Vibration-damping colloid

A technology of colloid and body, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

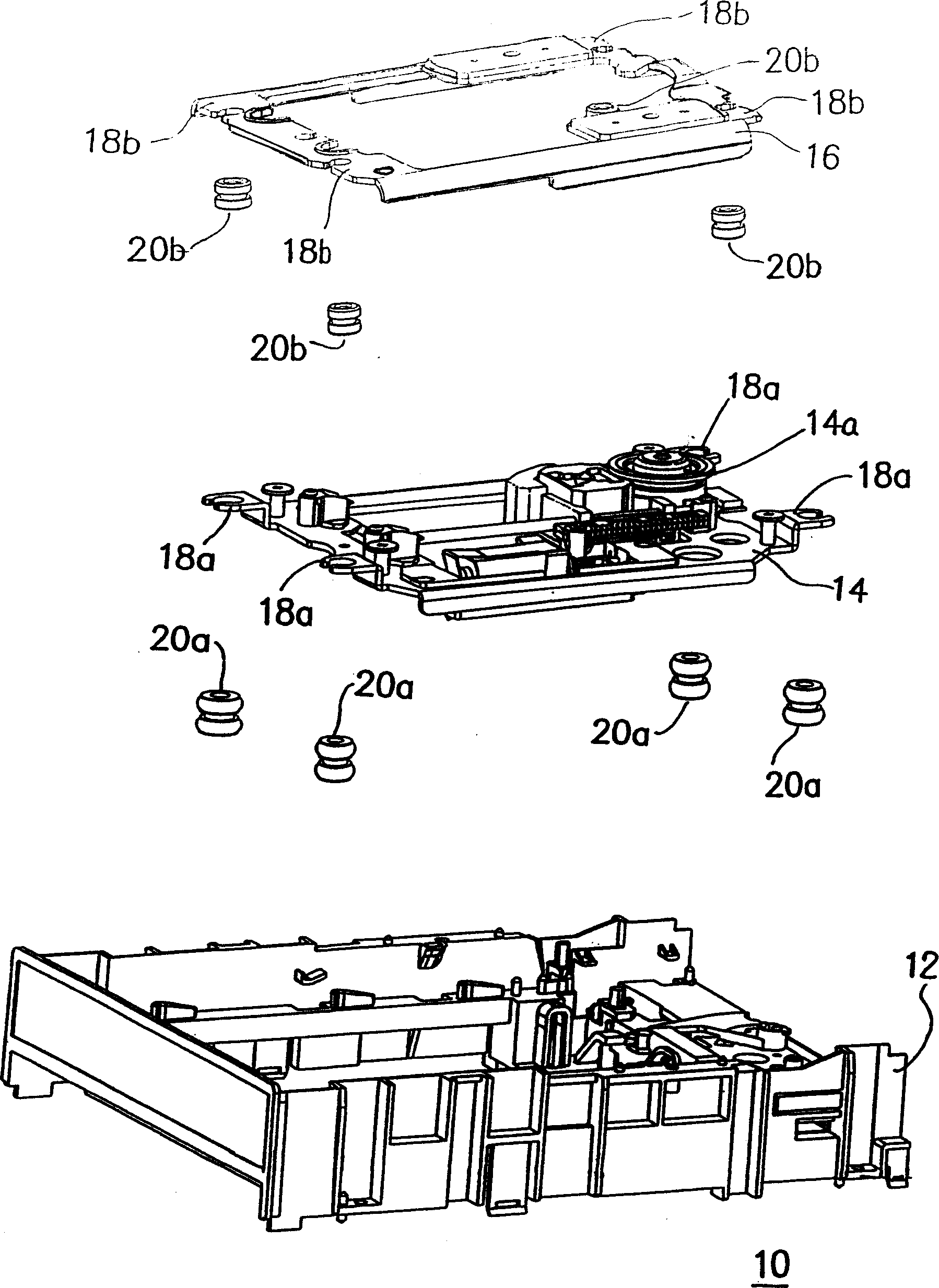

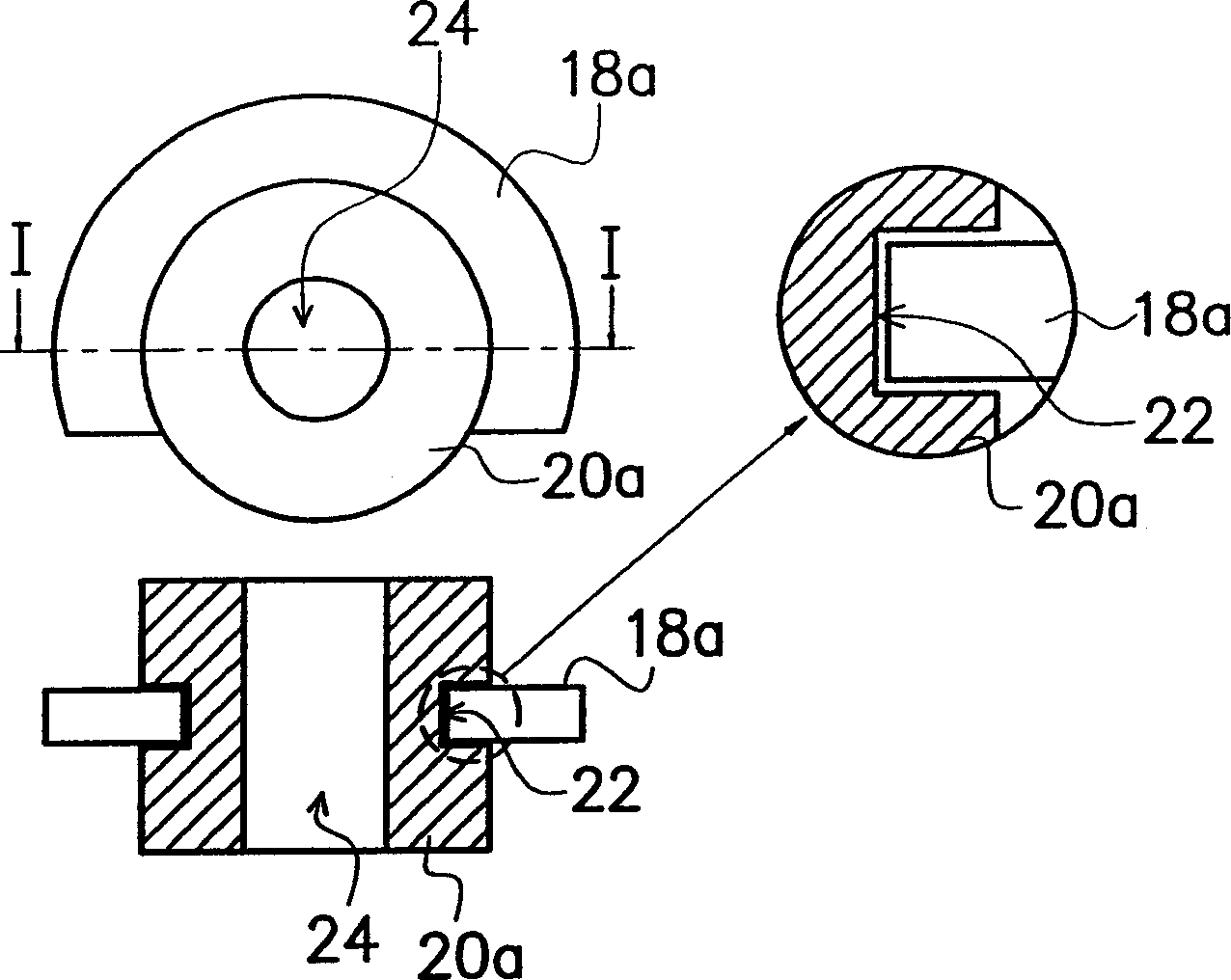

[0031] In order to enable the damping colloid to provide different damping capabilities in different axial directions, the first embodiment of the present invention mainly changes the shape of the partial cross-sectional profile of the damping colloid in the radial direction to an asymmetric shape, such as a rectangle, The ellipse or high-order curve etc. make the elastic coefficients of the damping colloid in different axial directions different, so the damping capacity of the damping colloid in different axial directions can be adjusted.

[0032] Please refer to Figure 3A , which is a schematic diagram of the first vibration-damping colloid according to the first embodiment of the present invention. The damping gel 120 has a radial groove 122, which is recessed on the outer edge of the damping gel 120 corresponding to the radial direction of the damping gel 120 (ie, the left and right direction in the drawing), and the clamp structure 118 can pass through the radial directi...

no. 2 example

[0038] Different from the first embodiment, the vibration-damping colloid of the second embodiment of the present invention forms grooves inside it to change the elastic coefficients of the vibration-damping colloid in different axial directions, thereby adjusting the different vibration-damping colloids. Axial damping capacity.

[0039] Please refer to Figure 4A , which is a schematic diagram of the first vibration-damping colloid according to the second embodiment of the present invention. The damping gel 120 has a radial groove 122, which is recessed on the outer edge of the damping gel 120 corresponding to the radial direction of the damping gel 120 (ie, the left and right direction in the drawing), and the clamp structure 118 can pass through the radial direction. The groove 122 clamps the damping glue 120 . It is worth noting that the damping gel 120 further has an axial groove 128, which is recessed on the outer edge of the vibration damping gel 120 corresponding to ...

no. 3 example

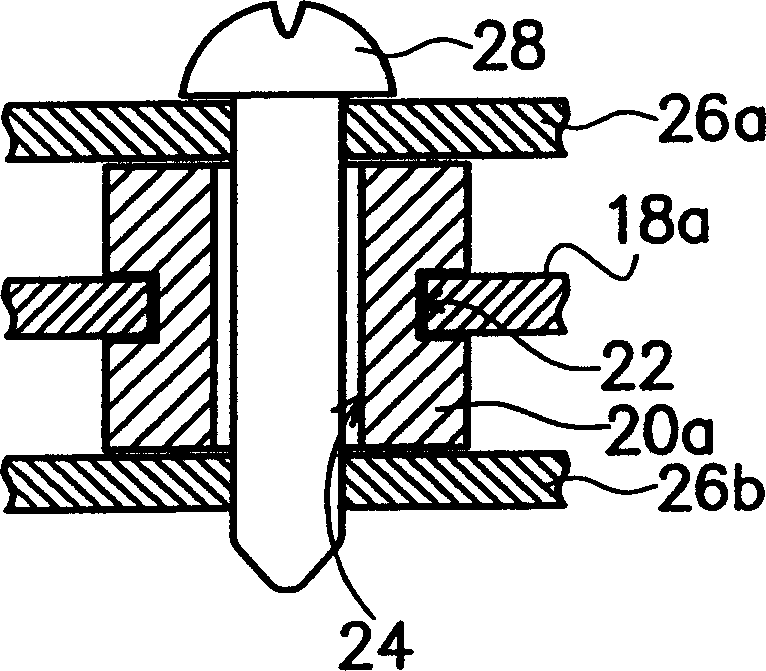

[0043] The third embodiment of the present invention discloses a vibration damping structure, which is mainly composed of vibration damping colloid and clamp structure, and can be changed by changing the size of the contact surface between the vibration damping colloid and the clamp structure. And distribution, and then adjust the damping capacity of the damping structure in different axial directions.

[0044] Please refer to Figure 5 , which is a schematic diagram of the damping structure of the third embodiment of the present invention. The damping structure 130 includes a damping colloid 120 and a clamp structure 118, wherein the damping colloid 120 has a radial groove 122, which is recessed in the vibration-damping colloid 120 corresponding to the radial direction (ie, the left and right directions in the drawing). The outer edge of the rubber body 120 and the clamp structure 118 can pass through the radial groove 122 to clamp the vibration-damping rubber body 120 . It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com