Safe toecap cover made of resin

A technology of resin type and toe cap, which is applied in the direction of shoe uppers, footwear, household components, etc., and can solve problems such as damage to the connecting part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] First, weigh out thermoplastic resin balls (60% by weight of glass fibers in polyurethane) that are cut into fibers with a diameter of about 0.5 mm and cut into lengths of 20 mm to increase strength, and complete plasticization by heating in a quasi-mold The way of preliminary molding (after applying a 0.5kg / cm 2 pressure, and under the temperature condition of 210° C., the operation was carried out for 0.5 minutes), so that a parison of a toe cap was prepared. Next, the parison is put into a toe cap die and heated in a 400kg / cm 2 Under the pressure of 135 ° C, compression molding was carried out, so that a toe cap for safety shoes with a size of 26 cm was made.

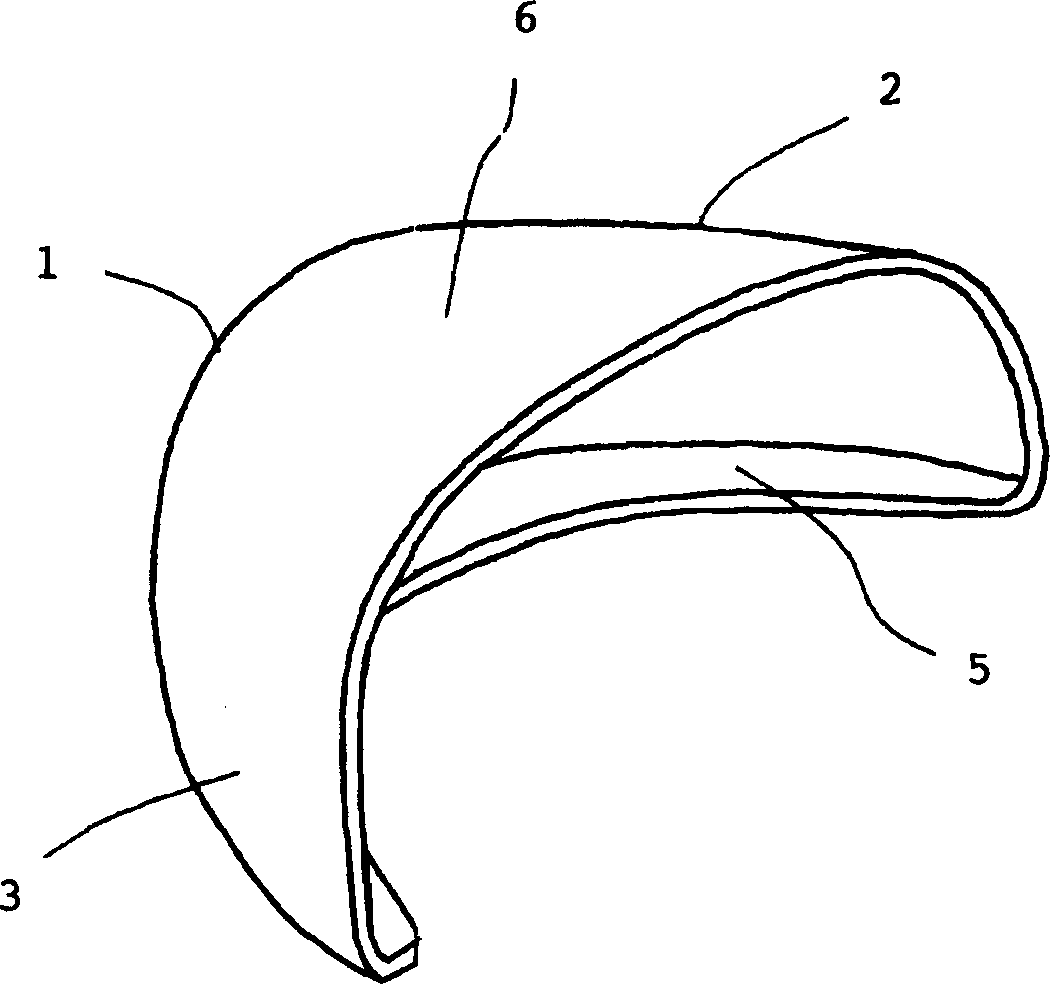

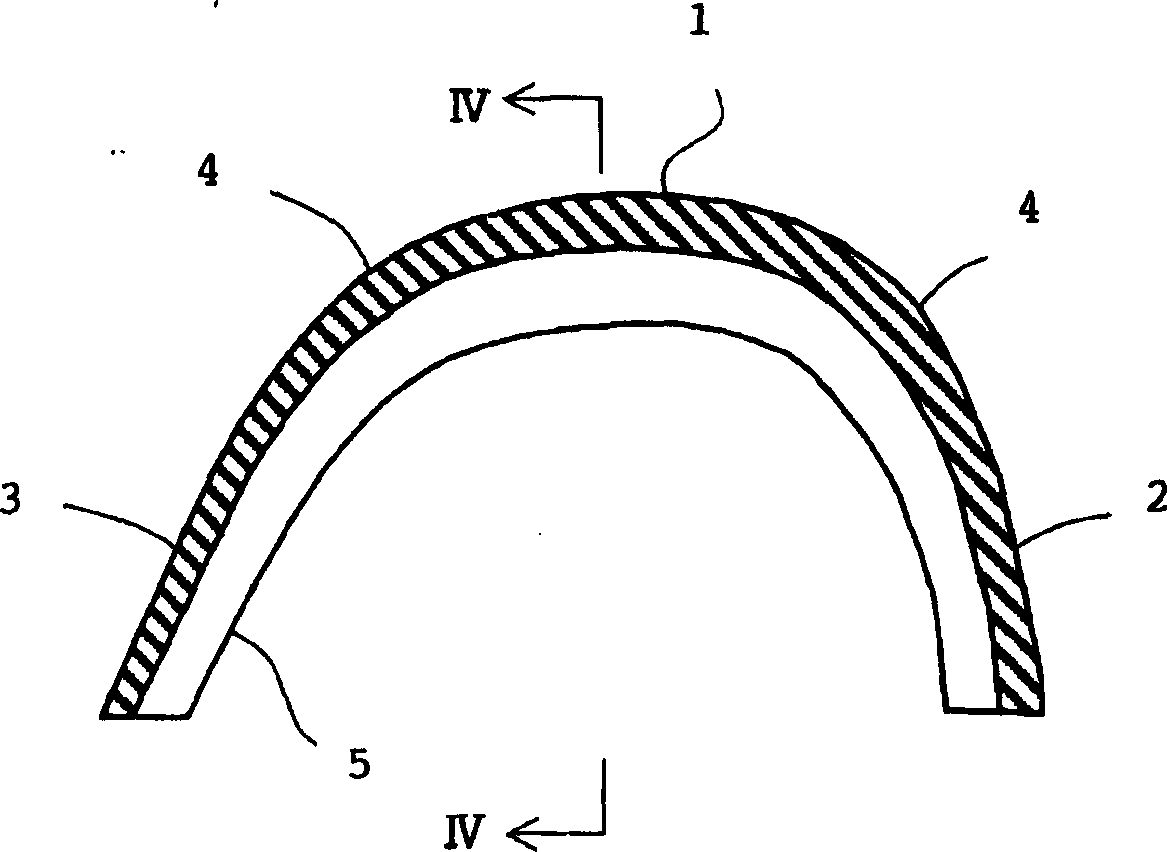

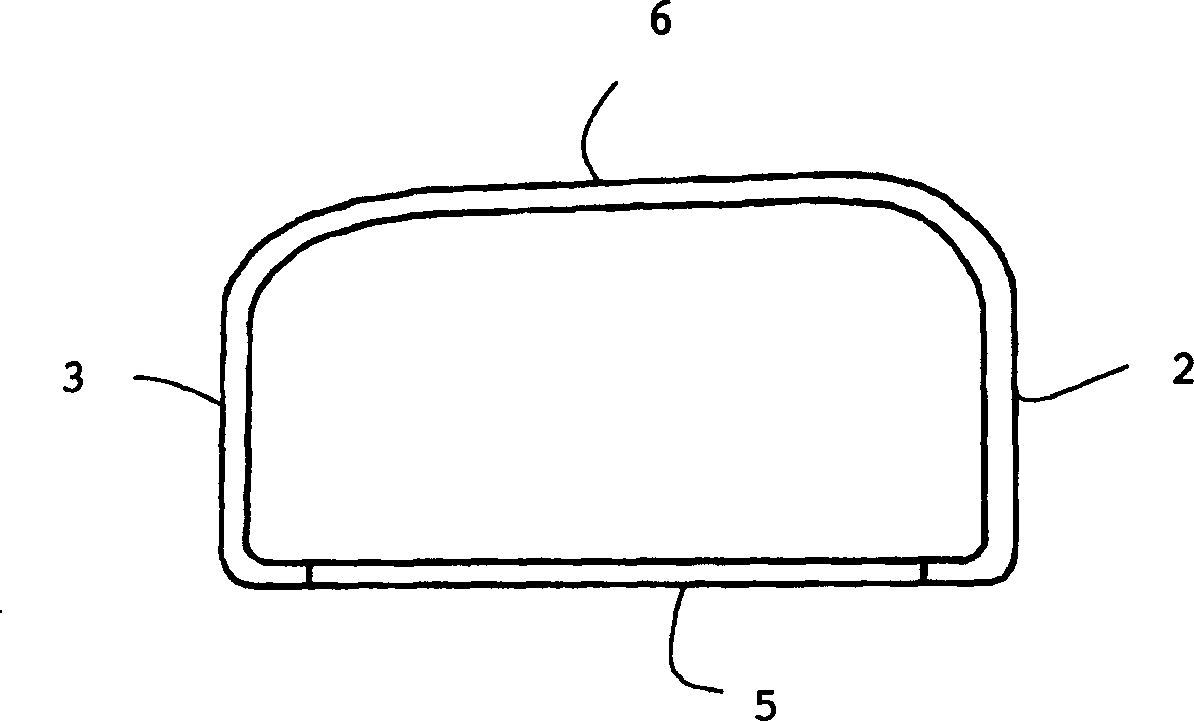

[0037] The structural form of the manufactured toe cap is as follows Figures 1 to 4 shown. like figure 2 As shown, this structure is provided with a front protruding part 1, a protruding part 2 on the side of the big toe and a protruding part 3 on the side of the little toe, and the protruding part of th...

example 2

[0039] Toe caps were manufactured in the same manner as in Example 1 above, except that fiber-reinforced thermoplastic resin balls containing 60% by weight glass fibers in nylon 6 were used. The structural form of the toe cap of making is also identical with example 1.

example 3

[0041] Toe caps were manufactured in the same manner as in Example 1, except that fiber-reinforced thermoplastic resin balls containing 75% by weight glass fibers in polypropylene were used. The structural form of the toe cap of making is also identical with example 1.

[0042] The headroom heights of the above-mentioned toe covers obtained in Examples 1 to 3 were measured with an impact energy of 200 Joules. This measurement shall be carried out in accordance with the measurement method in the CEN standard. The standard value specified in this standard is: when the impact energy is 200 joules (20kg×100cm), the headroom height is 14mm, and there must be no cracks that allow light to pass through the toe cap. The results are shown in Table 1.

[0043] Table 1

[0044] Headroom height when the impact energy is 200 joules (20kg×100cm)

[0045] Example 1

Example 2

Example 3

Polyurethane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com