Jetting controller for ink-jet printer, and its control method

A technology for inkjet printers and control devices, applied in printing devices, printing, etc., can solve problems such as deteriorating printing quality and obstructing inkjet volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the invention will now be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. The embodiments are described below in order to explain the present invention with reference to the figures.

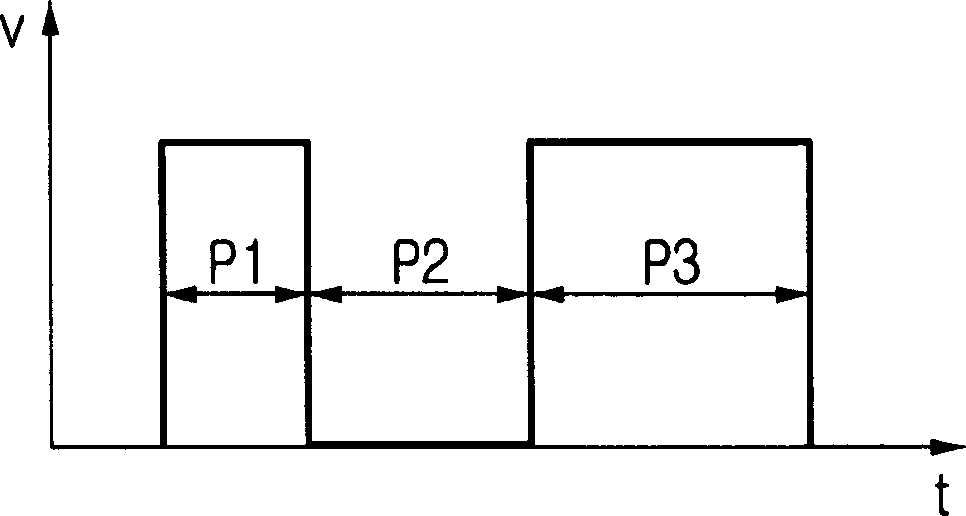

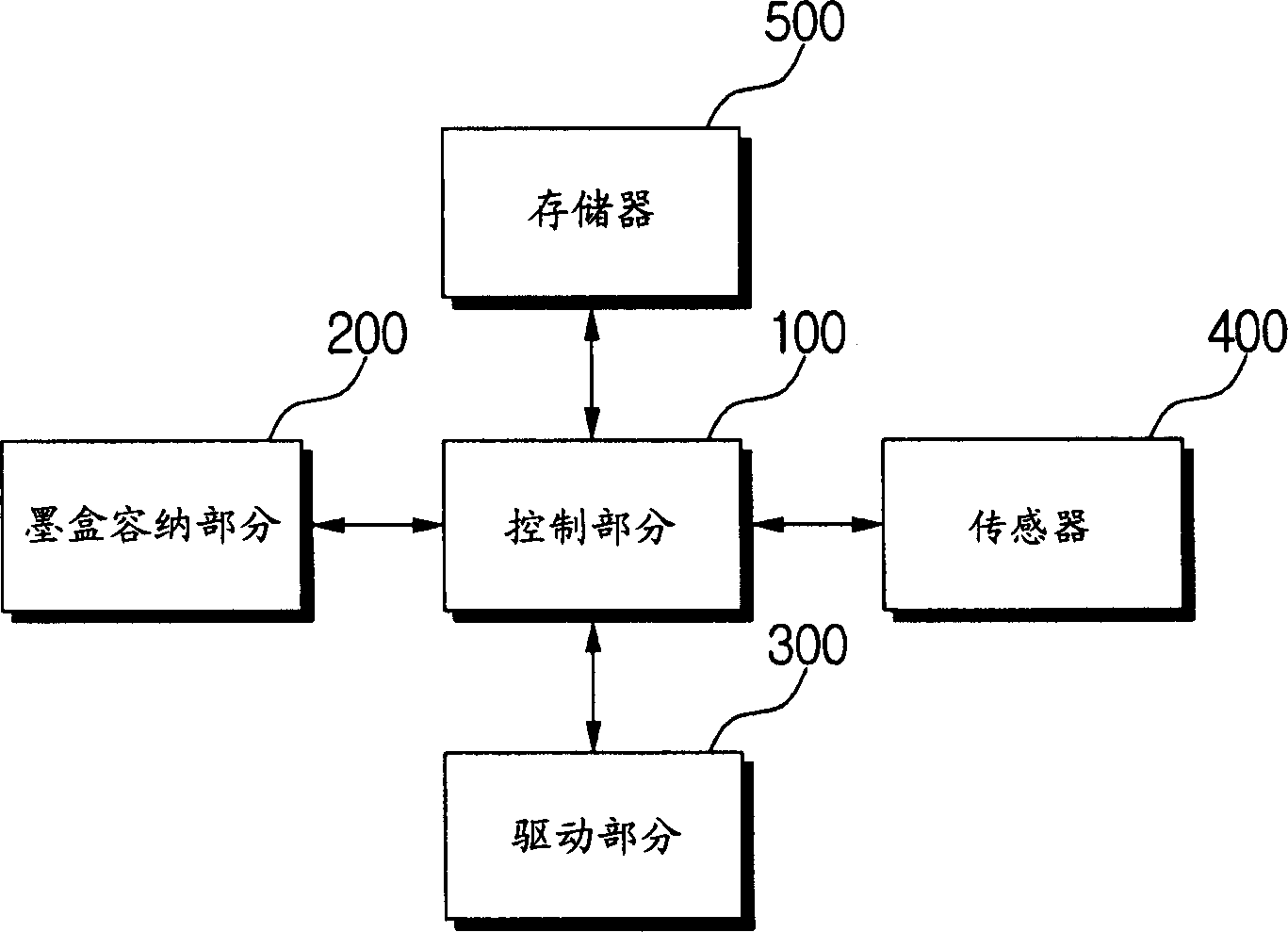

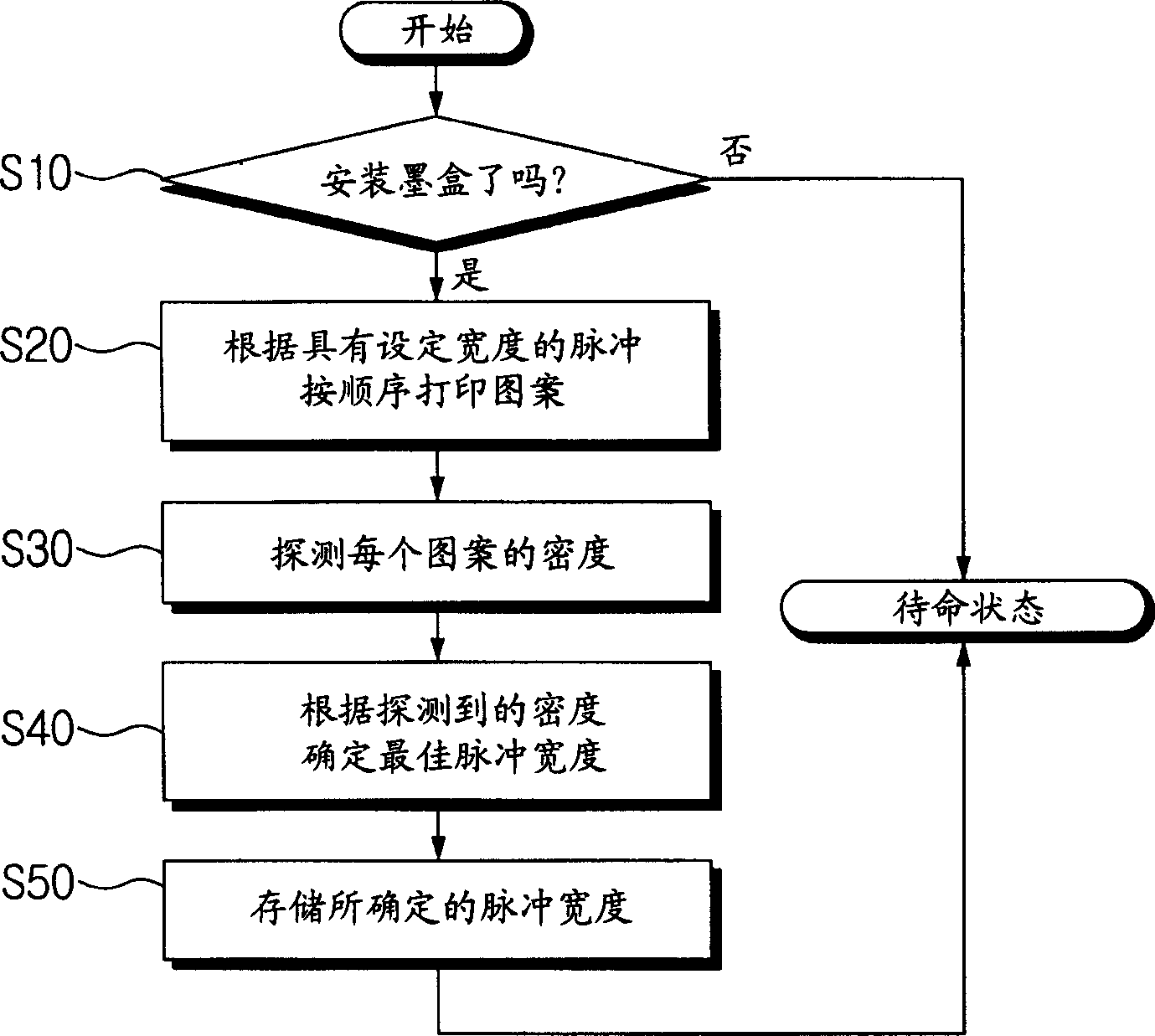

[0023] figure 2 is a block diagram of a control device for an inkjet printer according to an embodiment of the present invention. Such as figure 2 As shown, the control means includes an ink cartridge accommodating portion 200 for accommodating an ink cartridge, a driving portion 300 for driving an ink ejection heater to perform a printing operation, a sensor 400 for sensing a printing density of a printing pattern, setting a width of a pulse to be input into the ink ejection heater and A control section 100 that controls a control device for the inkjet printer as a whole, and a memory 500 for storing an optimum pulse width determined by the control section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com