Plasma display panel and producing method thereof

A technology for plasma display panels and display electrodes, which is applied to alternating current plasma display panels, tube structural parts, discharge tubes, etc., and can solve problems such as luminance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, a plasma display panel according to an embodiment of the present invention will be described with reference to the drawings.

[0017] Embodiment 1

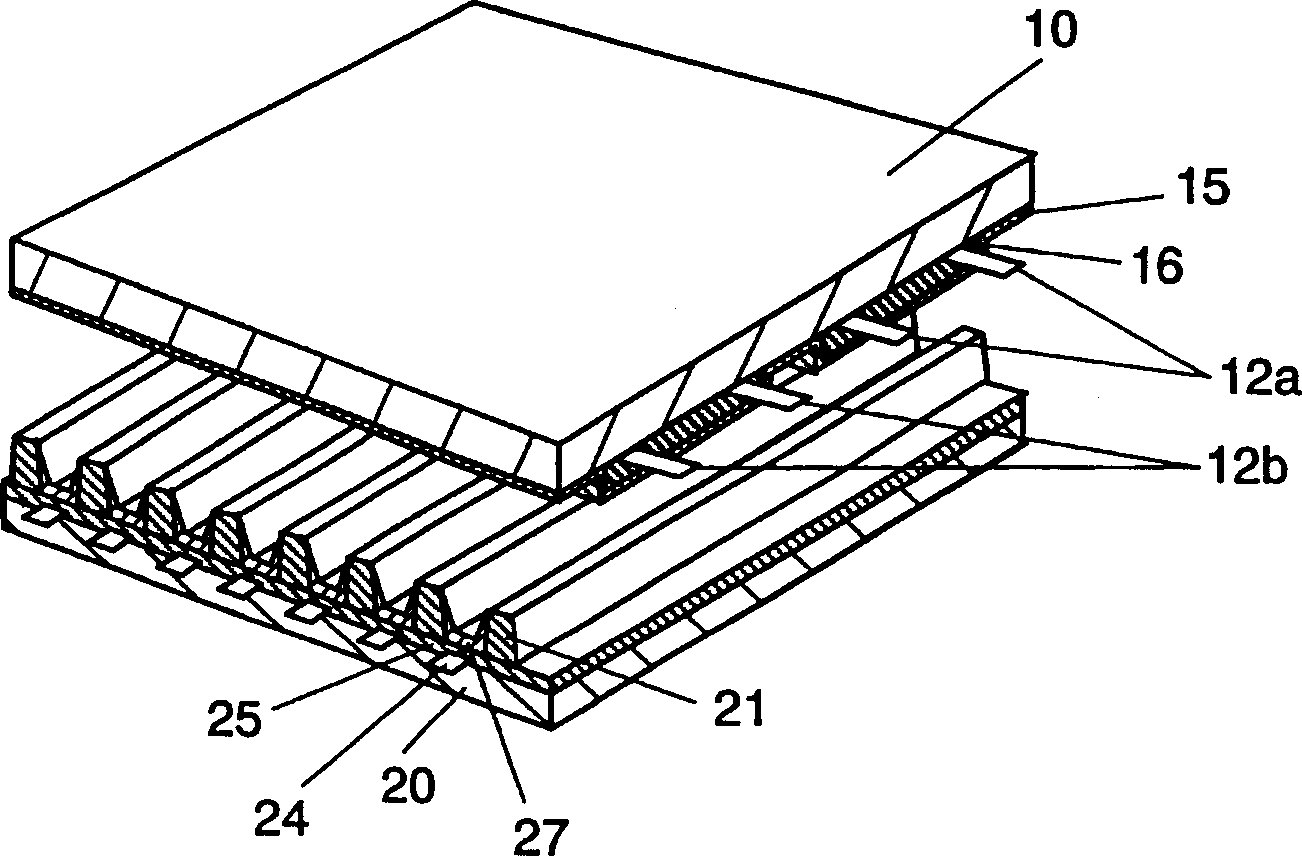

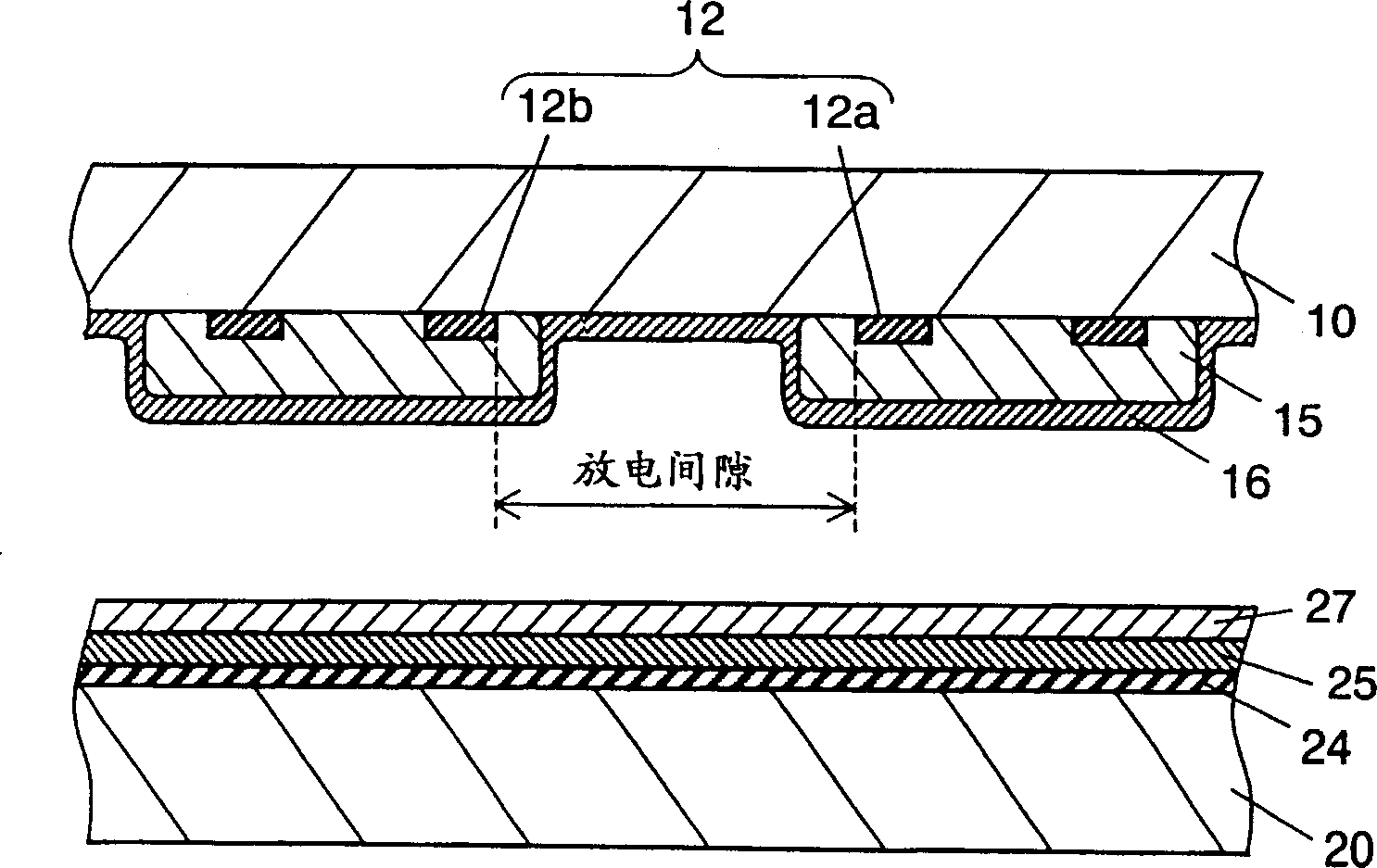

[0018] figure 1 is an exploded perspective view showing the structure of the plasma display panel according to Embodiment 1 of the present invention, figure 2 It is a sectional view showing the structure of the plasma display panel according to Embodiment 1 of the present invention.

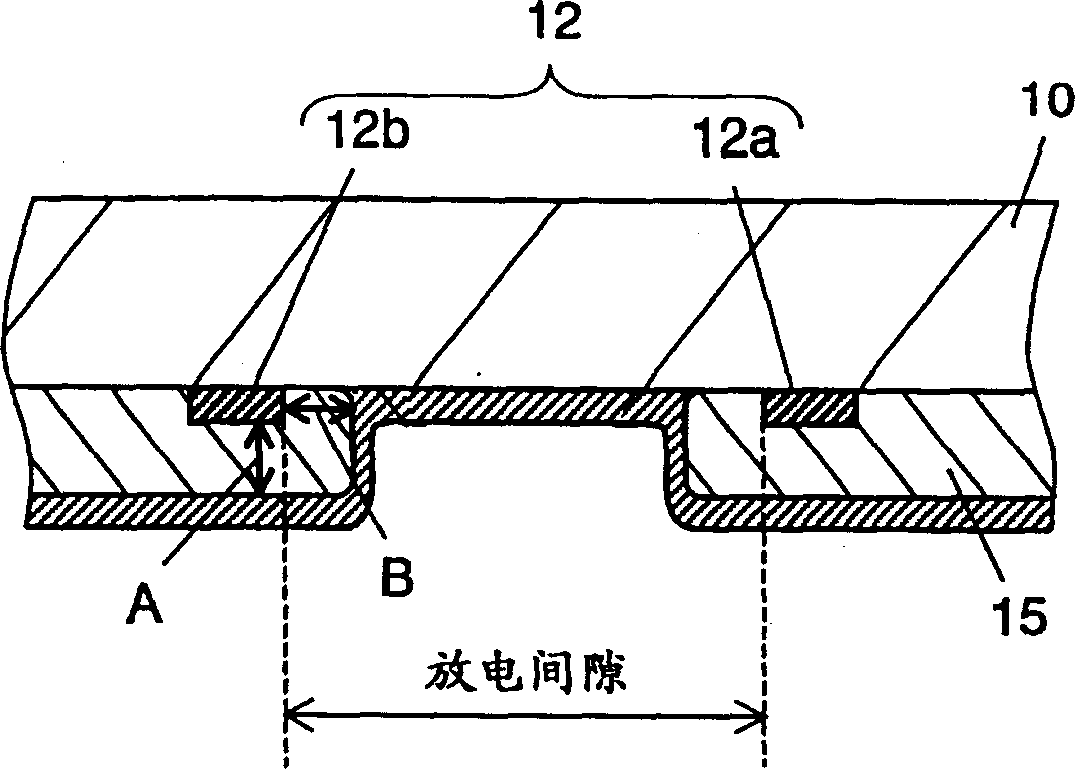

[0019] On the front substrate 10, a display electrode pair 12 composed of two display electrode pairs 12a and 12b parallel to each other is provided, and a discharge gap for performing display light emission is formed. The display electrode pairs 12a, 12b are covered with a dielectric layer 15, respectively. However, the dielectric layer 15 is not formed on the discharge gap formed between the display electrode pair 12a, 12b. The protective film 16 is formed so as to cover the dielectric layer 15 and the discharge gap. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com