Crane and control method for crane

A control method and crane technology, which can be applied to cranes, trolley cranes, load hanging components, etc., can solve problems such as difficulty in measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Next, the crane and the control method of the crane according to the embodiments of the present invention will be described with reference to the accompanying drawings.

[0070] First, the overall structure of a transfer crane to which the control method of the present invention is applied will be described.

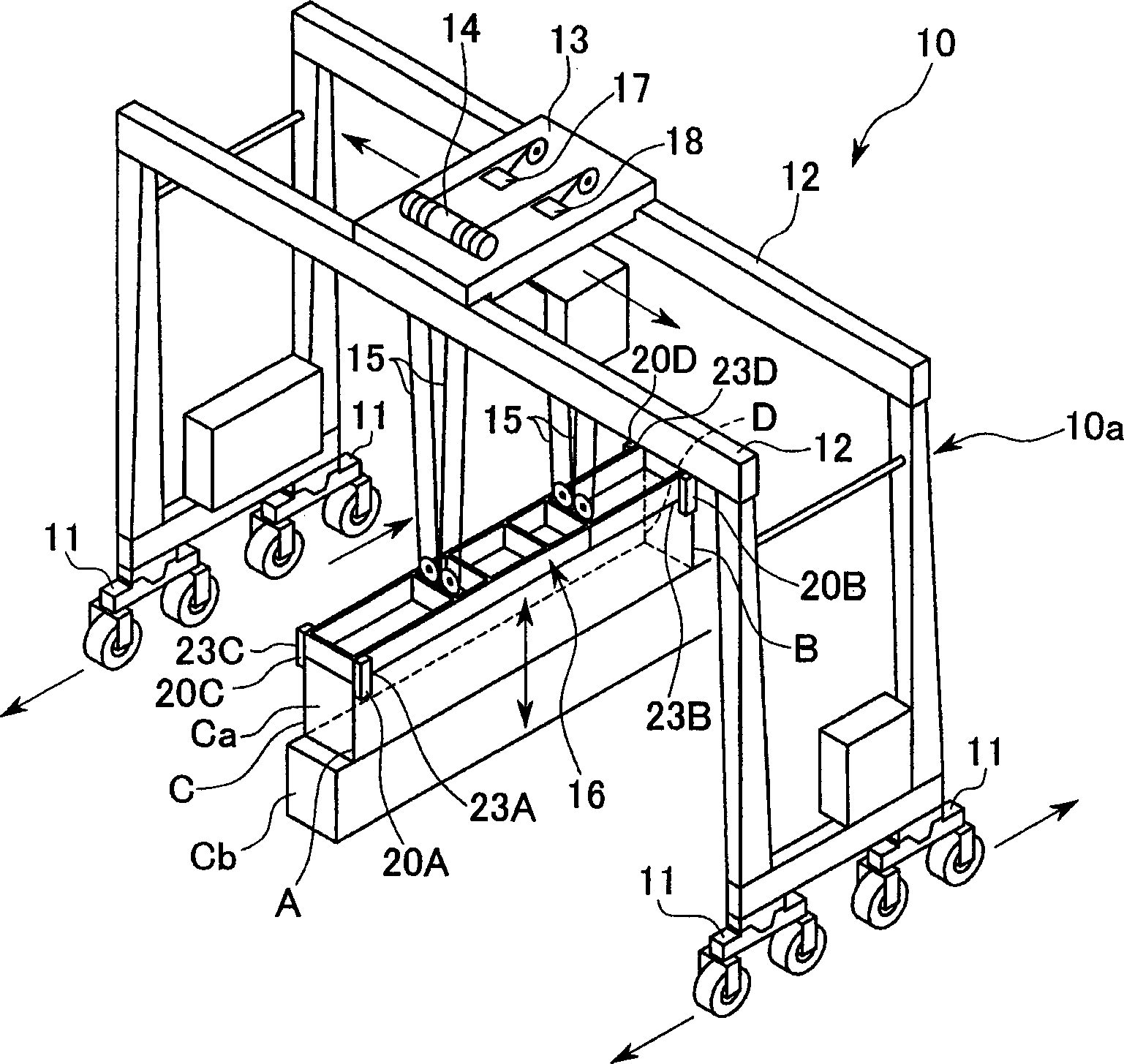

[0071] figure 1 Reference numeral 10 in the figure is a crane called a container handling crane (hereinafter referred to as a crane) that stacks a container Ca serving as a hoisted load on a target container Cb.

[0072] The crane 10 is a rubber-tyred bridge crane for stacking containers, and includes a traveling body 10 a of a gantry crane that travels on a trackless ground with a tire-type traveling device 11 . On the horizontal upper beam 12 of the crane traveling body 10a, a traverse block 13 that moves in the horizontal direction along the upper beam 12 is provided.

[0073] A winding device 14 is mounted on the traverse block 13, and the winding device 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com