Preparation and conveying system for constant-concentration solution

A delivery system and solution technology, which is applied in the field of constant concentration solution preparation and delivery system, can solve the problems of affecting flue gas temperature, unsustainable preparation, and unstable solution concentration, so as to achieve uninterrupted use, efficient and sustainable preparation, and prevent temperature Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

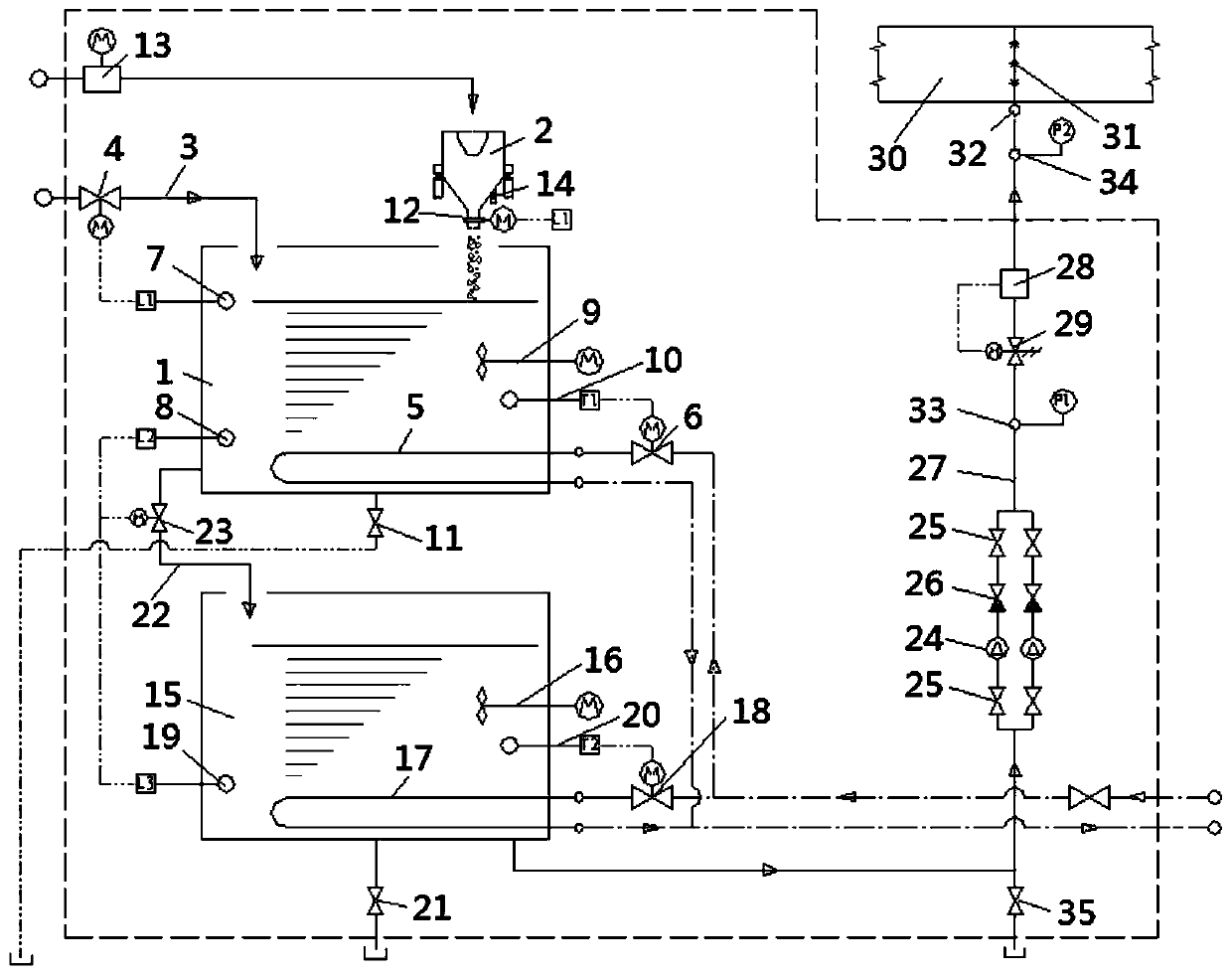

[0035] In the following, a constant concentration solution preparation and delivery system provided by the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments. According to the following description and claims, the advantages and features of the present invention will be clearer.

[0036] See figure 1 , This embodiment provides a constant concentration solution preparation and delivery system, including: a preparation and delivery controller, and a constant concentration solution preparation device;

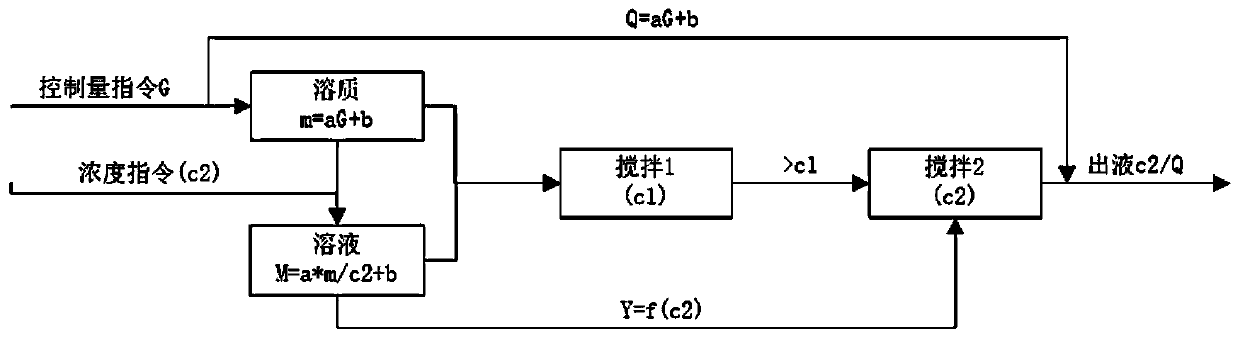

[0037] The constant concentration solution preparation device includes: a preparation cylinder 1, a solute adder 2, a solvent adder, a first temperature sensor 10, a first heater 5, and a first liquid level sensor. The preparation and delivery controller includes a temperature control unit and a solvent control unit. Unit, solute control unit, output control unit, the preparation cylinder 1 is provided with a solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com