Hingle structure

A hinge part and structure technology, which is applied in building structure, door/window fittings, hinge plates, etc., can solve the problems of wear and poor durability of the support part and the holding part, achieve improved durability and smoothness, and improve durability performance, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

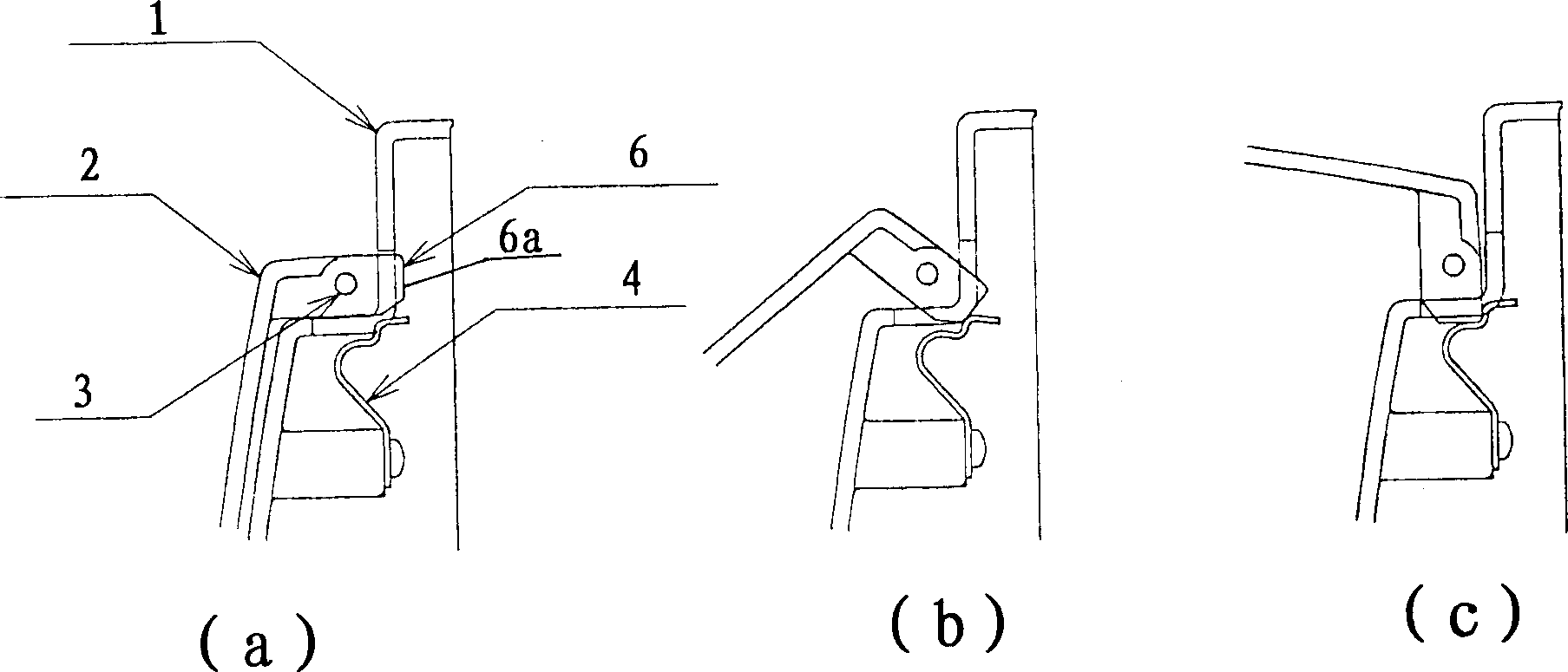

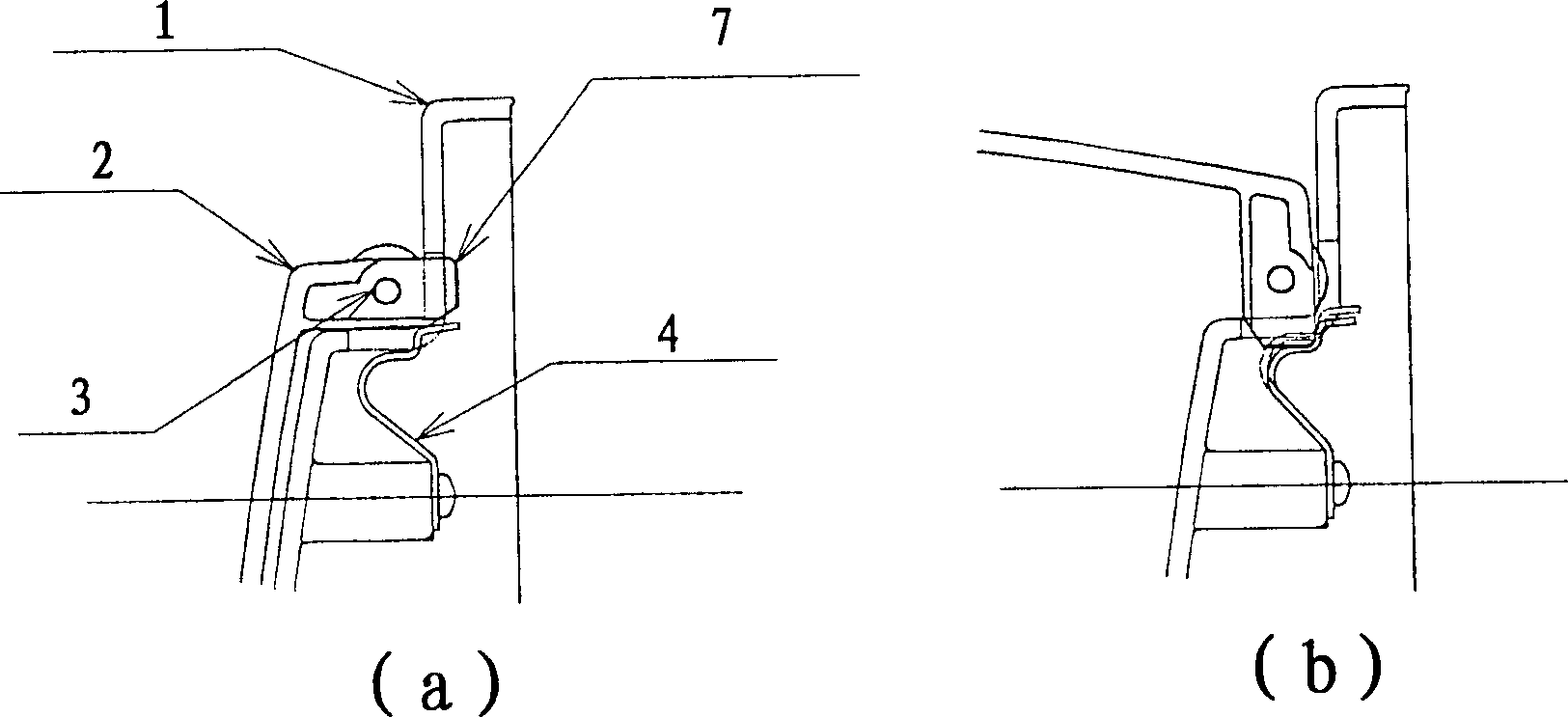

[0015] Refer below Figure 1-Figure 3 An example of the hinge structure of the present invention will be described. in Figure 1-Figure 3 Here, the same parts are given the same symbols, and repeated descriptions are omitted.

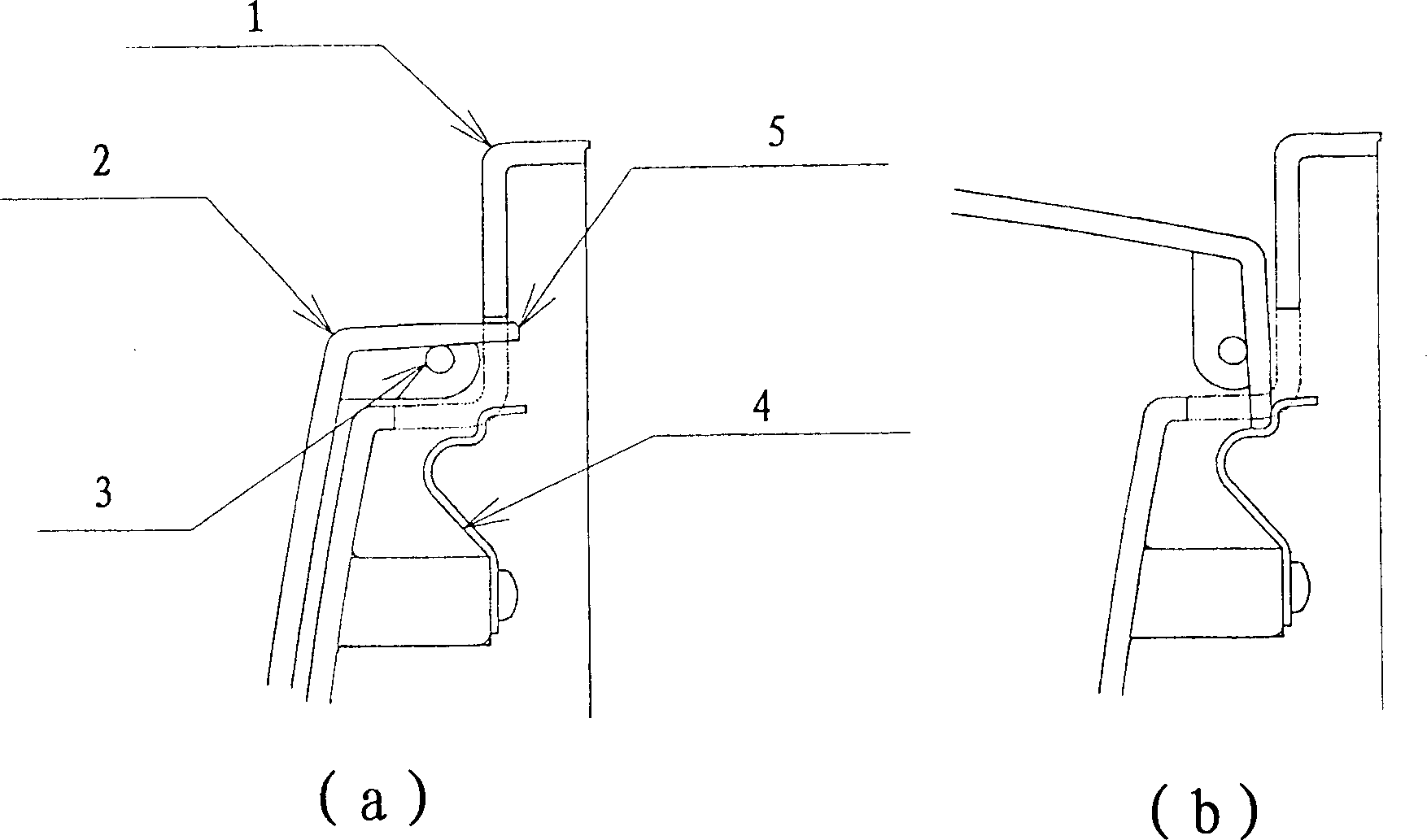

[0016] figure 1 It is a cross-sectional view showing the first embodiment of the hinge structure of the present invention. figure 1 (a) shows the state when the door is closed, figure 1 (b) shows the state when the door is opened.

[0017] The structure of the hinge part of the first embodiment of the present invention is as follows figure 1 As shown, the door 2 and the cover 1 are provided with a shaft 3, and the door 2 is rotated around the shaft 3 during opening and closing. When the door is opened, the support part 5 integrated with the door 2 passes over the holding part 4 provided in the cover, and the door is held. The materials of the cover 1, the door 2, and the support part 5 are all resin. The holding portion 4 is composed of a metal leaf spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com