Image quality tester of electronic display device

A technology for electronic displays and inspection devices, which can be used in measuring devices, televisions, instruments, etc., and can solve problems such as image quality inspection obstacles and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiment of the invention

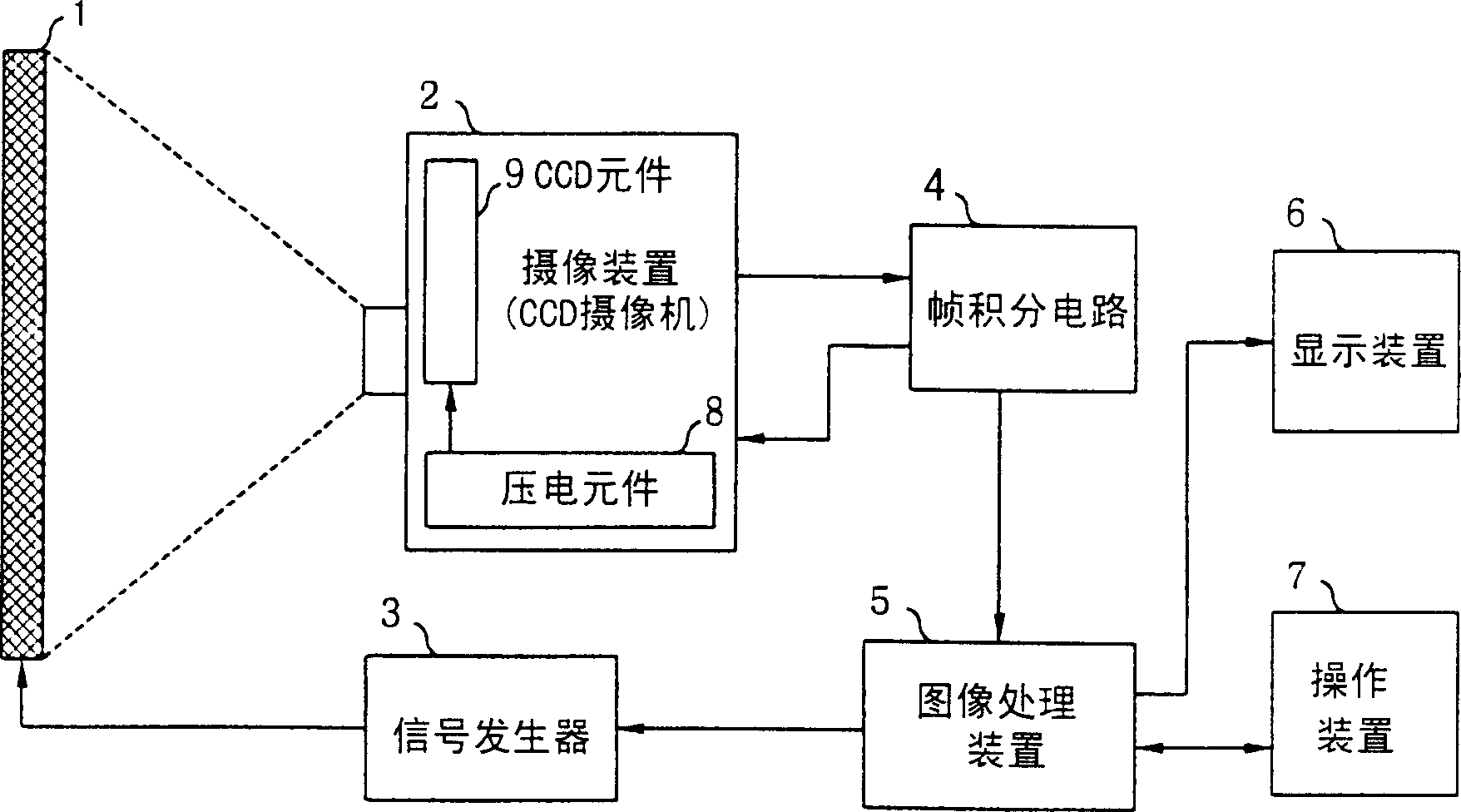

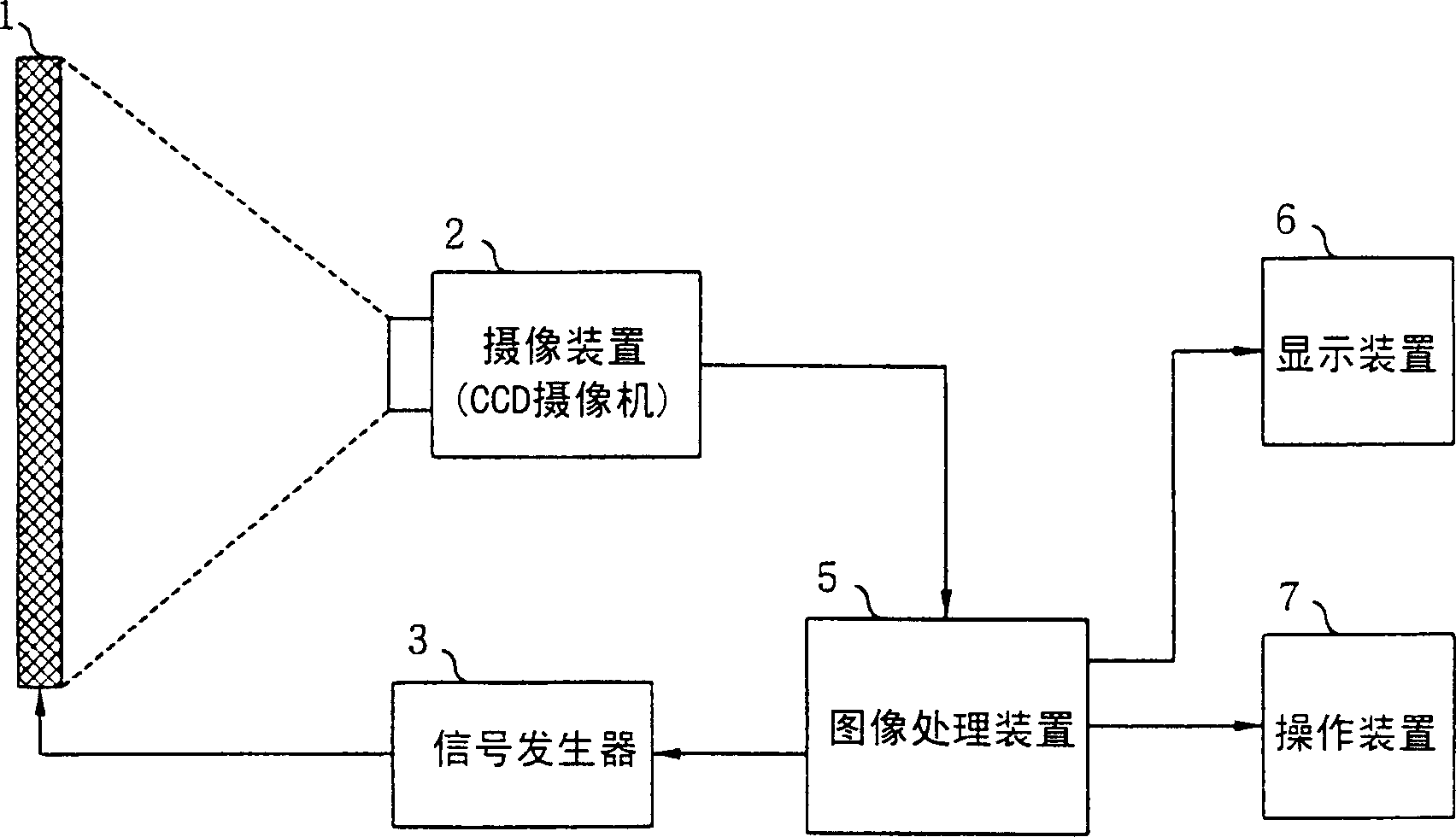

[0022] Below, refer to figure 1 An example in which the present invention is applied to a plasma display image quality inspection device will be described.

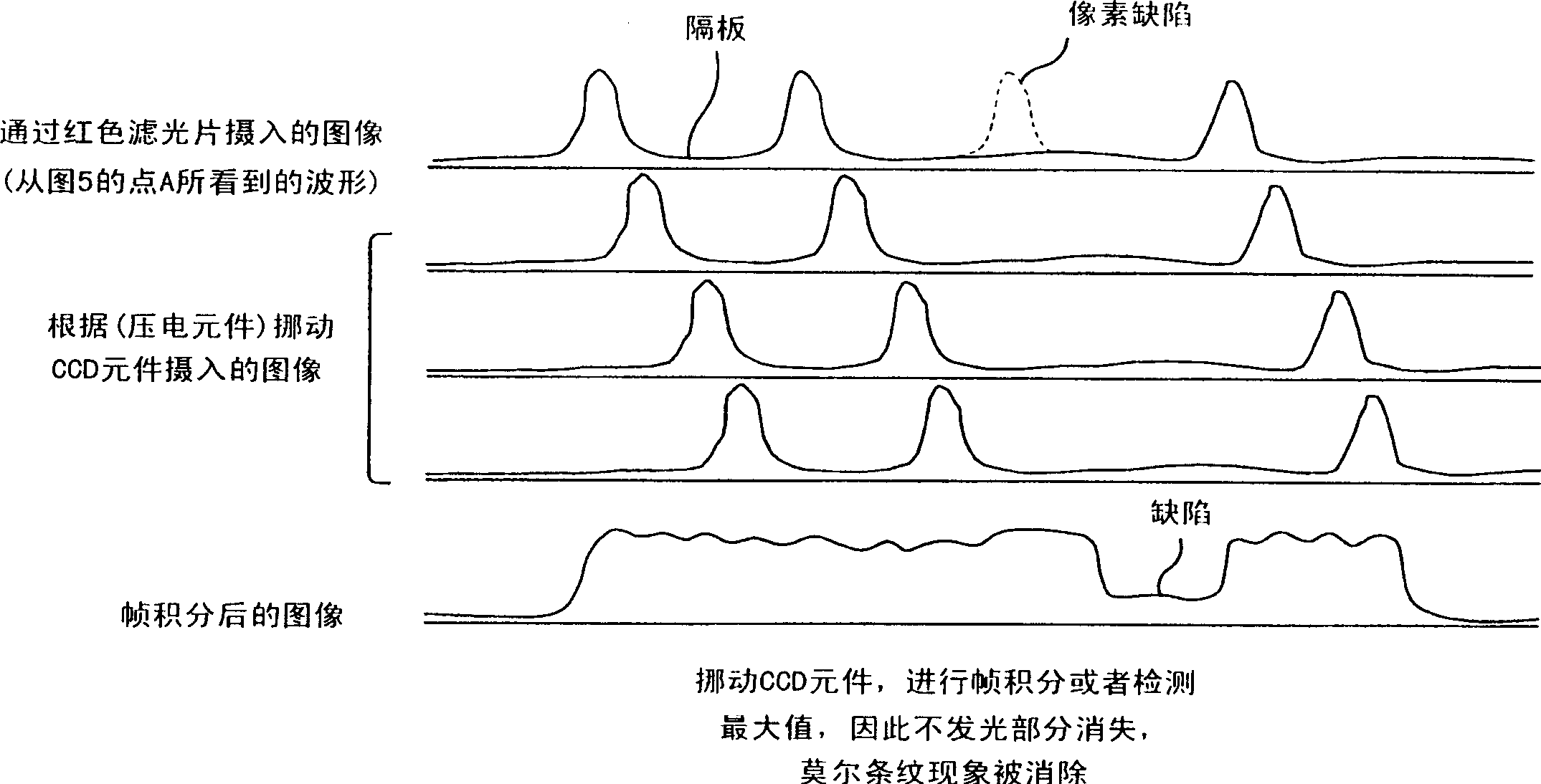

[0023] 1 is an electronic display device such as a plasma display, 2 is an imaging device such as a CCD camera, 3 is a signal generator for displaying images on a plasma display, and 4 is a frame integration circuit or a maximum value detection and holding circuit, for example, composed of a frame memory. If it is a frame integration circuit, each time a frame of image is read, the following action is repeated, that is, each pixel of the captured image and the image stored in the frame memory is integrated. If it is a maximum value detection and holding circuit, when each frame of image is read in, the following actions are repeated, that is, each pixel of the captured image is compared with the image stored in the frame memory, and then the higher-level In case it is updated to sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com