Engine for motor bicycle

A technology for motorized two-wheeled vehicles and engines, which is applied in the direction of machines/engines, motor vehicles, engine components, etc., and can solve problems such as obstruction, shortening the distance between the crankshaft and the transmission output shaft, shortening the overall length of the engine, etc., to reduce side thrust , Fuel cost improvement, and the effect of reducing sliding frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation form of the present invention will be described below according to an embodiment of the present invention shown in the drawings.

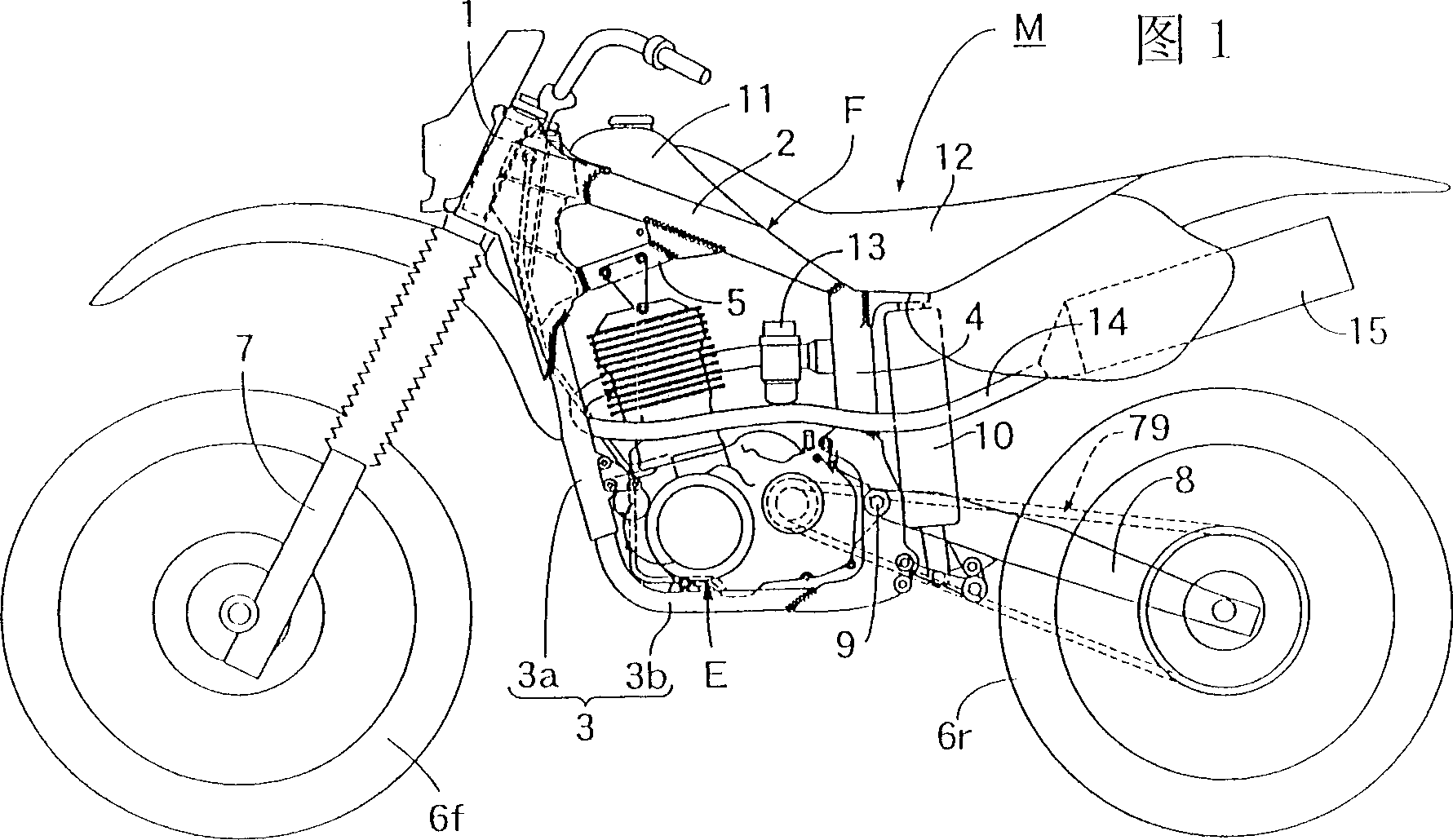

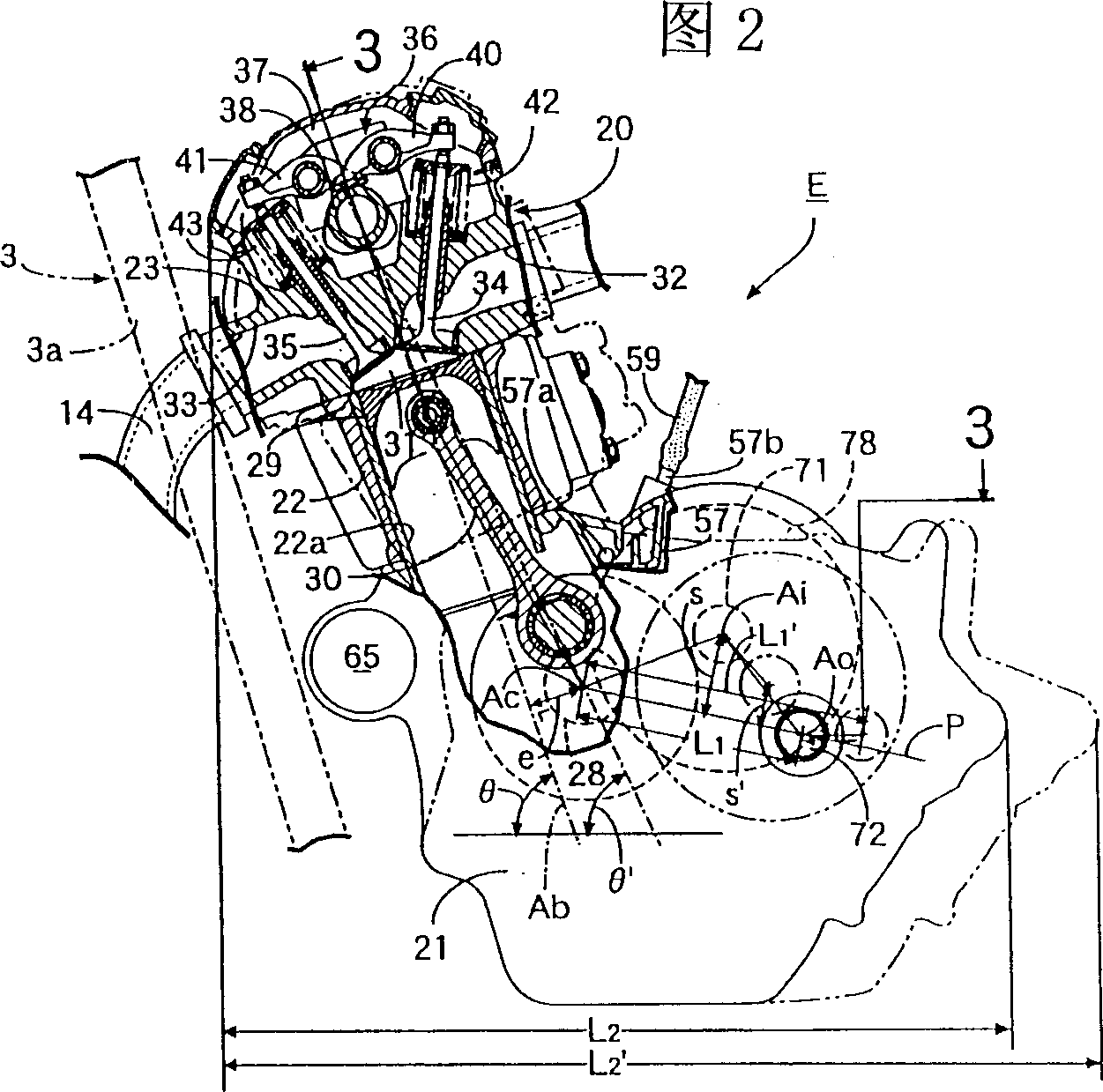

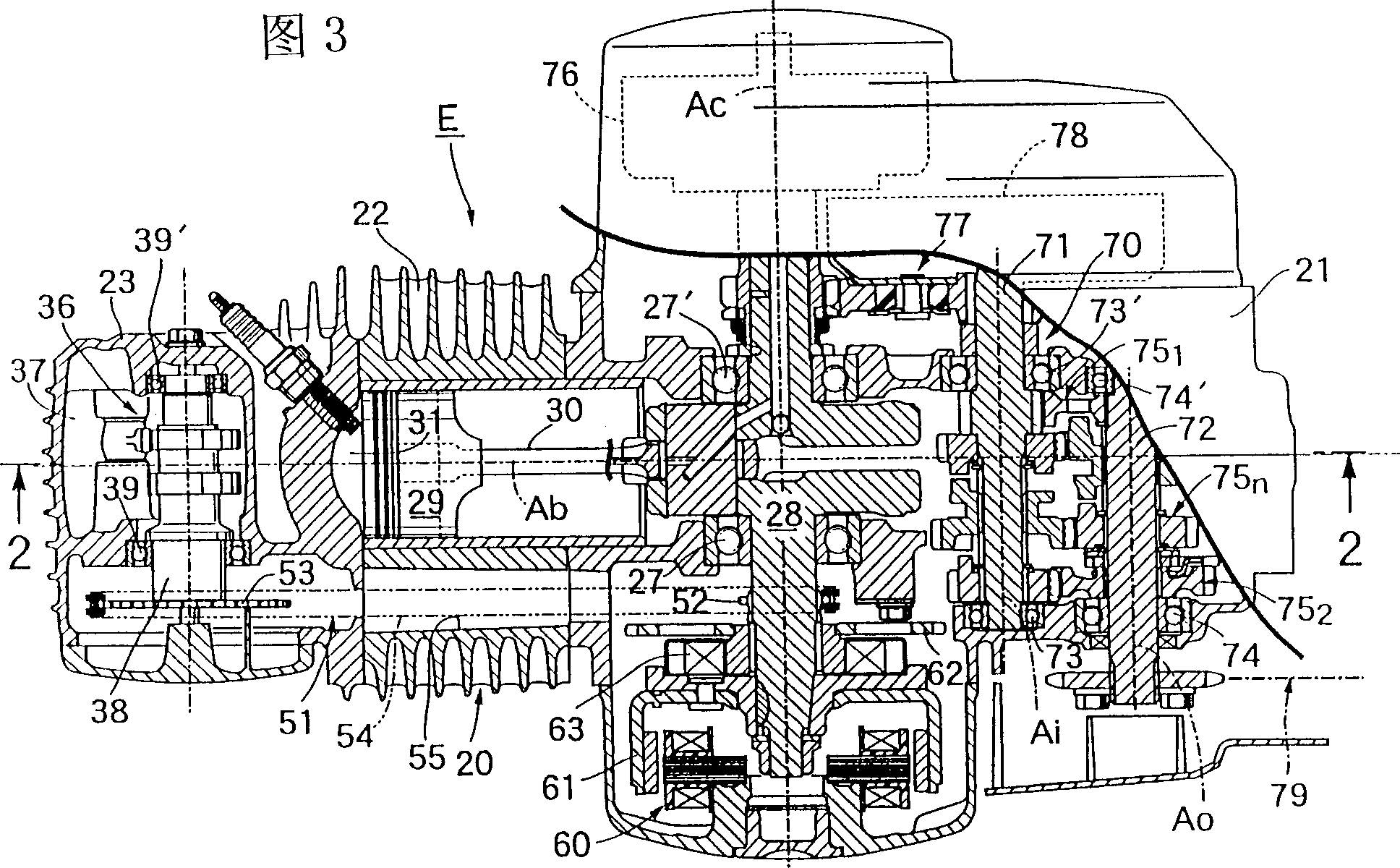

[0017] Fig. 1 is a side view of a motorcycle equipped with an engine of a first embodiment of the present invention, Fig. 2 is a vertical side view of the above-mentioned engine, Fig. 3 is a sectional view taken along line 3-3 of Fig. 2 , and Fig. 4 is a sectional view of the engine It is a longitudinal sectional side view of the engine of the second embodiment of the invention.

[0018] In the following description, front, rear, left, and right are based on the motorcycle M to which the present invention is applied.

[0019] First, a first embodiment of the present invention shown in FIGS. 1 and 2 will be described. In FIG. 1 , a frame F of a motorcycle M has a head pipe 1 , a main pipe 2 welded to the upper portion of the head pipe 1 and extending rearward and downward with a gentle slope, and a lower pipe 2 welded to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com