Blocking and explosion-proof underground oil storage tank capable of washing and maintenance

A technology for oil storage tanks and cleaning holes, which is applied in the direction of transportation and packaging, containers, packaging, etc., and can solve problems such as difficult tasks and difficult workloads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

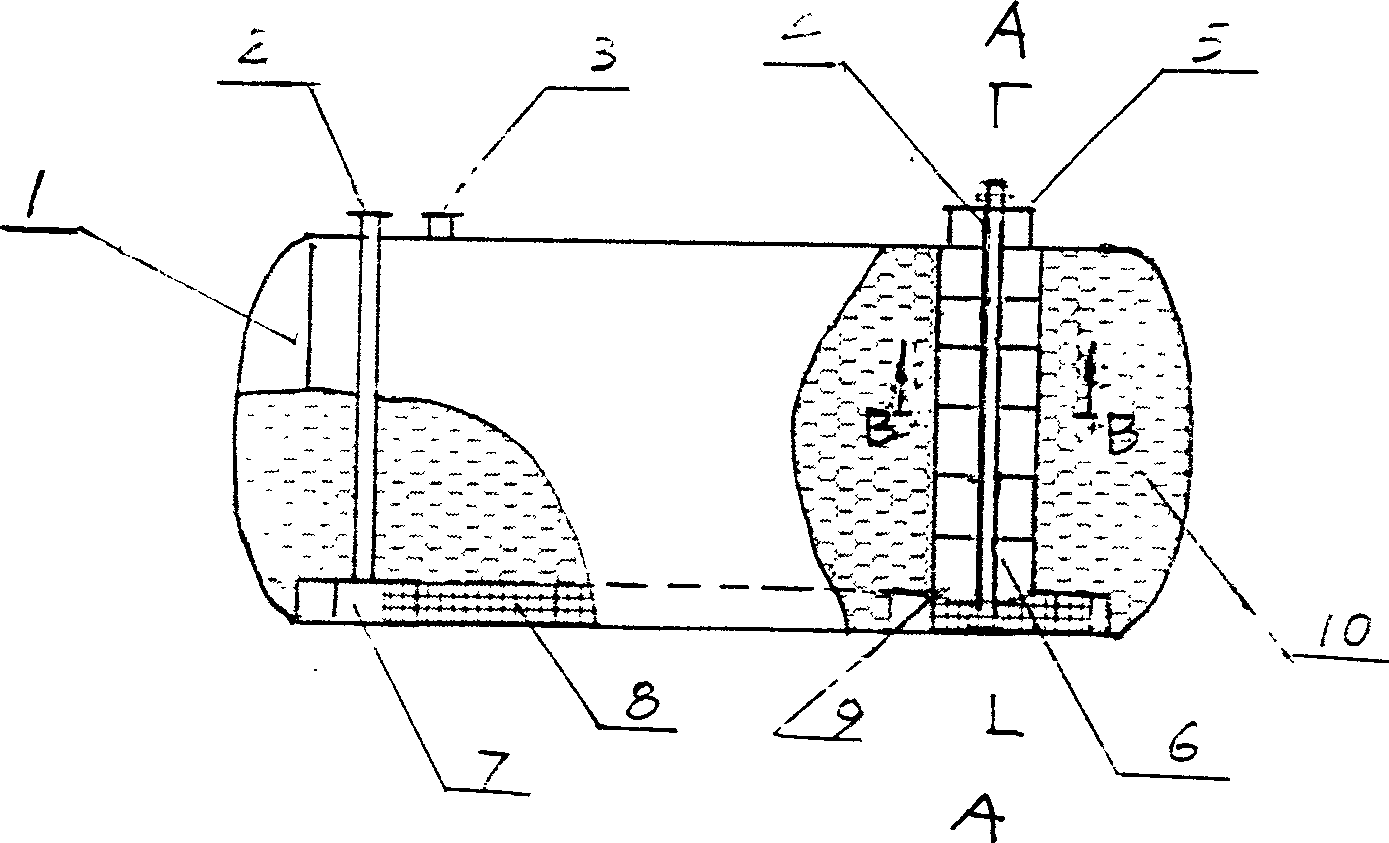

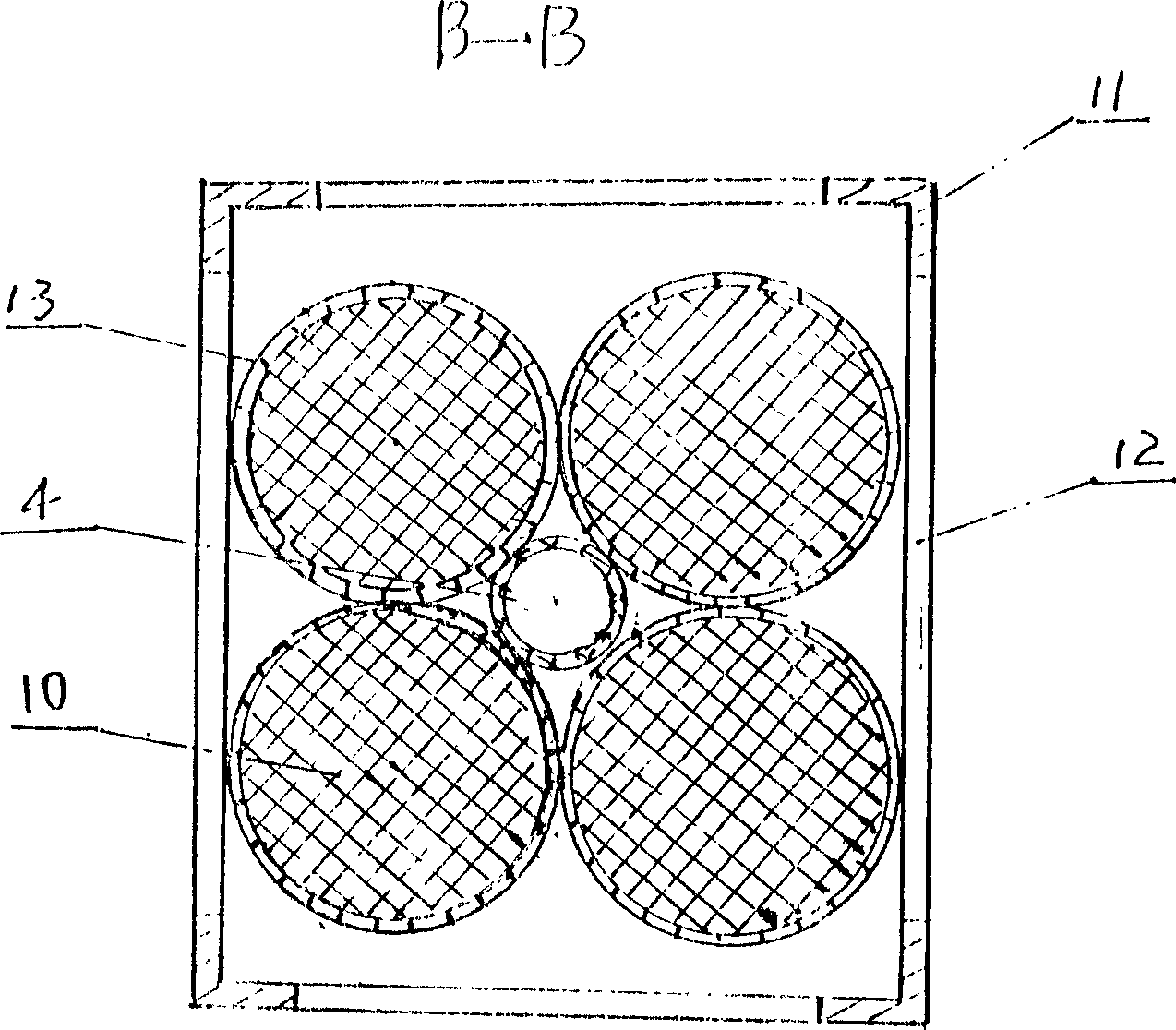

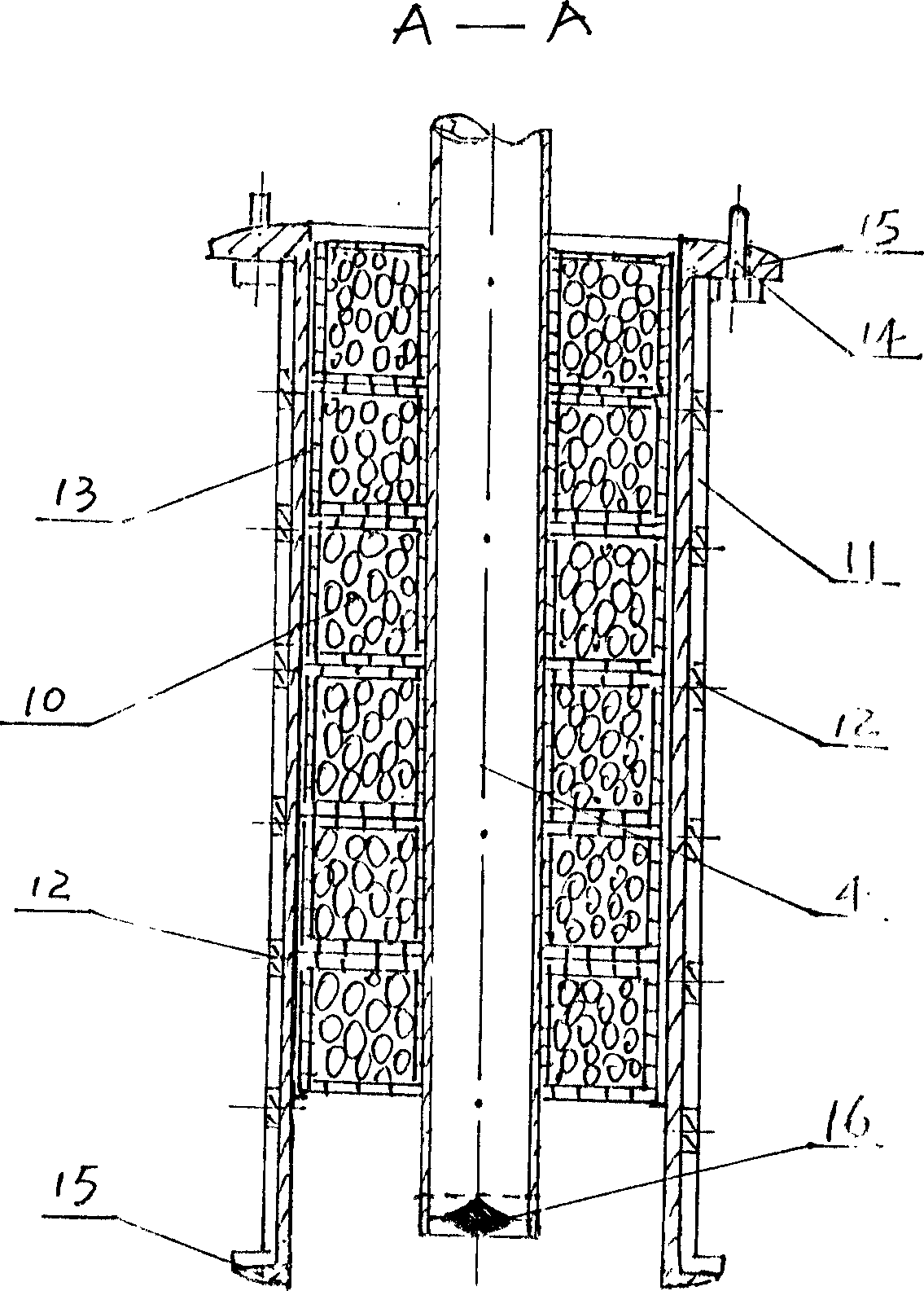

[0015] A barrier and explosion-proof underground oil storage tank that can be cleaned and maintained. It has a measuring pipe 2, an oil inlet pipe 3, an oil outlet pipe, a check valve or an oil immersion pump 4, and a manhole cover 5. A barrier is installed in the oil storage tank 1. Explosion-proof material 10, the bottom of the tank is also provided with a semicircular cleaning tunnel 7 surrounded by metal mesh 8, and the two ends of the cleaning tunnel reach the sealing head. A cleaning hole 9 is left at its end. A shaft 6 is arranged in the oil storage tank at the corresponding position of the manhole cover 3, and the shaft 6 has four columns 11, and the selection of the columns is an angle steel of 35 × 35 mm; The stringers 12 have surrounded a square frame. Stringer 12 is selected as the flat steel of 40 * 5 millimeters. The upper and lower end surfaces of the four columns are provided with arc-shaped end plates 15, and the lower arc-shaped end plates are on the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com