Mosquito net elevator with clutch

A lifting mechanism and clutch technology, applied in the field of lifting mechanism, can solve the problems of wear, easy automatic fall of mosquito nets, loss of function, etc., and achieve the effects of reducing manufacturing cost, shortening operation time, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

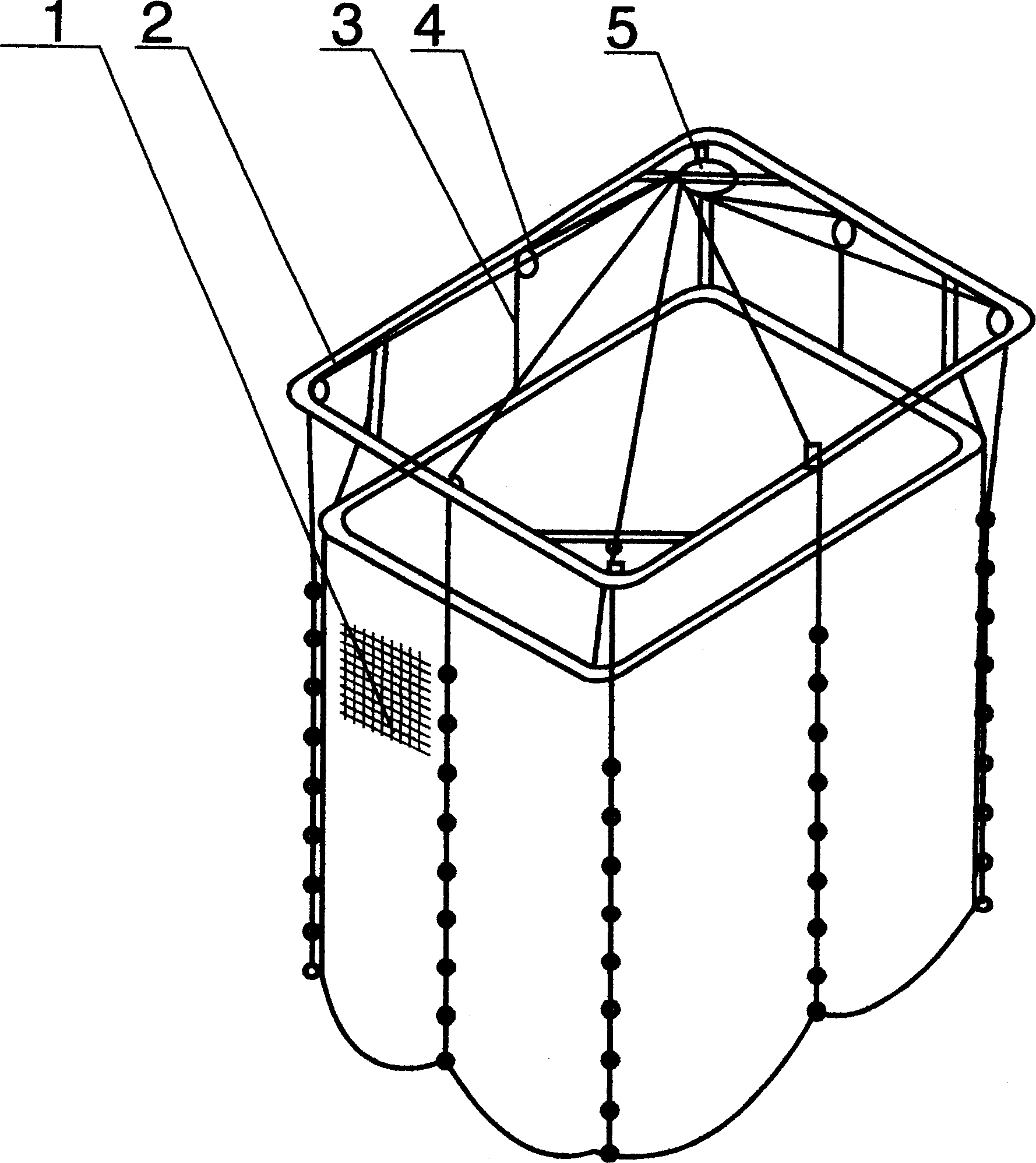

[0039] figure 1 Among them, the lifting mosquito net is mainly composed of a tent body 1, a bracket 2, a lifting rope 3, a pulley 4, and a rope wheel 5. The pulley 4 is installed on the bracket 2 above each traction point of the tent body 1, and any position in the bracket 2 Noose wheel 5 is housed, and the rim of noose wheel 5 should have groove, and the hole or the hook of connecting rope are arranged at the bottom of the groove, and one end of hoisting rope 3 is connected in the groove of noose wheel 5, and the other end is guided downwards with tent through pulley 4. 1 tow point connection.

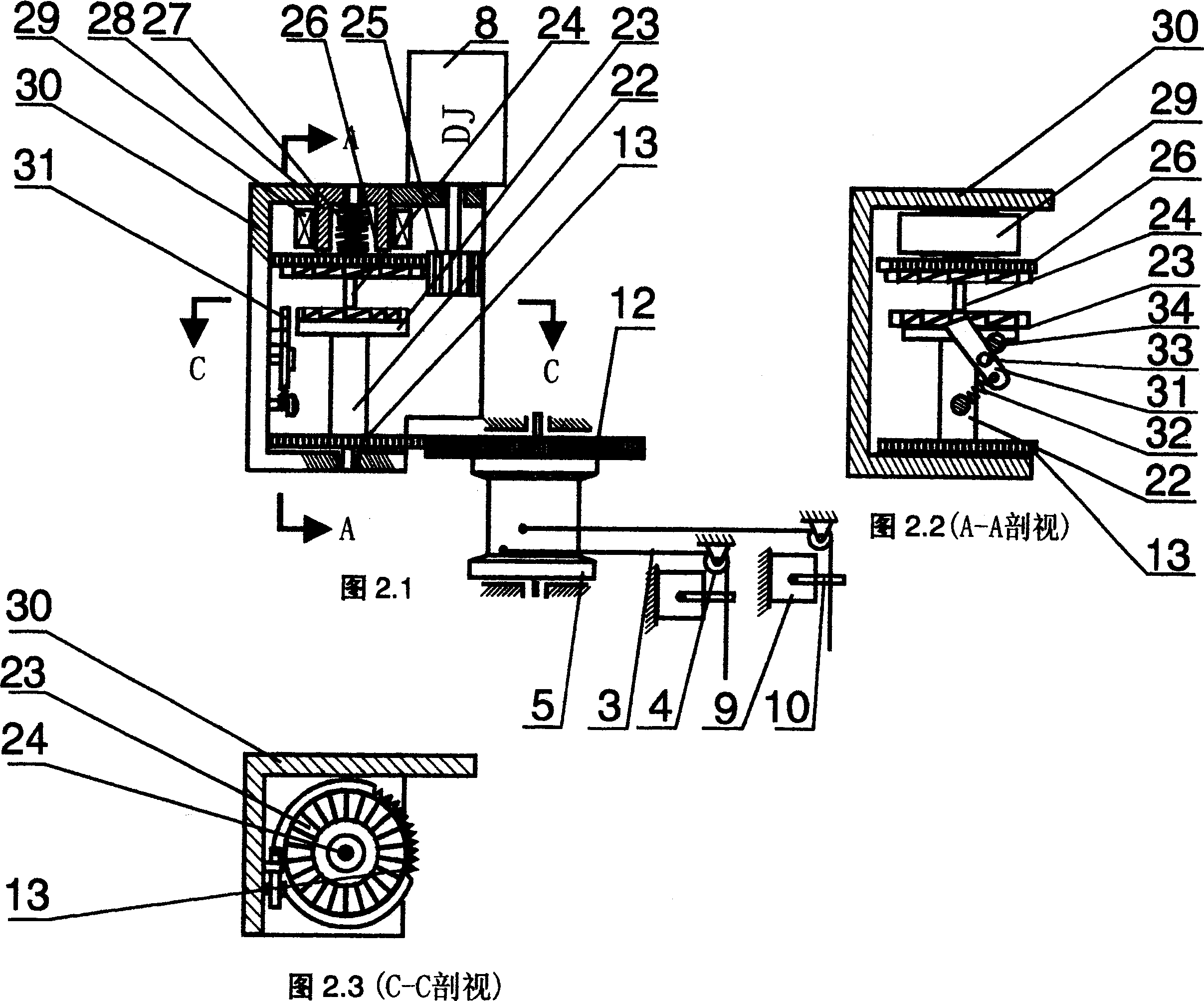

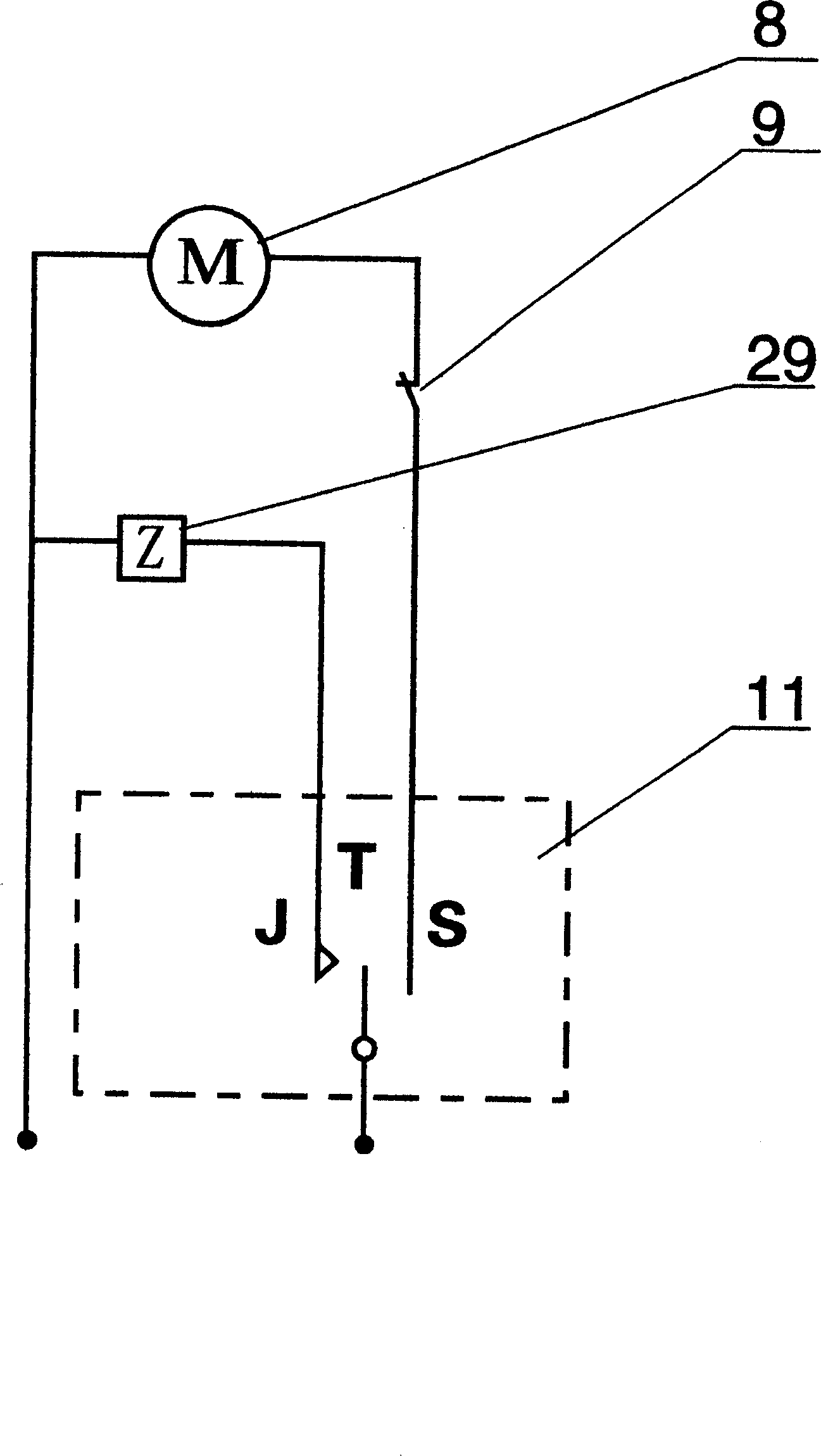

[0040] In Figure 2.1, Figure 2.2, and Figure 2.3, the main parts of the lifting mechanism include lifting rope 3, pulley 4, rope wheel 5, motor 8, travel switch 9, contact 10 of travel switch 9, driven gear 12, output gear 13. Transmission shaft 22, center shaft 24, gear 25, clutch and braking device. The components that make up the clutch include the driven toothed plate 23, the dri...

Embodiment 2

[0044] Figure 4 Among them, the parts that make up the lifting mechanism include the central shaft 24 and the driven toothed disc 23, the driving toothed disc 26, the advancing and retreating screw 39, and the screw propelling spring 40 that are mounted in series on the central shaft 24 in sequence. The housing 30 has a septum, and the septum There is a screw hole 42 cooperating with the advancing and retreating screw rod 39, and there are braking teeth 31, return spring 32, hinge pin 33, and limit pin 34; And can rotate on the central axis 24, the driving toothed disc 26 is coaxially connected with the advance and retreat screw rod 39 and can rotate on the central axis 24 and move along the central axis 24, and the side of the driven toothed disc 23 facing the driving toothed disc 26 has An annular tooth surface, one side of the tooth surface is steep and the other side is a gentle slope; the side of the driving tooth plate 26 facing the driven tooth plate 23 has an annular ...

Embodiment 3

[0048] Such as Figure 9 As shown, the mosquito net lifting mechanism includes tractors 50a equal to the number of necessary traction points of the tent body 1, and each tractor 50a is respectively installed above each traction point of the tent body 1, and each tractor 50a includes a motor 8, A set of clutches, a cable pulley 5, and a hoisting rope 3 are connected according to Fig. 5.1, Fig. 5.2, and Fig. 5.3.

[0049] In order to ensure the braking effect and the smooth driving of the driving chainring 26 and to reduce the wear of the braking teeth 31 and the driving toothing 26, the clutch of this embodiment is Figure 4On the basis of the shown clutch, an intermediate toothed plate 44 and a separation spring 43 are added between the driven toothed plate 23 and the driving toothed plate 26 to obtain the clutches shown in Figure 5.1, Figure 5.2, and Figure 5.3. Figure 5.1 shows that the clutch is in the separation state. The schematic diagram of the state, Figure 5.2 is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com