Plastic cell and method for manufacturing same

A plastic and plastic-based technology, applied in instruments, nonlinear optics, optics, etc., can solve the problem that glass substrates are difficult to meet the requirements of light weight and bendability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0133]

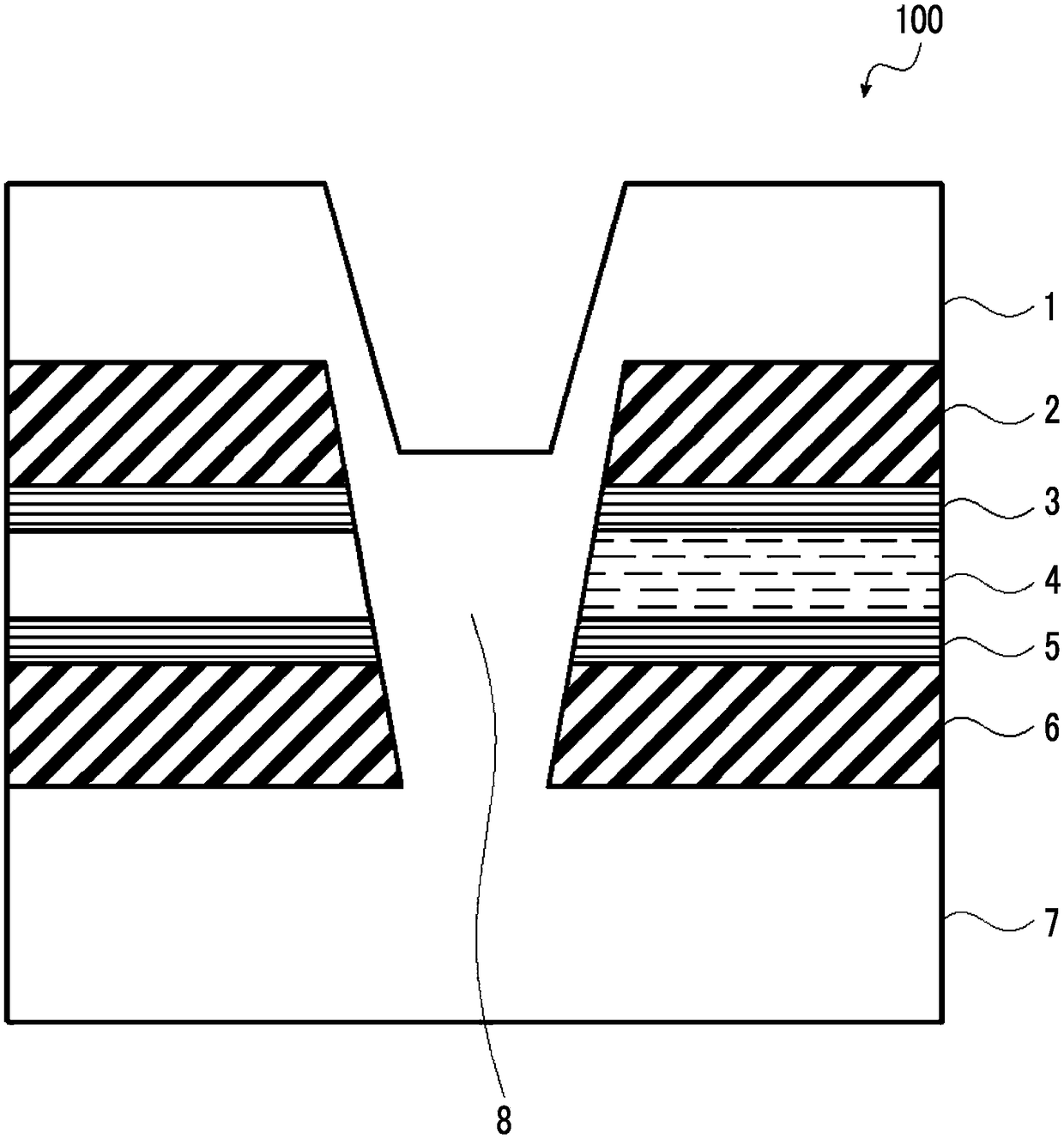

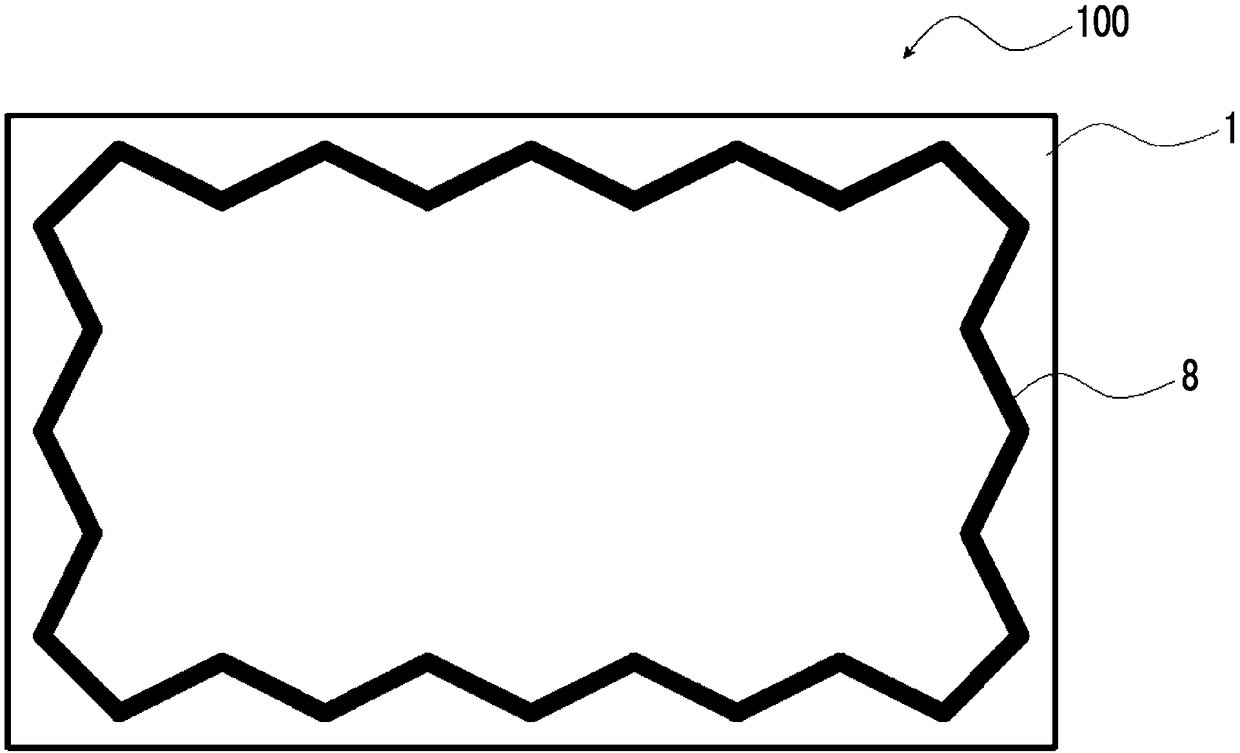

[0134] After biaxially stretching polycarbonate (PC-2151, thickness 250 μm) manufactured by TEIJIN LIMITED. at 150°C to 30% in the longitudinal direction and 30% in the transverse direction, the method described in Example 1 of US2013 / 0341074 A transparent conductive layer was fabricated using Ag nanowires, and a laminate was produced in which a plastic substrate containing polycarbonate and a transparent conductive layer containing Ag nanowires were laminated.

[0135]

[0136] The laminate produced above was cut into 6 cm in length and 10 cm in width, and a polyamic acid alignment layer coating solution (JALS684 manufactured by JSR Corporation) was applied as a liquid crystal aligning agent using bar coater #1.6. After that, it was dried at a film surface temperature of 80° C. for 3 minutes, thereby producing an alignment layer 101 . At this time, the film thickness of the alignment layer was 60 nm.

[0137] Two sets of laminates were prepared in which the plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com