Fuel feeding apparatus

A fuel supply device and fuel technology, applied in fuel injection devices, liquid fuel feeders, low-pressure fuel injection, etc., can solve problems such as difficulty in maintaining pump performance, unbalanced pump discharge, etc., to achieve suppression of steam generation, good The effect of maintaining and improving connection workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

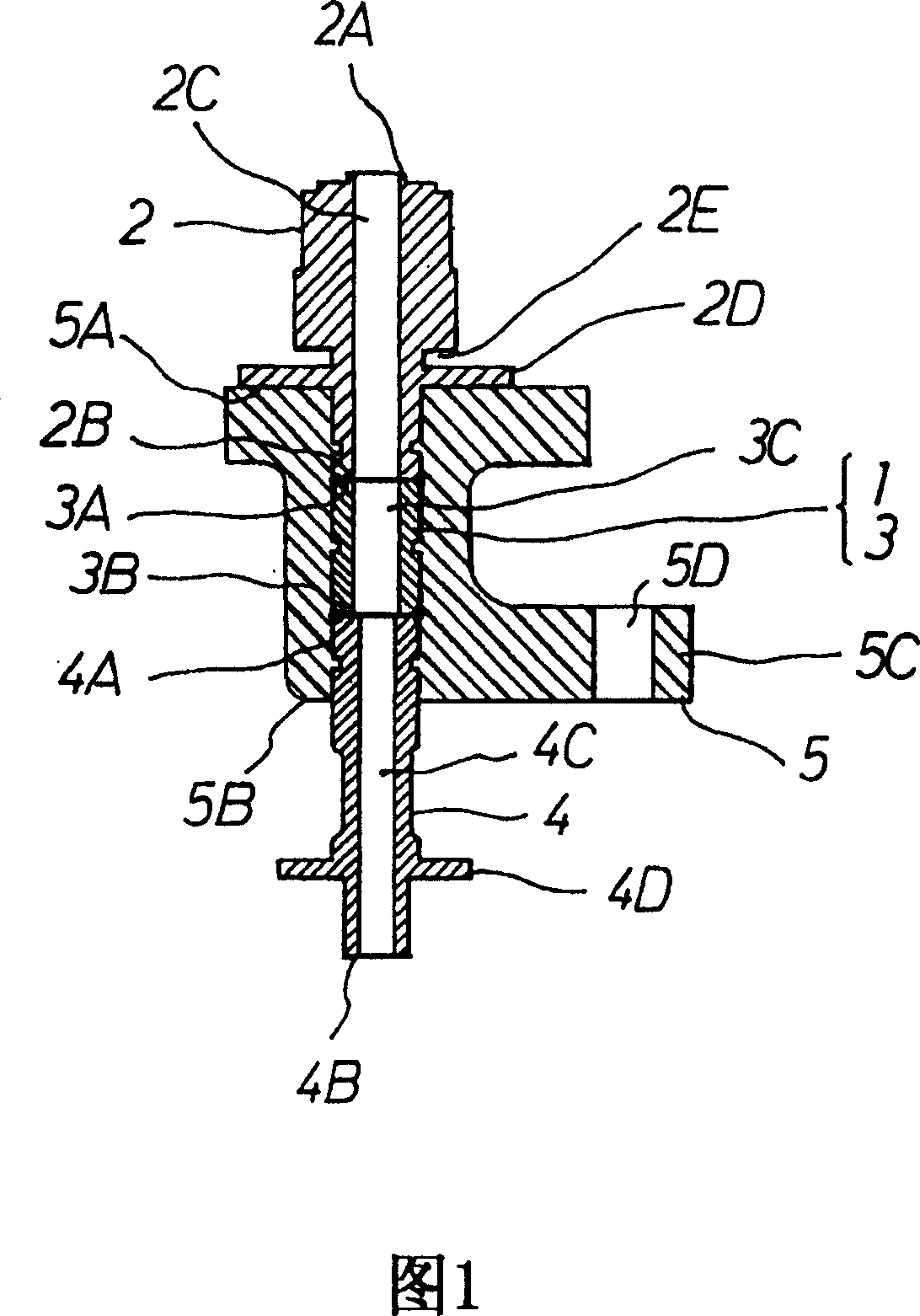

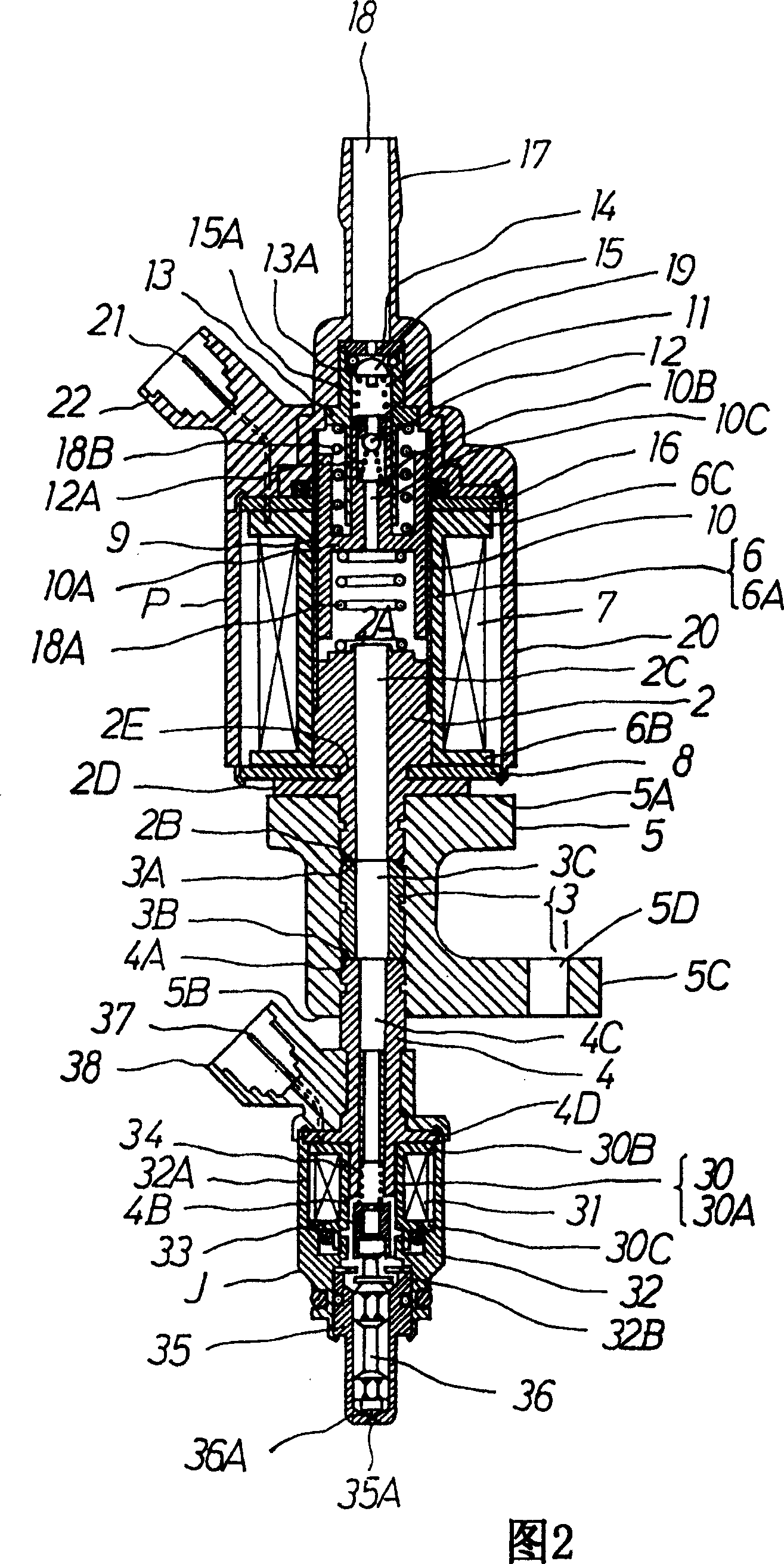

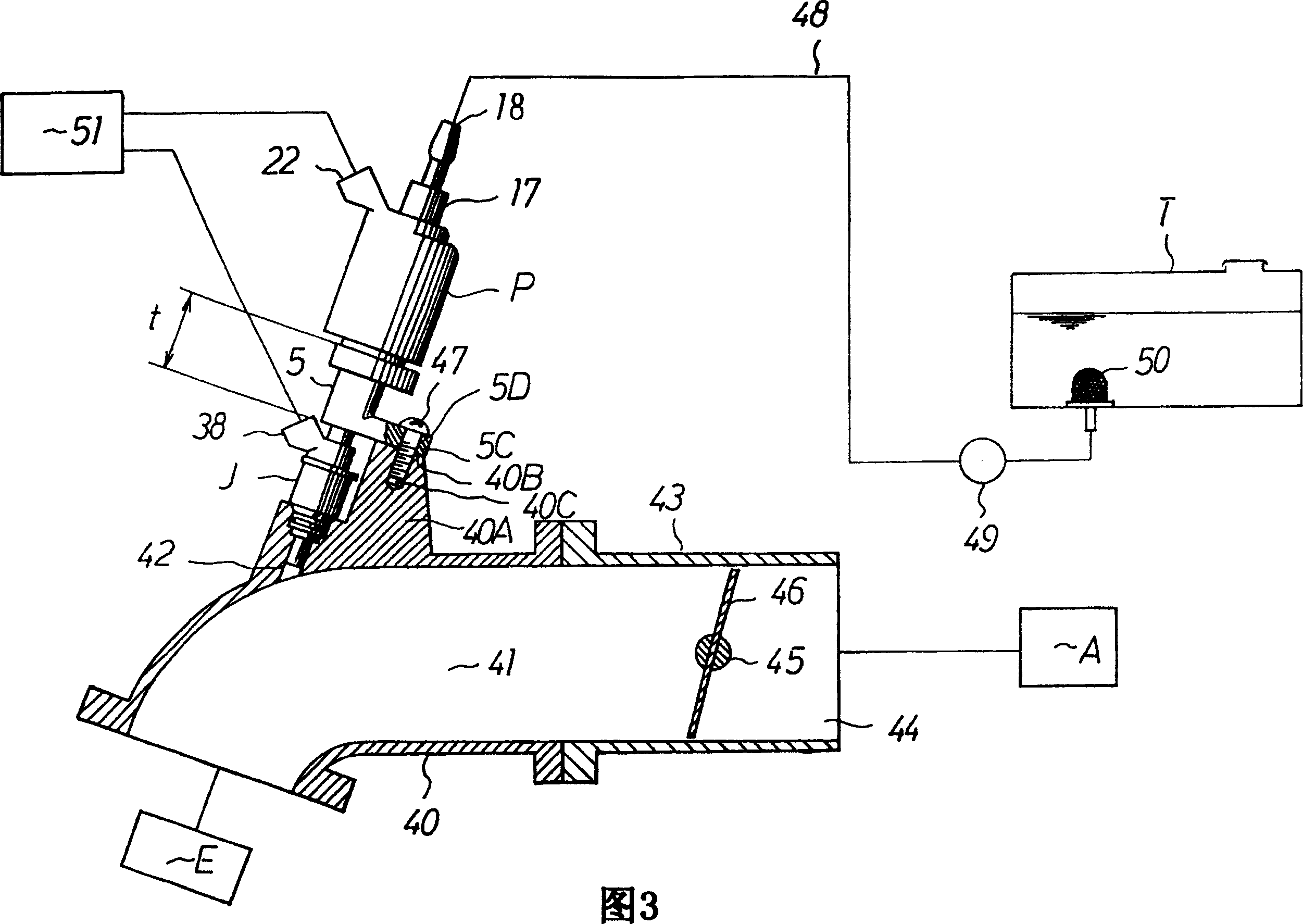

[0037] An embodiment of the fuel supply device of the present invention will be described below with reference to FIG. 1 .

[0038] 1 denotes a pipe assembly, and the pipe assembly 1 is formed of a pump stationary core 2, a tubular member 3, and an injection valve stationary iron core 4, and is formed as follows.

[0039] The pump fixed core 2 is made of magnetic material, the fuel discharge passage 2C is opened from the upper end 2A to the lower end 2B in a penetrating manner, and an engaging flange portion 2D and an engaging groove 2E are formed in the middle of its outer periphery.

[0040] The annular member 3 is formed of a non-magnetic material, and a fuel flow path 3C is formed penetratingly from the upper end 3A toward the lower end 3B.

[0041] The injection valve fixed core 4 is formed of a magnetic material, the fuel inflow passage 4C is opened from the upper end 4A to the lower end 4B in a penetrating manner, and an annular flange portion 4D serving as an upper mag...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap