Resonant cavity structure and semiconductor processing equipment

A resonant cavity, resonant cavity technology, applied in discharge tubes, electrical components, circuits, etc., can solve problems such as the inability to effectively ensure the effective sealing of the elastic electromagnetic shielding ring, mechanical interference in the removal of the resonant cavity, and the failure of the elastic electromagnetic shielding ring. , to shorten the opening time, improve the opening efficiency, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

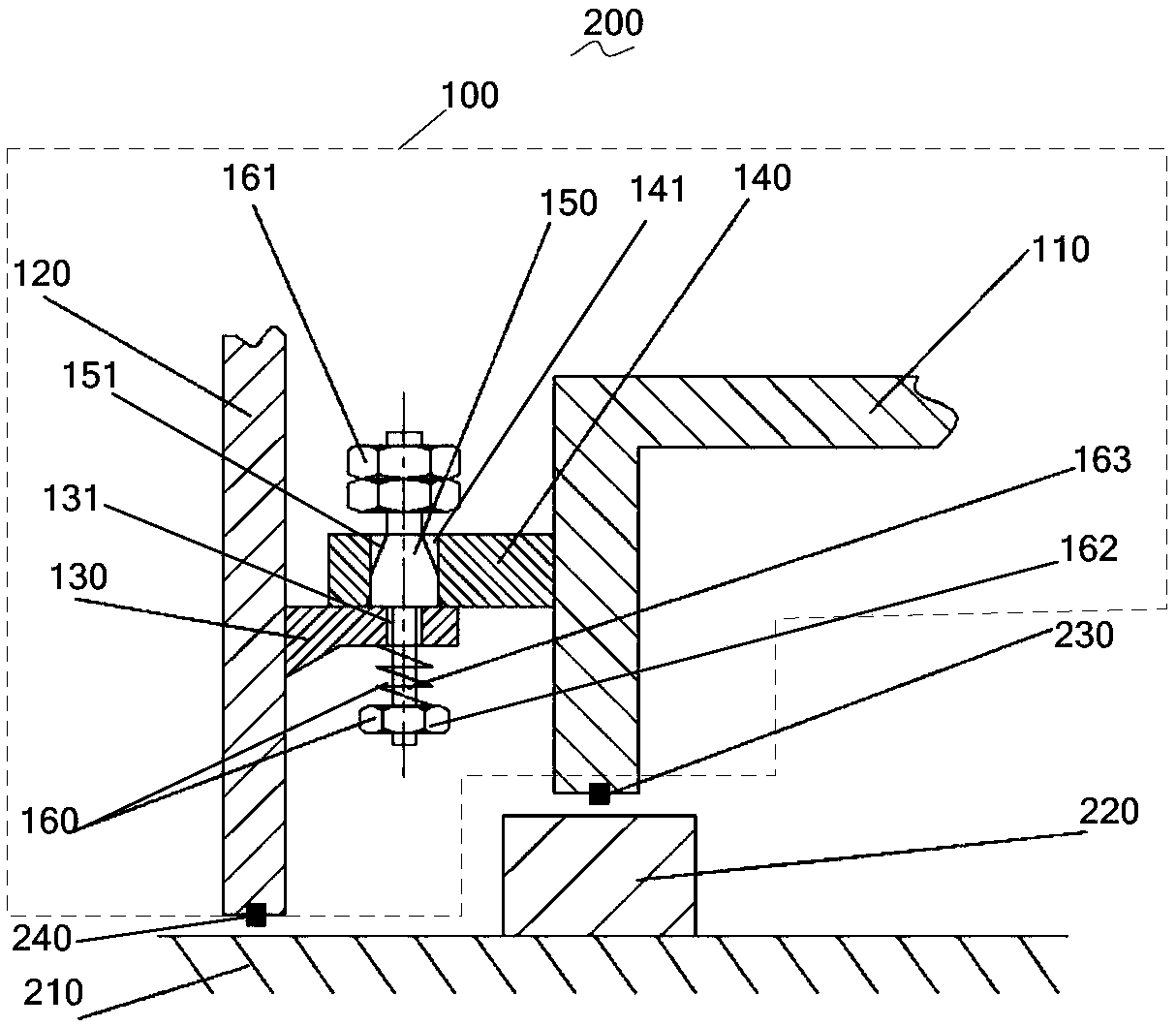

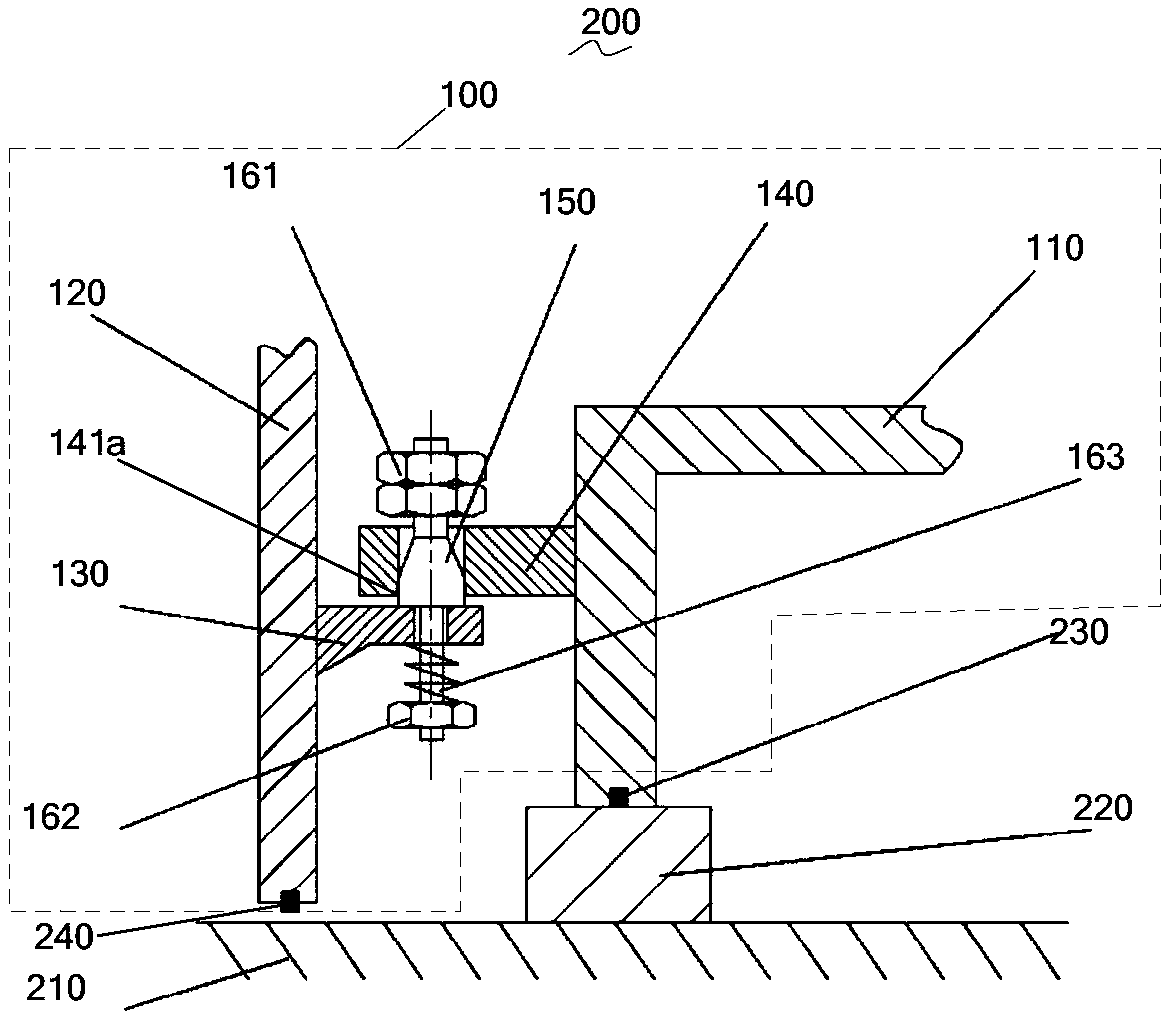

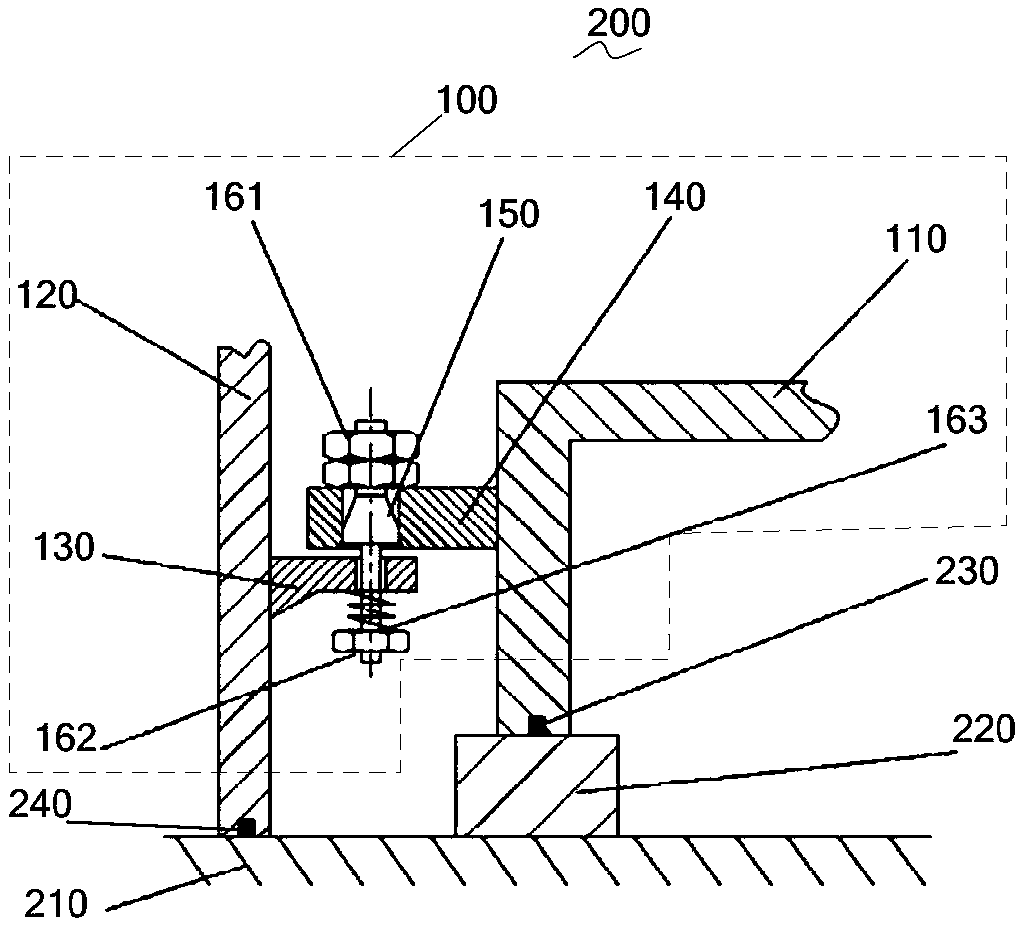

[0062] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0063] Such as Figure 1 to Figure 3 As shown, the first aspect of the present invention relates to a resonant cavity structure 100 , the resonant cavity structure 100 includes a resonant cavity body 110 , a protective shell 120 , a first support 130 , a second support 140 and a positioning member 150 . Wherein, the protective casing 120 is disposed outside the resonant cavity 110 . The first supporting member 130 is fixedly connected to the inner wall of the protective housing 120 . The second support 140 is fixedly connected to the outer wall of the resonant cavity 110, the second support 140 is located above the first support 130, and can overlap with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com