Fibre-optic grating two-D sensor

A two-dimensional sensor, fiber grating technology, applied in the field of sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

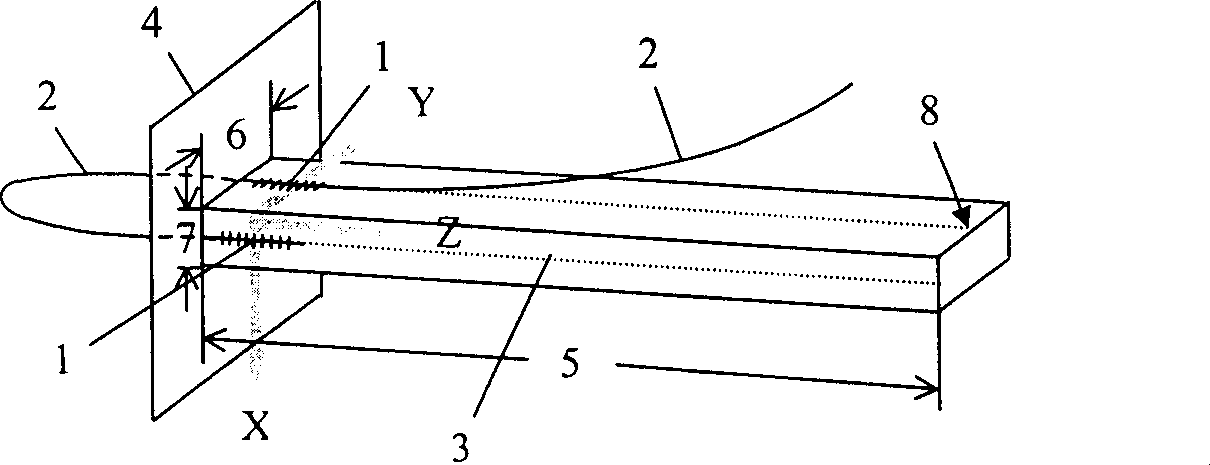

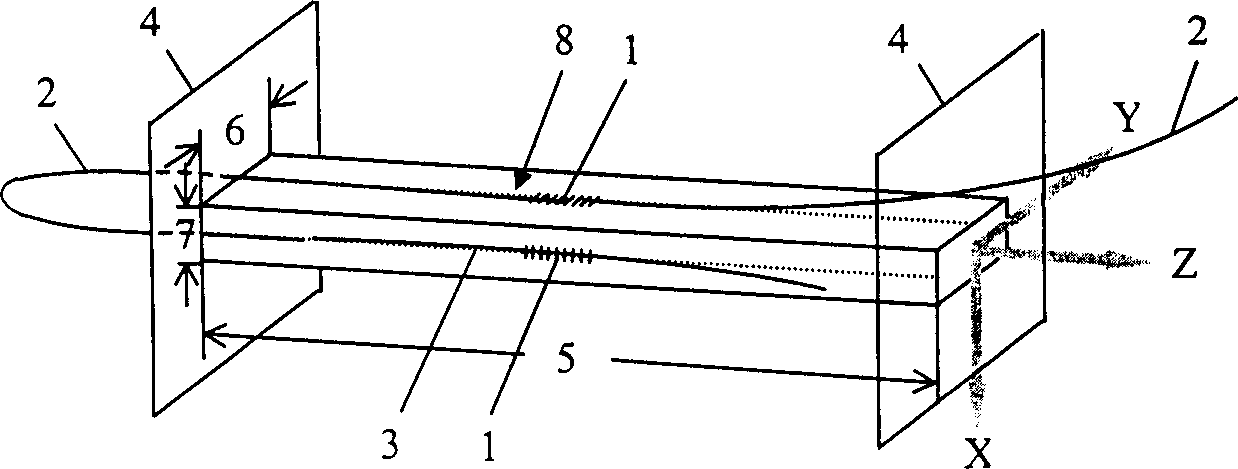

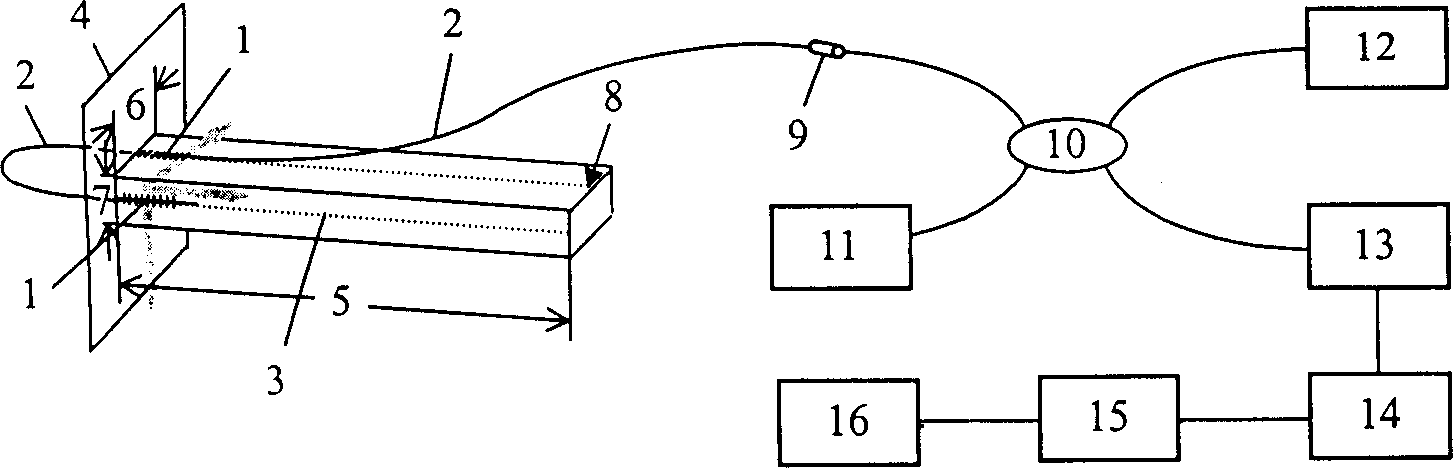

[0022] Basic structure of the present invention is as shown in accompanying drawing:

[0023] Fiber Bragg Grating 1, Optical Fiber 2, Rectangular Elastic Beam 3, Fixed End 4, Beam Length 5, Beam Width 6, Beam Thickness 7, Stress 8, Fiber Connector 9, Fiber Coupler 10, Matching Liquid 11, Light Source 12, Wavelength Tester 13, O / E circuit 14, data processor 15, display 16, sensing signal 17, signal digitization 18, data screening 19, logic judgment 20, sensing matrix calculation 21, data storage 22, data output 23.

[0024] In the specific implementation example of the present invention image 3 Among them, the sensor includes fiber Bragg grating 1, single-mode fiber 2, plexiglass rectangular beam 3, iron metal fixed end 4, heat shrinkable sleeve 9, 2×2 fiber coupler 10, matching liquid 11, broadband light source 12, F-P wavelength Tester 13, O / E circuit 14, data processor 15, display 16, etc. The two fiber gratings in the double grating string are respectively glued with 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com