Preparation device of gas solution and method for improving solubility of gas in liquid

A preparation device and gas technology, which are applied to the preparation device of supersaturated gas solution and the preparation field of supersaturated gas solution, can solve the problems of poor metal taste, slow reaction speed, toxicity and the like, and achieve the effect of improving gas storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

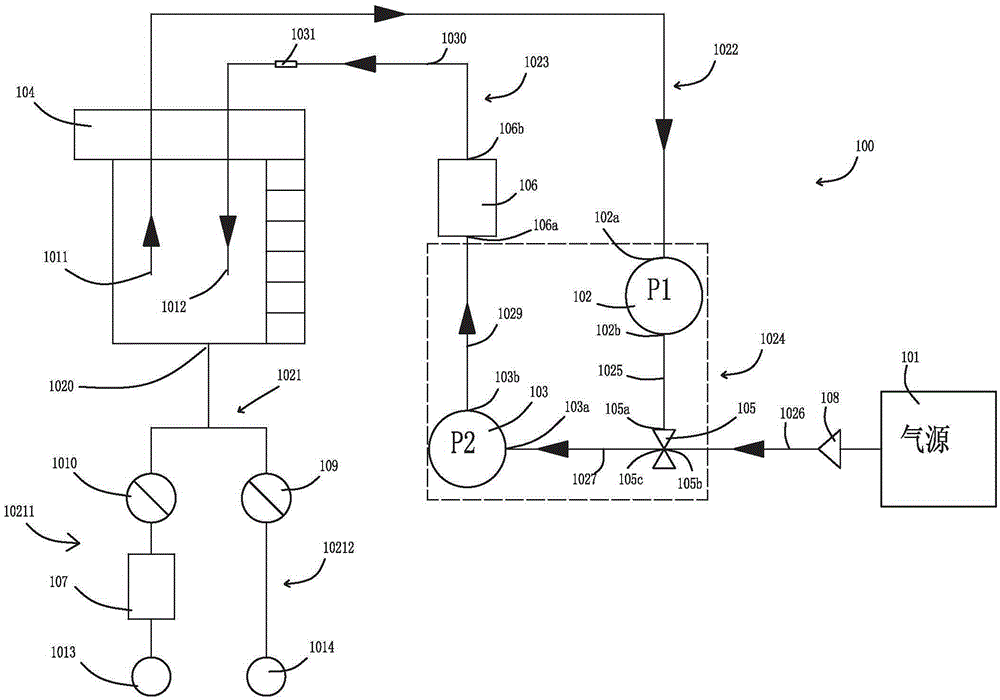

[0117] The key to the preparation device of the supersaturated gas solution in this embodiment is to provide a hollow fiber membrane group comprising a plurality of hollow fiber membrane tubes, and then make the liquid flow inside the hollow fiber membrane tubes, and at the same time allow the gas to pass through the hollow fiber membranes The membrane pores of the tube enter the interior of the hollow fiber membrane tube and mix with the liquid, thereby making a supersaturated gas solution. Under the above principle and method, various structural forms of the preparation device can be used to achieve the purpose of this embodiment.

[0118] Figure 11 is a schematic structural view showing a supersaturated gas solution preparation device 500 according to a fifth embodiment of the present invention. Such as Figure 11 As shown, the supersaturated gas solution preparation device 500 includes a gas-liquid mixing device 61, and the gas-liquid mixing device 61 is used to form a ...

preparation example 1

[0142] Preparation Example 1: Preparation of Supersaturated Oxygen Solution

[0143] Gas source concentration: 90% pure oxygen source.

[0144] Preparation device: figure 1 The preparation apparatus of the examples shown.

[0145] System hydraulic pressure: 3KG.

[0146] System fluid flow rate: 3L / min.

[0147] The inner diameter of the fifth pipe of the system drainage flow branch: 6.165mm.

[0148] After running for 2 minutes, the system does not add a reducing tube, the oxygen content of the water outlet: 36PPM.

[0149] If the reducing pipe is added, the oxygen content of the effluent water will be 44PPM under other conditions.

preparation example 2

[0150] Preparation Example 2: Preparation of Supersaturated Nitrogen Solution

[0151] Gas source concentration: 99.99% pure nitrogen source.

[0152] Preparation device: Figure 7 The preparation apparatus of the examples shown.

[0153] System hydraulic pressure: normal pressure.

[0154] System air pressure: 0.8KG.

[0155] System fluid flow rate: 1.5L / min.

[0156] System outlet pipe inner diameter: 6.165mm.

[0157] After running for 2 minutes, the system does not add a reducing pipe, and the nitrogen content of the water outlet: 40PPM.

[0158] If the reducing tube is added, the oxygen content of the effluent water will be 48PPM under other conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com