Solution configuration method used for vapor pressure measurement and vapor pressure measurement method

A technology of configuration method and measurement method, applied in the directions of dissolution method, measurement device, separation method, etc., can solve the problems of loss of glassy state of solution, increase of concentration uncertainty, difficulty of solution concentration, etc., and achieve short experimental operation time. , Improve the preparation accuracy and save the effect of the degassing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

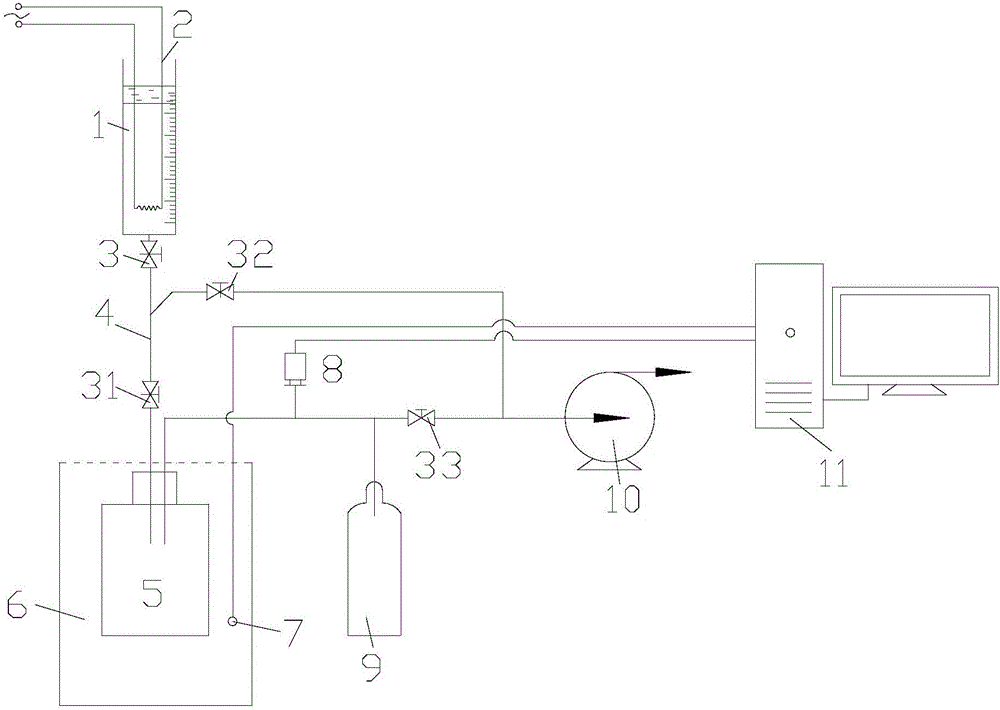

[0044] Such as figure 1 As shown, the vapor pressure measurement method of this embodiment includes the preparation of the solution to be tested and the determination of vapor pressure, and the following tools need to be prepared:

[0045] Solvent container 1, transparent and marked with a volume scale, the upper end is open, the lower end is closed and leads to a diversion tube, which is provided with a valve 3;

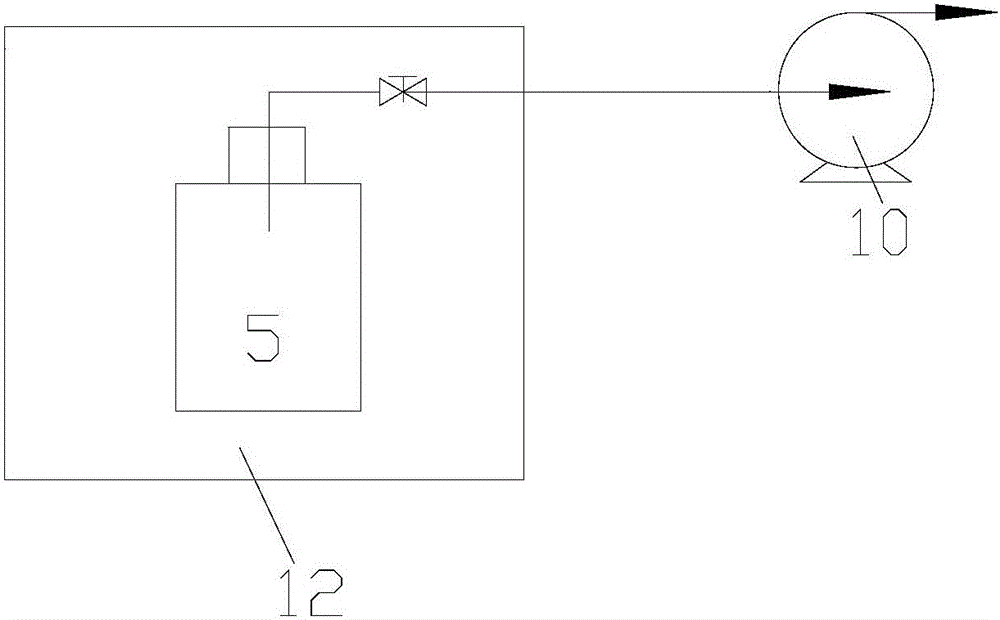

[0046] The solute container 5 is fully sealed, the upper end cover is opened to lead out the diversion pipe, and the diversion pipe is provided with a valve 31;

[0047] The three-way pipe 4, the first port and the second port are in line, so that the third port is not bypassed when the solvent is injected into the solute container. The third port is set at an angle of 45 degrees upwards relative to the horizontal plane. The third port has There is a valve 32; the third port is used to connect to the vacuum pump to suck out the air in the tee 4, and a valve 32 is set betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com