Open-end spinning frame

A technology of open-end spinning and rotors, which is applied to spinning machines, open-end spinning machines, continuous winding spinning machines, etc., which can solve the problem of accidental opening of the swing casing, the tightness of the swing casing and the rotor casing. Reassurance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

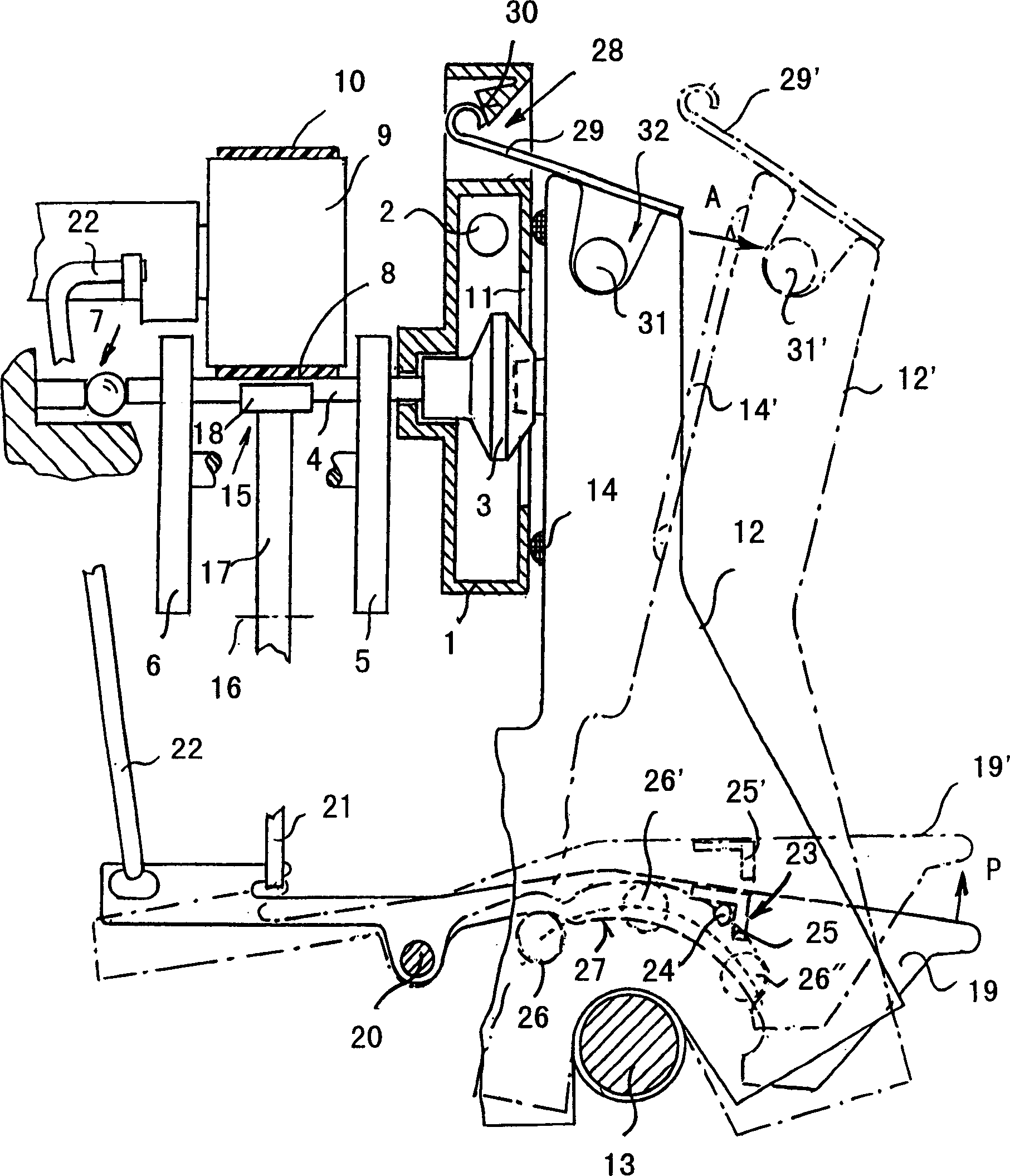

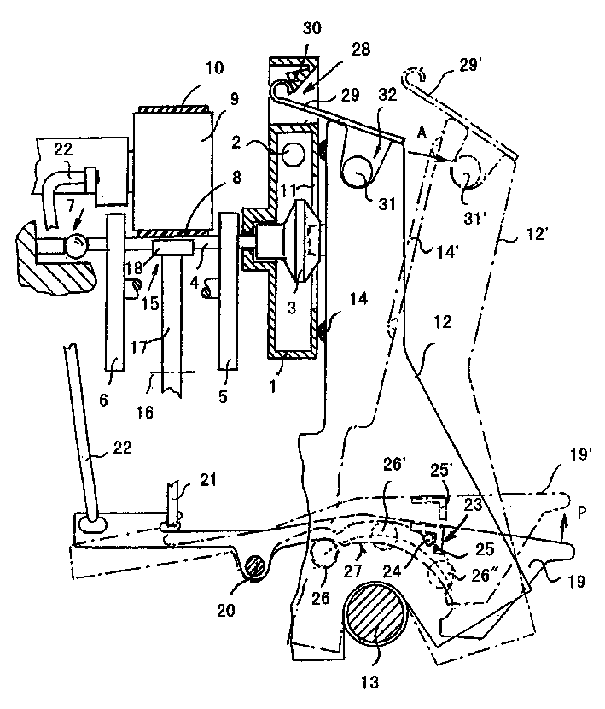

[0007] The device comprises a rotor cup housing 1 under negative pressure, which is connected to a vacuum source not shown in the figure by means of a negative pressure connecting pipe 2 . During production, a rotor 3 rotates inside the rotor housing 1, and the rotor is supported and driven outside the rotor housing 1. For this purpose, a rotor shaft 4 of the rotor 3 extends through the rear wall of the rotor housing 1 .

[0008] In a known manner, a pair of support discs 5 and 6 serve as radial bearings for the rotor shaft 4, while the rotor 3 is fixed axially in its operating position by means of a vertical thrust bearing 7. The rotor shaft 4 is driven by a tangential drive belt 8 running longitudinally of the machine, which is pressed onto the rotor shaft 4 via each pressure roller 9 . The pressure roller 9 simultaneously serves as a guide for the return run 10 of the tangential drive belt 8 .

[0009] For installation and maintenance, the rotor housing 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com