Baseplate frame of bulldozer and ROPS operator cabin for bulldozer with said baseplate frame

A bulldozer and cab technology applied to the structural field of the ROPS cab floor frame, which can solve uneconomical problems and achieve high sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below with reference to the drawings.

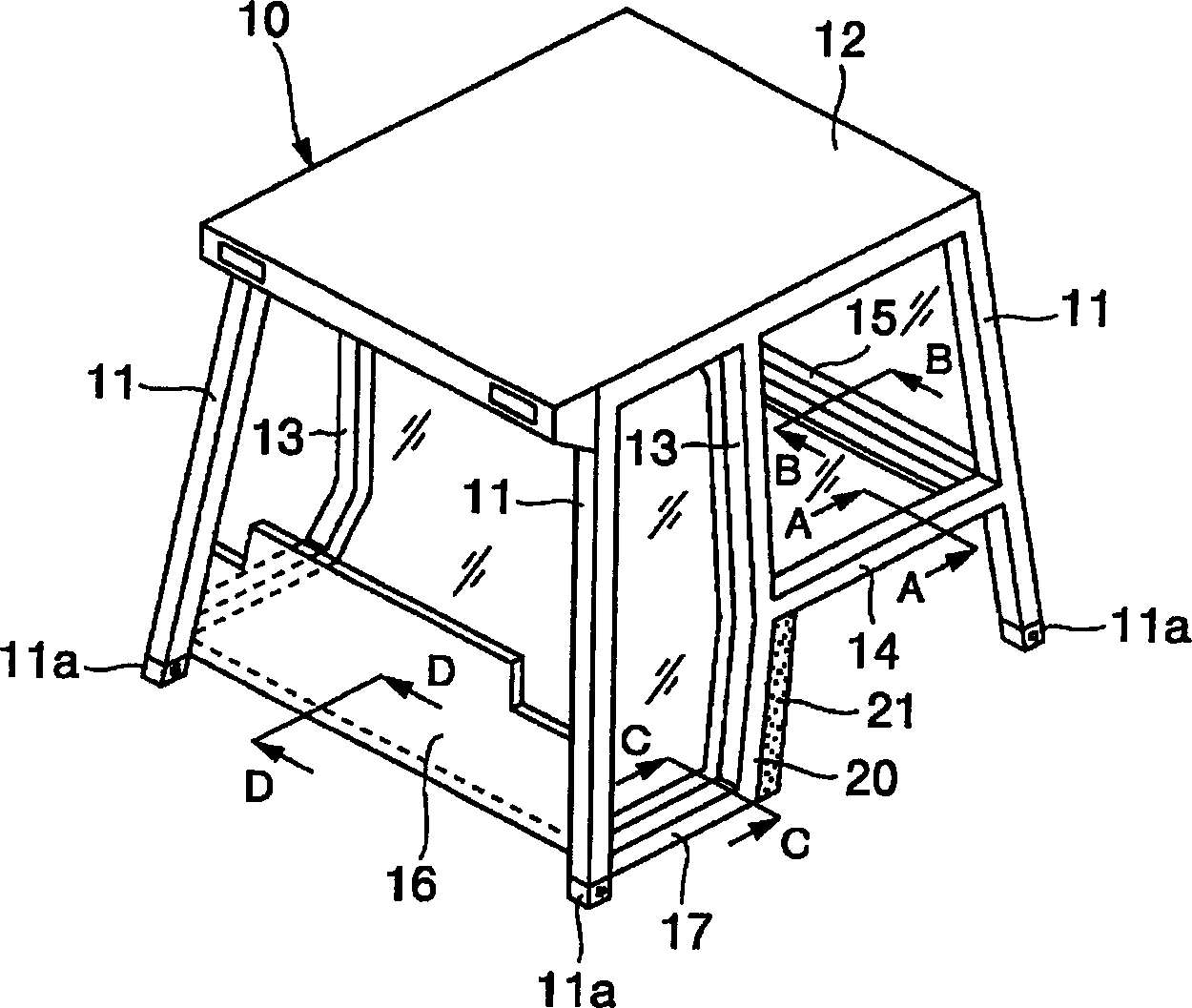

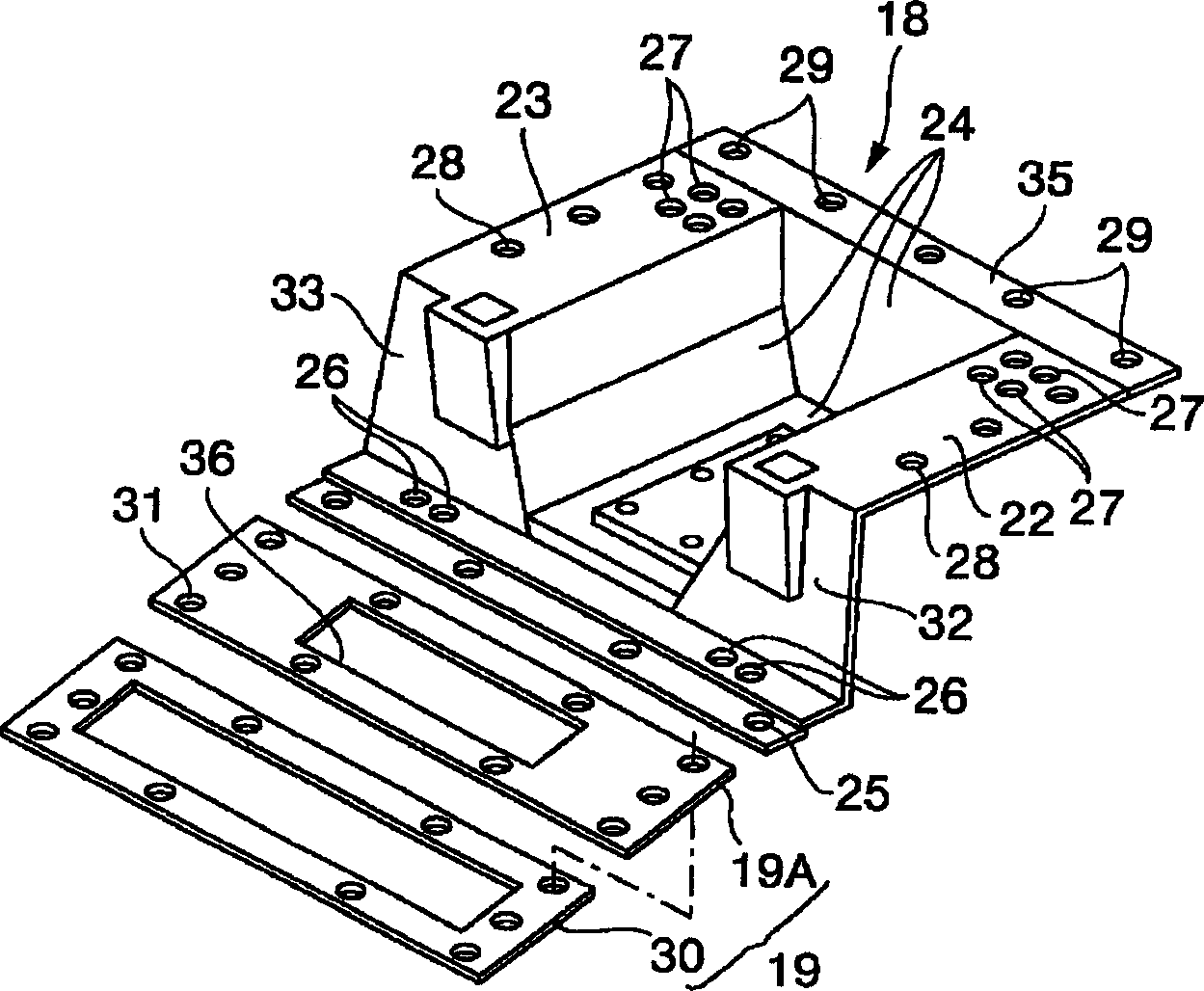

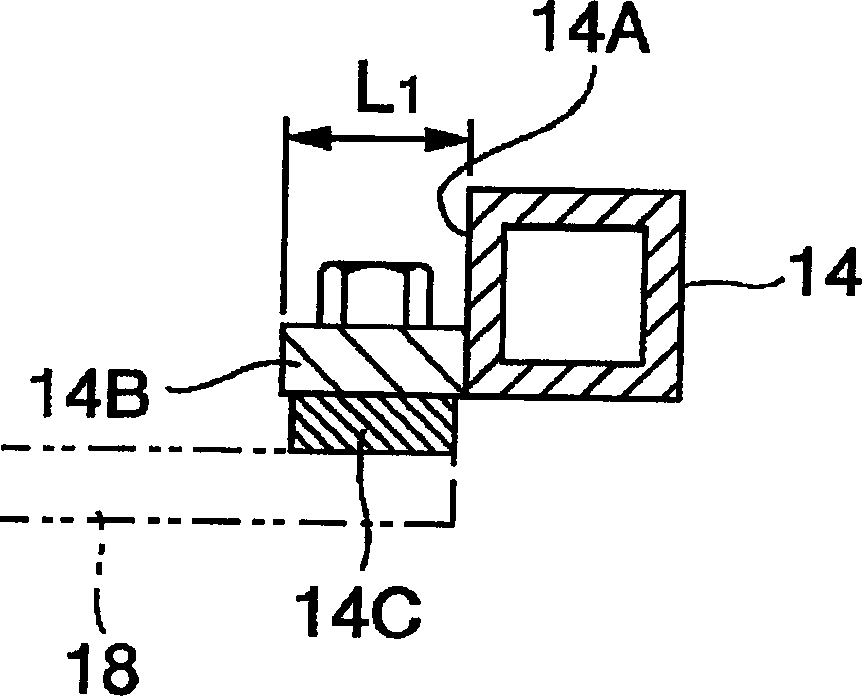

[0024] figure 1 It is a perspective view of the ROPS cab of the embodiment of the present invention. exist figure 1 Among them, the ROPS cab 10 is equipped with elastic feet 11a at the lower ends of each ROPS pillar 11 at the four corners, and the upper end of each ROPS pillar 11 is integrally equipped with a cab roof 12 covering the whole. Between the left and right front and rear ROPS pillars 11, 11, door frames 13, 13 are respectively arranged in the up and down direction; in the bottom between the left and right door frames 13 and the ROPS pillars 11, 11 at the back, they are arranged in the front and rear direction Left and right lower window frames 14, 14; left and right door lower frames 17, 17 are arranged in the front and rear directions at the lower ends between the left and right door frames 13, 13 and the front ROPS pillars 11, 11. In addition, at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com