Method for uniforming solution and solution tank

A solution tank and solution technology, applied in dissolution methods, chemical instruments and methods, dissolution and other directions, can solve the problems of high power consumption, difficult maintenance, low productivity, etc., and achieve increased movement space, convenient use, and increased equipment volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

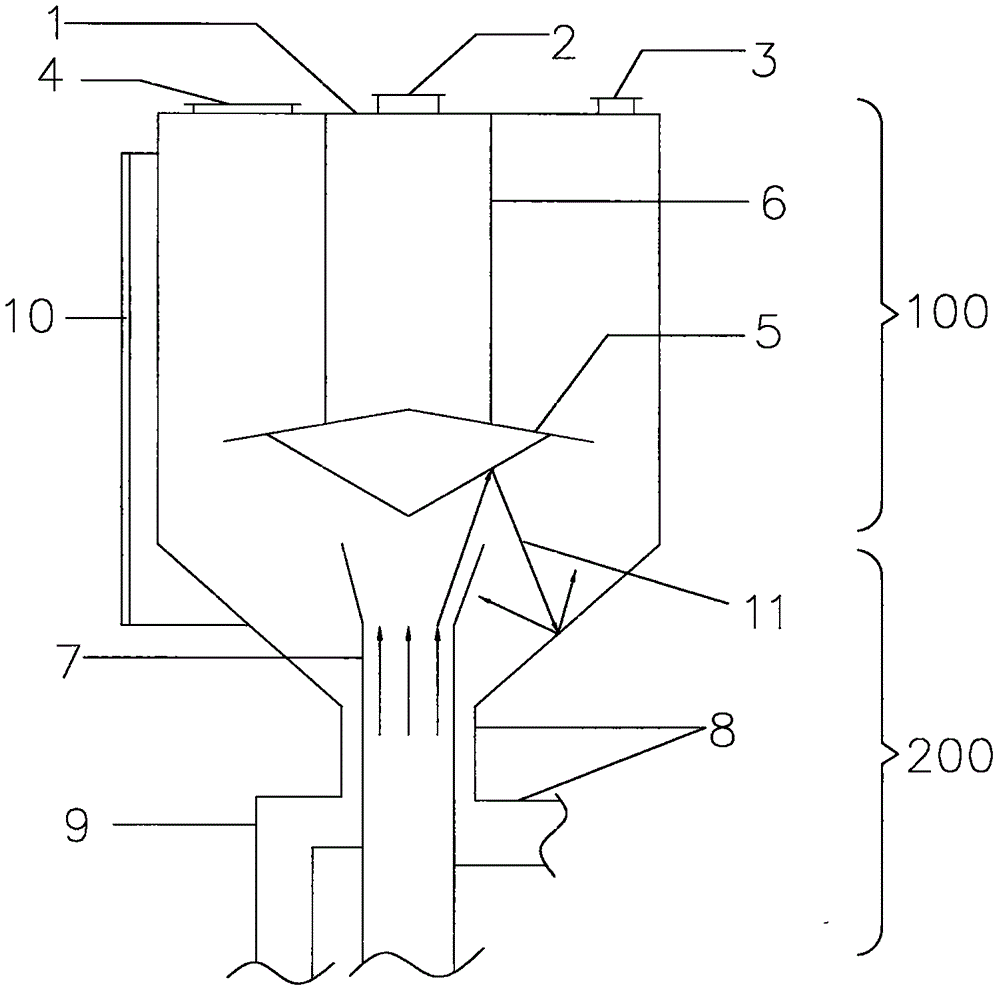

[0030] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0031] A method for preparing a homogeneous solution, comprising the steps of:

[0032] Step 1: Draw the solution out from the liquid outlet of the container and spray it out from the liquid inlet pipe of the container;

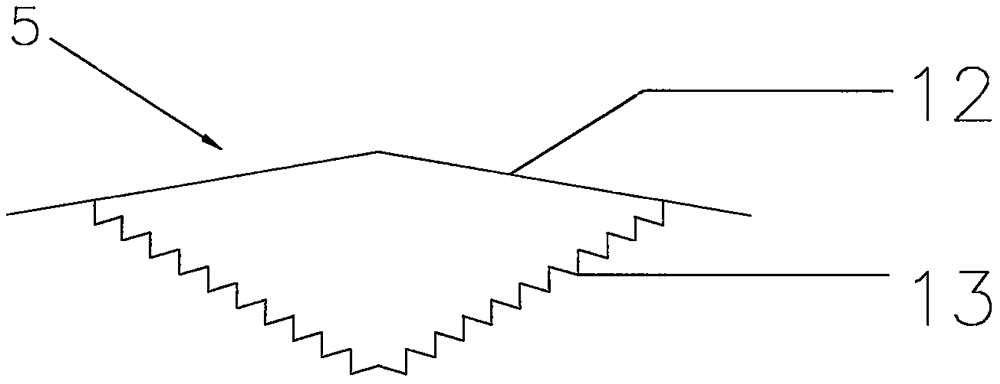

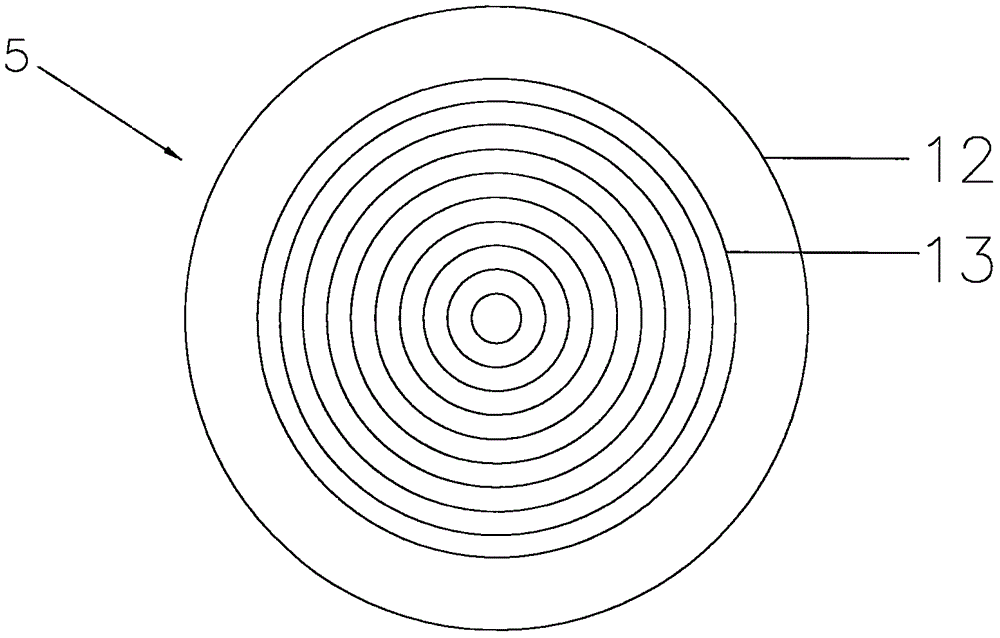

[0033] Step 2: Hit the sprayed solution on the liquid baffle device in the container, the solution is deflected to the bottom of the container, and the bottom solution is kicked up to make the solution in the container form a vertical vortex, and the solutions collide and agitate with each other, resulting in strong Turbulent flow, rapid mixing;

[0034] Step 3: After the vortex solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com