Ultrasonic dissolution promotion device

A technology that promotes dissolution and ultrasonic waves. It is applied in the directions of dissolution, dissolution, and dissolution methods to achieve rapid heat dissipation, improve service life, and promote rapid dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

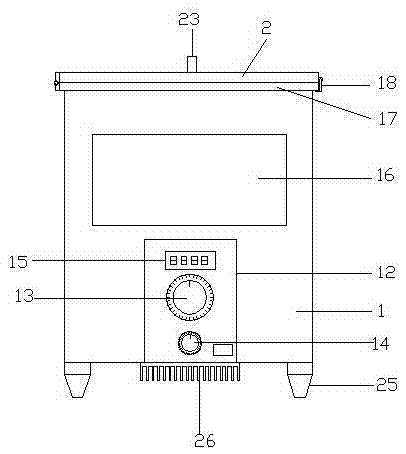

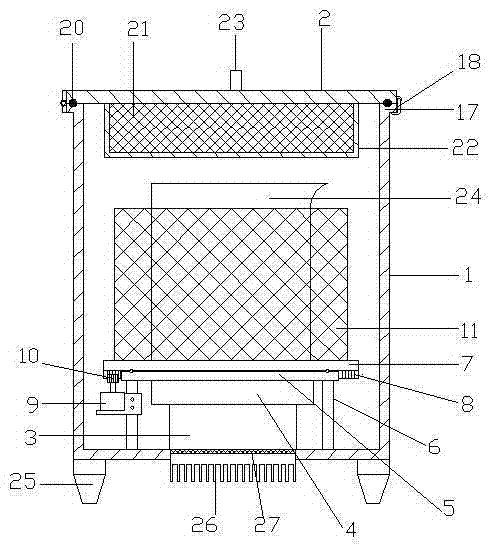

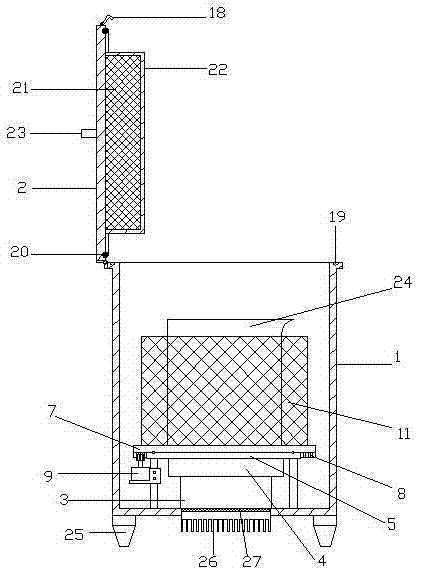

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0019] Such as figure 1 and figure 2 A kind of ultrasonic wave promoting dissolving device shown, comprises housing 1, is arranged on the cover plate 2 of housing upper end, and the bottom of housing 1 is provided with ultrasonic generator 3, and the top of ultrasonic generator 3 is provided with transducer 4, and The top of the energy device 4 is provided with a horizontal support plate 5, the lower side of the support plate is fixed to the bottom of the housing through a number of support rods 6, and the upper side of the support plate 2 is provided with a tray 7, which is rotatably connected to the support plate 5. , the lower side edge of the tray 7 is provided with an internal gear 8, the support rod is provided with a motor 9, the shaft end of the motor 9 is provided with a driving gear 10 meshing with the internal gear, the top surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com