Apparatus and method for detecting imbalance in washing machines

A technology of balance detection and washing machine, applied in the control device, washing device, measuring device of washing machine, etc., can solve problems such as hindering the smooth running of washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiment of the invention

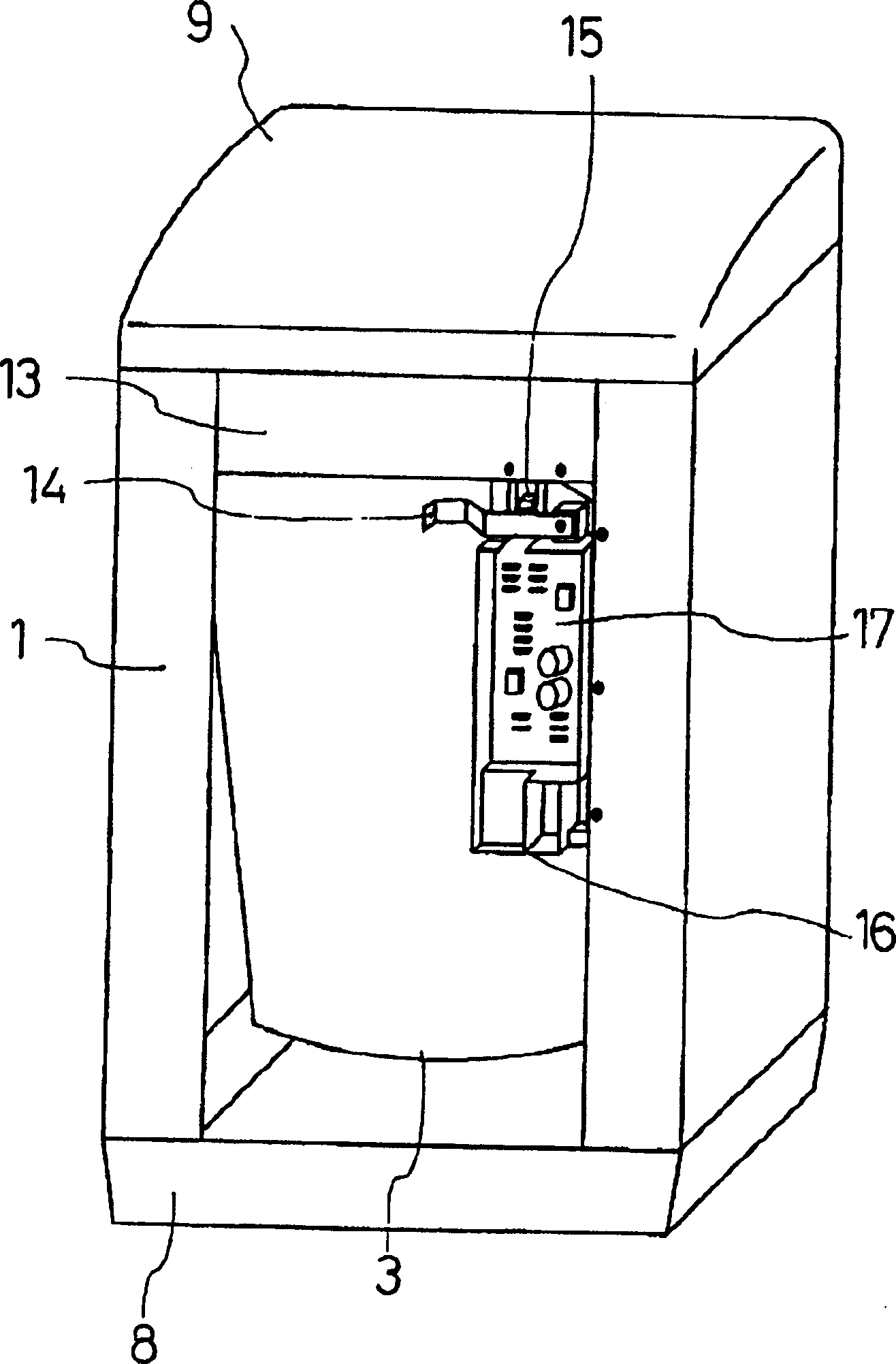

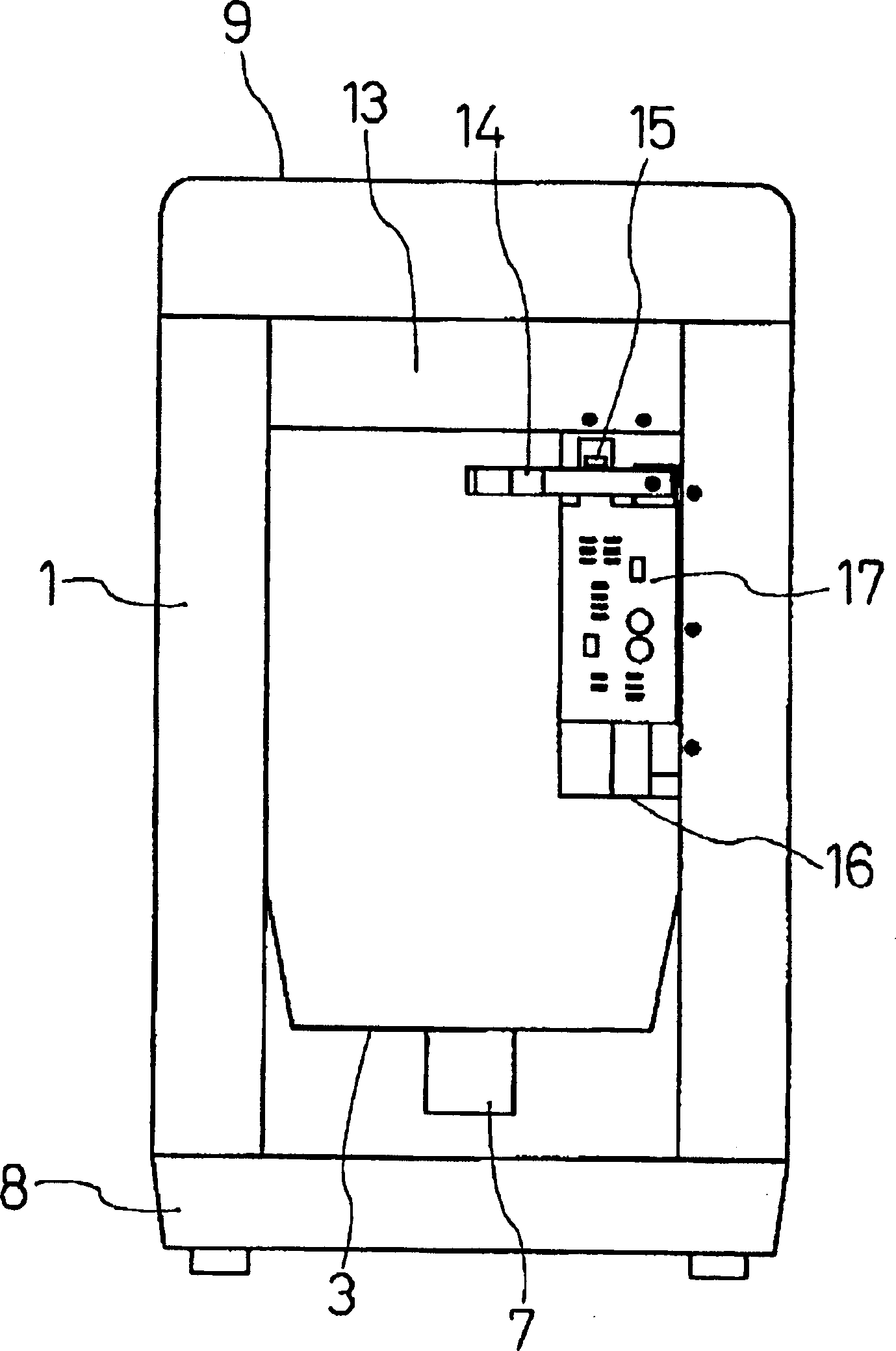

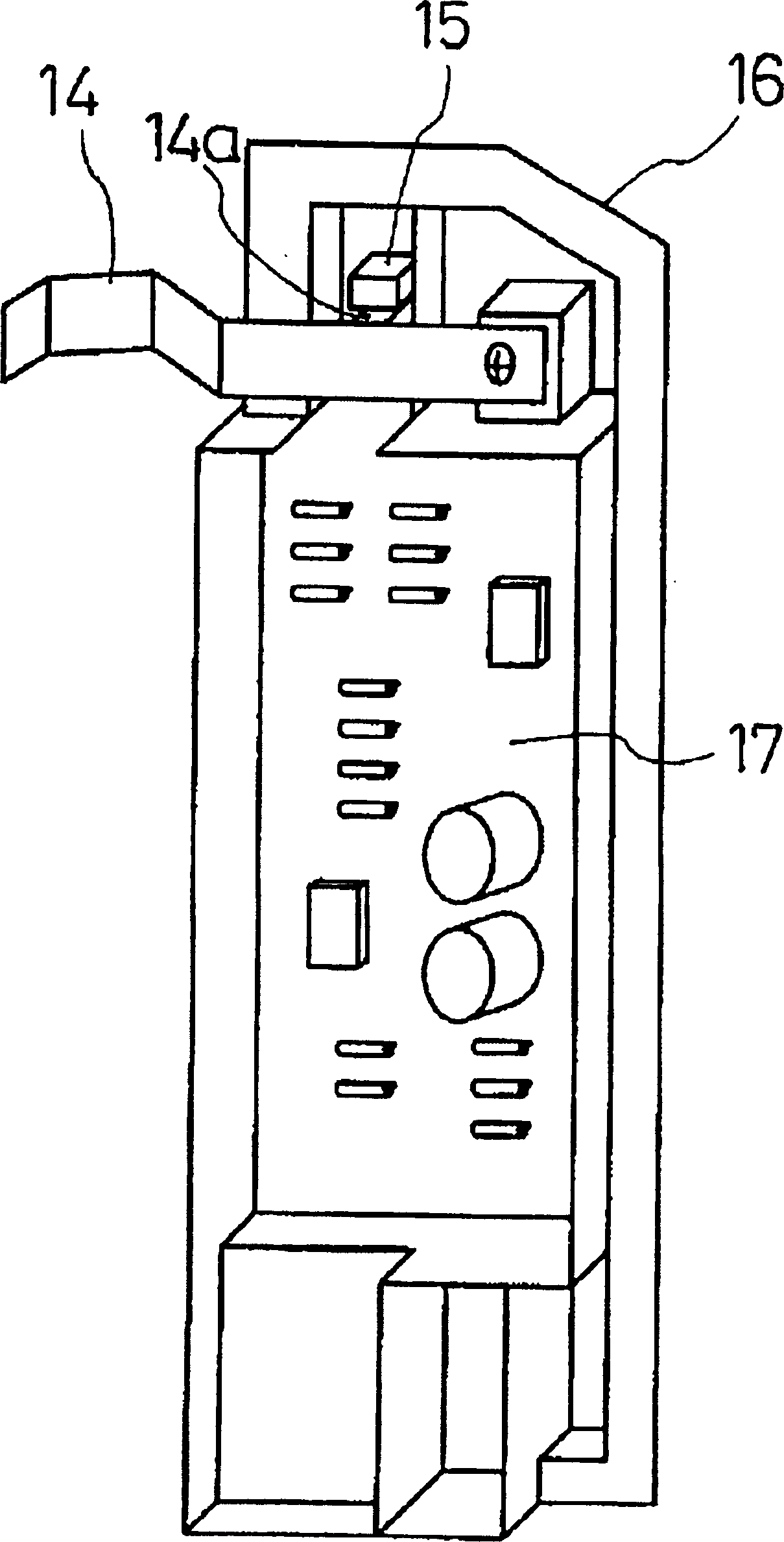

[0026] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a perspective view of a washing machine with the unbalance detection device of the present invention with the front panel removed, figure 2 For the front view of the same as above, image 3 is a perspective view showing an embodiment of the unbalance detecting device of the washing machine of the present invention, Figure 4 It is the top view of the same, and Fig. 5 is the exploded perspective view of the same, because Figure 7 The overall configuration of the single-tub type washing machine has been described, and its detailed description is omitted here.

[0027] The unbalance detecting device of the present invention is composed of a lever 14 that is displaced by the swing of the water tank 3 and a sensor 15 that detects the displacement of the lever 14. The sensor 15 is, for example, a light circuit f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com