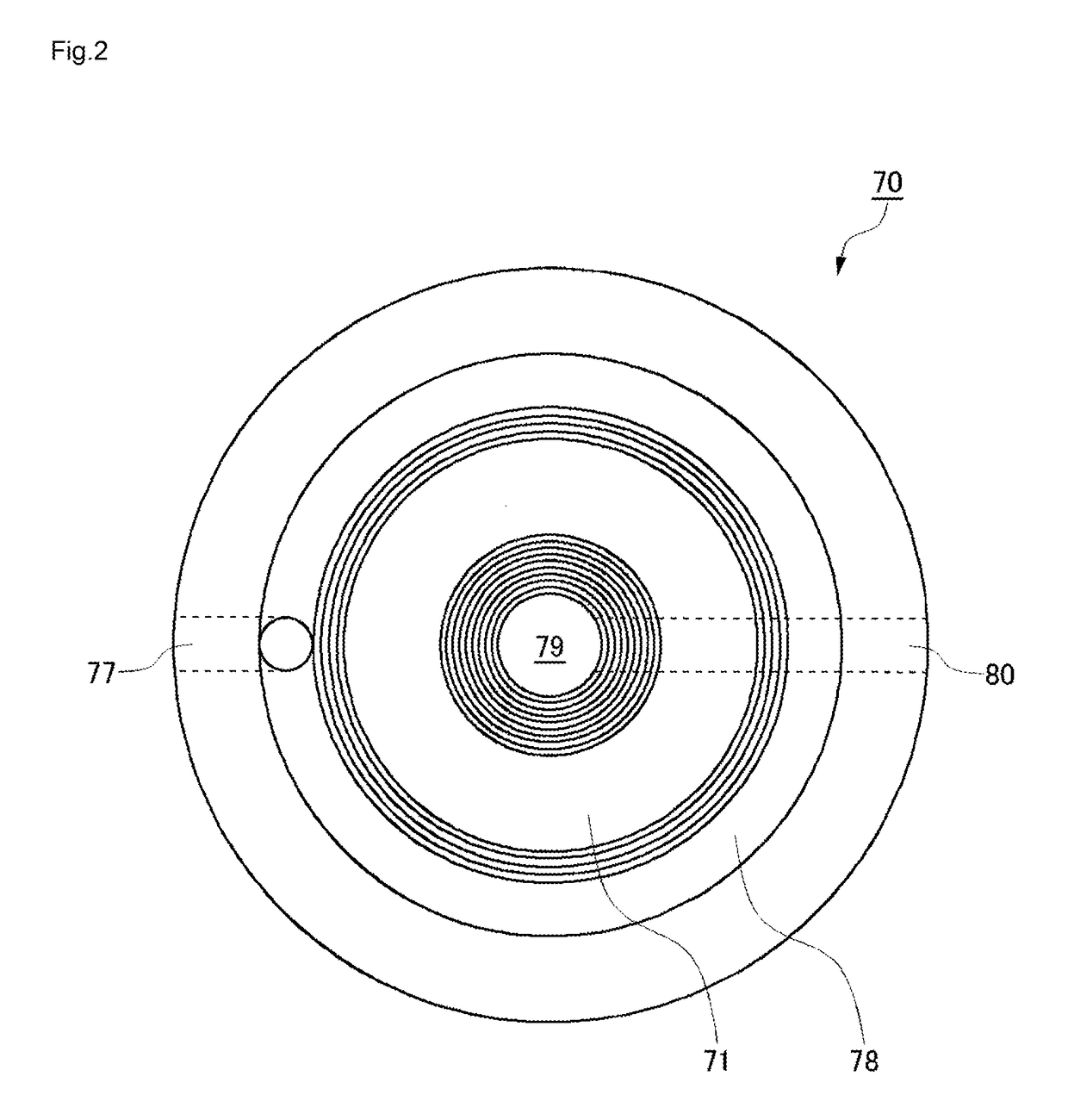

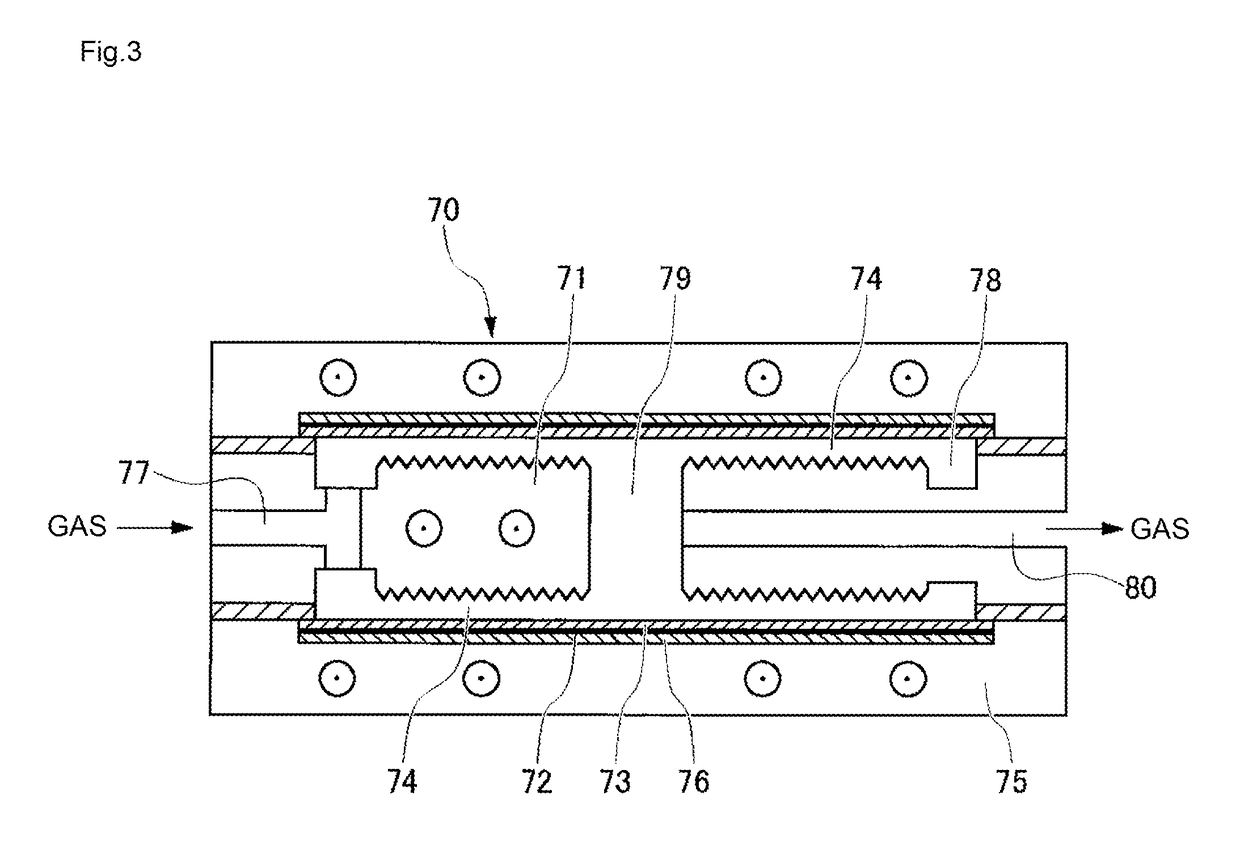

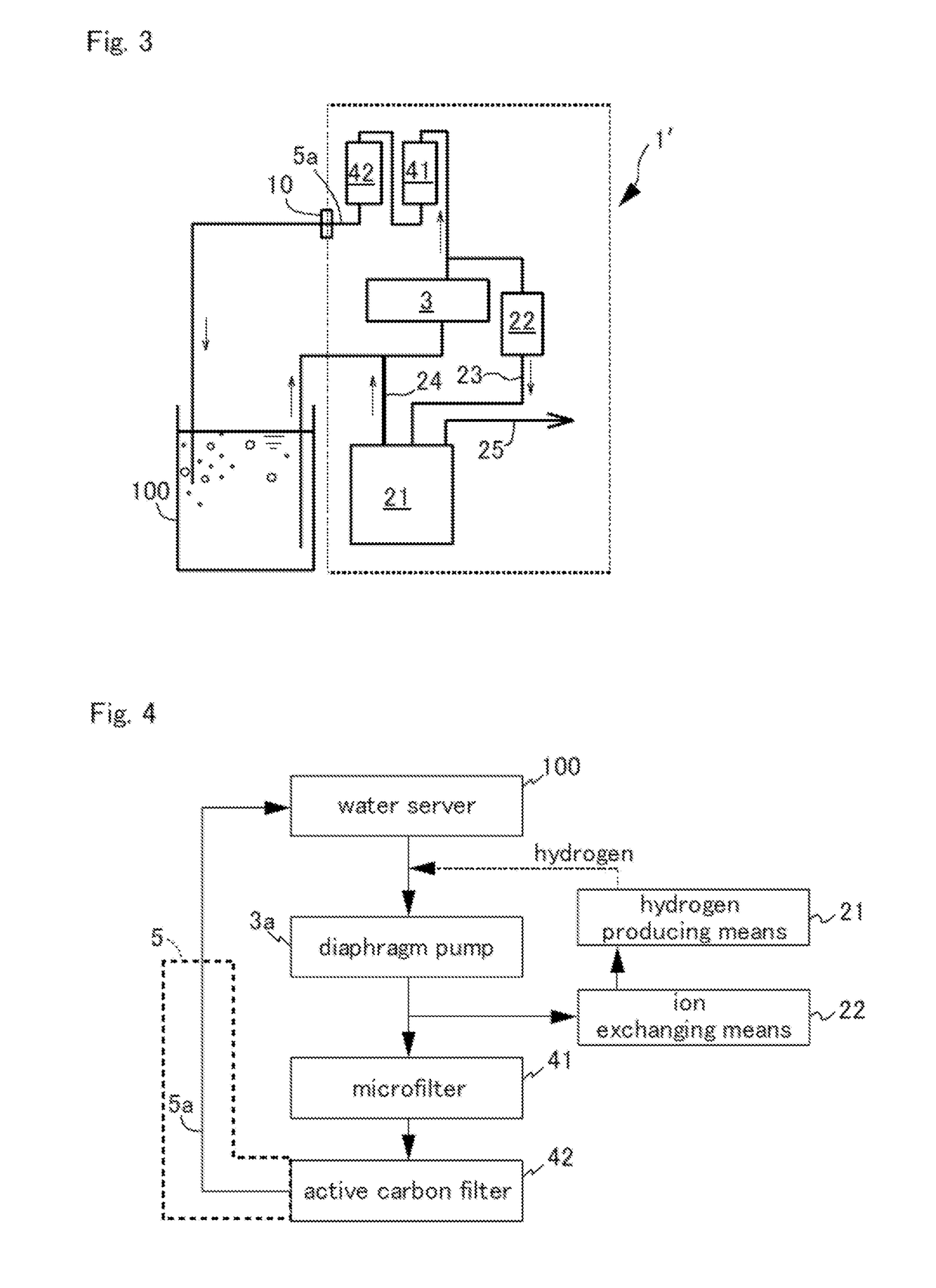

Gas-Dissolving Device and Gas-Dissolving Method

ActiveUS20170065940A1Easily attached to water serverSuppress mutationFlow mixersTransportation and packagingPressure reductionDissolved hydrogen

Provided is a gas dissolving device capable of dissolving gas in a liquid in a supersaturated state and maintaining such a saturated state in a stable manner, and being easily attached to a water server or the like.The gas dissolving device generates hydrogen water by dissolving hydrogen in water, and discharges the hydrogen water from an outlet. The gas dissolving device includes a dissolving chamber that stores under pressure generated hydrogen water introduced therein, and pressure reduction and transfer means for preventing pressure variation in a tube-shaped passage that connects the dissolving tank and the outlet due to an action of discharging the hydrogen water from the outlet, and for forming a laminar flow.

Owner:HIKARIMIRAI

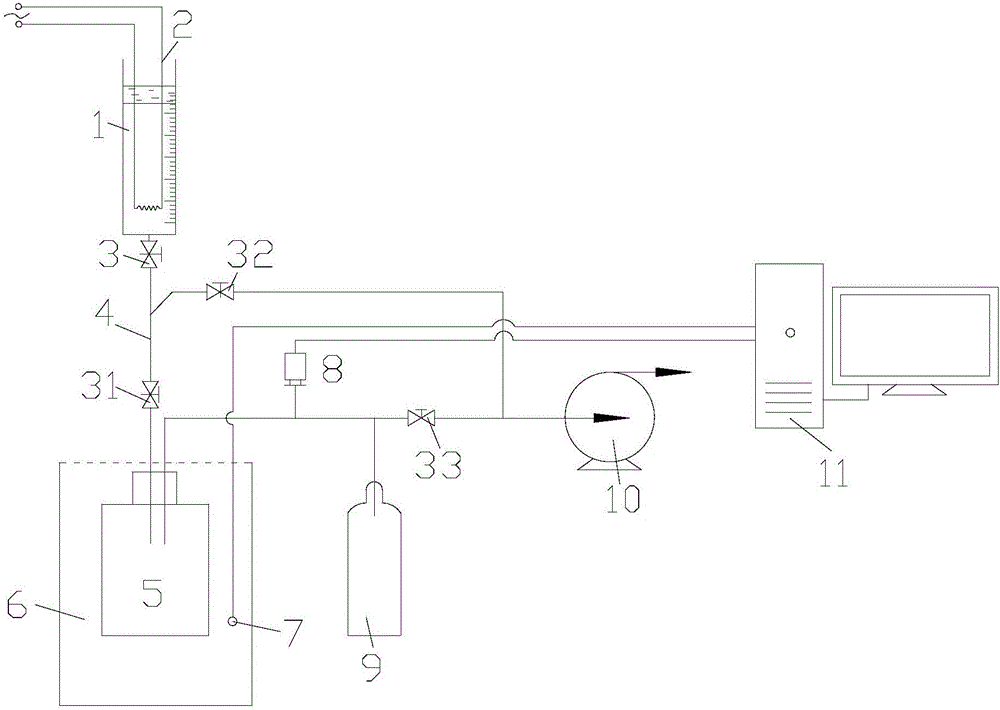

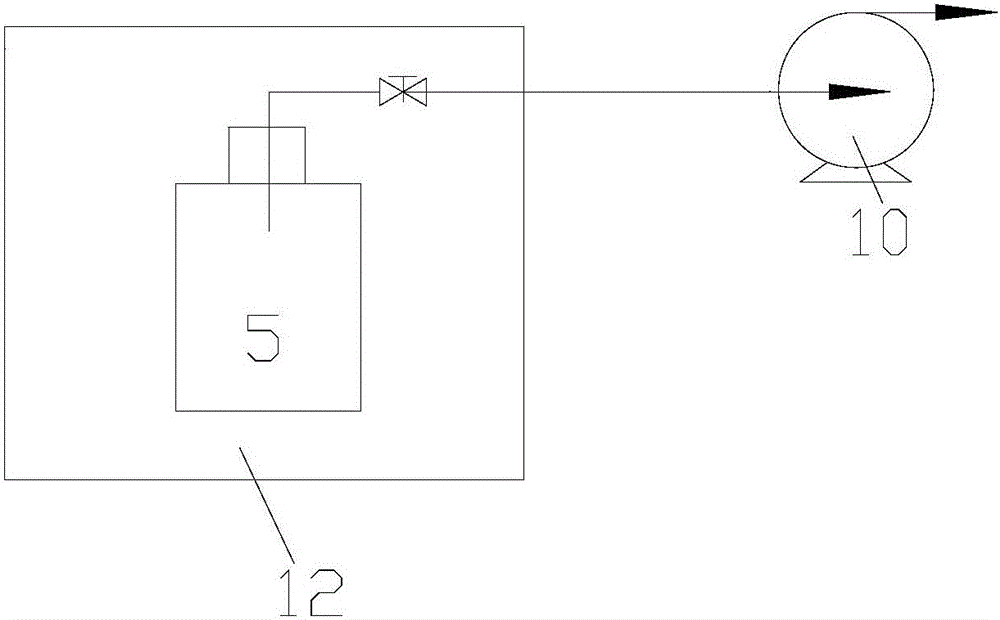

Solution configuration method used for vapor pressure measurement and vapor pressure measurement method

InactiveCN106052945AReduce the amount of dissolutionReduce distractionsLiquid degasificationDissolving systemsSolubilityProduct gas

The present invention discloses a solution configuration method used for vapor pressure measurement. The method comprises the following steps of (1) vacuumizing, sealing and weighing a solute container, and recording the mass as m1; (2) adding n predetermined solutes in the solute container, and recording the total mass as m2; (3) injecting a predetermined amount of solvent in a solvent container, and then injecting a protection liquid; (4) heating the solvent in the solvent container to reduce the air solubility; (5) connecting the solute container and the solvent container via a connecting pipe; (6) vacuumizing the interior of the connecting pipe; (7) injecting the solvent processed in the step (4) from the bottom of the solvent container in the solute container in the step (2) via the connecting pipe; (8) weighing the solute container processed in the step (7), recording the total mass as m3, and calculating an accurate concentration, thereby finishing the configuration of the solution. The present invention also discloses a vapor pressure measurement method. According to the methods of the present invention, the interference of the foreign gases when the vapor pressure is measured is small, and a measurement result is more accurate.

Owner:ZHEJIANG UNIV

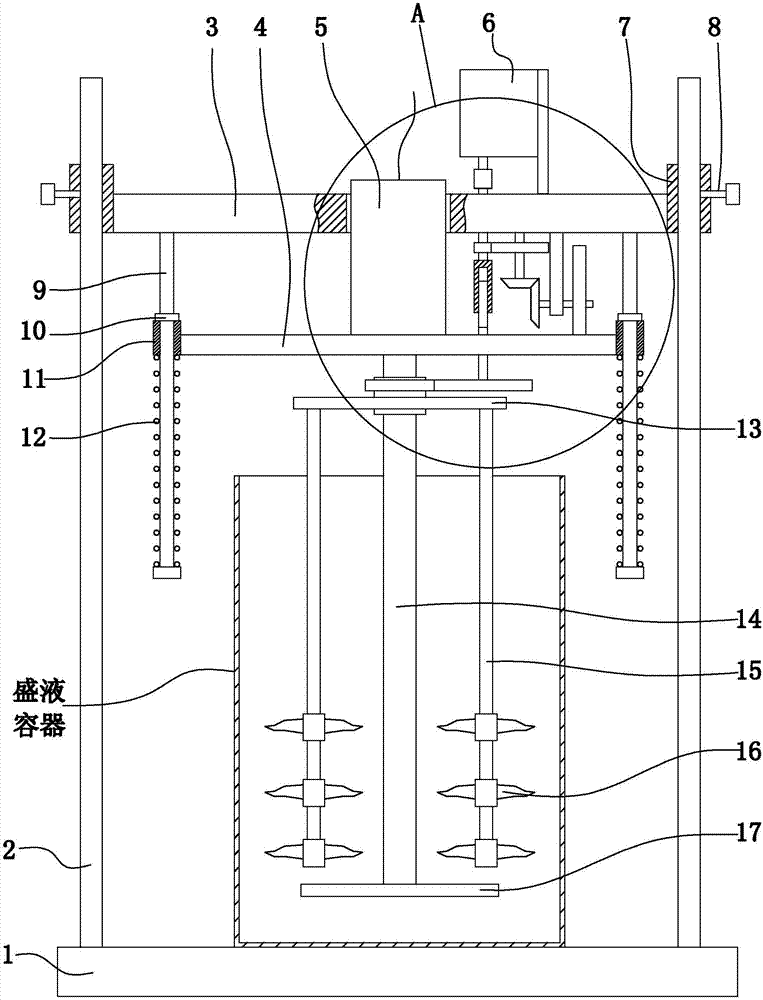

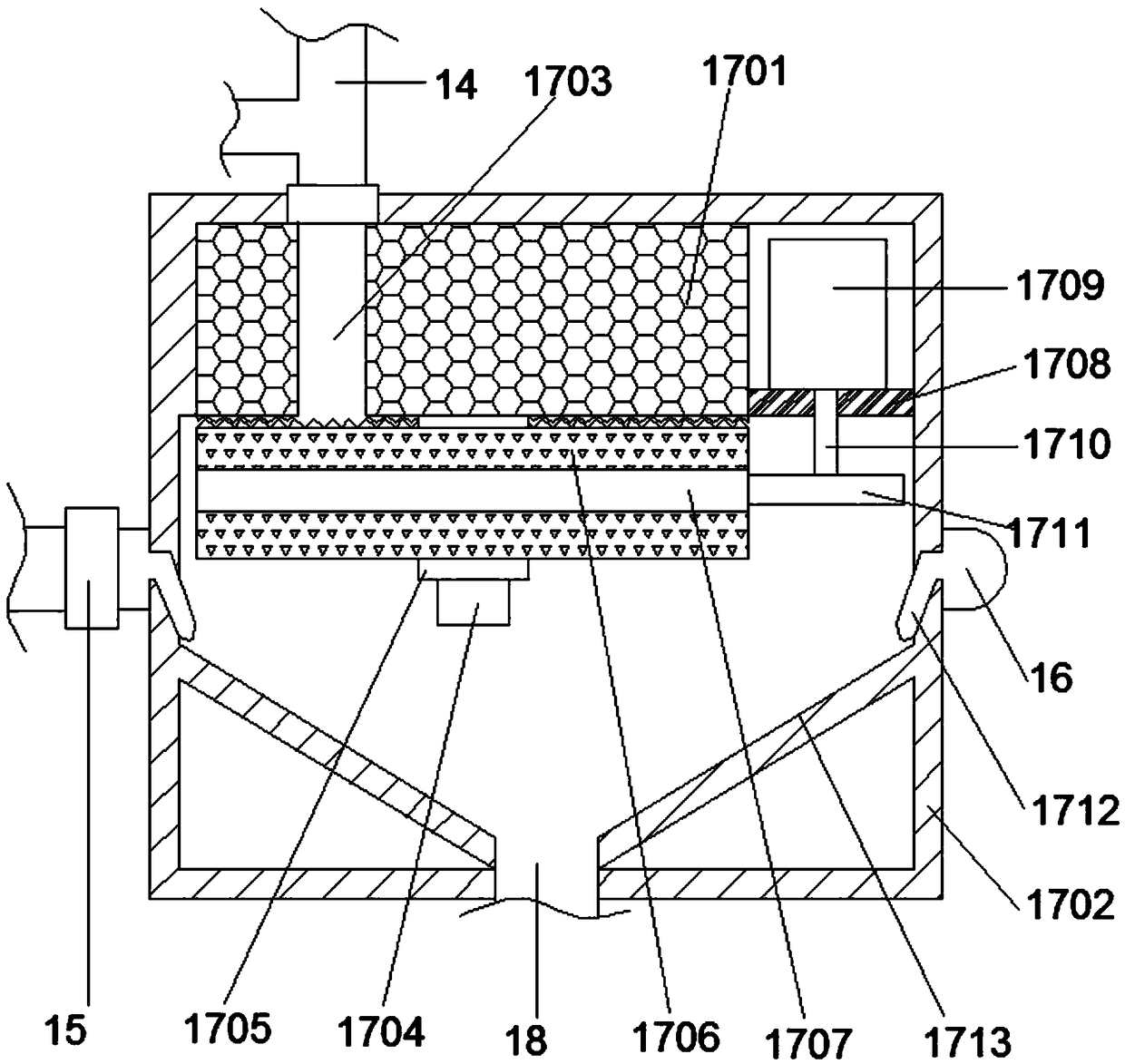

Ultrasonic accelerated dissolution stirring device

InactiveCN107138089AImprove solubilityImprove accuracyShaking/oscillating/vibrating mixersTransportation and packagingUltrasonic sensorMarine engineering

The invention discloses an ultrasonic accelerated dissolution stirring device, and aims at providing an ultrasonic accelerated dissolution stirring device which is good in stirring uniformity and high in stirring efficiency, can accelerate sample dissolution, and can further improve the accuracy of a detection result. The ultrasonic accelerated dissolution stirring device comprises a stirring ultrasonic dissolution device, wherein the stirring ultrasonic dissolution device comprises a base, vertical guide columns arranged on the base, a main mounting flat plate ascending and descending along the vertical guide columns, vertical guide rods arranged on the lower surface of the main mounting flat plate, a floating mounting flat plate ascending and descending along the vertical guide rod, a first ultrasonic transducer arranged on the floating mounting flat plate, a vertical vibrating rod connected with the ultrasonic transducer, lower agitating flat plates arranged at the lower end of the vertical vibrating rod, rotating discs rotationally arranged at the upper part of the vertical vibrating rod by bearings, and vertical stirring rods arranged on the rotating discs.

Owner:CHAOWEI POWER CO LTD

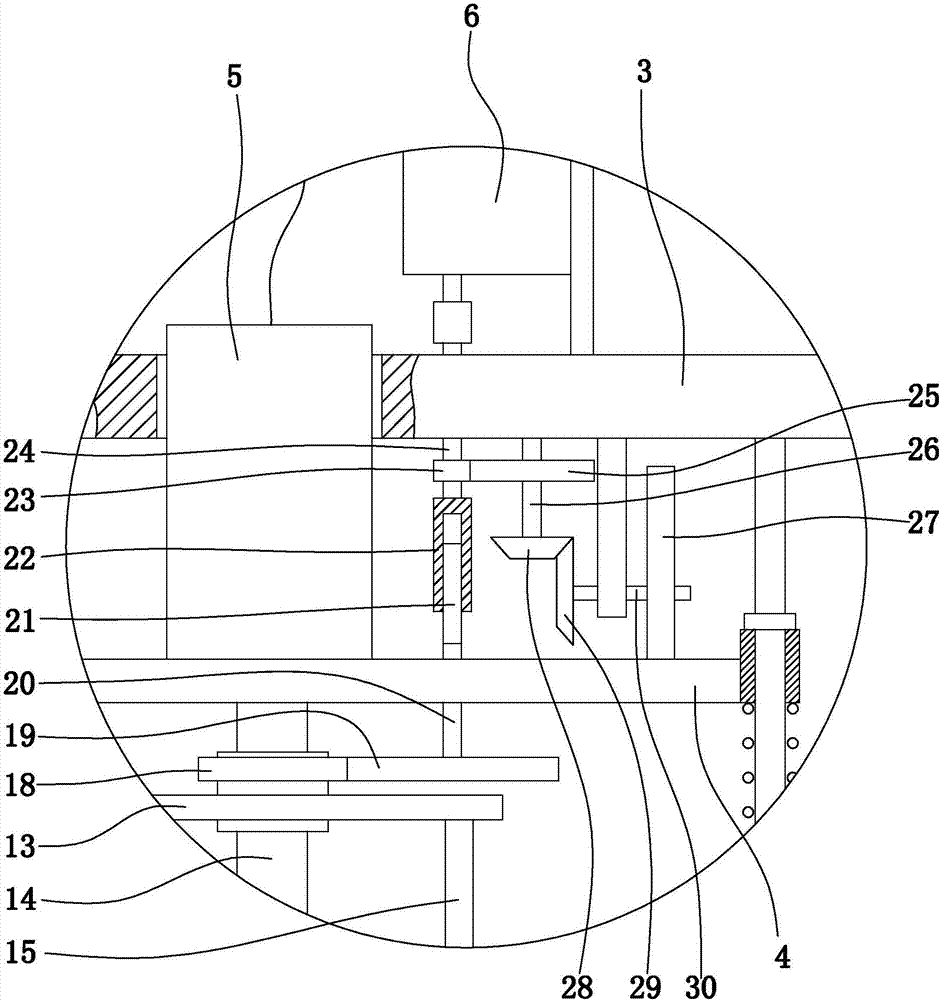

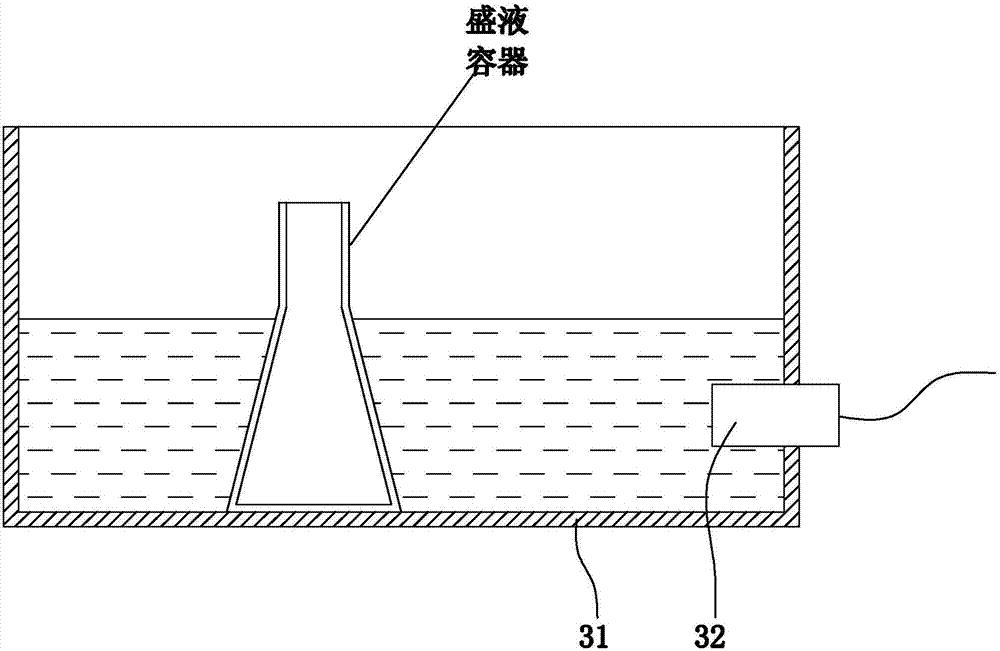

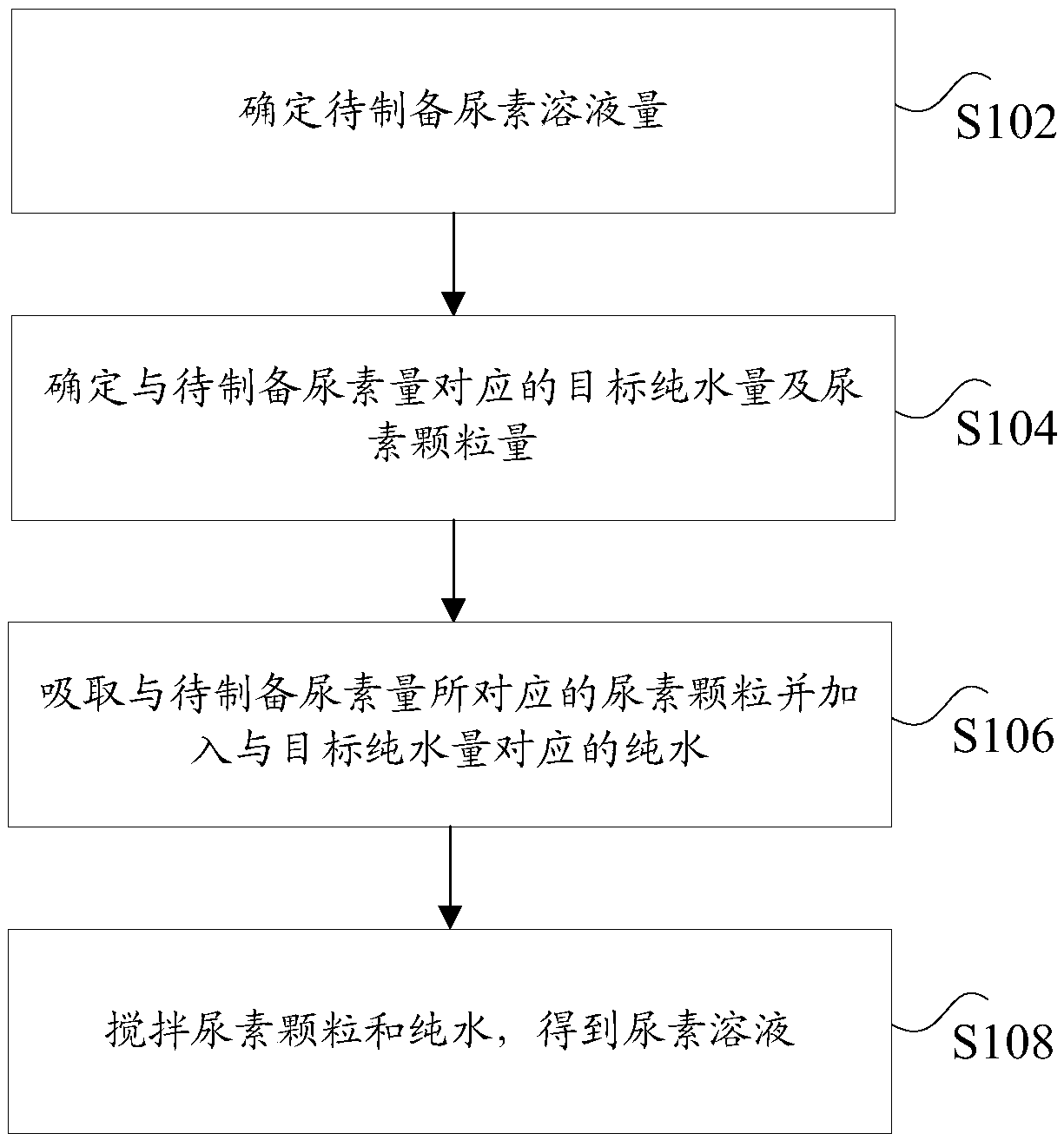

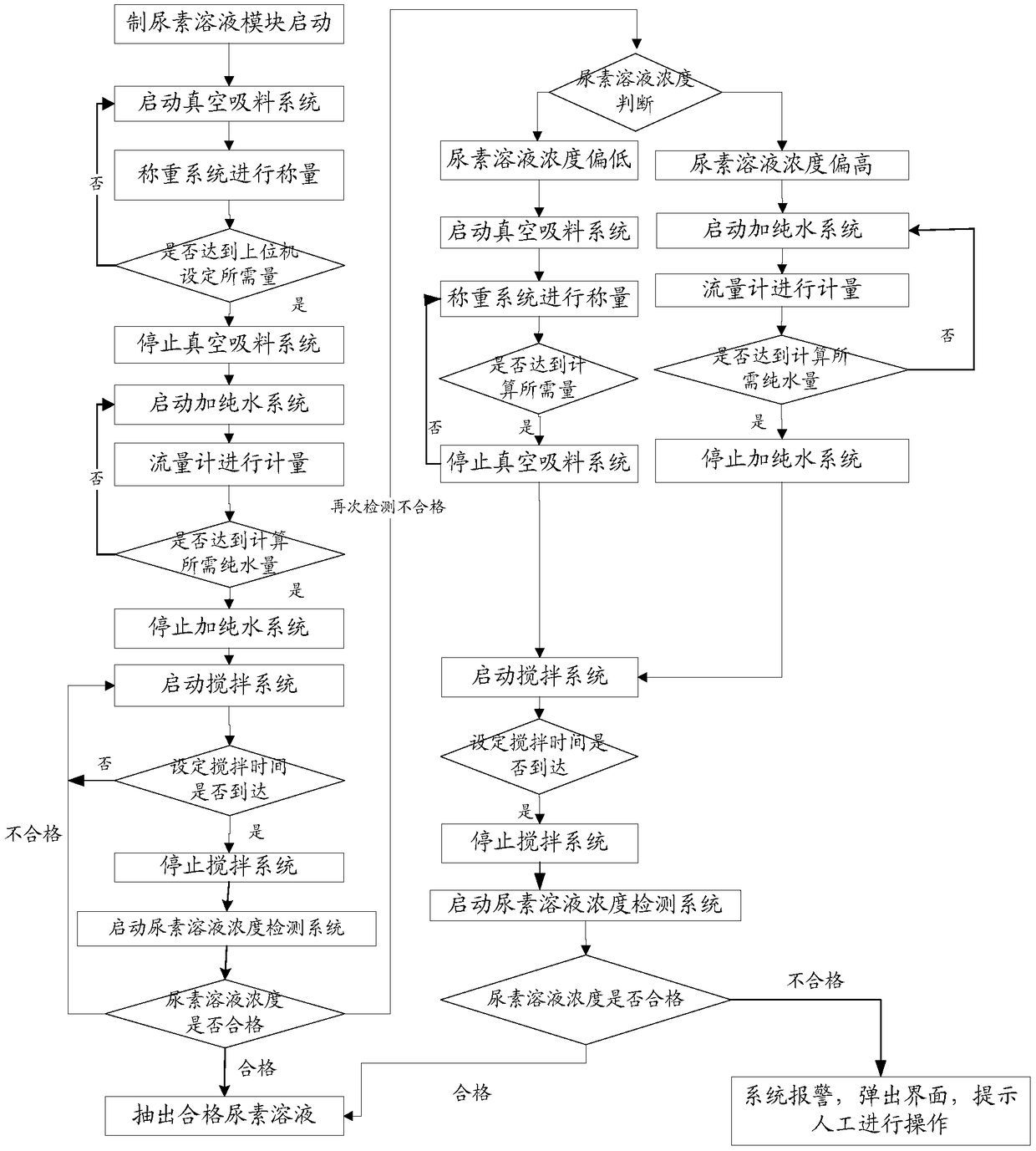

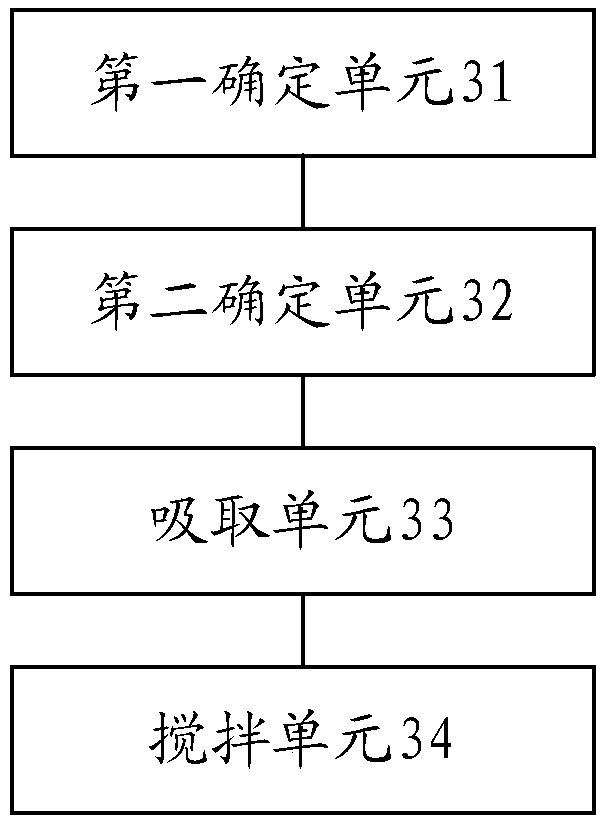

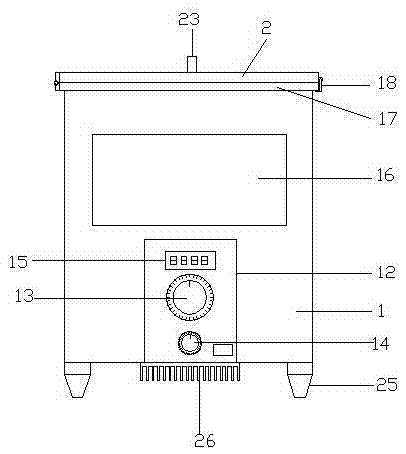

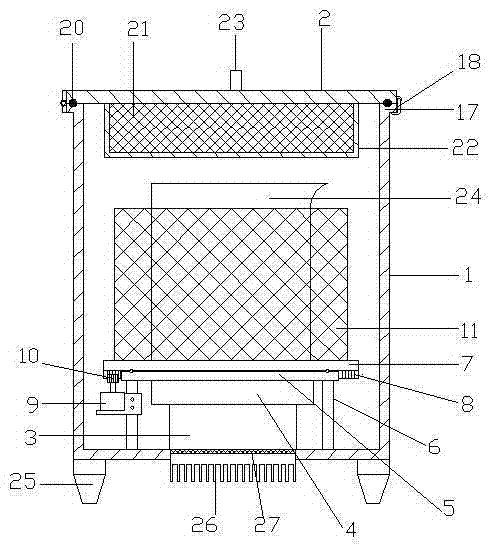

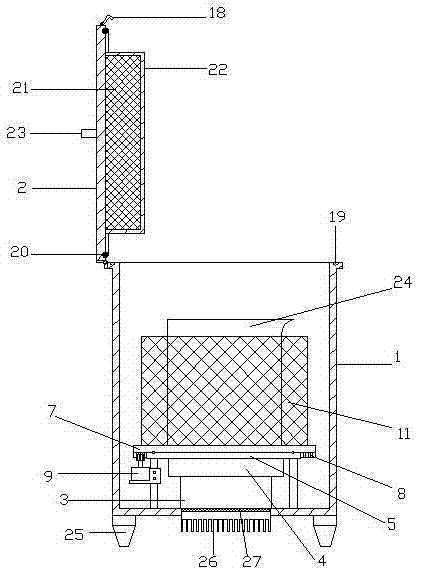

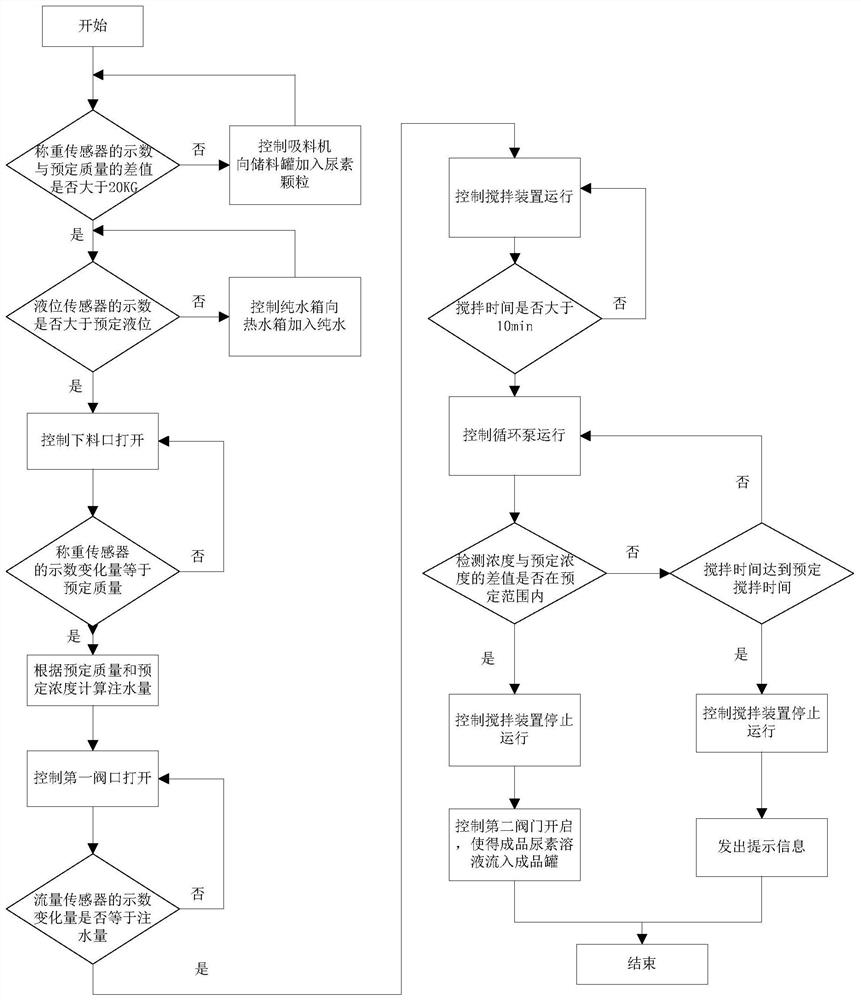

Preparation method and device of urea solution

InactiveCN109126490AImplement automatic configurationRealize automatic weighingTransportation and packagingMixer accessoriesUreaEnvironmental chemistry

The invention discloses a preparation method and device of a urea solution. The method includes: determining the quantity of the to-be-prepared urea solution; determining target pure water quantity and urea particle quantity corresponding to the quantity of the to-be-prepared urea solution; sucking urea particles corresponding to the quantity of the to-be-prepared urea solution, and adding into pure water corresponding to the target pure water quantity; stirring the urea particles and the pure water to obtain the urea solution. By the method, the technical problems that frequent preparation errors occur due to manual urea solution preparation is adopted in the prior art, and the generation efficiency of the urea solution is affected are solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Maker for saturated solution

InactiveCN107376675ANot easy to polluteRotary stirring mixersTransportation and packagingWater storageFiltration

The invention relates to a device for making a solution. A maker for a saturated solution comprises a container, wherein the container is of a transparent structure and can be further detachably connected with a container cover; a filter plate is hermetically connected into the container; the container cover is provided with a motor; a rotor stretches into the container; a driving shaft is arranged in the container; the driving shaft is vertically arranged and is further connected with the rotor together; a separation plate which can be upwards floated by the saturated solution in a solution preparation chamber is hermetically connected into the container in a liftable manner; the separation plate divides the container into a water storage chamber and the solution preparation chamber; the separation plate is provided with via holes; an osmotic membrane through which only water can penetrate covers the separation plate; a stator is provided with a plurality of water inlet flow passages; the driving shaft is connected with an assistance vane located in the solution preparation chamber; a saturated solution storage chamber is defined between the filtration plate and the container; the solution storage chamber is provided with a solution outlet. The invention provides the maker for the saturated solution, which is used for preparing the solution in a closed manner; the problems that an existing container is inconvenient when making the solution, a solute particle is easily mixed in the solution, and the pollution is easily generated are solved.

Owner:JIANGSHAN XIANJIN ELECTRICAL & MECHANICAL TECH SERVICES CO LTD

Water-soluble particle mixing and stirring mechanical device

ActiveCN108786505AImprove liquidityImprove solubilityTransportation and packagingDissolving systemsWater solubleDissolution

The invention discloses a water-soluble particle mixing and stirring mechanical device, comprising a main body box, wherein support legs are arranged at the left and right sides of the lower end of the main body box, a filter is arranged on the right side of the bottom in the main body box, a discharge pipe I is arranged at the lower end of the filter, a motor I is arranged in the middle of the upper end of the main body box, a stirring shaft is arranged at the lower end of the motor I, the lower end of the stirring shaft runs through the main body box and is connected to the bottom in the main body box, a plurality of stirring blades are arranged in the middle of the stirring shaft, and secondary stirring blades are disposed in the middle of the lower ends of the stirring blades. Througha feeding hole, a feeding pipe, a water pump and a water pipe in cooperation, water-soluble particles can be preliminarily dissolved and the fluidity of the water-soluble particles is further increased, which are favorable for further dissolution. The water-soluble particles are ground into fine powder by a fixed grinding disc, a rotating grinding disc, a motor II and a gear in cooperation, and the contact area between the fine powder and water is larger, which is more favorable for dissolution.

Owner:诸暨市旺润针织厂

Efficient stirring device for organic compound biofertilizer and use method

PendingCN107684855AAvoid stickingDissolve fastRotary stirring mixersTransportation and packagingAgricultural engineeringOrganic compound

The invention discloses an efficient stirring device for an organic compound biofertilizer and a use method and relates to a stirring device. A rotating motor (34) is arranged in the middle of a bottom plate (35); a rotating rod (26) is arranged at the upper end of the rotating motor; a plurality of vertical plates (32) are arranged on the upper surface of the bottom plate at the bottom of the rotating rod (26); uprights (33) matched with a bucket body (5) are arranged at the upper parts of the outer ends of the vertical plates; a plurality of side rods (30) are sequentially arranged on the inner side faces of the uprights; and motors (29) are arranged at the front ends of the side rods (30) on the inner side faces of the uprights (33). The device can achieve quick and convenient fertilizer stirring for people, greatly improves stirring efficiency of the fertilizer, allows the fertilizer to be stirred more sufficiently and completely, avoids an non-ideal crop fertilization effect caused by nonuniform stirring of the fertilizer and provides powerful guarantee for healthy growth of crops.

Owner:武兴友

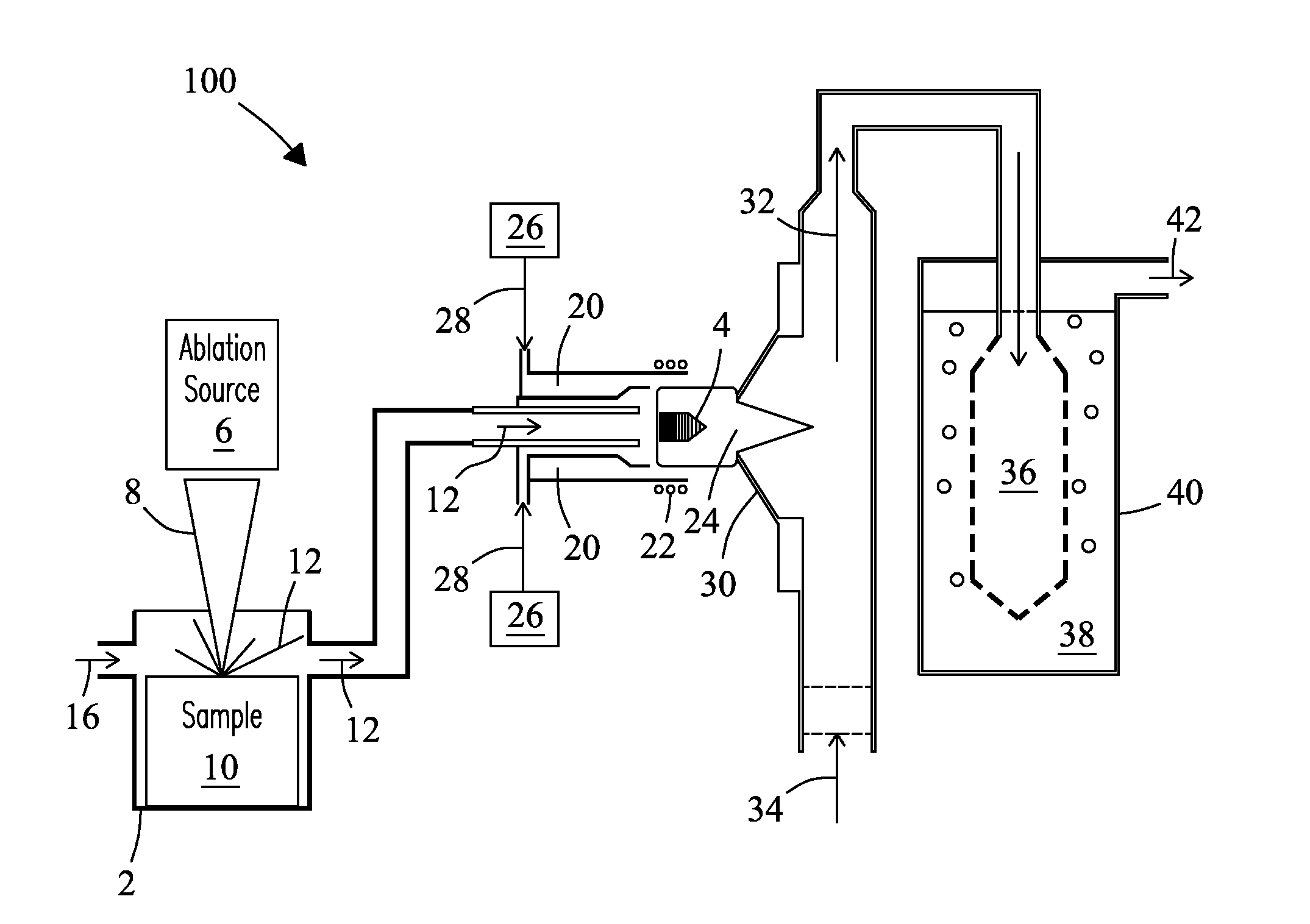

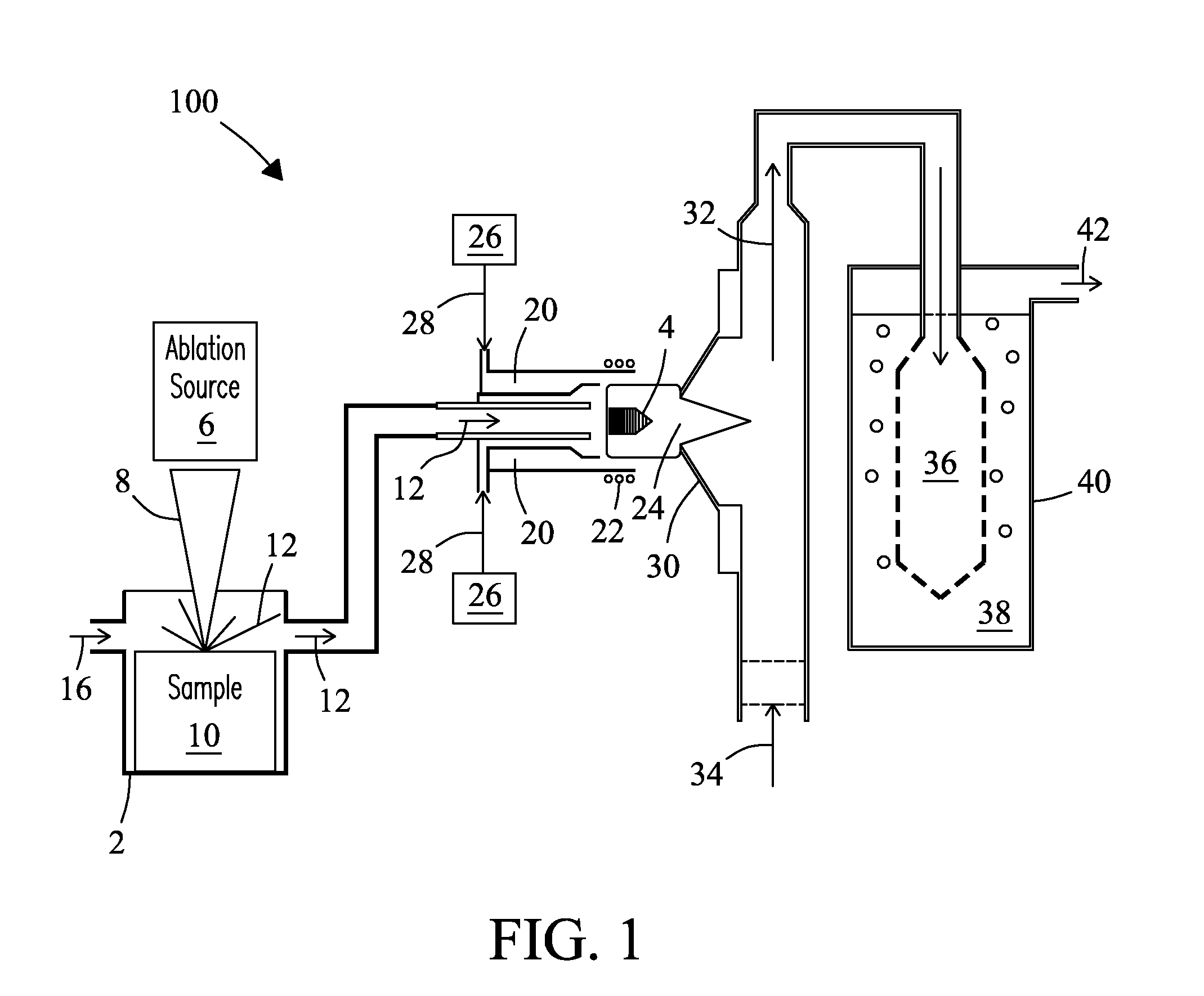

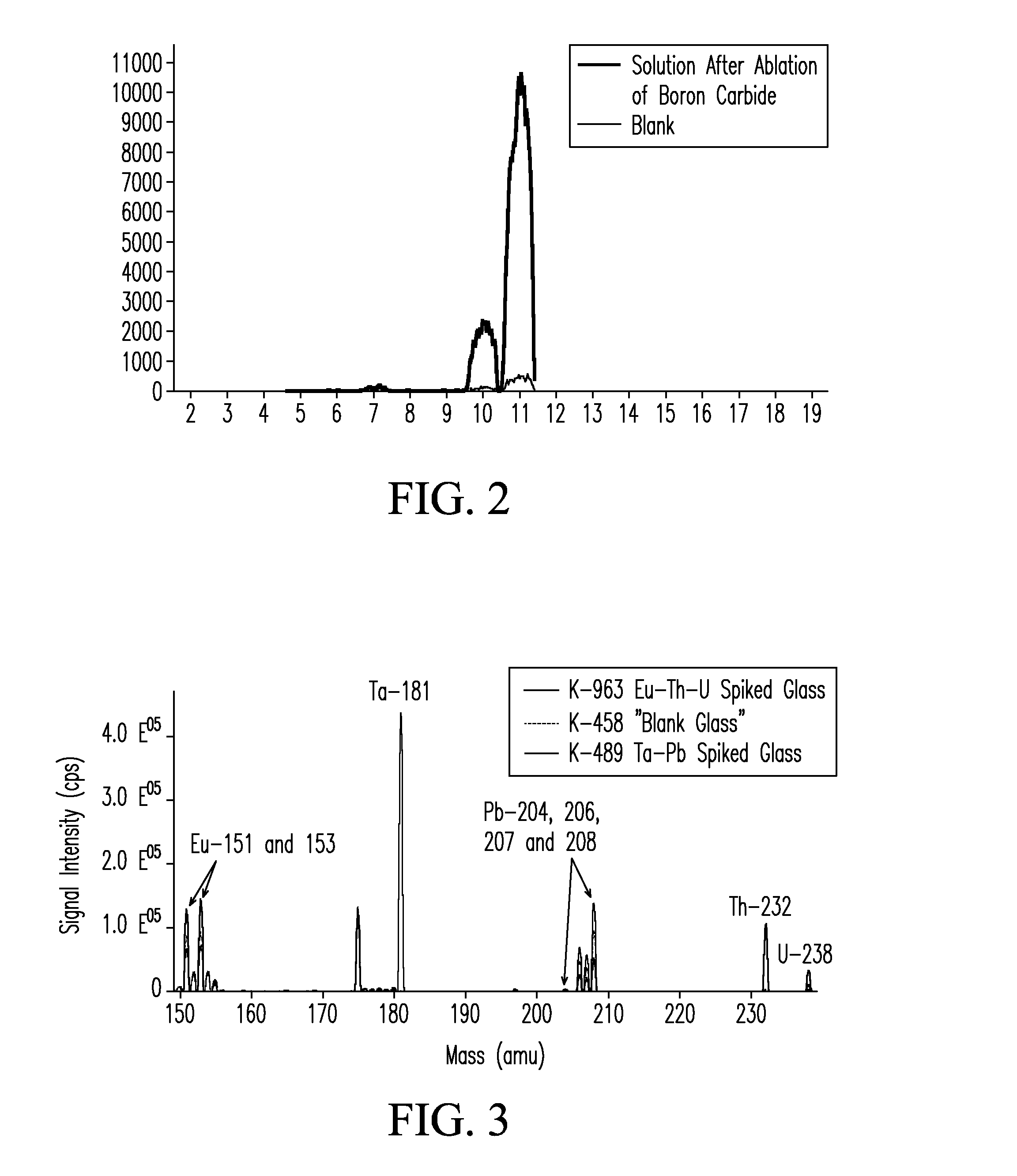

System and process for dissolution of solids

ActiveUS20150343411A1Measurement stabilityDissolving systemsTransportation and packagingAnalytical chemistry

A system and process are disclosed for dissolution of solids and “difficult-to-dissolve” solids. A solid sample may be ablated in an ablation device to generate nanoscale particles. Nanoparticles may then swept into a coupled plasma device operating at atmospheric pressure where the solid nanoparticles are atomized. The plasma exhaust may be delivered directly into an aqueous fluid to form a solution containing the atomized and dissolved solids. The composition of the resulting solution reflects the composition of the original solid sample.

Owner:BATTELLE MEMORIAL INST

Oral megestrol acetate nano-suspension and preparation method thereof

InactiveCN108309933ASmall particle sizeImprove bioavailabilityOrganic active ingredientsShaking/oscillating/vibrating mixersMegestrol acetateSolid particle

The invention discloses an oral megestrol acetate nano-suspension and a preparation method thereof. The oral megestrol acetate nano-suspension contains effective amounts of megestrol acetate, a wetting agent, a suspending aid, a deflocculating agent, a pH adjusting agent, a flavoring, a bacteriostatic agent, a perfume and purified water. The preparation method comprises the following steps: respectively dissolving above materials in a part of water, mixing the obtained solutions to prepare an initial suspension, performing high-speed shearing to prepare a crude suspension, and performing micro-jet high-pressure homogenization treatment to prepare the oral megestrol acetate suspension. The oral megestrol acetate nano-suspension has the characteristics of small particle size of solid particles, high bioavailability, uniformity in distribution, stable system and good mouthfeel, the average particle size is less than 500 nm, and the dispersiveness is small; and the preparation method of the product has the advantages of simple process and easiness in realization of industrial production.

Owner:青岛国海生物制药有限公司

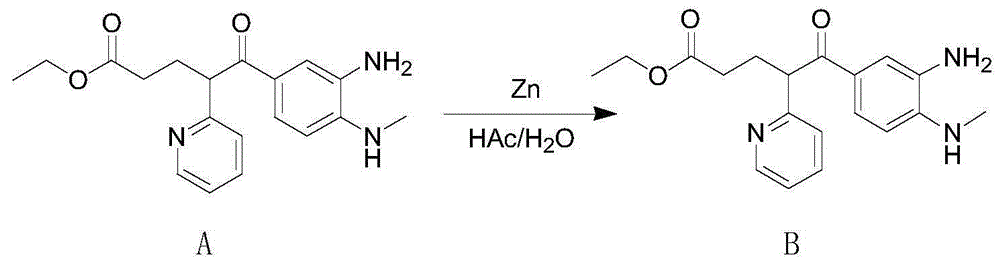

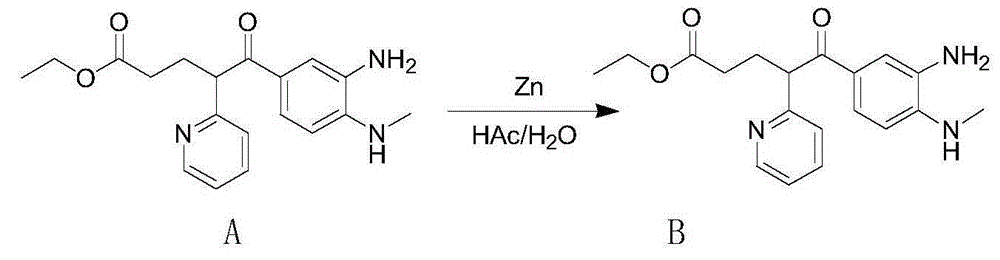

Method for purifying compound through ultrasonic crystal precipitation

InactiveCN105037253AHigh puritySignificant technological progressOrganic chemistryTransportation and packagingOrganic solventOrganic synthesis

The invention relates to a method for purifying a compound through ultrasonic crystal precipitation. According to the method, after completing an organic synthesis reaction, a dissolved amount of a first organic solvent is added to the obtained crude product, and ultrasonic dissolving is performed; a second organic solvent is added after completely dissolving, and ultrasonic dissolving is performed, wherein the addition amount of the second organic solvent is 1-3 times the volume of the first organic solvent; and after the target compound is precipitated from the solution, suction filtration is performed, and washing is performed with a mixed solution of the first organic solvent and the second organic solvent so as to obtain the high-purity target compound. According to the present invention, the ultrasonic crystal precipitation method is used, such that the byproducts and the pigment generated during the organic synthesis reaction can be removed, the purity of the target product during the organic synthesis is substantially increased, and the high-purity target compound is obtained.

Owner:SHANGHAI INST OF TECH

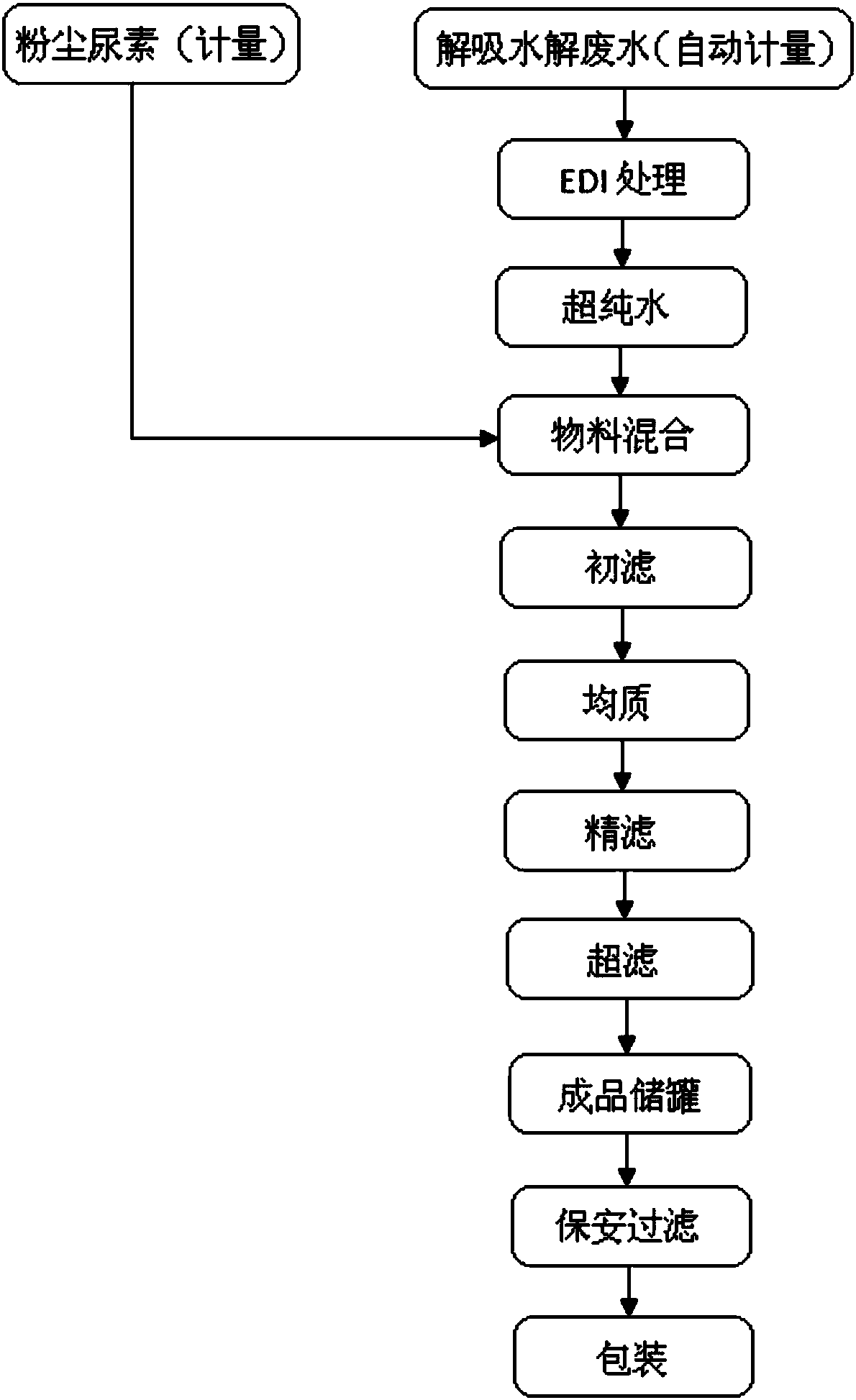

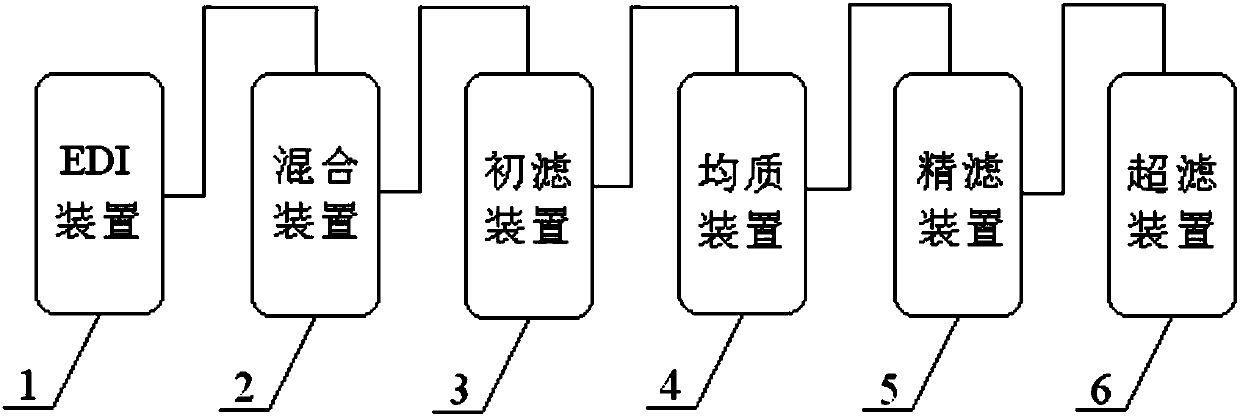

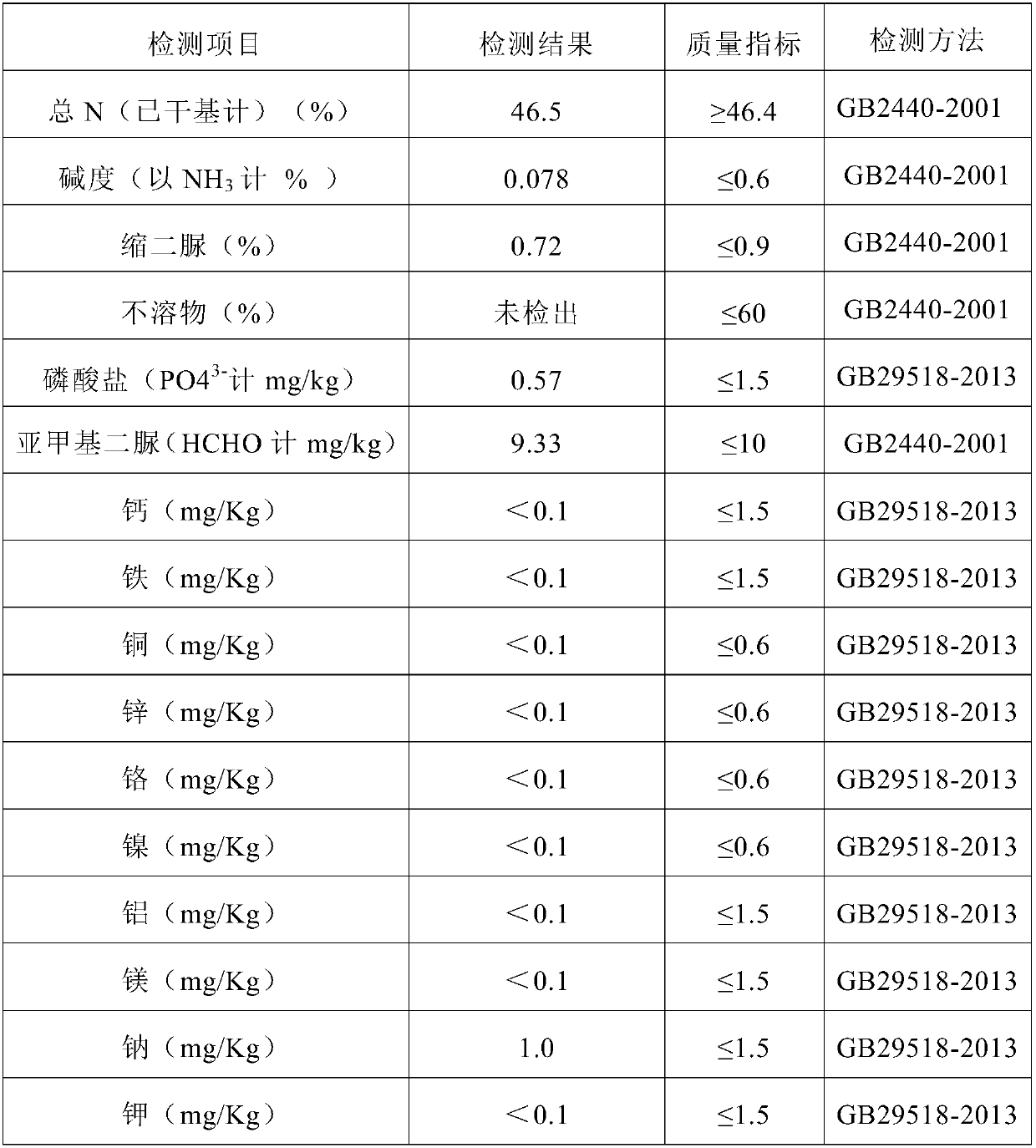

Method and system for preparing urea aqueous solution for vehicles

ActiveCN110215853ADissolve fastSave heatDissolving systemsTransportation and packagingDesorptionUltrafiltration

The invention provides a method and a system for preparing urea aqueous solution for vehicles. The method for preparing the urea aqueous solution for the vehicle comprises the following steps of: carrying out EDI treatment on desorption hydrolysis wastewater to prepare ultrapure water with conductivity less than or equal to 0.1 mu s / cm; Dissolving dust urea in the ultrapure water to prepare urea aqueous solution; sequentially carrying out primary filtration, homogenization, fine filtration and ultrafiltration on the urea aqueous solution to prepare the urea aqueous solution for vehicles; Wherein the filtration precision of the primary filtration is 25-50 mu m, the filtration precision of the fine filtration is 5 mu m, and the filtration precision of the ultrafiltration is 0.01mu m. The method uses dust urea and desorption hydrolysis waste water as raw materials to prepare the vehicle urea aqueous solution, which not only provides an effective way for the rational utilization of dust urea and desorption hydrolysis waste water, but also the prepared vehicle urea aqueous solution can meet the requirements of GB 29518-2013 standard.

Owner:PETROCHINA CO LTD

Ultrasonic dissolution promotion device

InactiveCN106914157ADissolve fastHeat dissipation fastShaking/oscillating/vibrating mixersTransportation and packagingHeat conductingDisplay device

The invention relates to the technical field of solid solute dissolution and discloses an ultrasonic dissolution promotion device. The ultrasonic dissolution promotion device comprises a shell and a cover plate arranged at the upper end of the shell. The bottom of the shell is provided with an ultrasonic generator. A transducer is arranged on the ultrasonic generator. A horizontal supporting plate is arranged on the transducer. The lower side face of the supporting plate is connected with the bottom surface of the shell through a plurality of supporting rods. A tray is arranged on the upper side face of the supporting plate. The outer side of the shell is provided with a control panel. An ultrasonic adjusting knob and a frequency displayer are arranged on the control panel. The bottom of the shell is provided with support legs. The bottom surface of the shell is provided with a radiator. The upper end of the radiator is connected with the ultrasonic generator through heat conducting glue. The ultrasonic dissolution promotion device has the beneficial effect of promoting rapid dissolution of solutes.

Owner:ZHEJIANG JM IND

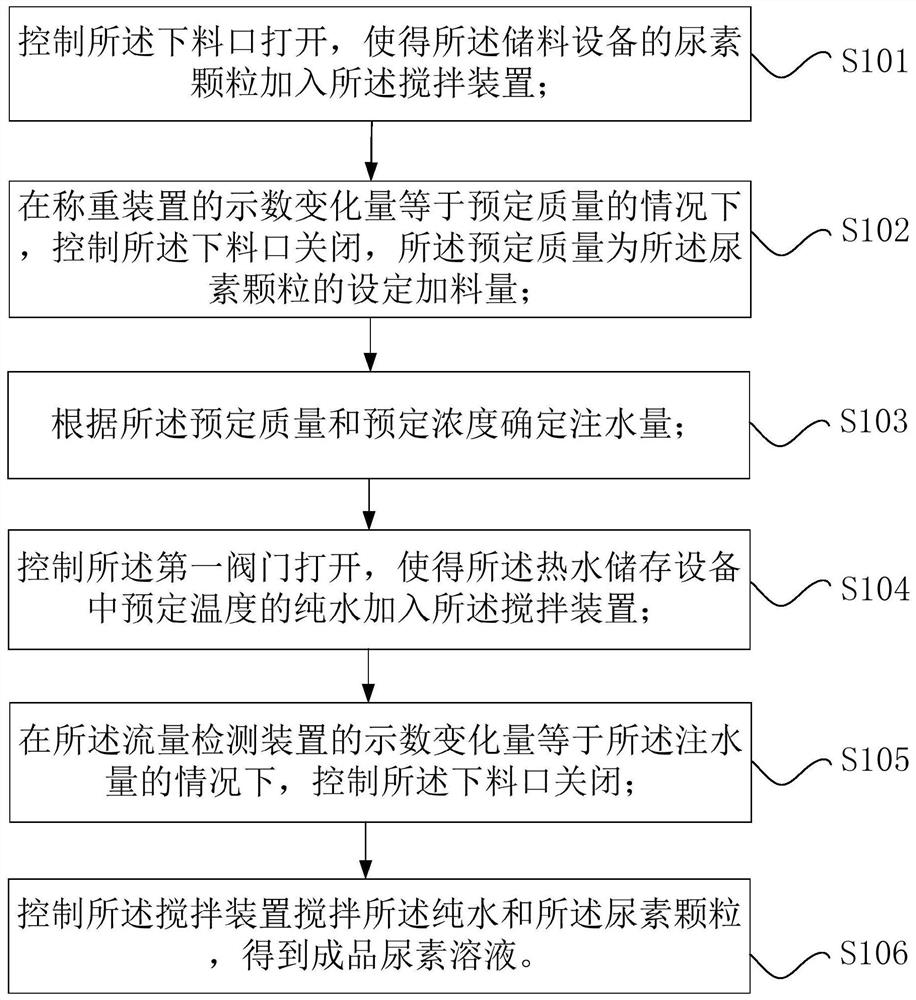

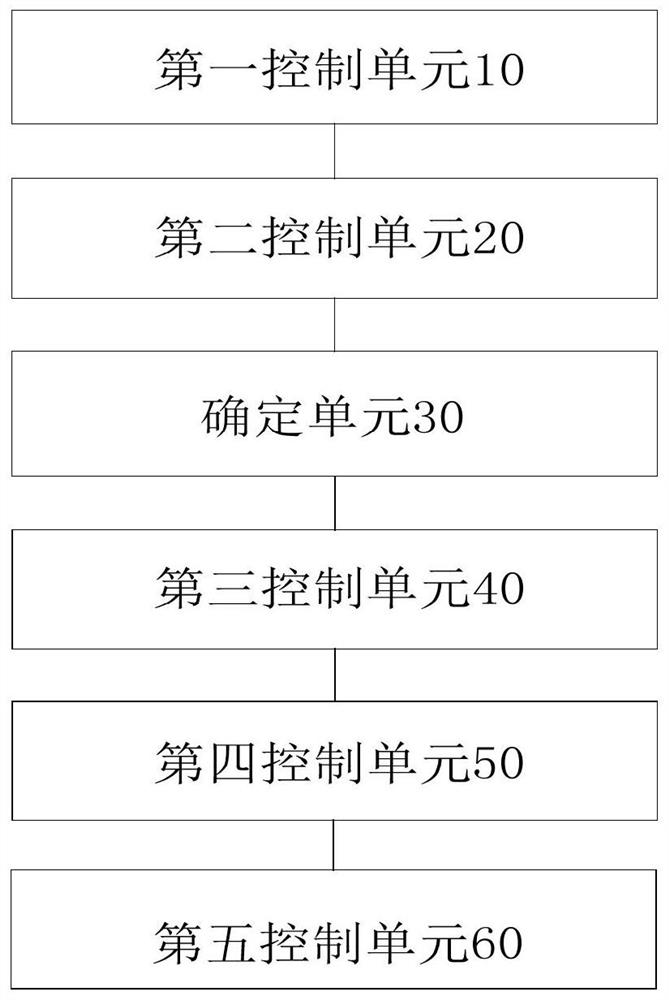

Control method and control device of preparation device of vehicle urea solution, and processor

ActiveCN111715126AReduce concentrationReduce mistakesInternal combustion piston enginesFlow mixersControl engineeringProcess engineering

The invention provides a control method and a control device of a preparation device for a vehicle urea solution, and a processor. The method comprises the following steps: controlling a feed openingto be opened to make urea particles of storage equipment added into a stirring device; under the condition that the reading change amount of a weighing device is equal to a preset mass, controlling adischarging opening to be closed, wherein the preset mass is the preset feeding amount of the urea particles; determining a water injection amount according to the predetermined mass and the predetermined concentration; controlling a first valve to be opened, and adding pure water at a preset temperature in hot water storage equipment into the stirring device; under the condition that the readingchange amount of a flow detection device is equal to the water injection amount, controlling the discharging opening to be closed; controlling the stirring device to stir the pure water and the urea particles to obtain the finished urea solution. Compared with manual weighing and feeding in the prior art, the method has the following advantages: the automation level of the preparation device of the vehicle urea solution is improved, the labor cost and the time cost are saved, errors caused by manual weighing are avoided, and the percent of pass of the finished urea solution is increased.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Modulating surface and aerosol iodine disinfectant system

InactiveUS20140271925A1Reduce and negateReduce thermal interferenceBiocideControlling ratio of multiple fluid flowsDisinfectantIodine solutions

A method and apparatus for producing aqueous iodine solutions to be used as a surface and aerosol disinfectant under continuous and dynamic flow conditions for medical applications comprises dissolving iodine into a first water flow thereby producing a concentrated aqueous iodine solution. The iodine solution is stored and then blended with a second water flow to produce a predetermined iodine disinfectant concentration of aqueous iodine. The disinfectant concentration is then stored and chemically adjusted to polarize to the species of iodine. The disinfectant concentration is then thermodynamically adjusted to maximize retention and disinfection variables. The iodine disinfectant is then ready to be used in an application requiring disinfection using iodine.

Owner:NEET INNOVATIONS

Dissolving system and dissolving method for dissolving graphite phase carbon nitride

ActiveCN111659271AImprove solubilityDissolve fastTransportation and packagingChemical/physical processesNitrate saltsCarbon nitride

The present invention discloses a dissolving system and a dissolving method for dissolving graphite phase carbon nitride. The dissolving system comprises: a chemical reagent comprising at least one ofhalide, nitrate or sulfate of lithium, zinc, aluminum and tin; water used as a solvent; and graphite phase carbon nitride to be dissolved, wherein the dosage of the chemical reagent is 20-80% of themass of the total mixture, the solvent accounts for 20-80% of the mass of the total mixture, and the total mixture is a mixture of the graphite phase carbon nitride, the chemical reagent and the solvent. The system and the method have the advantages of environmental protection and good dissolvability.

Owner:MINNAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com