Paper clamping board

A cardboard and liner technology, applied in file folders, printing, etc., can solve the problems that it is difficult to close the clamping body 3, it is difficult to open the clamping body, it is difficult to operate the operating parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

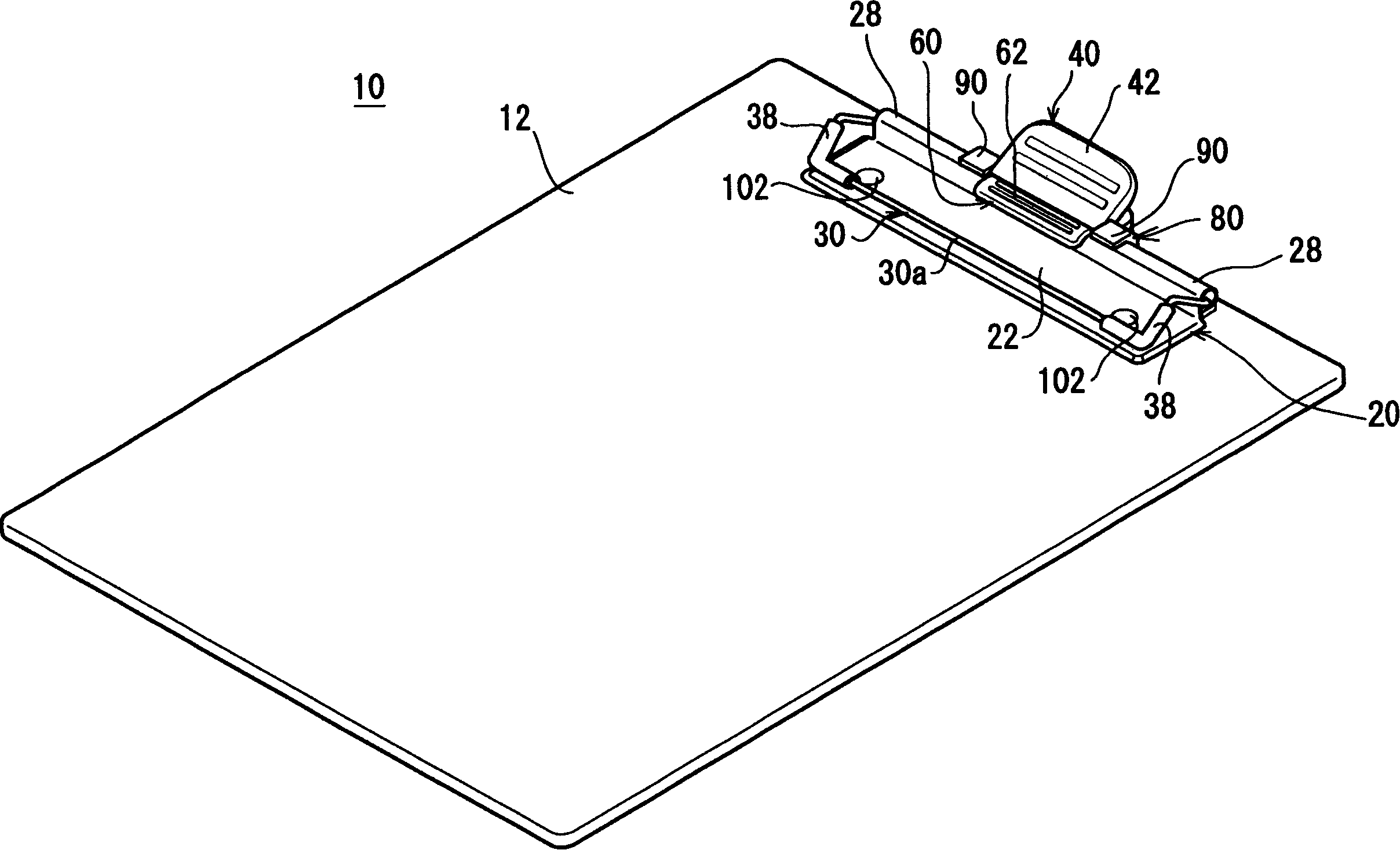

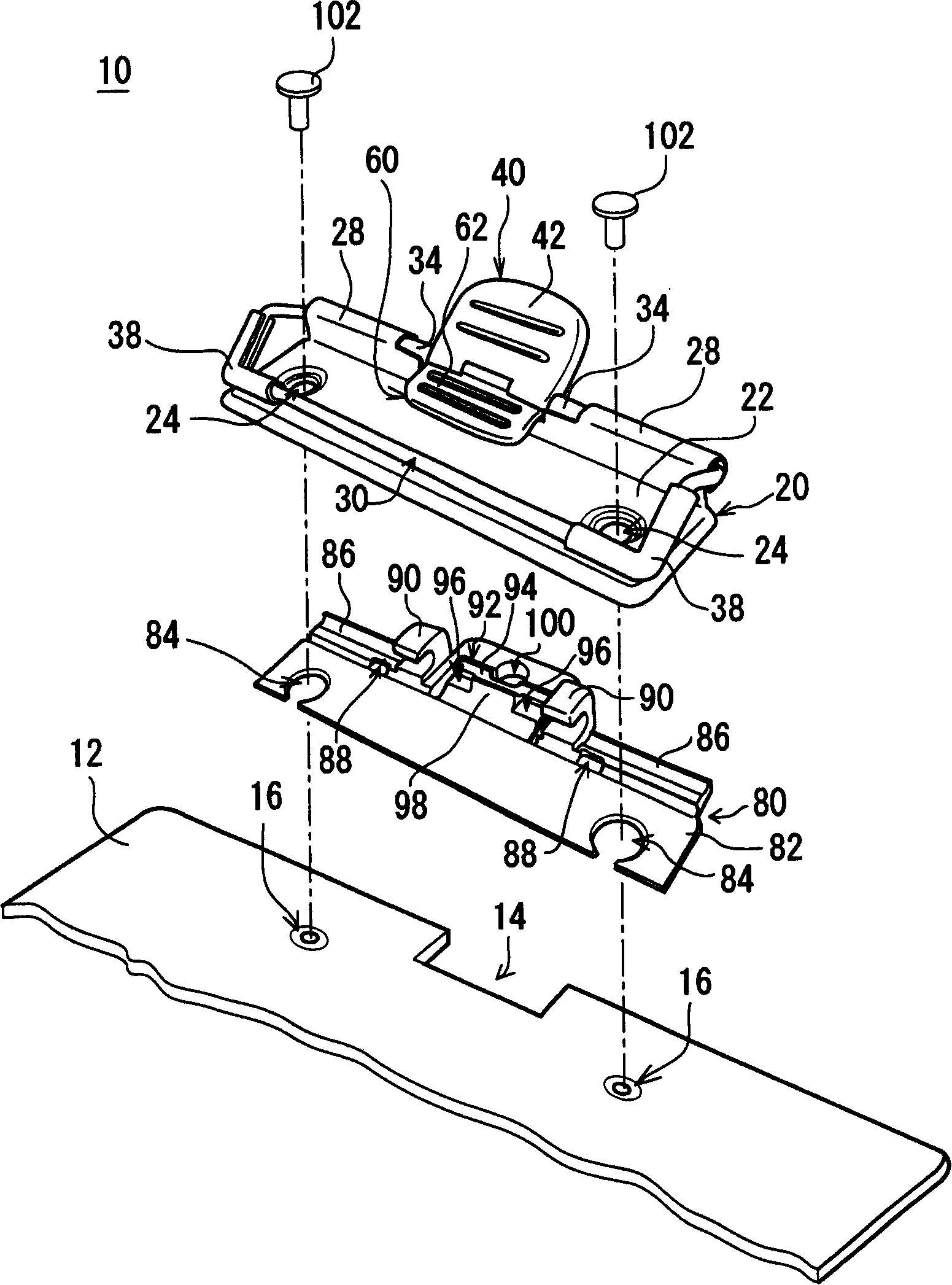

[0038] figure 1 It is a perspective view of an example of the clipboard of the present invention, figure 2 yes figure 1 An exploded perspective view of the main parts of the clipboard shown. figure 1 The illustrated paperboard 10 includes, for example, a rectangular base plate 12 molded of synthetic resin. One end of the bottom plate 12 is formed with a rectangular notch 14 as shown. Two circular mounting holes 16 , 16 are formed at regular intervals on both sides of the notch 14 on the bottom plate 12 .

[0039] On the bottom plate 12 are fixed a metal base 20 formed of a metal such as stainless steel and a resin base 80 formed of a synthetic resin such as ABS resin as a backing plate.

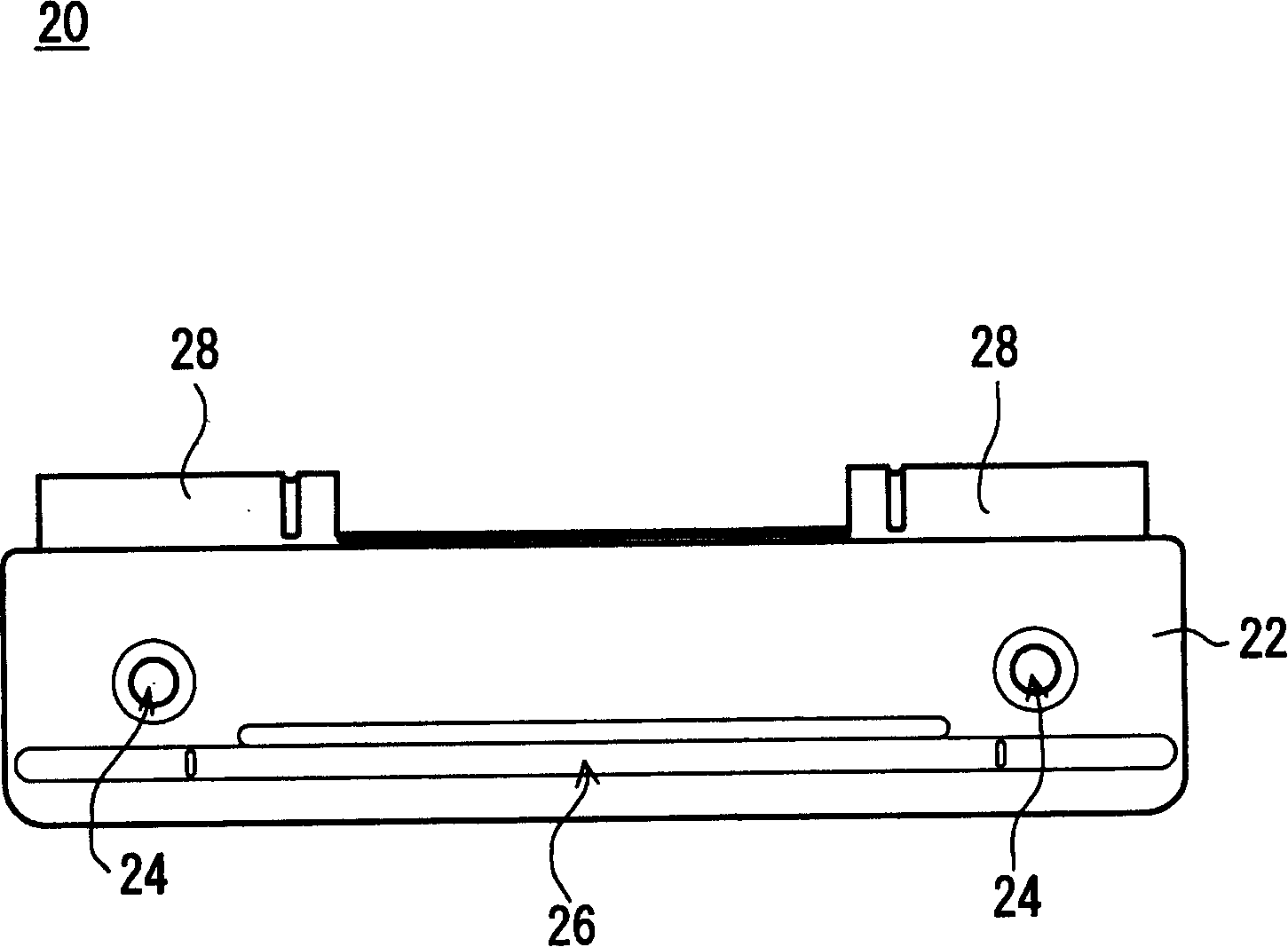

[0040] Such as image 3 and 4 As shown, the metal base 20 includes a rectangular plate-shaped main surface member 22 . Two circular mounting holes 24, 24 are formed at regular intervals on the main surface member 22. As shown in FIG. In addition, one end of the main surface member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com