Adhesive-free carpet tiles and methods of installing adhesive-free carpet tiles

An adhesive-free, carpet-free technology for applications in carpet-fastening fixtures, carpets, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

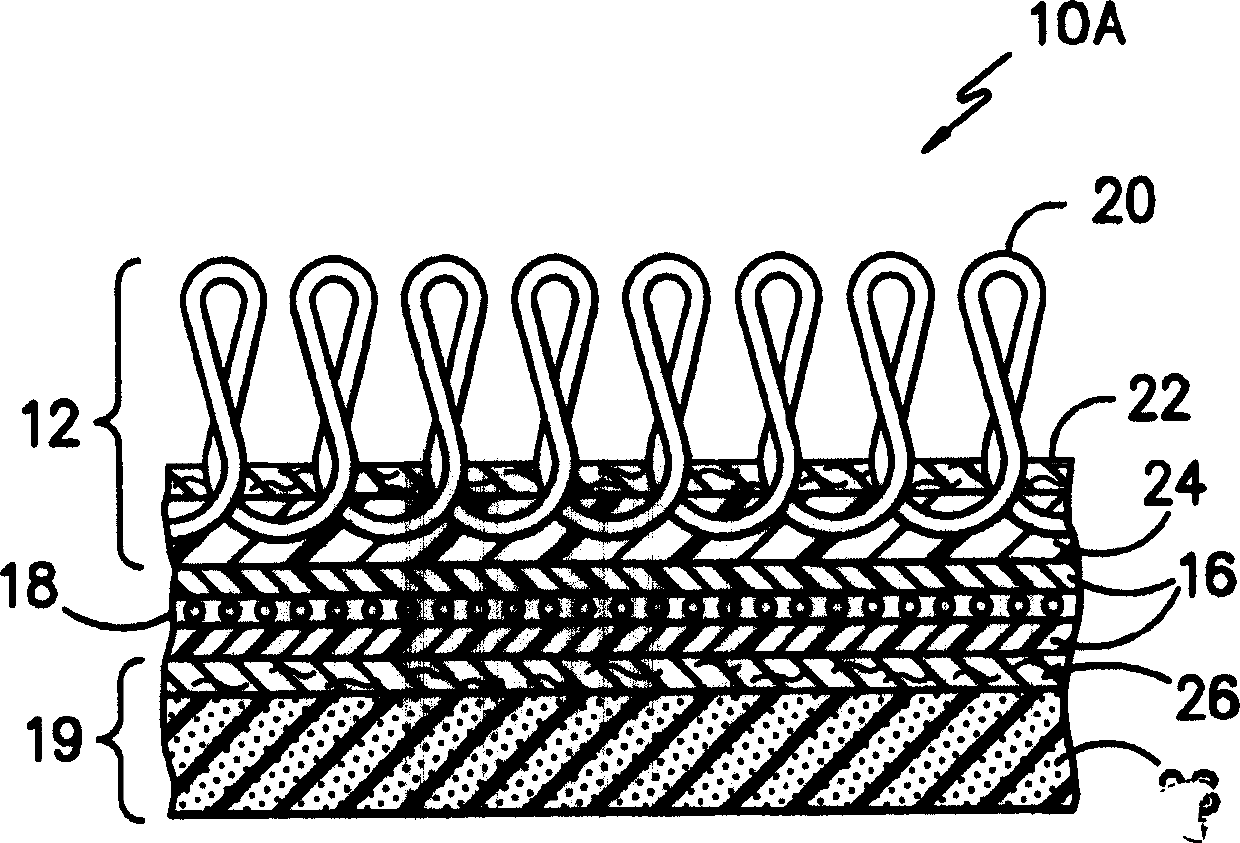

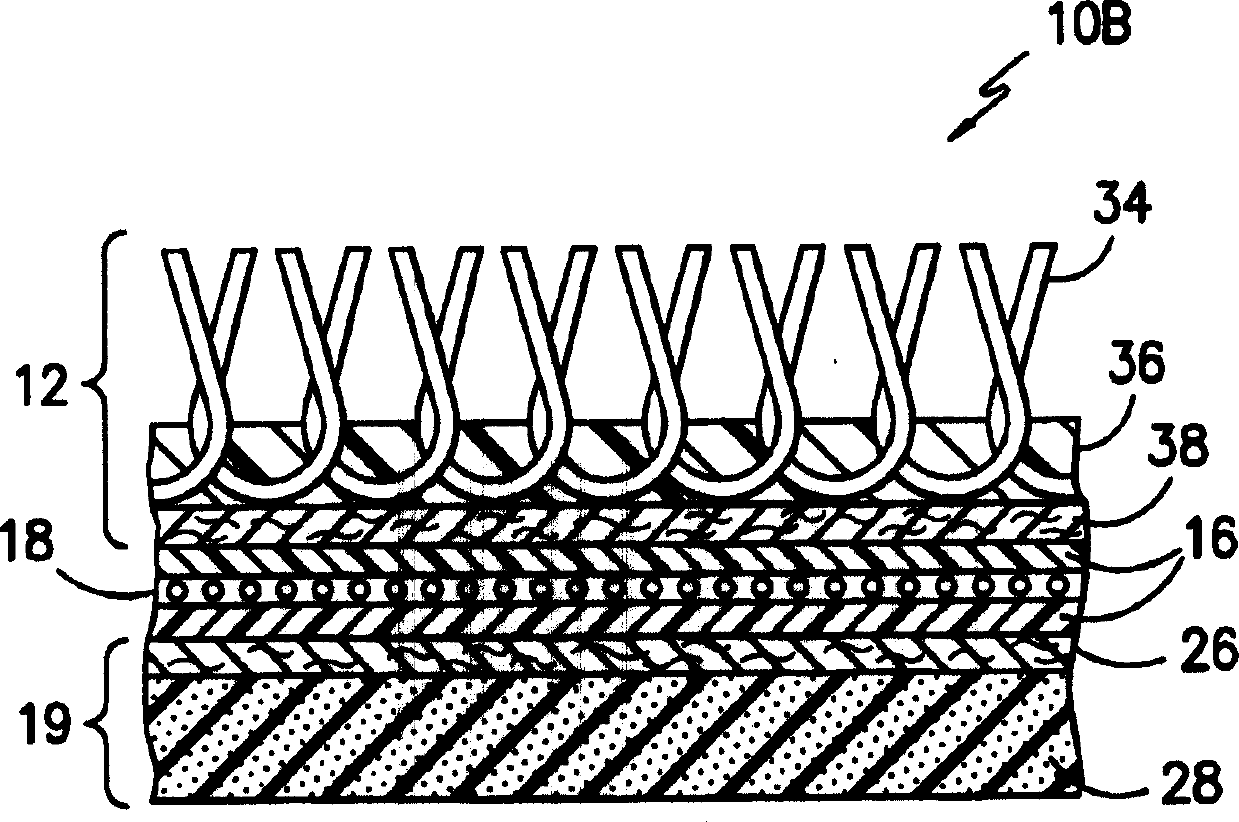

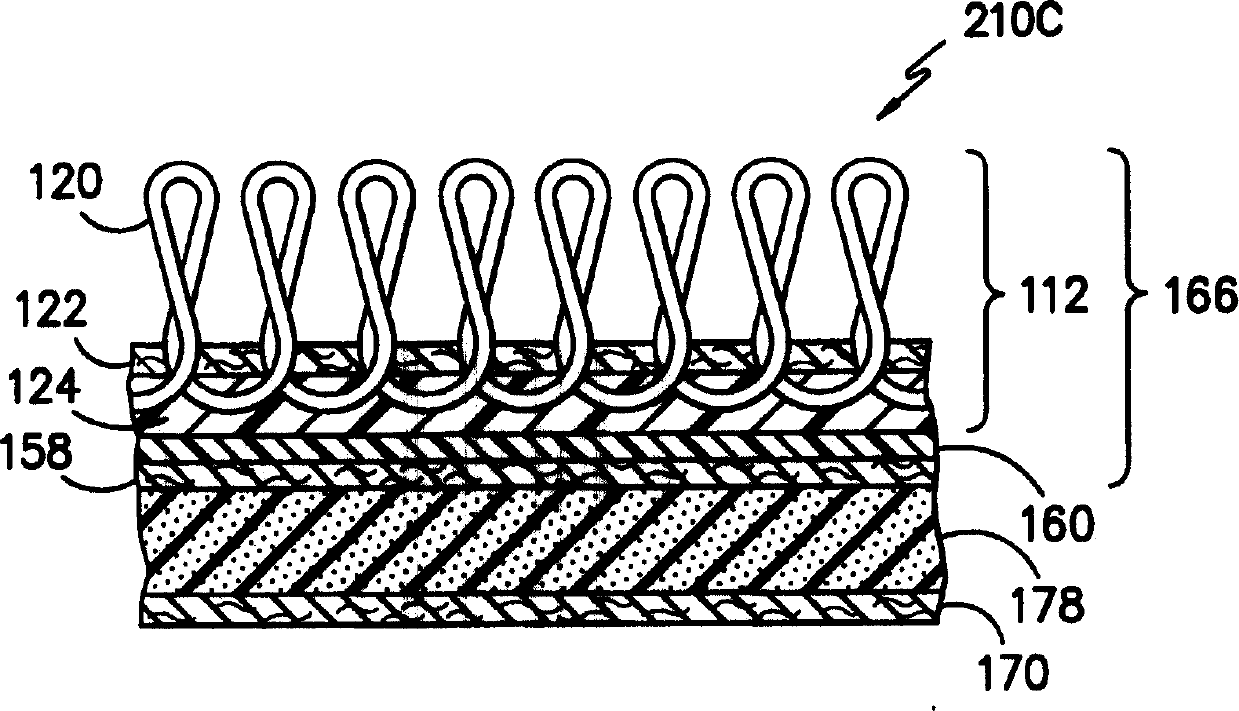

[0186] Tufted carpets were produced by using the apparatus and method shown in FIG. 2 . The carpet product produced had the configuration shown in Figure 3A. Production parameters are described below.

[0187] yarn

15 oz / yd2, nylon 6,6, bouclé

continuous filament

main backing

4 oz / sq yd, non-woven polyester

precoat

16 oz / yd2 with 100 parts CaCO 2

Filled SBR Latex

hot melt adhesive

42 oz / square yard

Modified polypropylene

Lamination strength

2 oz / sq yd with acrylic adhesive

non-woven glass

polyurethane foam covering

20 oz / square yard

Polyurethane Foam Density

16 oz / cubic foot

Backing material

4 oz / sq. yd., nonwoven (50% polypropylene

vinyl, 50% polyester)

[0188] structure

surface fiber

100% Milliken Certified WearOn®

nylon

soil protection agent

MilliGuard®

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com