Valve assembly for compressor

A valve assembly and compressor technology, applied in the directions of engine components, control valves, valve devices, etc., can solve the problems that the discharge valves 43 cannot contact each other and the discharge valves 43 cannot operate stably, and achieve the effect of noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

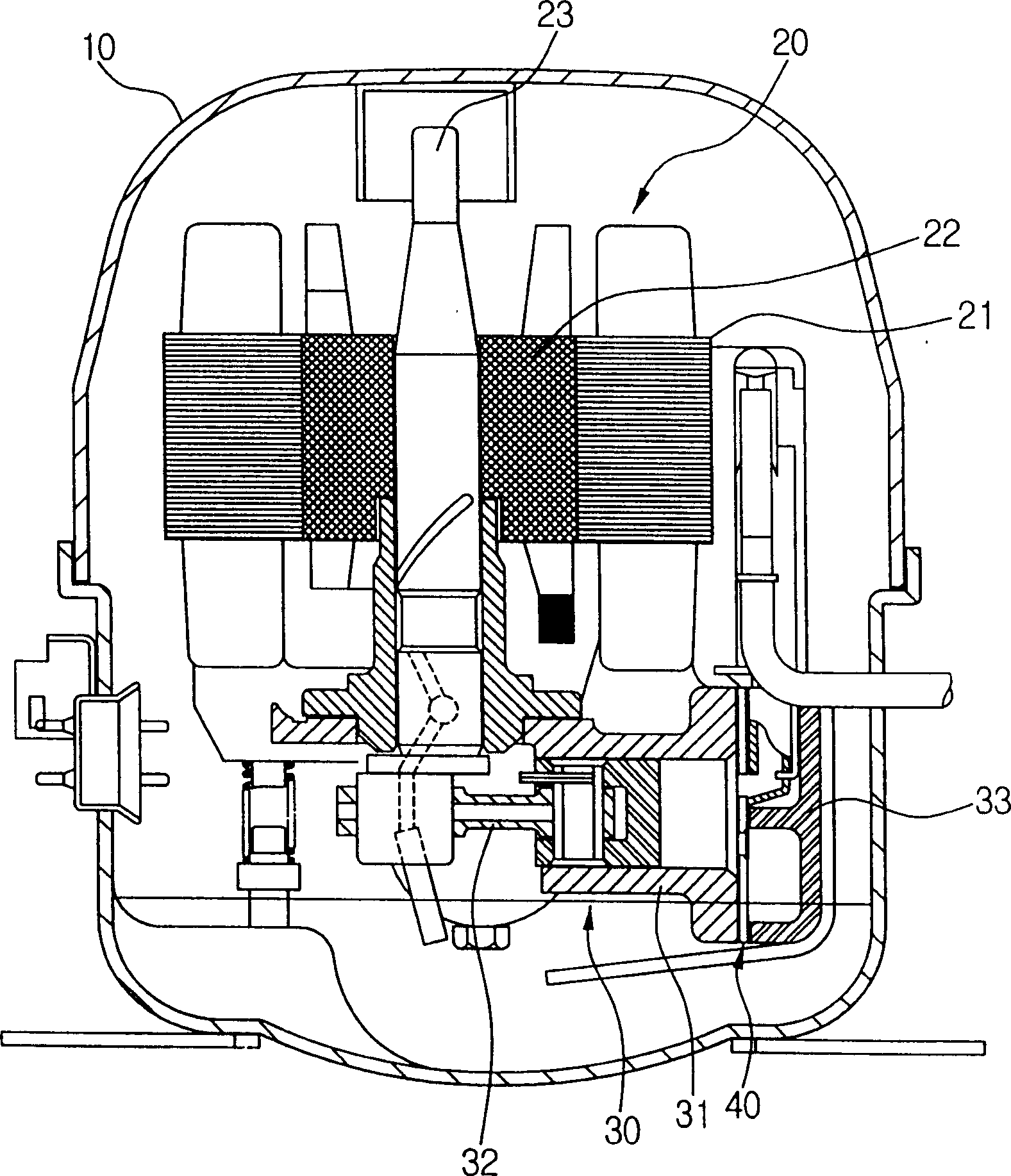

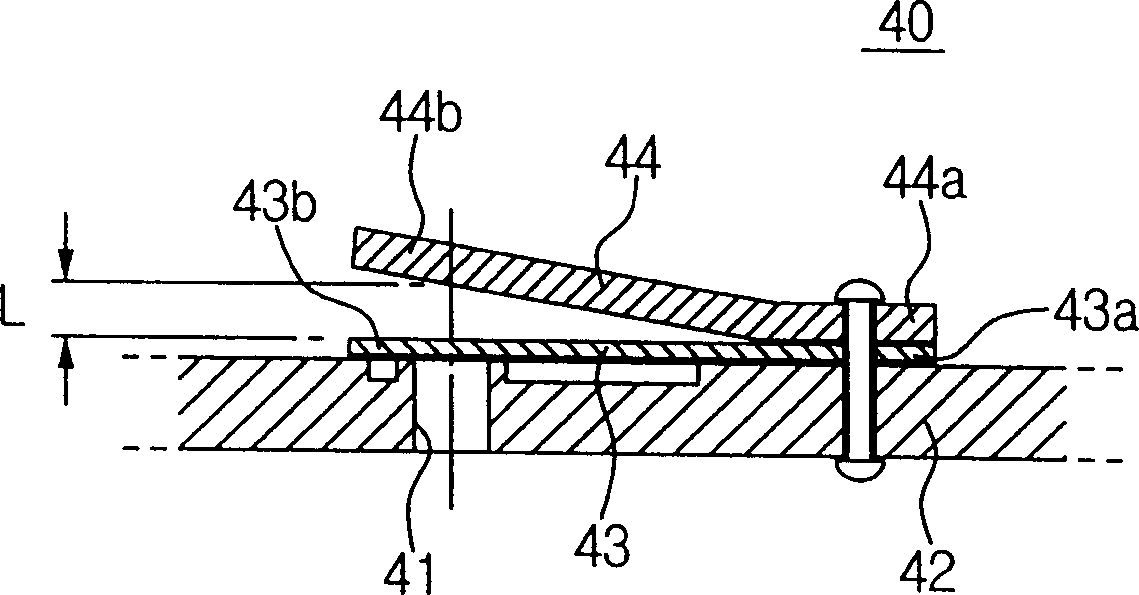

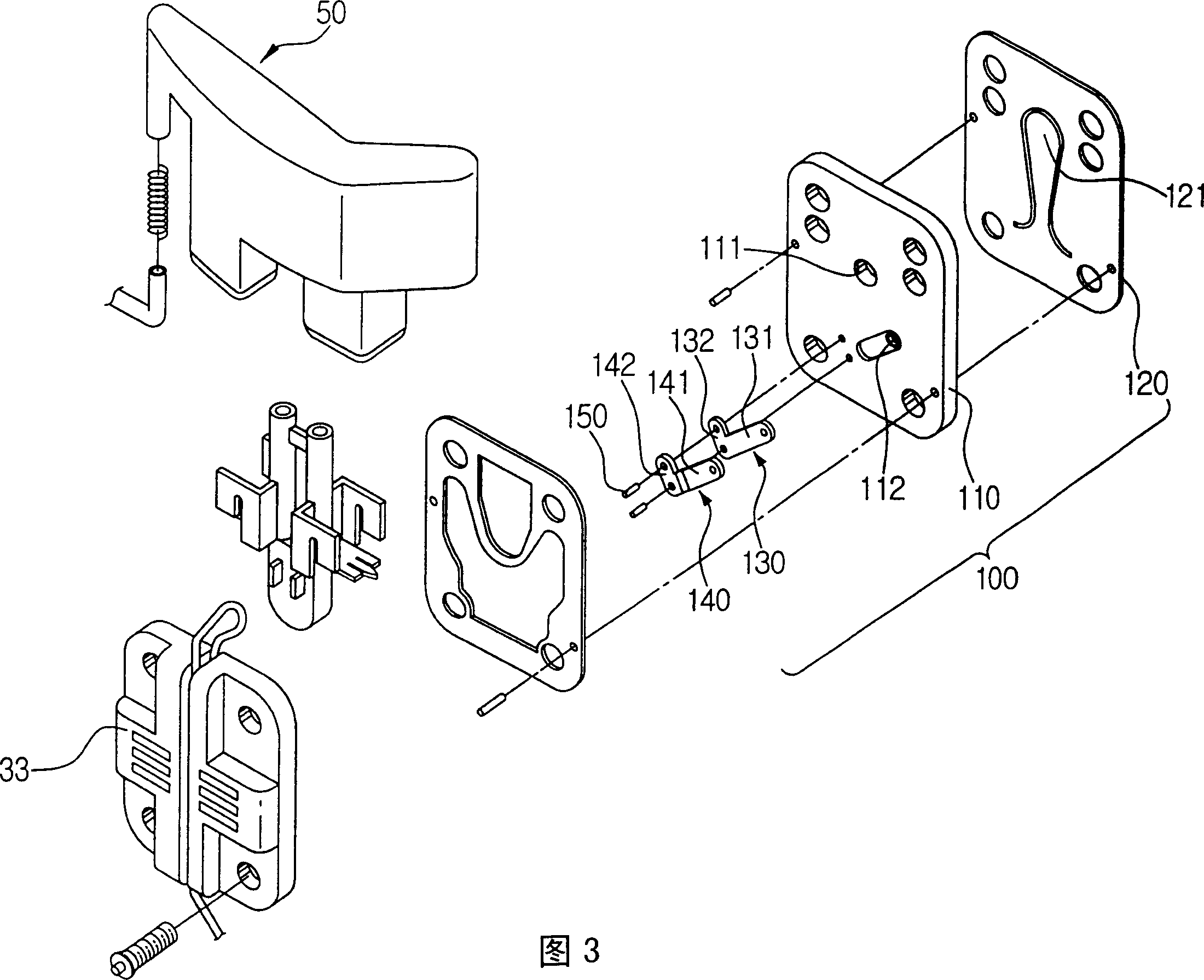

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the same reference numerals denote the same parts as those of the conventional compressor, and corresponding descriptions are omitted.

[0023] As shown in Figure 3, the valve assembly 100 of the present invention includes a valve plate 110 having a refrigerant suction hole 11 and a refrigerant discharge hole 112, and a suction valve plate 120 with a suction valve 121, which is arranged on the valve plate 110 and the cylinder (refer to figure 1 31) is used to open or close the refrigerant suction hole 111, the discharge valve 130 located between the valve plate 110 and the cylinder head 33 is used to open or close the refrigerant discharge hole 112, and is arranged on the discharge valve The retaining plate 140 on the upper part of 130 is used to control the opening range of the discharge valve 130 .

[0024] The discharge valve 130 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com