Plastic unit and manufacturing method thereof

一种塑料、塑料基的技术,应用在化学仪器和方法、其他家里用具、纤维素塑性物质层状产品等方向,能够解决玻璃基板难以满足轻量且可弯曲等问题,达到保持导电性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125]

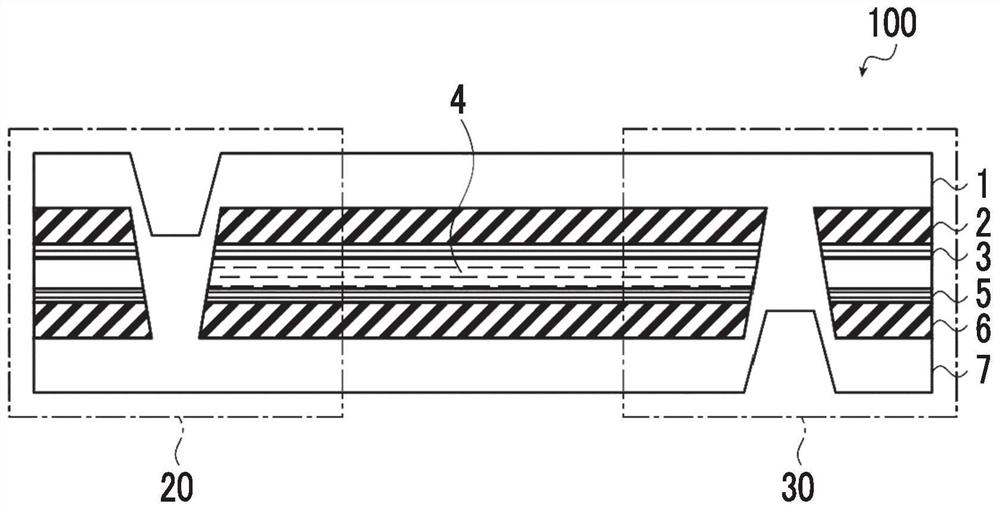

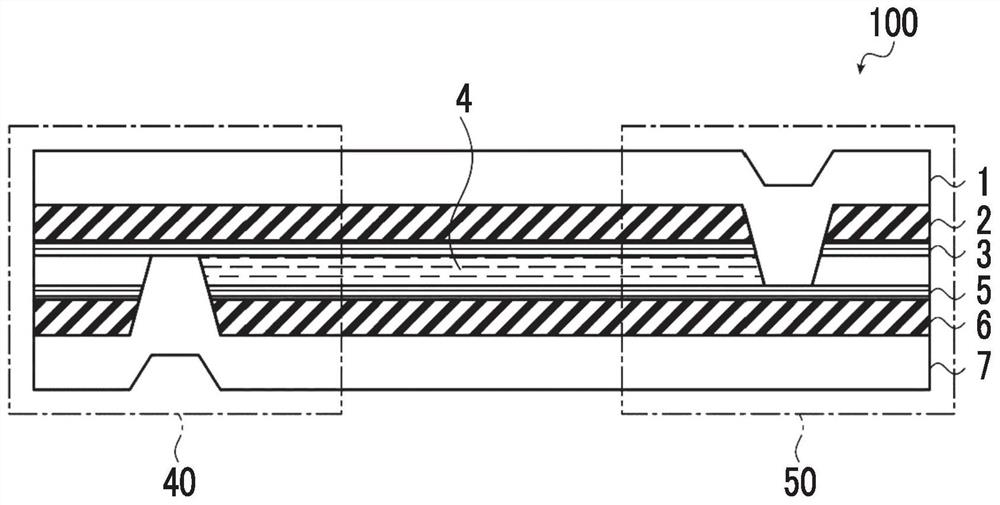

[0126] The transparent conductive layer is made on the surface manufactured by the AG nanowires in TeijinLimited. The surface of the polycarbonate (PC-2151, a thickness of 250 μm) manufactured by the AG nanowires is made of the polycarbonate (250 μm) of TeijinLimited. The ester plastic substrate and a laminated body formed by a transparent conductive layer comprising Ag nanowires.

[0127]

[0128] The laminated bodies made in the above-described formulation were cut into 10 cm, and the polyamic acid alignment layer coating liquid (JSR Corporation manufacturing JALS684) was coated as a liquid crystal alignment using a rod coater # 1.6.

[0129] Thereafter, the liquid crystal alignment layer 101 was produced at 80 ° C for 3 minutes at 80 ° C. At this time, the film thickness of the liquid crystal alignment layer is 60 nm.

[0130] 2 groups of laminated stacks are prepared in the order of plastic substrates, transparent conductive layers, and liquid crystal alignment laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com