Pivoting fluid conduit joint and one-way brake

A technology of fluid pipelines and brakes, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve problems such as problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

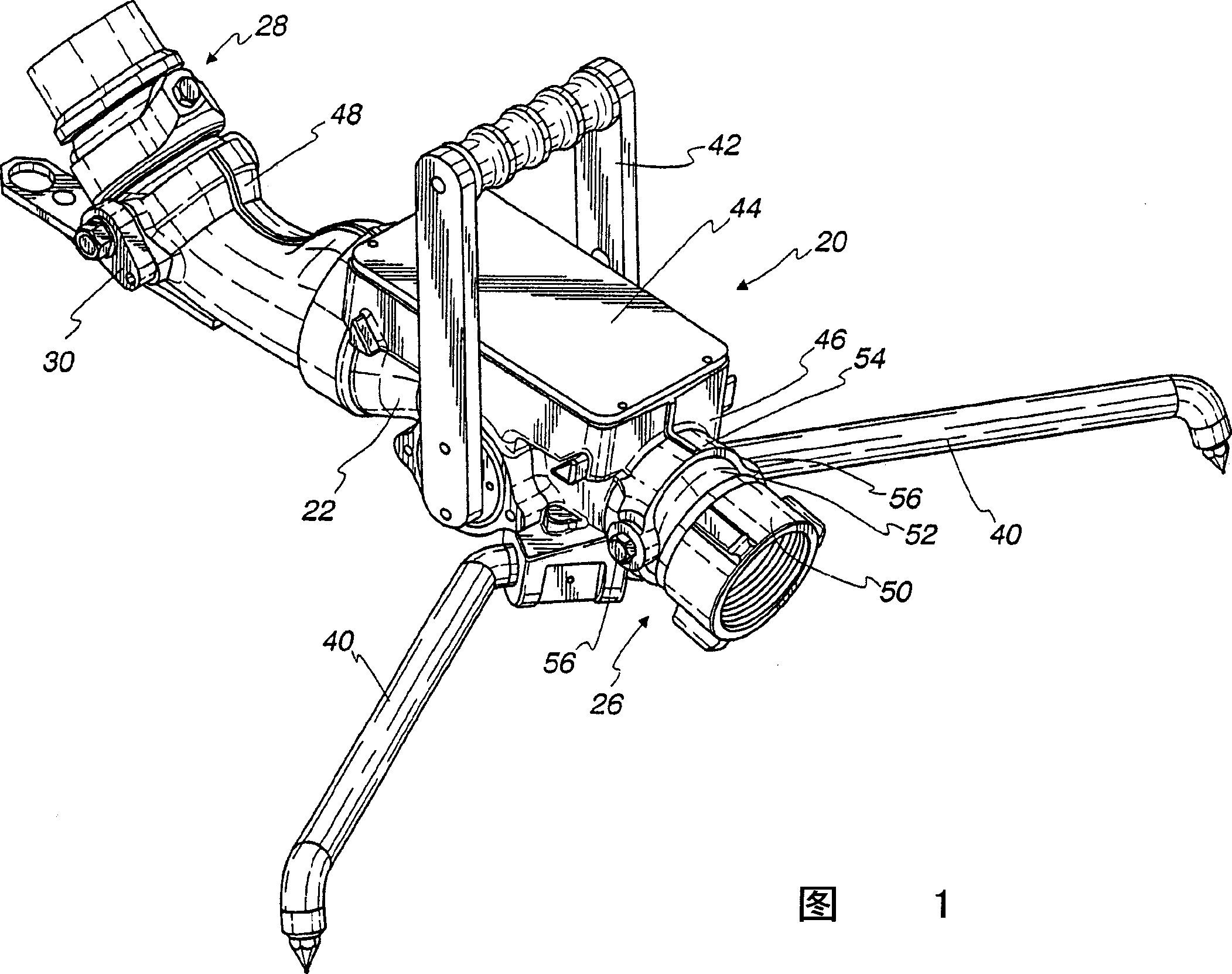

[0023] In the following description of the drawings, like elements are denoted by like numerals in each drawing. Generally speaking, in FIG. 1 , the safety device 20 has a housing 22 , a pivotable inlet connection 26 , a pivotable outlet connection 28 and a one-way stop 30 . Safety device housing 22 is shown as a rigid tube with spike-like folded legs 40 , a valve handle 42 and emergency valve shut-off mechanism 44 . The folding legs 40 are provided with a wide base on which the reaction forces of the safety device 20 can be supported and thus have a stabilizing effect. The valve handle 42 allows easy operation and is directly controlled by the operator. When the situation of sliding or overturning occurs, these situations will cause the next operation of the safety device 20 to be unsafe, and the emergency valve cut-off mechanism 44 can automatically cut off the safety device. Although safety device 20 is shown as a preferred shape and form of safety device for reasons of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com