Device for producing color lines on high borosilicate glass tube inner wall

A high borosilicate glass, tube wall technology, applied in glass forming, glass forming, glass manufacturing equipment, etc., can solve problems such as inability to distinguish glass tubes, and achieve the effect of maintaining goodwill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

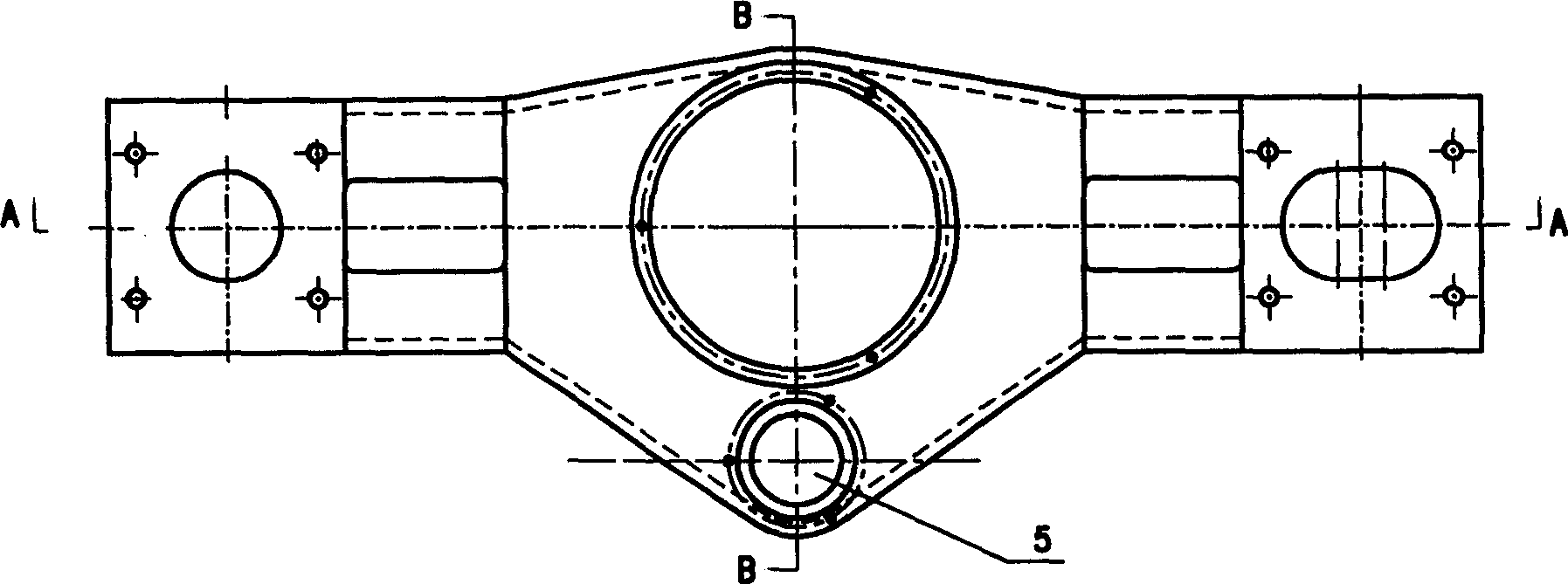

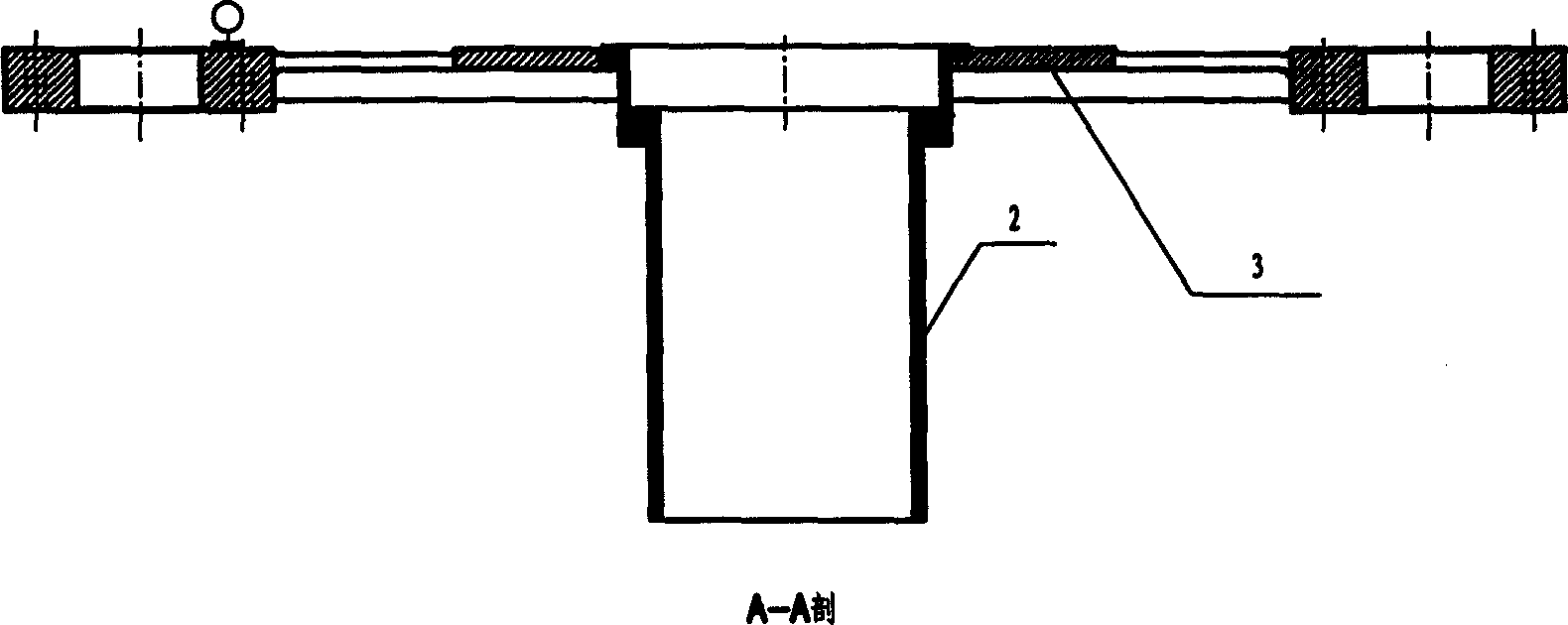

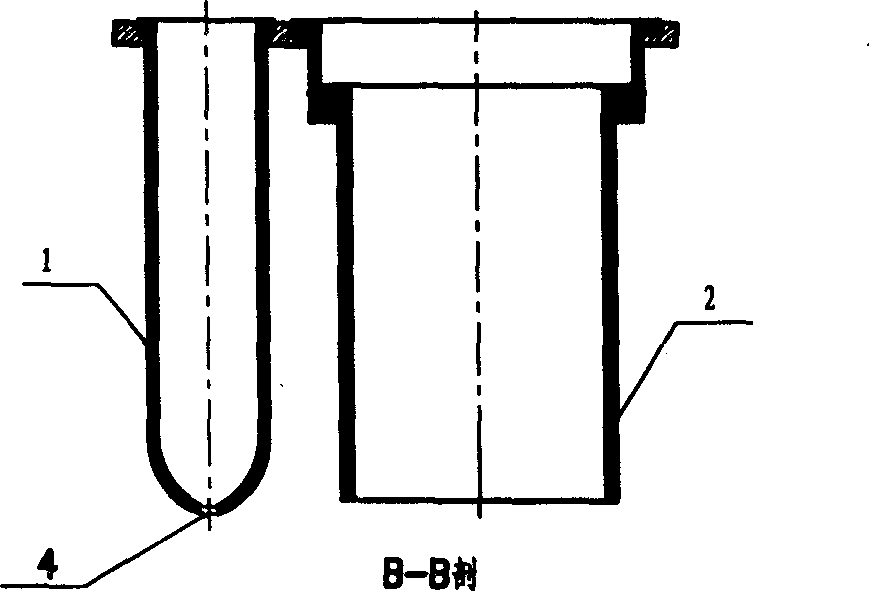

[0010] A device for producing colored lines on the inner wall of a high borosilicate glass tube, including a leveling cylinder 2 and a leveling cylinder frame 3, the leveling cylinder is fixed on the leveling cylinder frame, and a long-necked crucible with a hole at the bottom, said The long-necked crucible is arranged beside the leveling cylinder, and its protruding upper edge is stuck on the hole 5 of the leveling cylinder frame. During production, the color glaze is put into the long-necked crucible according to the color selected by the enterprise, and the color glaze is heated and melted by the molten glass liquid around the crucible and is in a molten state. The colored glaze in the molten state flows into the forming flow of molten glass through the hole at the bottom of the long-necked crucible, and the forming flow of molten glass passes through the end to form a glass tube prototype with colored lines in the wall.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap