Fixture for heat insulating layer of outer wall

A technology of insulation layer and fixing parts, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of easy aging of plastics, cracking of adhesives, cracking of rock wool boards of thermal insulation materials, etc., to achieve excellent durability, reduce maintenance costs, Excellent fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

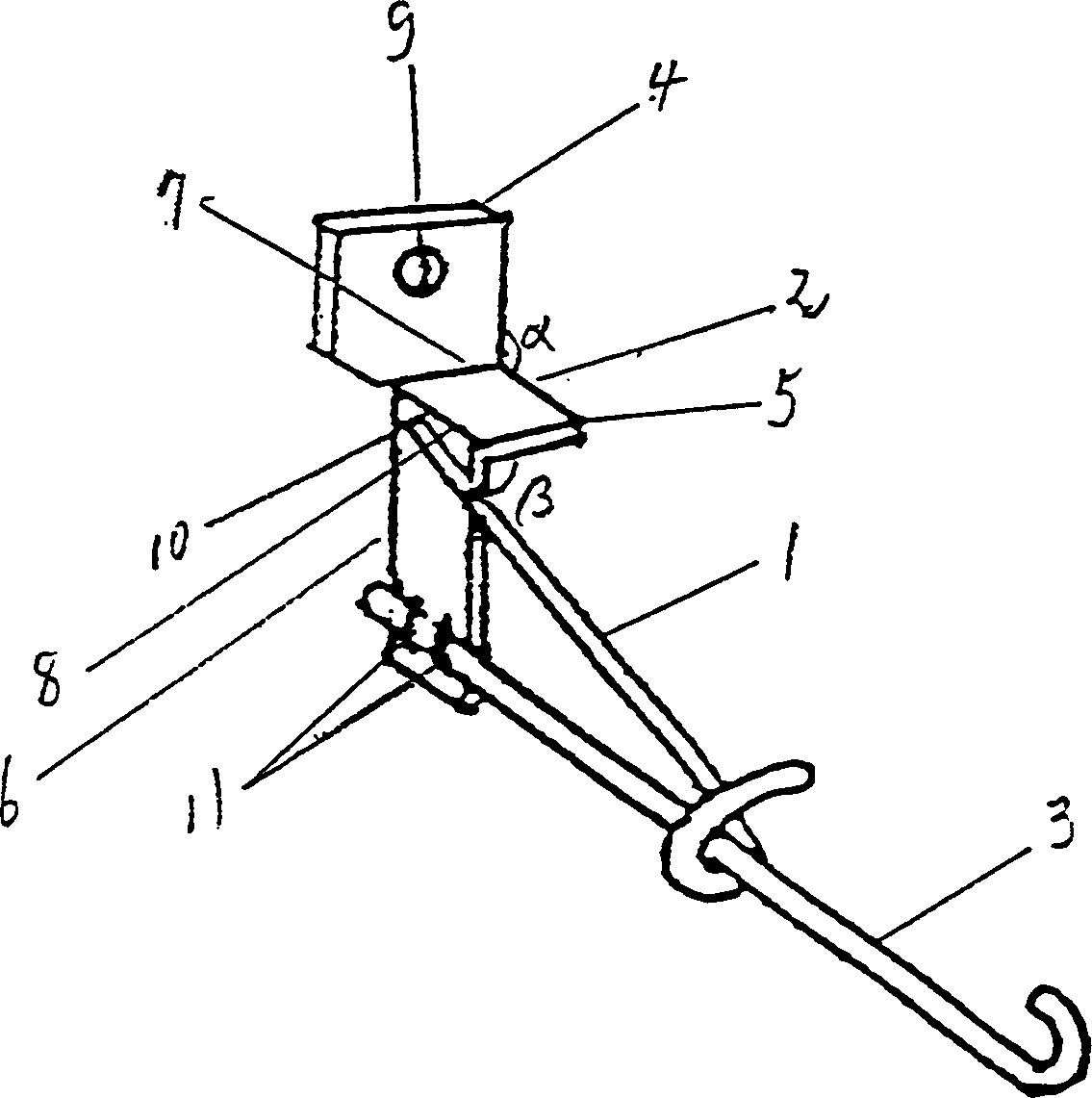

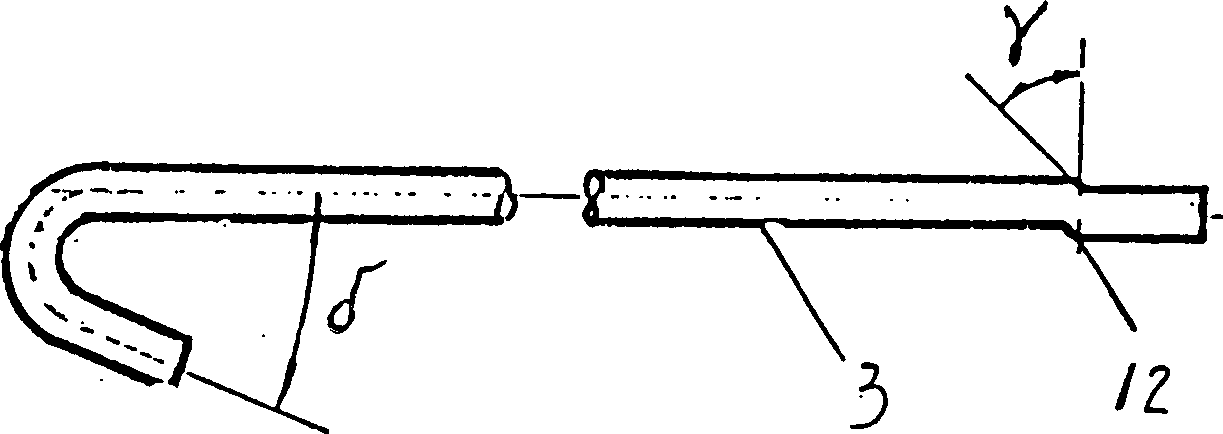

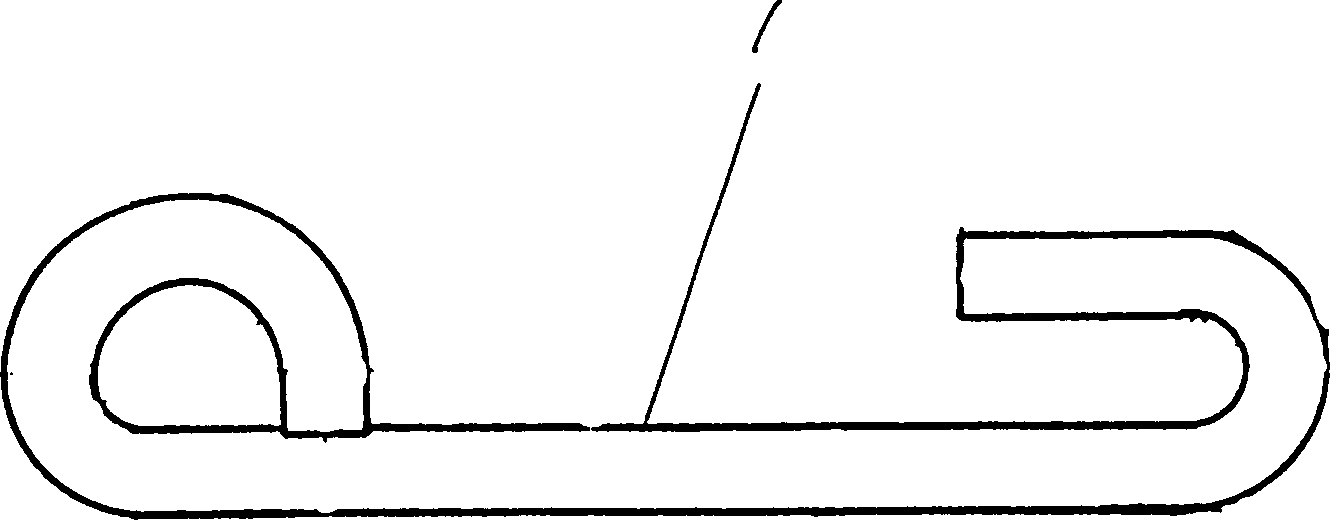

[0023] The outer wall insulation layer fixture of the present embodiment is made up of pendulum hook 1, bracket 2, pin bar 3, and bracket 2 is made up of upper panel 4, horizontal panel 5, lower panel 6. The upper panel 4 is above the horizontal panel 5 and is vertically integrated with an end edge 7 of the horizontal panel 5. The angle α between the upper panel 4 and the horizontal panel is 90°, and the lower panel 6 is connected to the horizontal panel below the horizontal panel. The other end edge 8 of the horizontal panel intersected by one end edge 7 of the horizontal panel 5 is vertically connected into one, the angle β formed between the horizontal panel 5 and the lower panel 6 is 90°, the upper panel 4 of the bracket 2, the horizontal Panel 5 and lower panel 6 are all made of galvanized steel sheet with a thickness of 1 mm. A circular hole 9 is arranged on the upper panel 4 top, and the diameter Φ of the circular hole 9 is 7 millimeters, and a circular hole 10 is also ...

Embodiment 2

[0025] The structure of the fixture is basically the same as that of Embodiment 1, except that the upper panel 4 is substantially vertically integrated with an end edge 7 of the horizontal panel 5 on the horizontal panel 5, and the included angle α is 85°. Under the horizontal plane 5, the lower panel 6 intersects with the other end edge 8 of the horizontal panel 5 which is intersected with the one end edge 7 of the horizontal panel 5. The other end edge 8 of the horizontal panel is roughly vertically connected into one body, and the plane angle β85° is formed between the horizontal panel 5 and the lower panel 6, and the pin bar 3 The hole passing through the closed ring at the other end of the swing hook 1 is connected to the swing hook 1, the angle δ formed by the U-shaped hook of the pin rod is 19°, and the bending angle r is 42°.

Embodiment 3

[0027] The structure of the fixing part is basically the same as that of Embodiment 1, except that the included angle α is 95°, the included angle β is 95°, the angle δ formed by the U-shaped hook of the pin rod 3 is 24°, and the bending angle r is 47°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com