Method of measuring temperature of object to be measured, dust temperature and dust concentration

A technology for measuring objects and dust, applied in radiation pyrometry, measuring devices, optical radiation measurement, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

[0047] First, the measurement method of the present invention will be described by taking the case where the number of the above-mentioned objects is one as an example.

[0048]

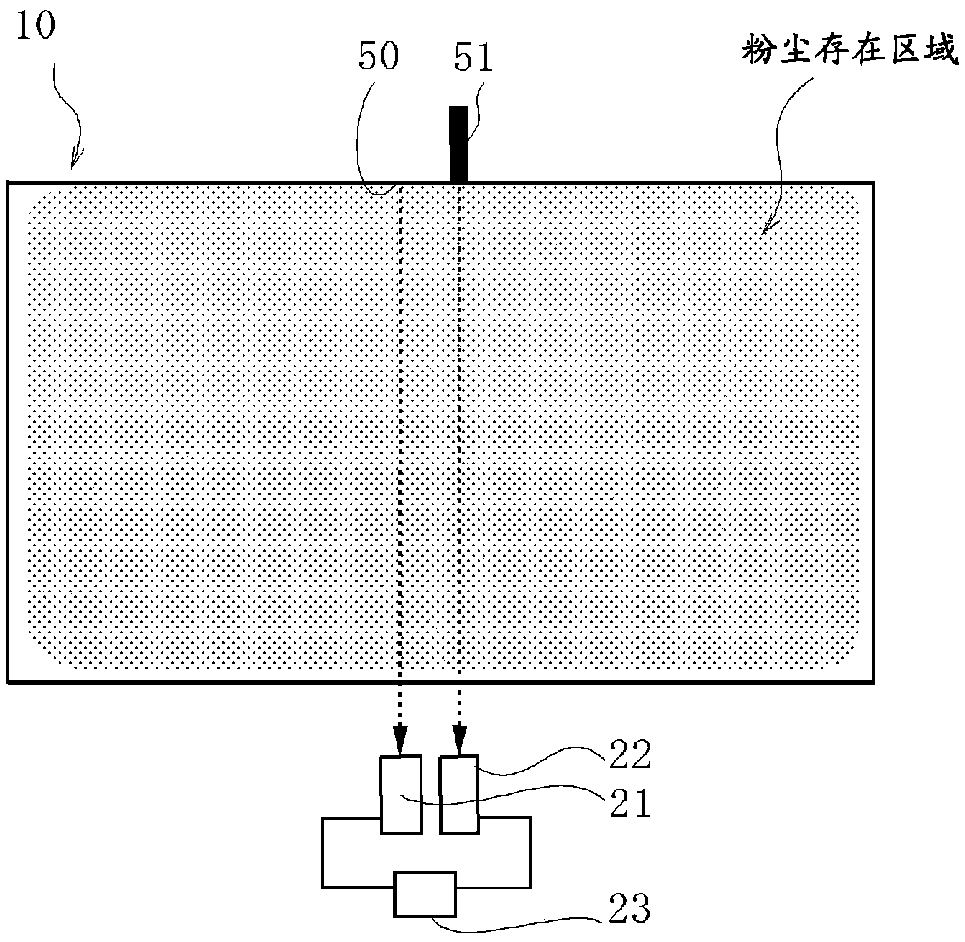

[0049] In the measurement method of the first embodiment, if figure 1 As shown, the temperature and the like of the object to be measured 50 present in the container 10 are measured using the first radiance meter 21 and the second radiance meter 22 installed outside the container 10 containing the object to be measured 50 . The first radiance luminance meter 21 measures radiance through a space in which dust exists, with the radiance meter facing the object 50 so that the object 50 exists on the optical axis. On the other hand, the second radiance luminance meter 22 faces the object 51 with the radiance luminance meter facing the object 51 in such a manner that an object 51 having a temperature different from that of the object 50 to be measured exists on the optical axis. Space to measure radianc...

no. 2 Embodiment approach >

[0111] Next, the measurement method of the present invention will be described by taking the case where the number of the above-mentioned objects is two as an example.

[0112]

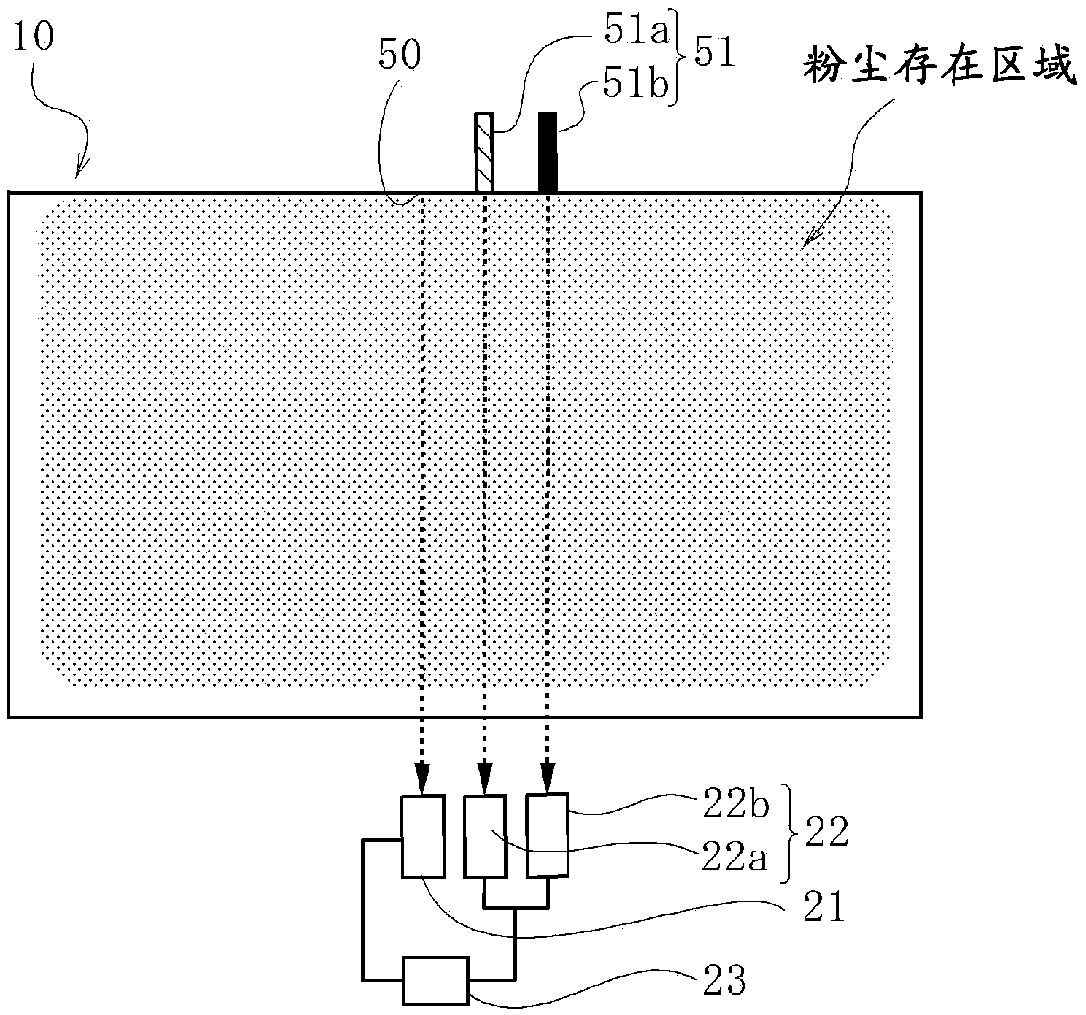

[0113] In this second embodiment, if image 3 As shown, the number of objects 51 is set to 2, and as the second radiance meter 22, two second radiance meters 22a, 22b are used, and the above-mentioned 1st embodiment is similarly measured respectively. Radiance.

[0114] The first radiance luminance meter 21 is directed toward the object 50 so that the object 50 to be measured exists on the optical axis, and the radiance luminance is measured across a space where dust exists. On the other hand, as for the second radiance meters 22a and 22b, the second radiance meters 22 are respectively directed toward The above-mentioned objects 51a and 51b were respectively measured for radiation luminance through a space where dust exists. In addition, for the same reason as that described in the above-mentione...

Embodiment 1

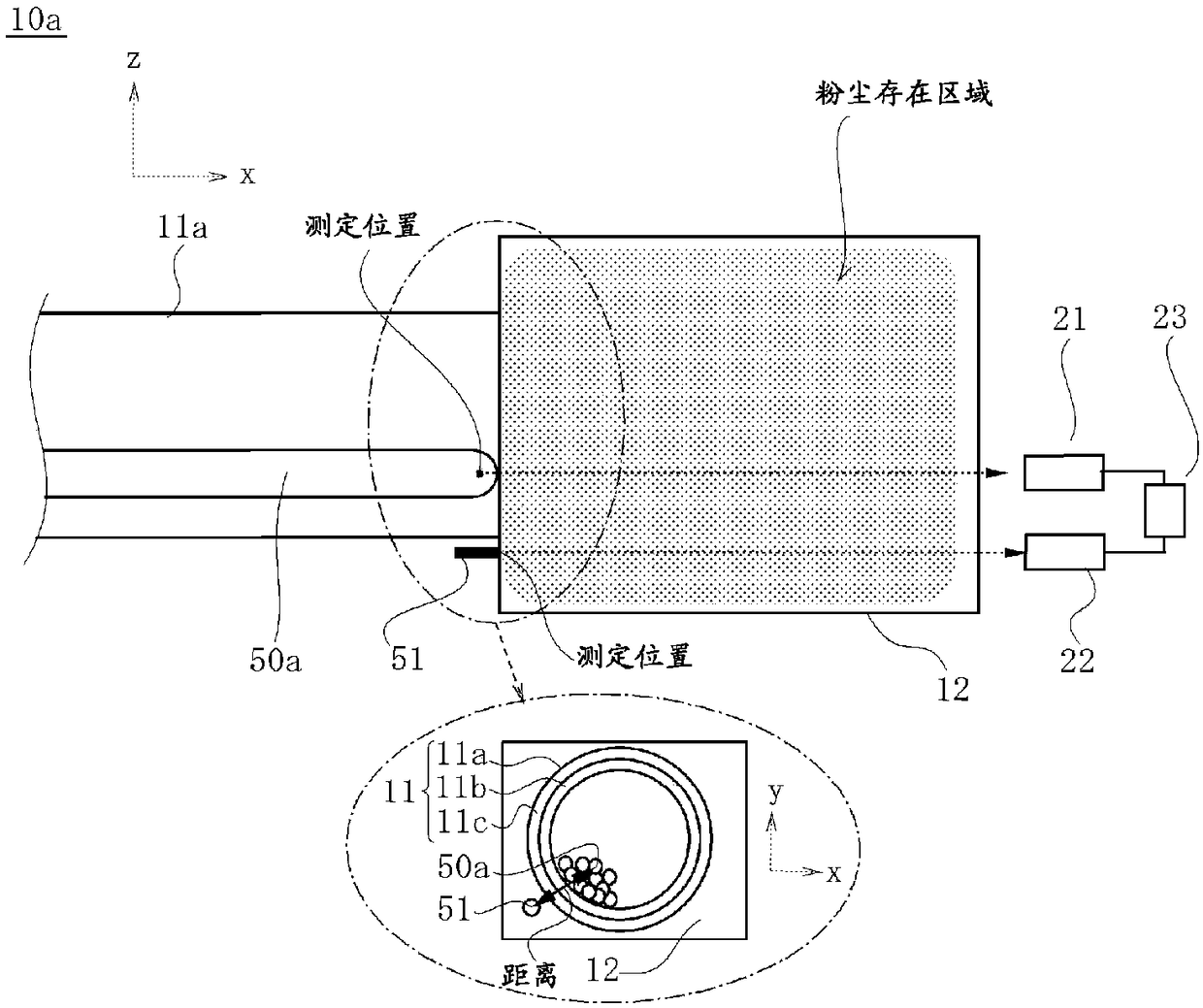

[0159] Such as figure 2 As shown, the radiant luminance of the clinker 50 a present at the outlet-side end of the kiln shell 11 a is measured by the first radiance meter 21 , and the radiance of the object 51 is measured by the second radiance meter 22 . Furthermore, in this embodiment, the black body cavity located outside the outer periphery of the outlet of the kiln shell 11 a and provided on the inner wall of the kiln cover 12 is taken as the object 51 . In addition, the distance between the measurement position of the object 51 and the measurement position of the object to be measured (frit 50a) was 100 cm, and the distance between the first radiation thermometer 21 and the second radiation thermometer 22 was 30 cm. Here, the measurement position refers to the intersection point of the optical axis of the radiance meter and the object 51 or the object to be measured (frit 50a).

[0160] Here, let the measurement wavelength be the wavelength λ 1 =0.65μm, wavelength λ 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com