Multi-section compression type rotary compressor and set-up method of discharge volume ratio

A rotary compressor and compression technology, applied in the direction of rotary piston machinery, mechanical equipment, rotary piston pump, etc., can solve the problems of increased operation time and increased processing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

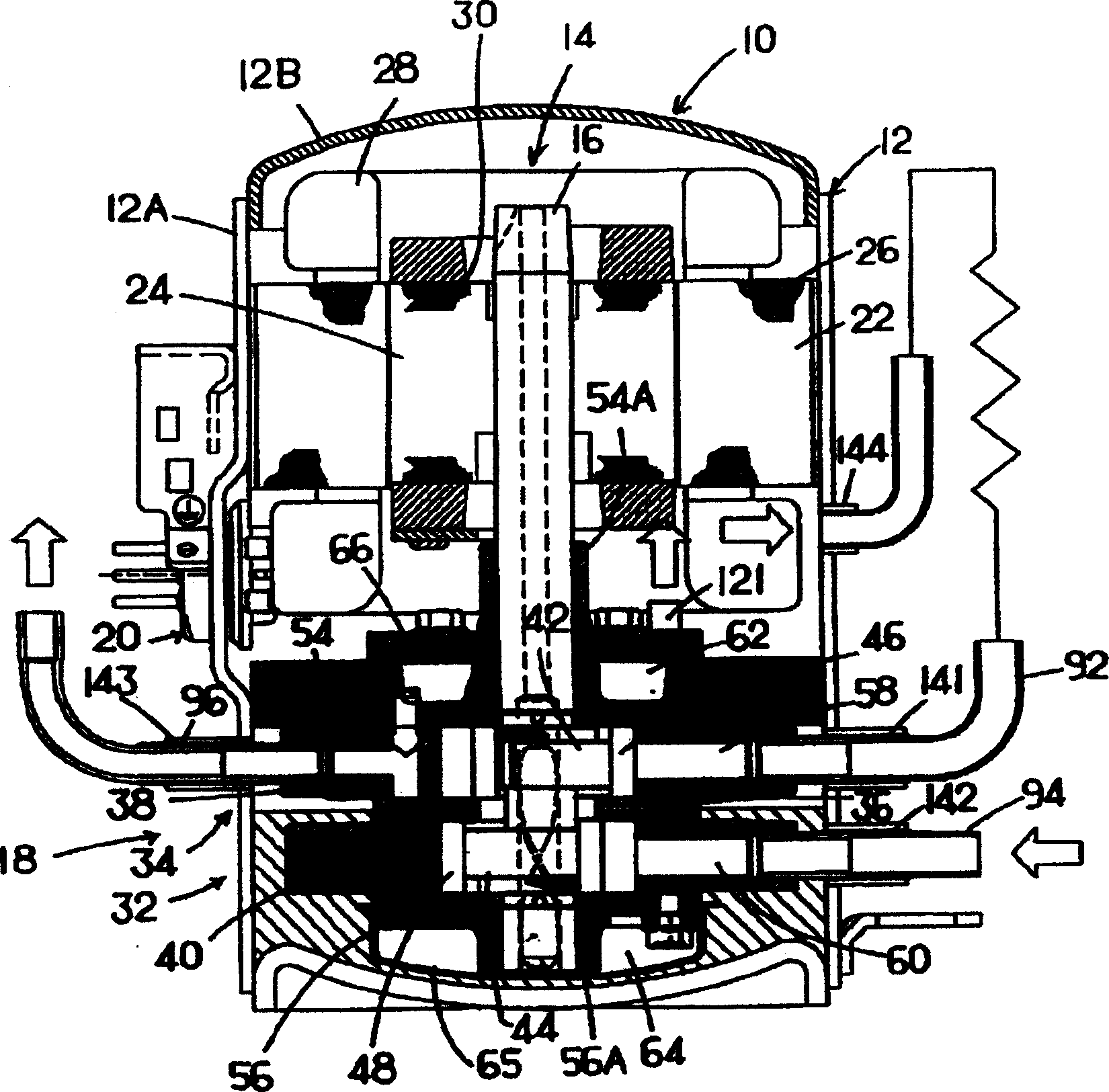

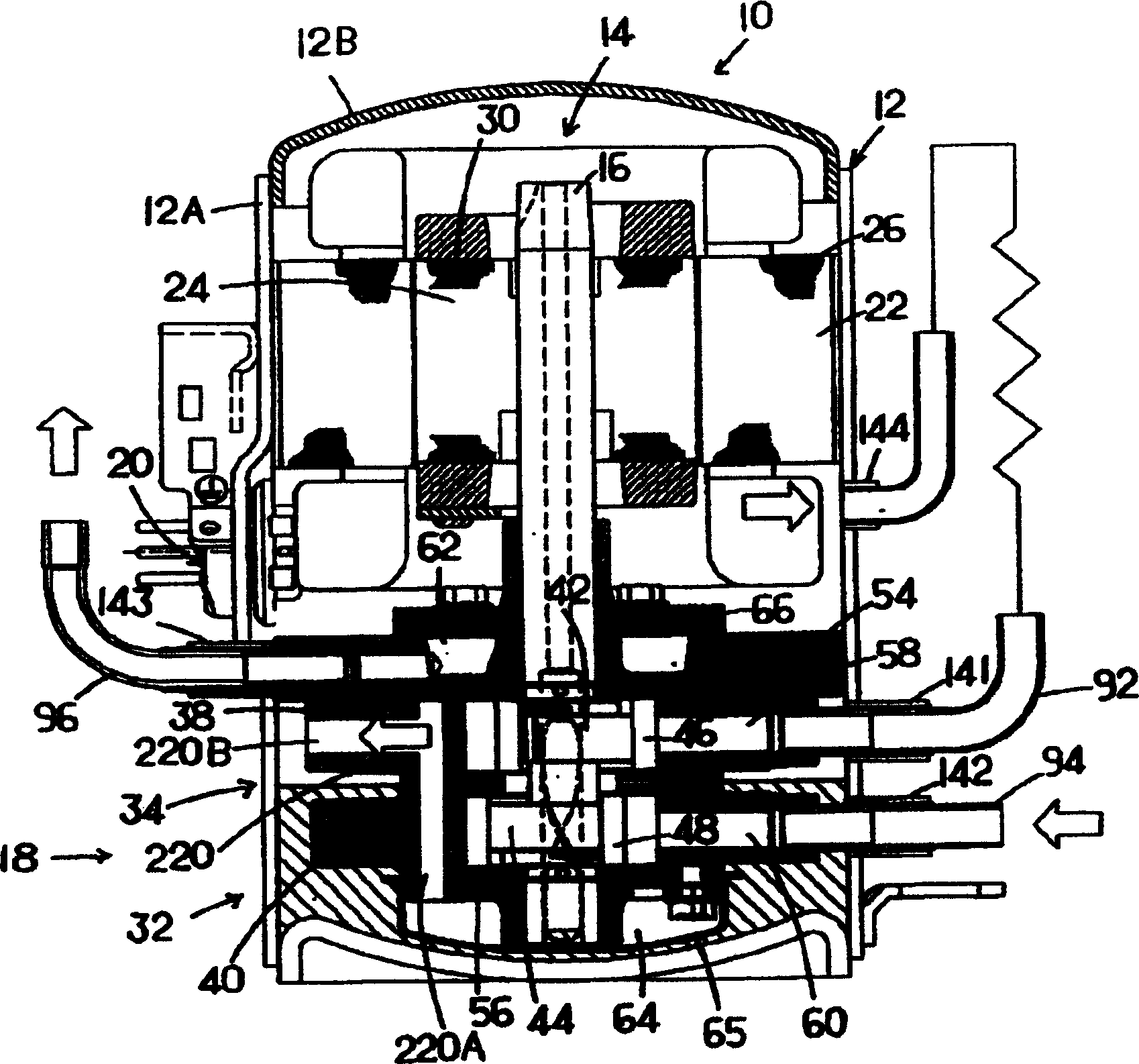

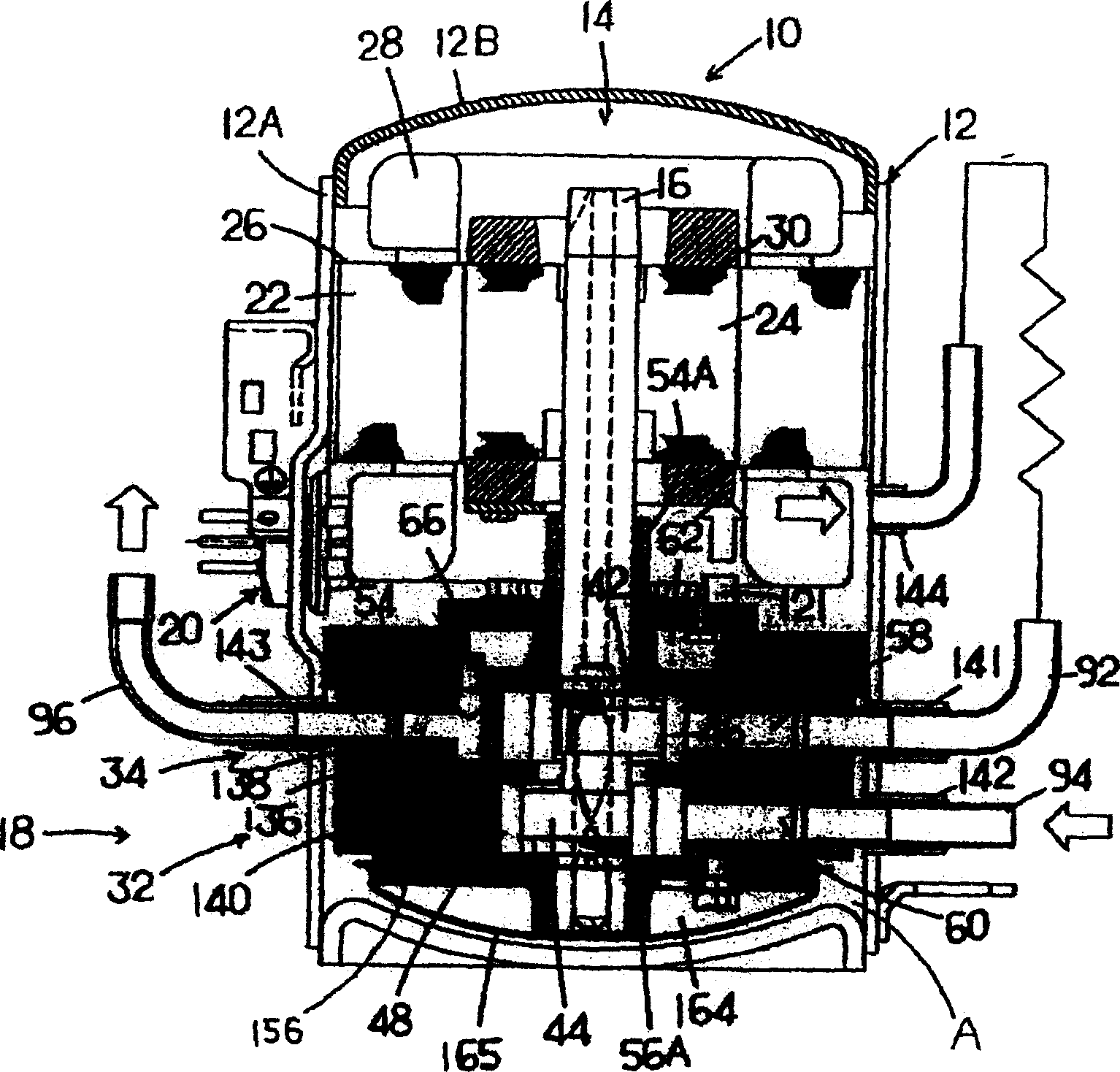

[0061] Next, embodiments of the present invention will be described in detail based on the attached drawings. figure 1 A longitudinal section view of a multi-stage compression rotary compressor according to a preferred embodiment of the present invention is shown. The internal intermediate pressure type multi-stage (two-stage) compression rotary compressor 10 includes first and second rotary compression elements 32 , 34 .

[0062] exist figure 1 In the figure, the rotary compressor 10 of the embodiment is an internal intermediate pressure type multi-stage compression rotary compressor using propane (R290) as a refrigerant. This multi-stage compression rotary compressor 10 is composed of the following components: a cylindrical airtight container body 12A made of steel plates and a bowl-shaped end cap (cover) that closes the upper opening of the airtight container body 12A 12B forms the airtight container 12 as the housing, the electric element 14 arranged on the upper side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com