Linear chirp optical fiber grating based two-dimensional stress sensor

A technology of stress sensor and optical fiber grating, which is applied in the direction of using optical device to transmit sensing components, fluid pressure measurement using optical method, instruments, etc., to achieve the effects of wide application, easy system integration, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

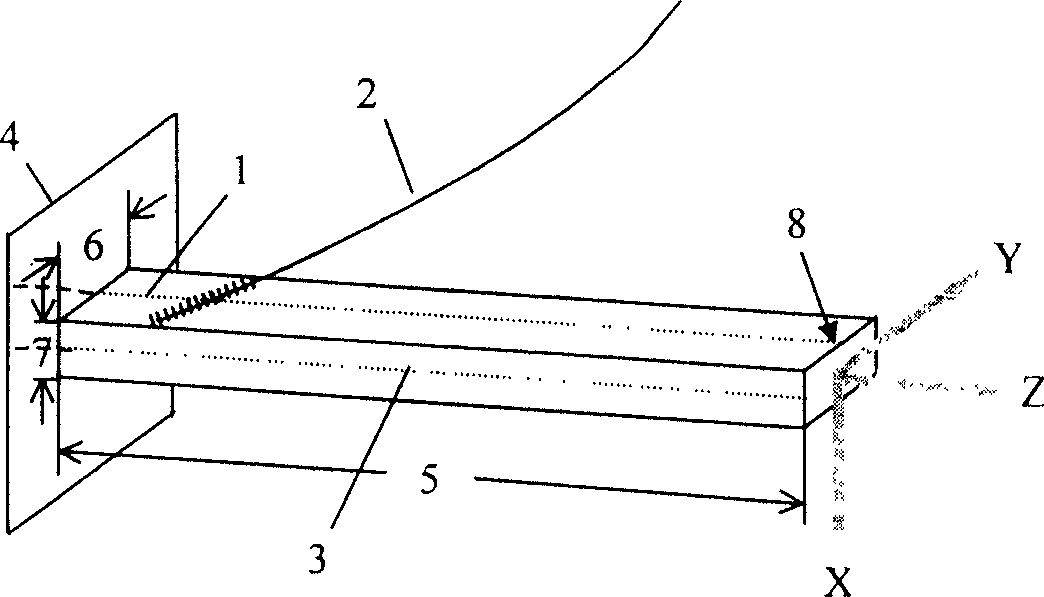

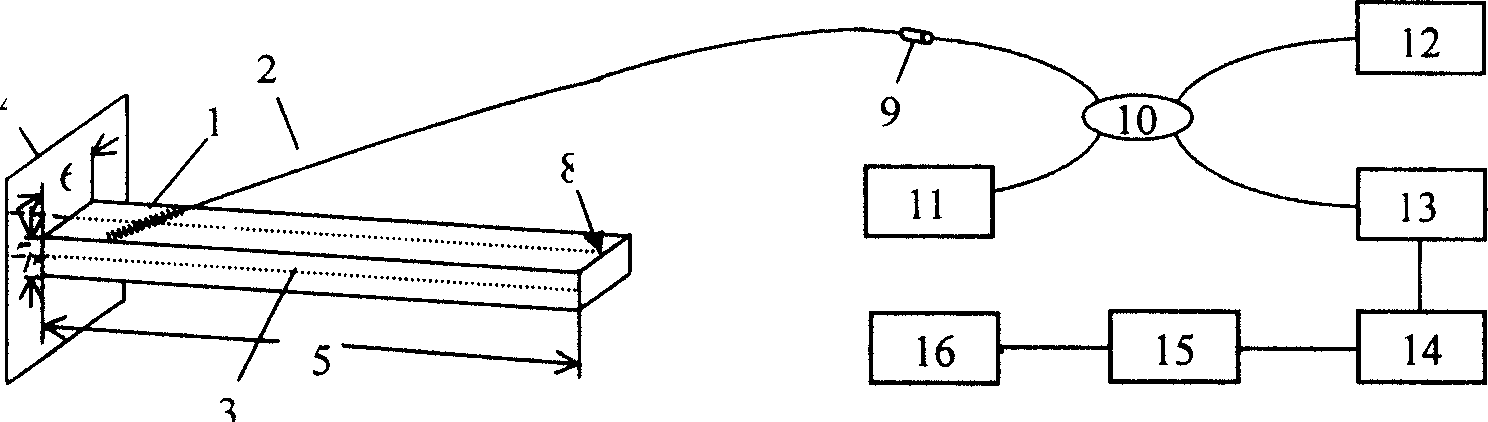

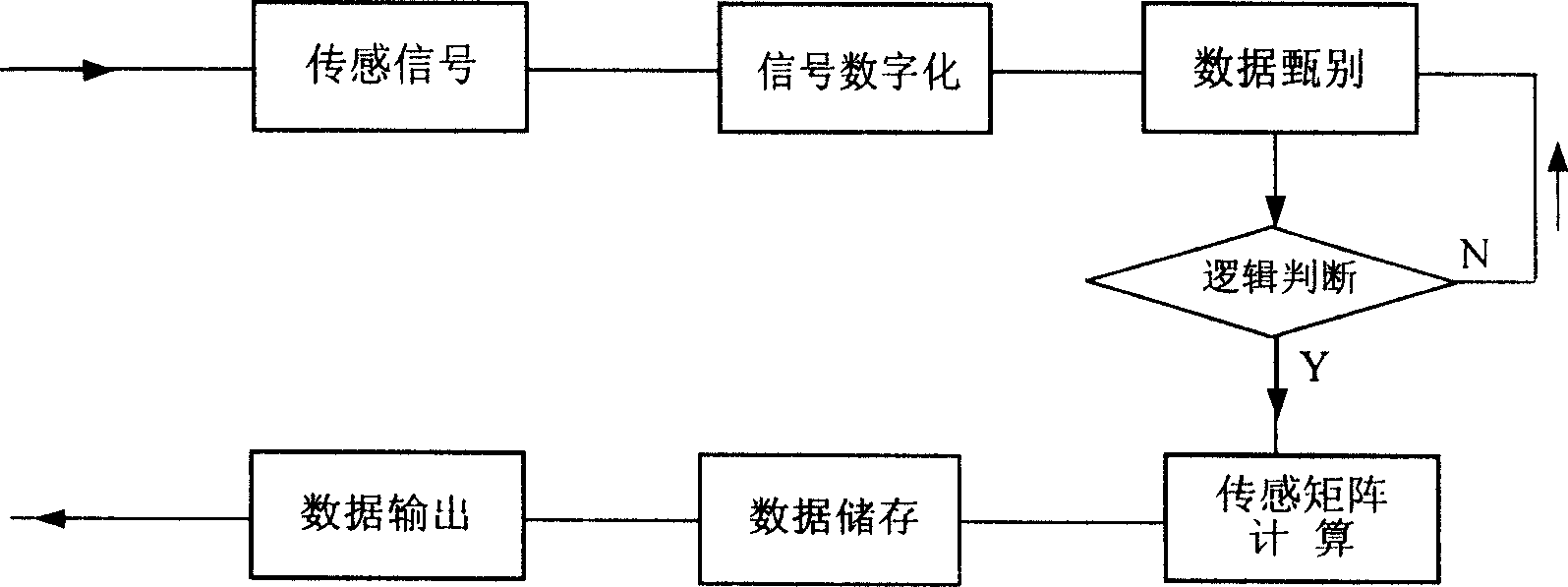

[0014] This two-dimensional stress sensor based on linear chirped fiber grating includes linear chirped fiber grating, optical fiber, cantilever beam, fixed end, optical fiber connector, optical fiber coupler, matching liquid, light source, wavelength tester, O / E A circuit, a data processor, and a display; it is characterized in that: the sensor fiber grating 1 is pasted on the surface of the cantilever beam 3 near the fixed end with an adhesive, so that the grating area is just all attached to the surface of the beam, and the grating is in contact with the surface. Line, that is, the intersection line between the neutral plane of the cantilever beam and the surface is at a certain angle;

[0015] There are two connection methods:

[0016] Reflective connection, that is, the two ports on one side of the fiber coupler 10, one end is connected to the pasted linear chirped fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com