Actuator assembly for motor-cycle

A motorization and bicycle technology, applied to bicycle accessories, bicycle gear transmission mechanisms, vehicle components, etc., can solve problems such as motor overload, drive train damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

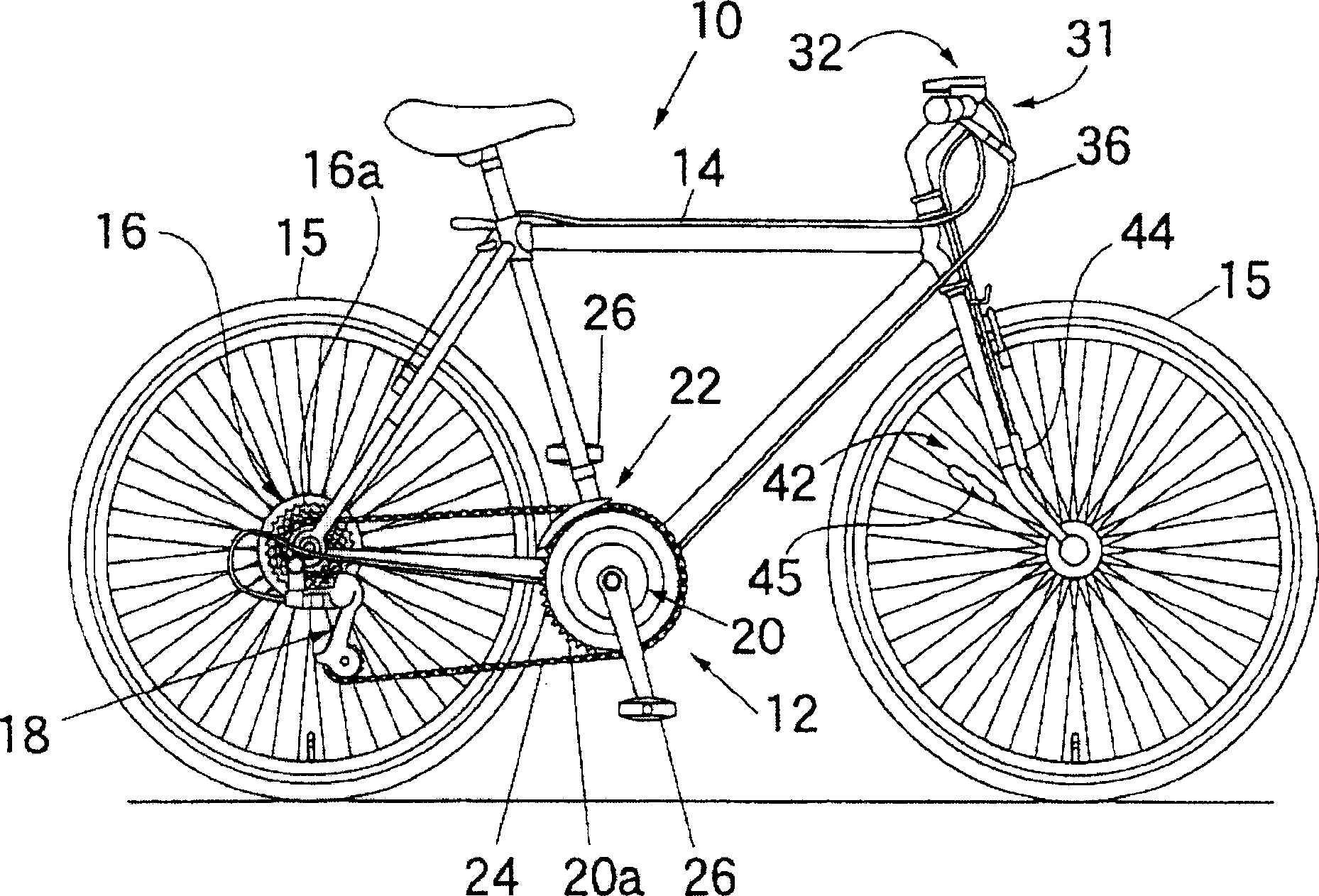

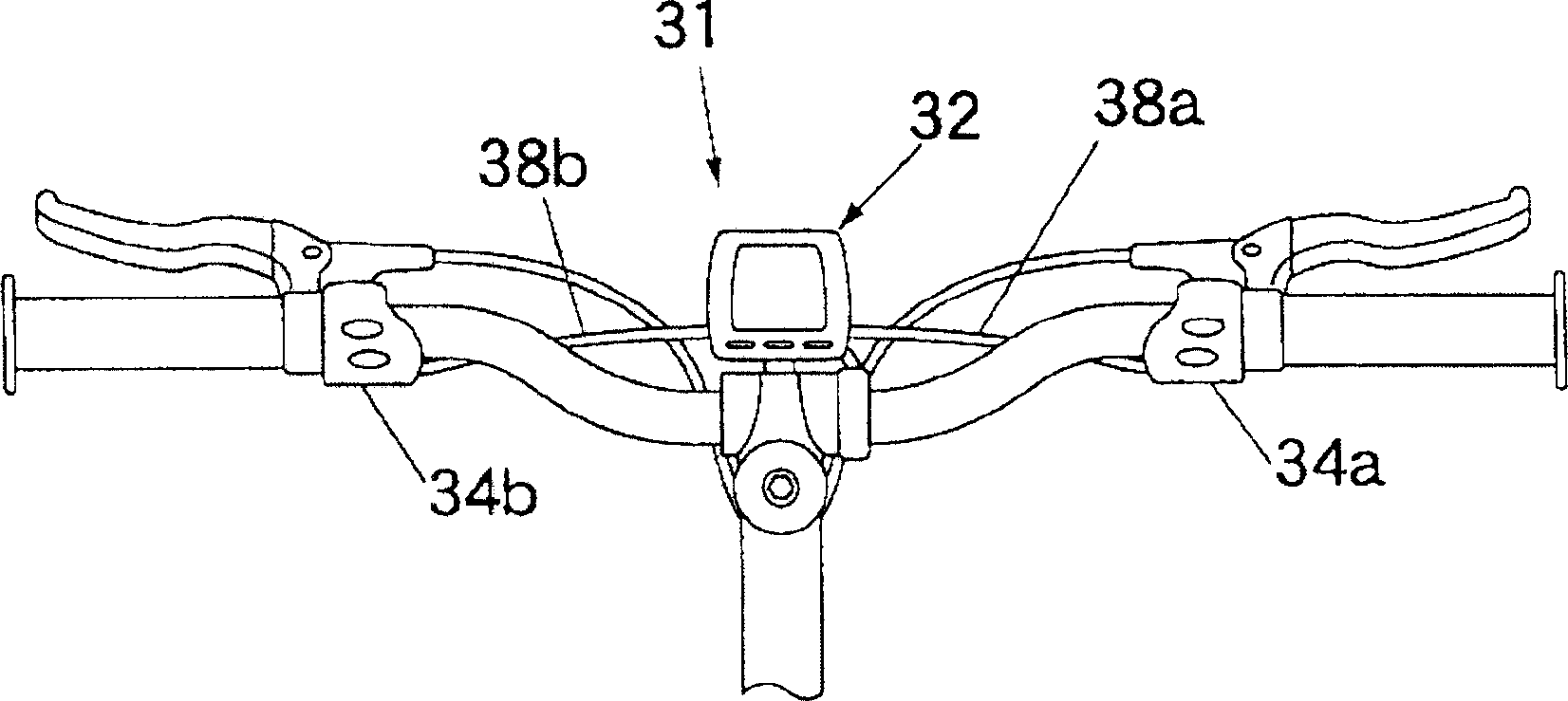

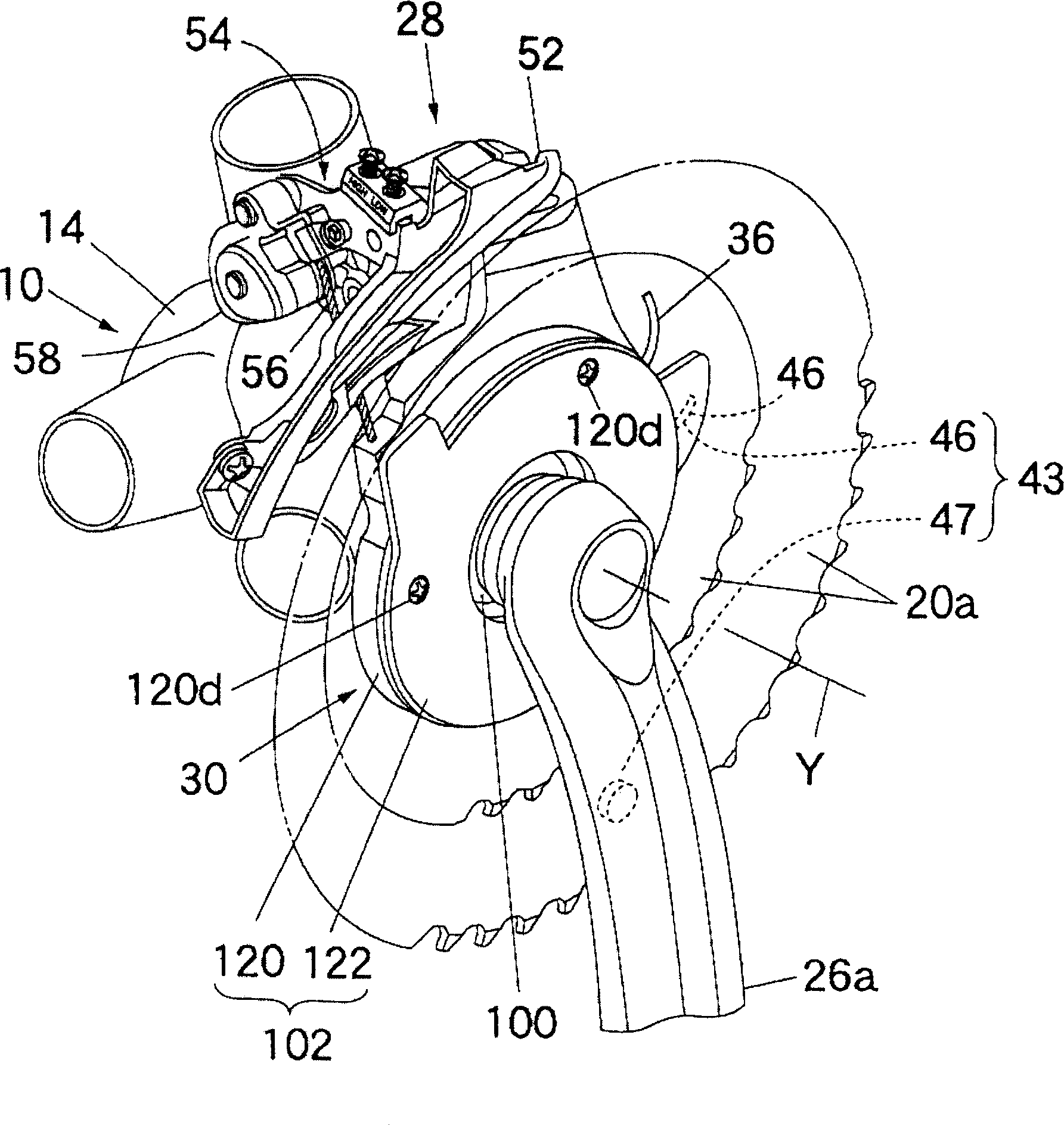

[0051] start reference Figure 1-3 , the illustrated bicycle 10 has an electronically controlled drive train 12 in accordance with a first embodiment of the present invention, as discussed below. The bicycle 10 basically has a frame 14 and a pair of wheels 15 , the rear wheels being driven by a drive train 12 . The bicycle 10 and its various elements are well known in the prior art, except for the improvements of the drive train 12 of the present invention. Therefore, the bicycle 10 and its various elements will not be discussed or illustrated in detail here, other than those associated with the drive train 12 of the present invention. Also, various conventional bicycle components that will not be detailed and / or discussed herein, such as brakes, auxiliary sprockets, etc., may be used with the present invention.

[0052] As used herein, the terms "forward, rearward, upward, above, downward, below and laterally" refer to those directions of the bicycle in its normal riding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com