Scissors with hole parts

A technology of scissors and blades, applied in the field of hairdressing scissors, which can solve the problems of thread connection strength reduction, discharge, and difficult chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Certain embodiments of the invention are described in more detail below.

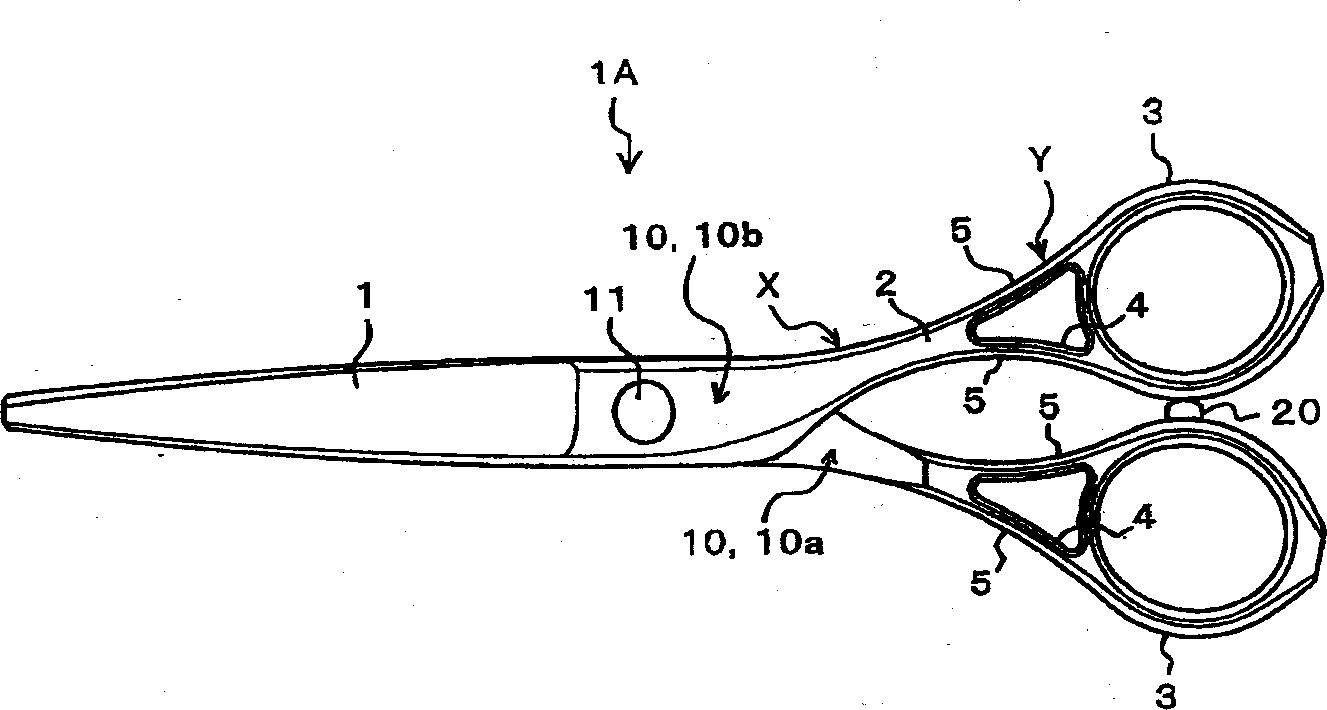

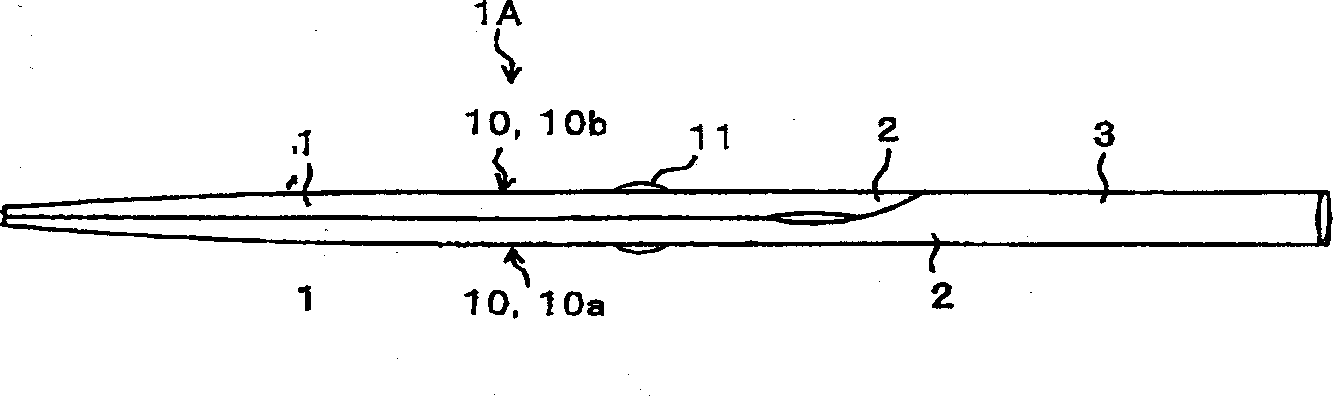

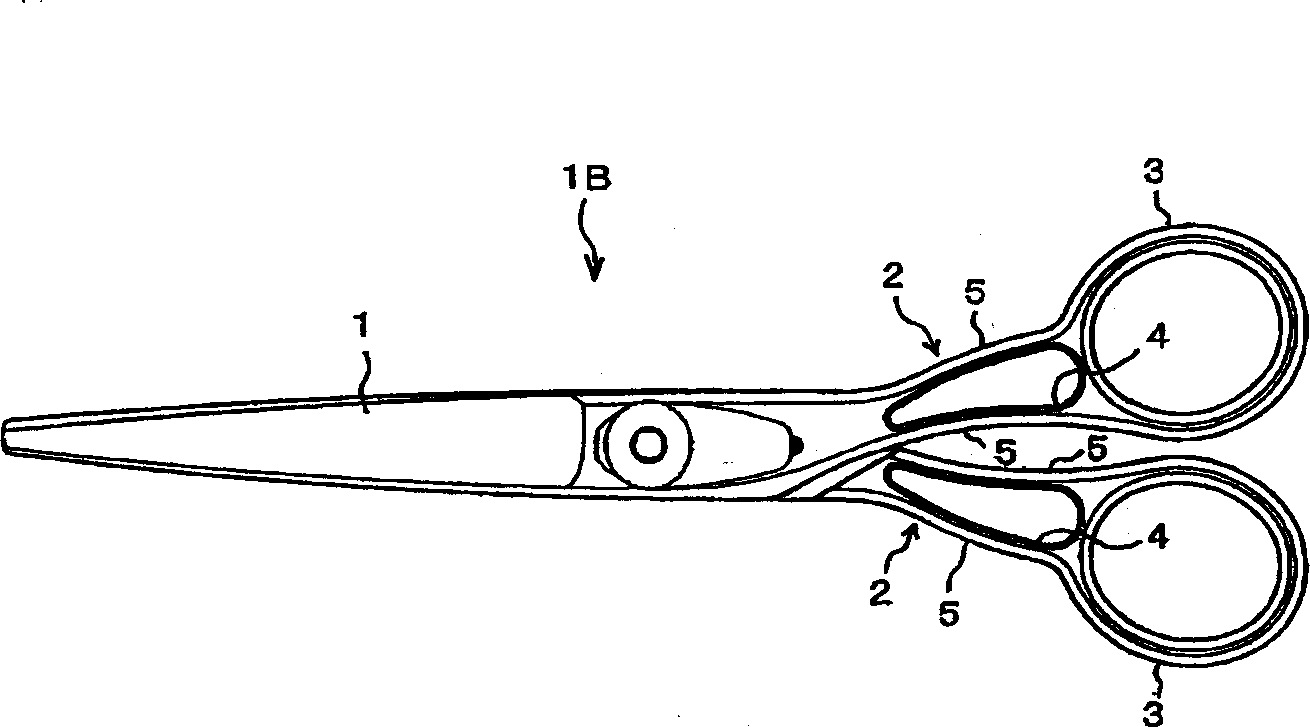

[0035] Figure 1 shows a hairdressing scissors 1A comprising cutting bodies 10 made of stainless steel interconnected for pivoting about a pivot 11 to open and close the scissors. Each cutting body 10 , 10 comprises a blade 1 , a handle 2 and a finger loop 3 .

[0036] Such as Figure 13 As shown, the proximal side X (near the pivot 11 ) of the handle 2 is generally rod-shaped and the distal side Y (near the finger loop 3 ) is generally disc-shaped. In particular, the overall shape of the handle 2 is similar to that of an elongated triangle with the proximal side X as the vertex and the distal side Y as the base. The lengthwise direction of the handle 2 has a first opening 4 that is substantially elongated and triangular in shape. Both sides of the first opening 4 form two branching ribs 5 , 5 of the handle 2 .

[0037] A rubber collision element 20 is installed on the finger loop 3 of the shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com