Liquid spawn inoculator

A technology of liquid strain and inoculation device, which is applied in fungi, horticulture, agriculture, etc., can solve the problems of complicated preparation work, fluctuation in the amount of strains extracted, and increase in the number of days required for cultivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

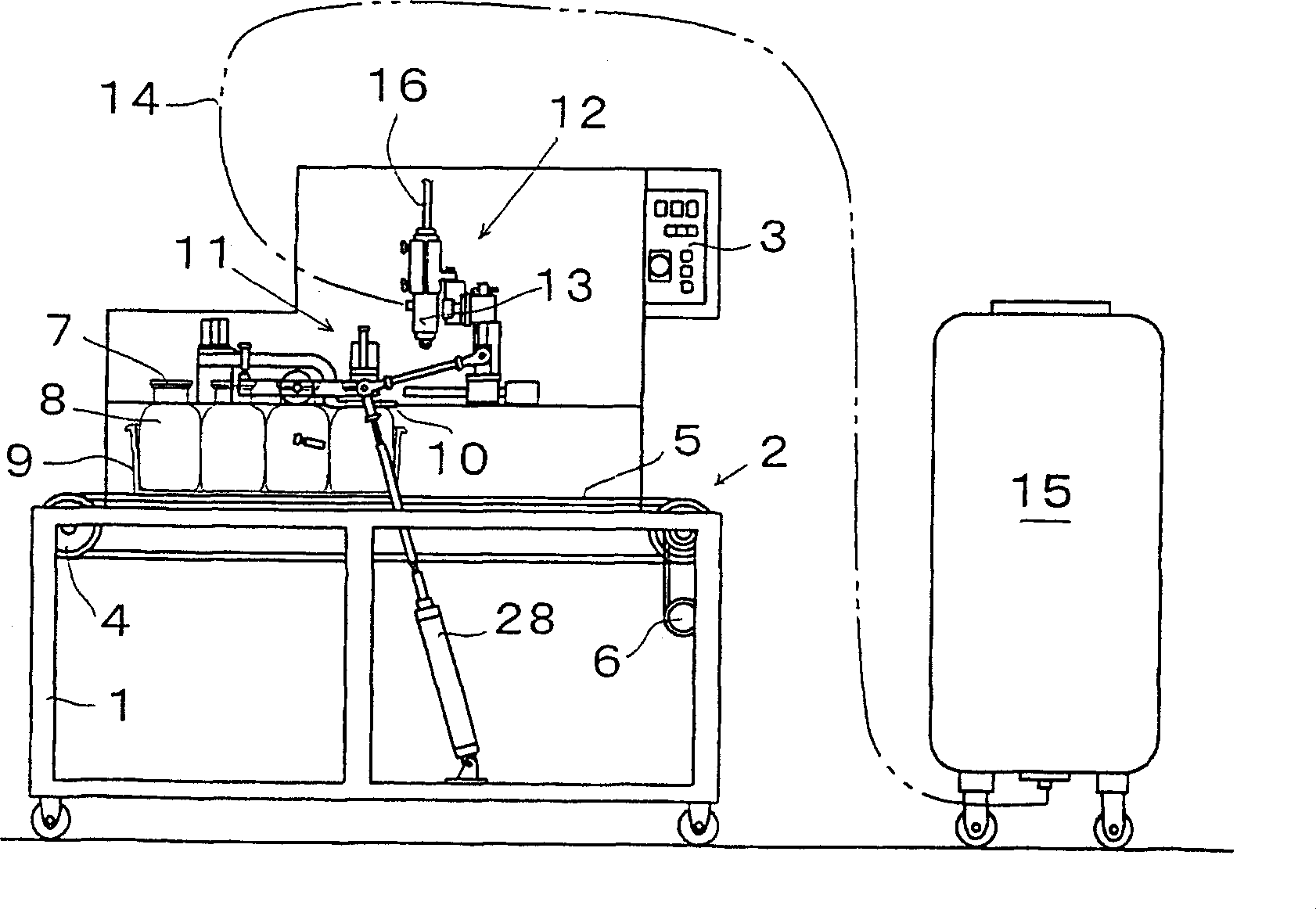

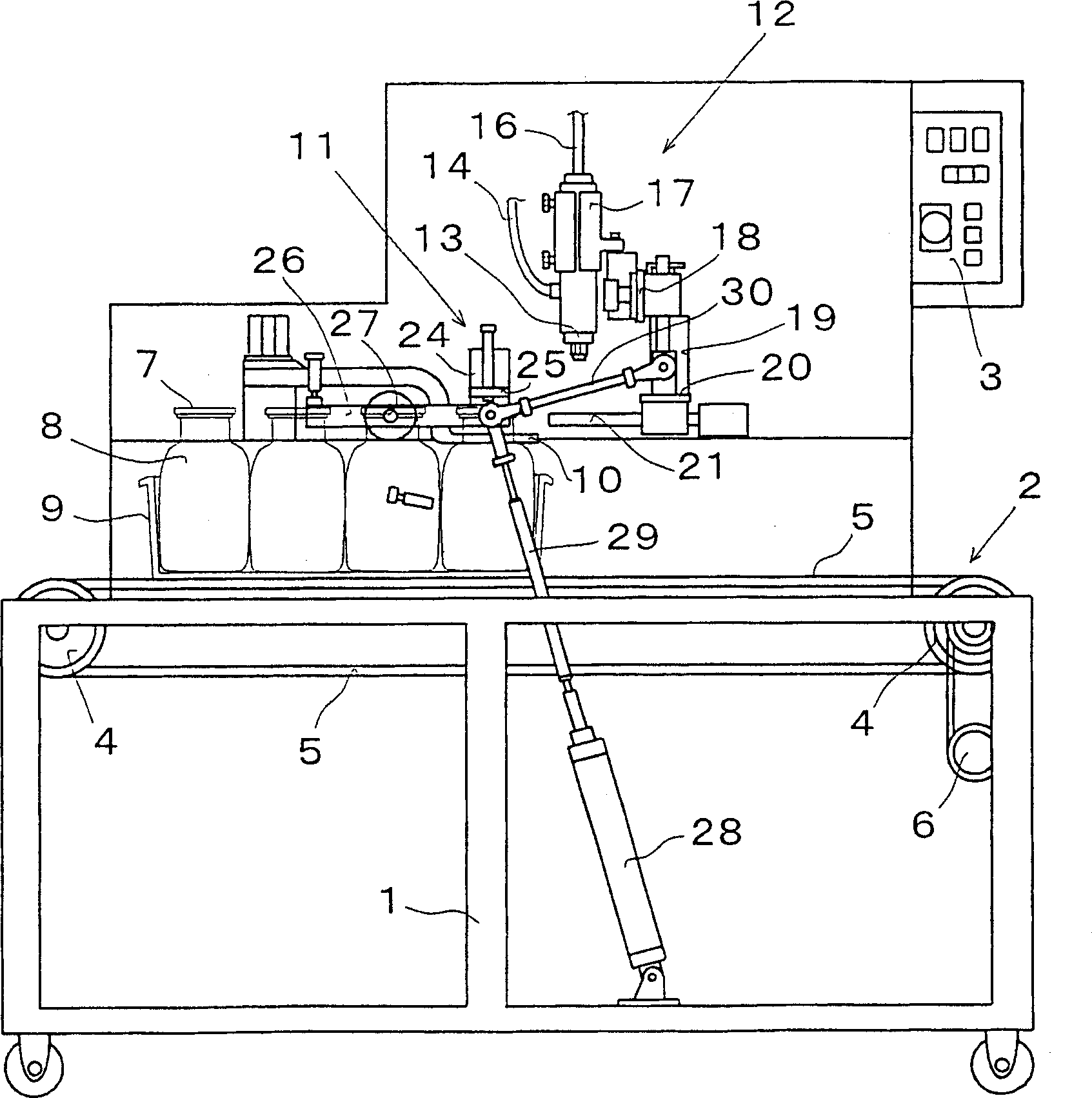

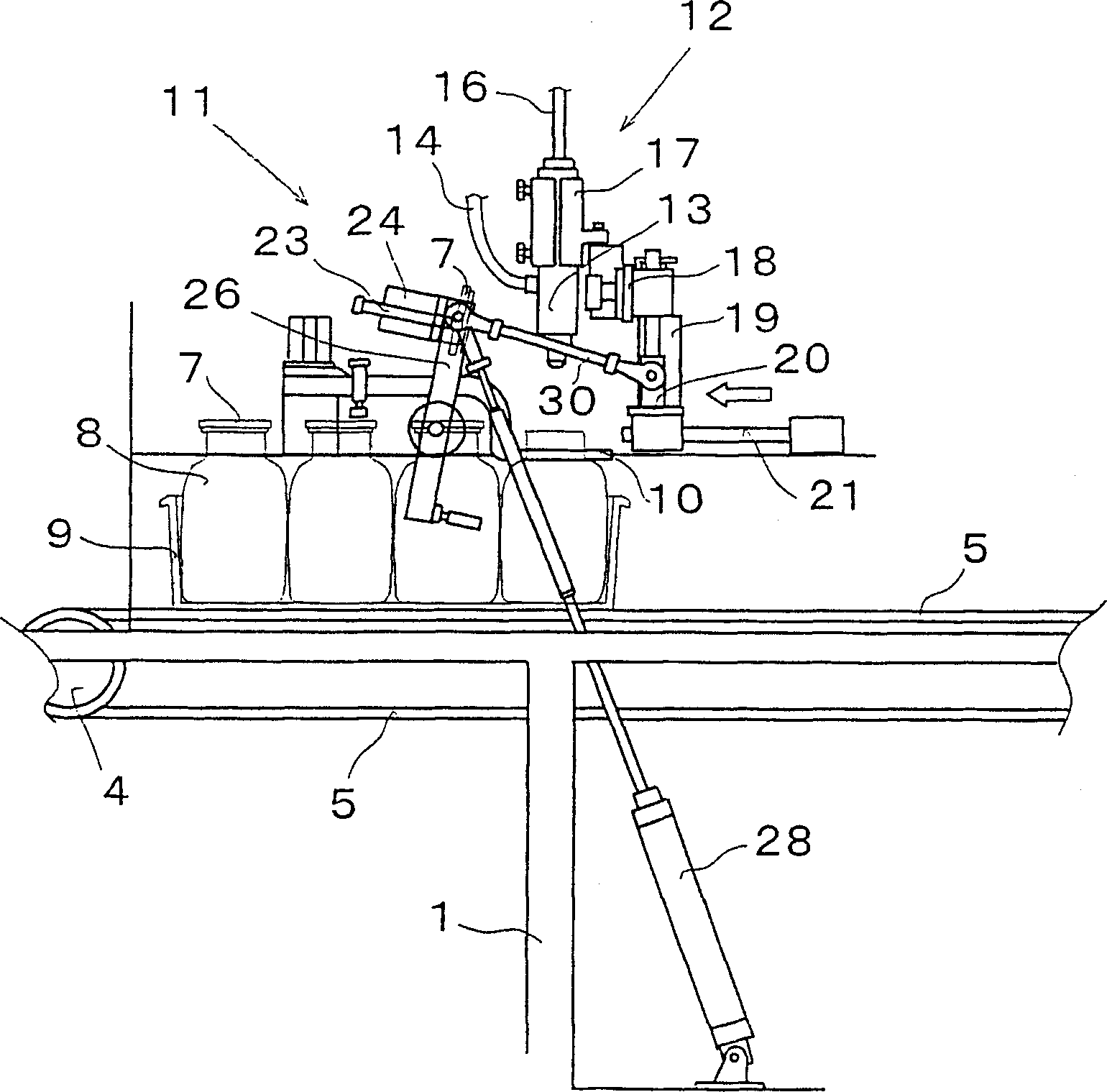

[0027] Refer to the following Figure 1 to Figure 11 The first embodiment of the device for inoculating liquid strains of the present invention will be described. Wherein it is provided with a conveying mechanism 2 composed of a conveying mechanism substantially spanning the entire length of the main body frame 1 of the liquid strain inoculation device. This conveying mechanism 2 can be started and stopped with the operation of the switch of the operation panel 3. There are several sprockets 4 supported by shafts on the sides of both ends respectively, and endless chains 5 are suspended in parallel between the sprockets 4 at both ends of the frame 1, and the rotational driving force of the motor 6 is transmitted to the above-mentioned chains on the drive source side. round 4.

[0028] The culture container 8 that will be filled with culture medium such as sawdust and rice bran and sealed by lid 7, such as according to longitudinal four and horizontal four is placed in the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com