Double-face electronic processor-camera mechanism and method for controlling its toner image concentration

A technology of toner image and developing mechanism, which is applied in the direction of electric recording process applying charge pattern, equipment for applying electric recording process of charge pattern, electric recording technique, etc. control the toner image density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Reference will now be made in detail to the presently preferred embodiments of the invention, examples of which are shown in the accompanying drawings, wherein corresponding reference numerals represent corresponding elements throughout. The embodiments are described in order to explain the present invention by referring to the figures.

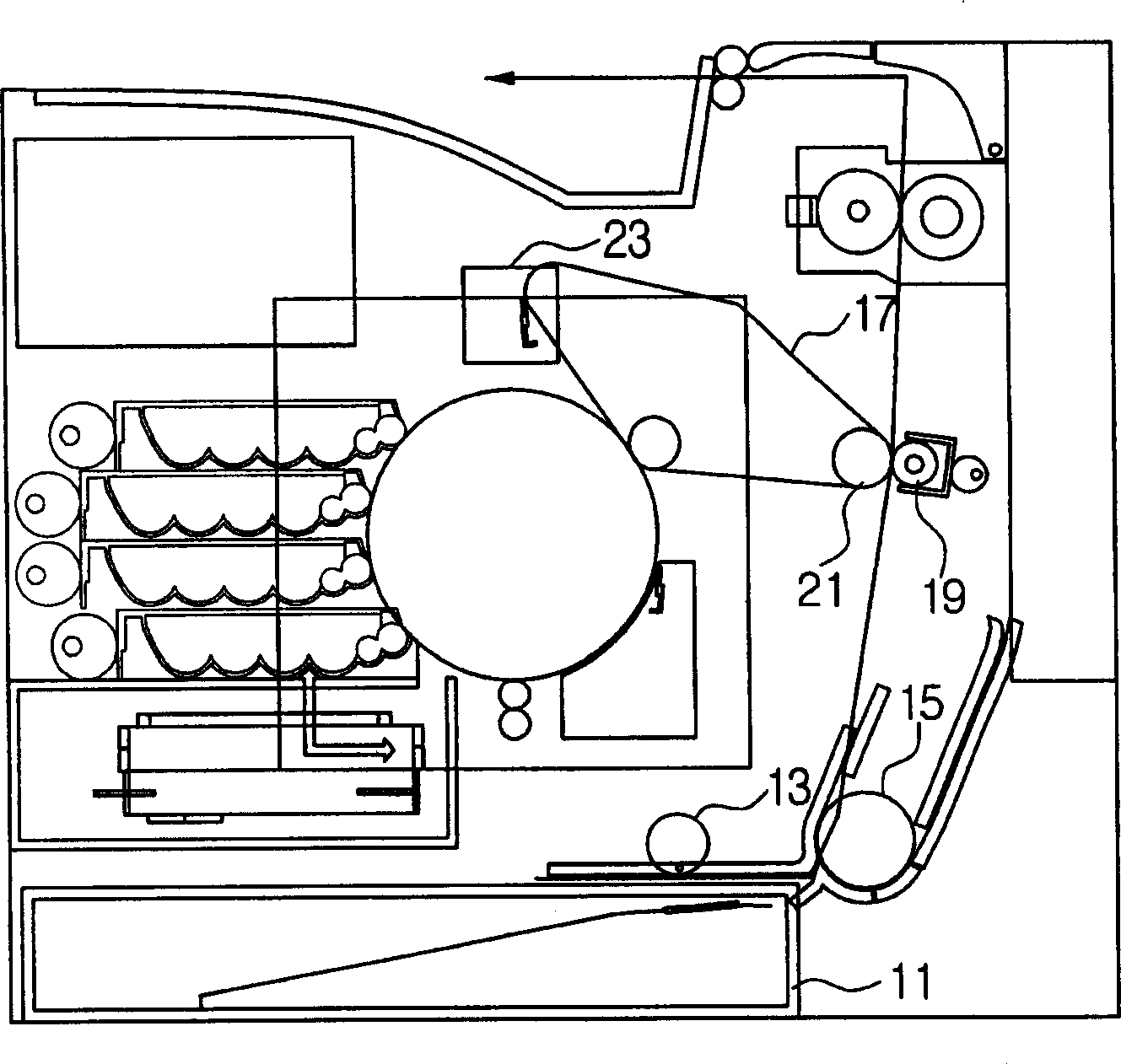

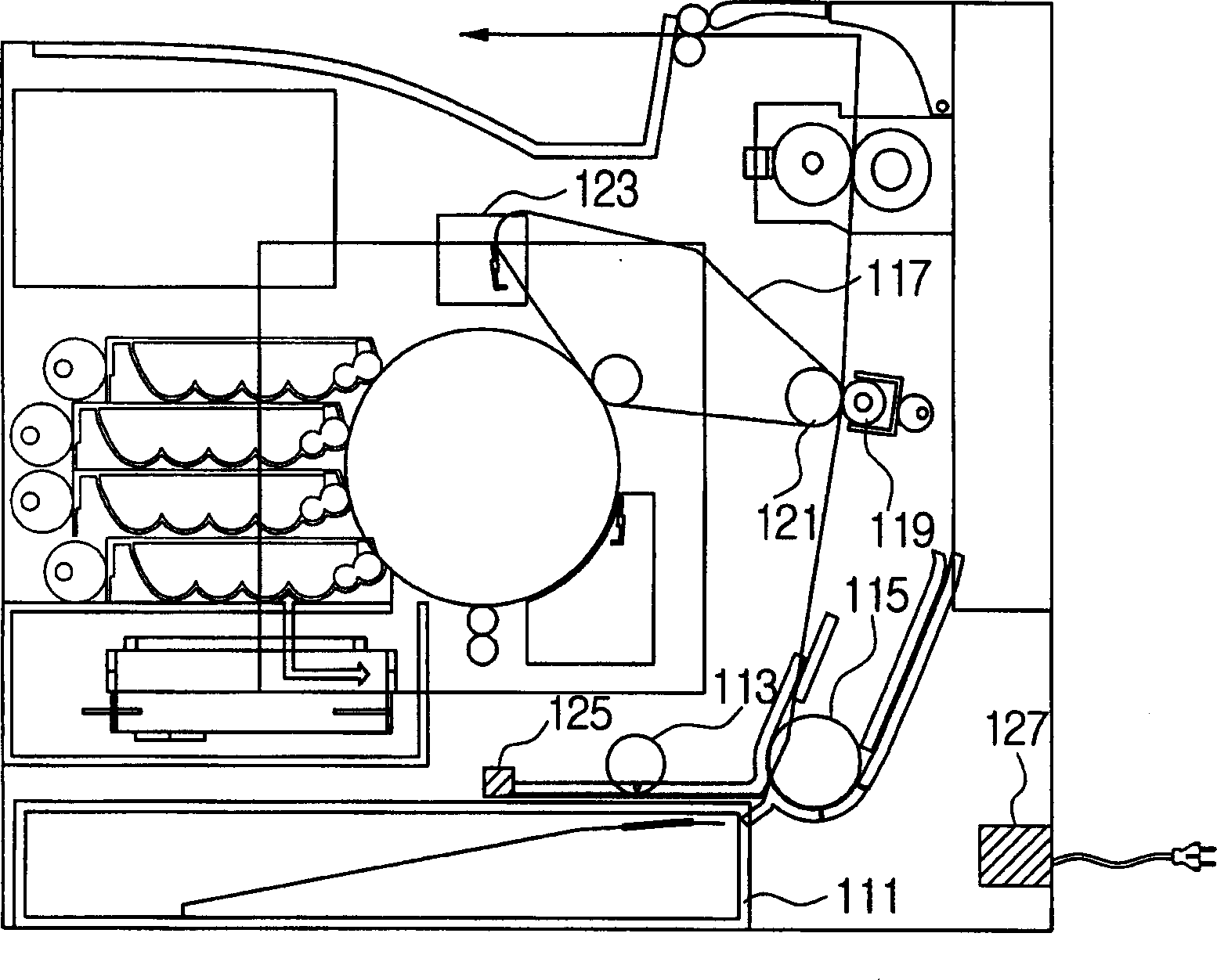

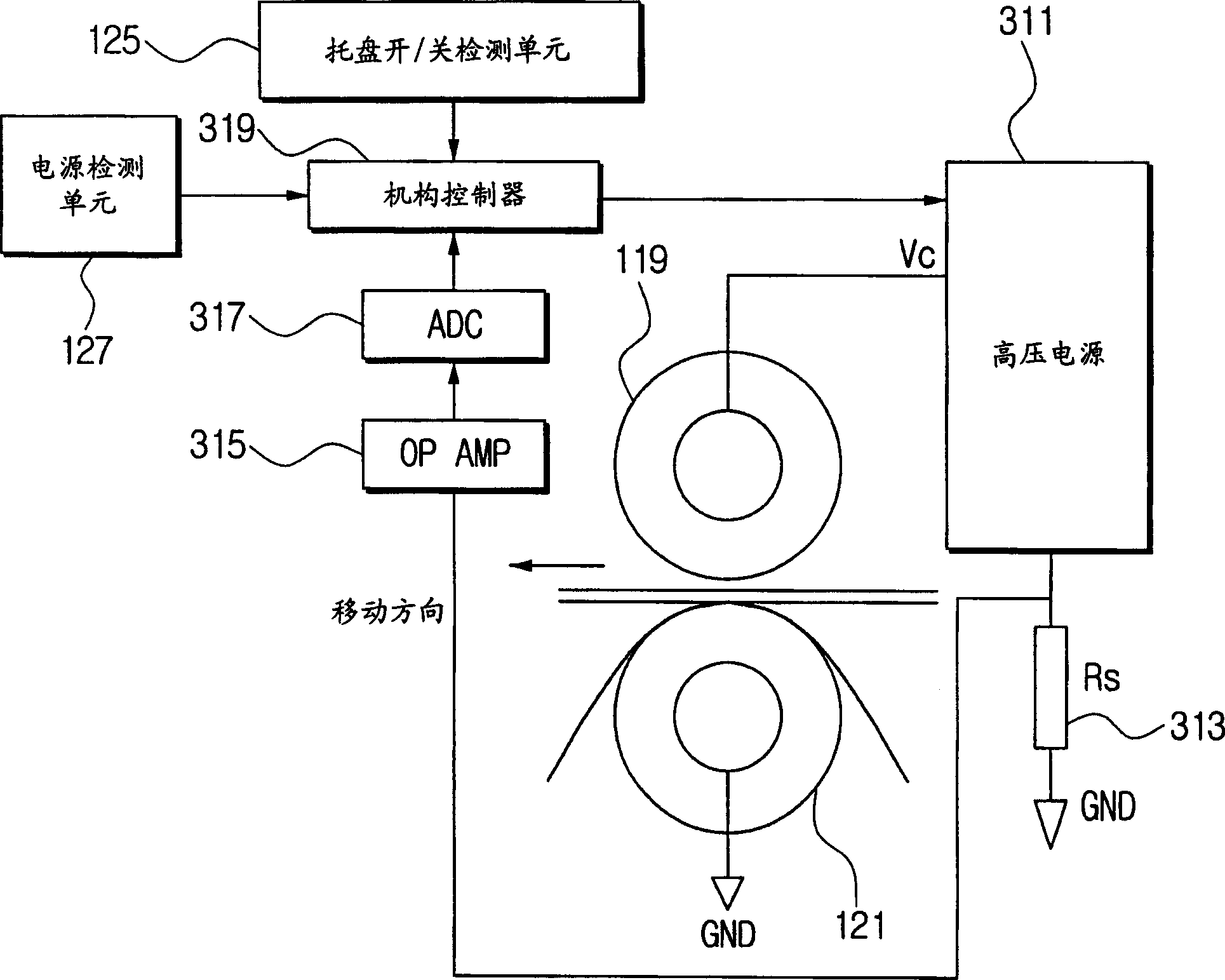

[0025] figure 2 It is a schematic diagram of a double-sided electrophotographic developing mechanism according to an embodiment of the present invention. refer to figure 2 , the double-sided electrophotographic developing mechanism includes: a printing medium tray 111, a pick-up roller 113, a supply roller 115, a photosensitive belt 117, a transfer roller 119, a fixing roller 121, a toner image forming unit 123 , a tray opening / closing detection unit 125 and a power detection unit 127 .

[0026] The print medium tray 111 is located at a desired position of the electrophotographic developing mechanism, and sorts and loads print med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com