Method of continuous dissolution of polyacrylamide emulsions for enhanced oil recovery (eor)

A technology of enhanced oil recovery and inverse emulsion, applied in dissolution methods, chemical instruments and methods, dissolution, etc., can solve the problems of long residence time and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] 1. Preparation of emulsion

[0070] In order to obtain the maximum viscosity under the conditions of use, the standard product is a polyacrylamide emulsion containing 70% acrylamide and 30% acrylic acid.

[0071] The standard emulsion is prepared by methods well known to those skilled in the art, with many possible variations.

[0072] Mix the following in the water phase in a dissolution tank cooled to 20°C:

[0073] - 4596 kg of 50% acrylamide solution obtained by biological methods,

[0074] -1108kg of high-purity glacial acetic acid,

[0075] -1104kg of water,

[0076] -1086kg of high-purity 50% sodium hydroxide solution,

[0077] - 360 g of sodium bromate,

[0078] -Versenex 80 of 4680g,

[0079] - 240kg of sodium acetate,

[0080] - 4320 g of sodium formate.

[0081] In a 10000 liter reactor, prepare the oil phase by mixing:

[0082] - 49kg of Hypermer 2296 (CRODA) - 3037kg of Exsol D100

[0083] -197kg of sorbitan oleate

[0084] -39kg of Tween81 (CR...

Embodiment 1

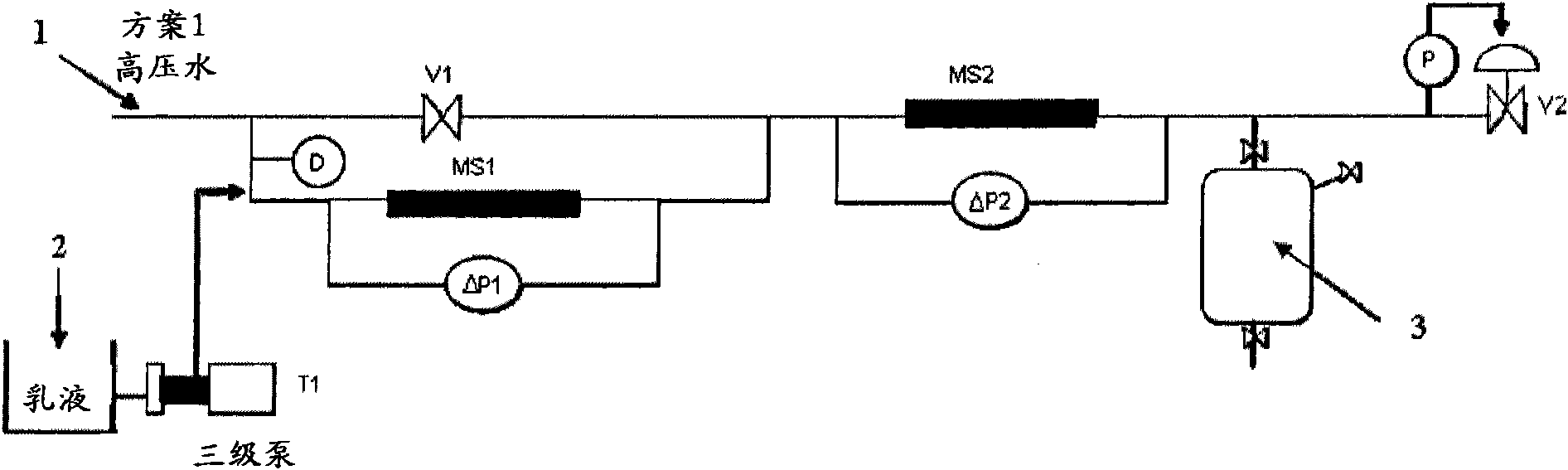

[0111] Injection device such as figure 1 shown.

[0112] It is necessary to repeatedly inject 200m into the oil well 3 / h of brine containing 1000 ppm polymer or 3300 ppm emulsion (660 l / h). This volume is much higher than that commonly used for flocculation and there is little previous experience in this field.

[0113] The following conditions apply to this system:

[0114] MS1 water flow: 20m 3 / h

[0115] Emulsion flow: 660 liters / h

[0116] Pressure drop: 2.8bar

[0117] MS2 total flow: 200m 3 / h

[0118] Pressure drop: 2.4bar

[0119] A sample was collected and stirred with a magnetic stirrer for 5 minutes to obtain a filtration ratio of 1.3

Embodiment 2

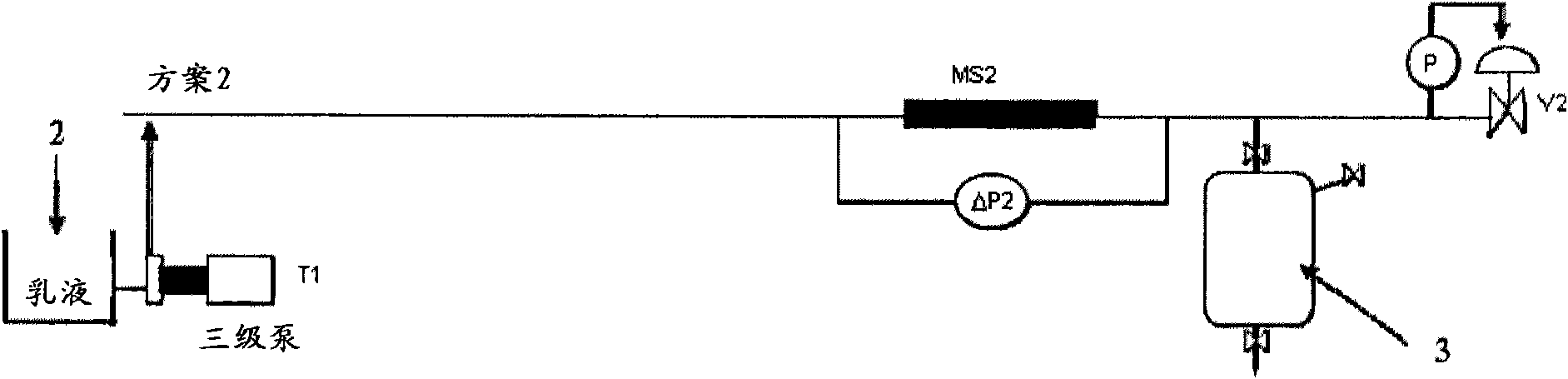

[0121] Assembly No.2 is used under the following conditions:

[0122] MS2 total flow: 200m 3 / h

[0123] Mixer pressure drop: 2.3bar

[0124] Difficult to filter test this solution, FR higher than 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com