Debarking shaft arrangement for debarking mechanism

A shaft device and bark technology, which is applied to bark, manufacturing tools, wood processing appliances, etc., can solve the problems of inconvenient maintenance and high cost of worn teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

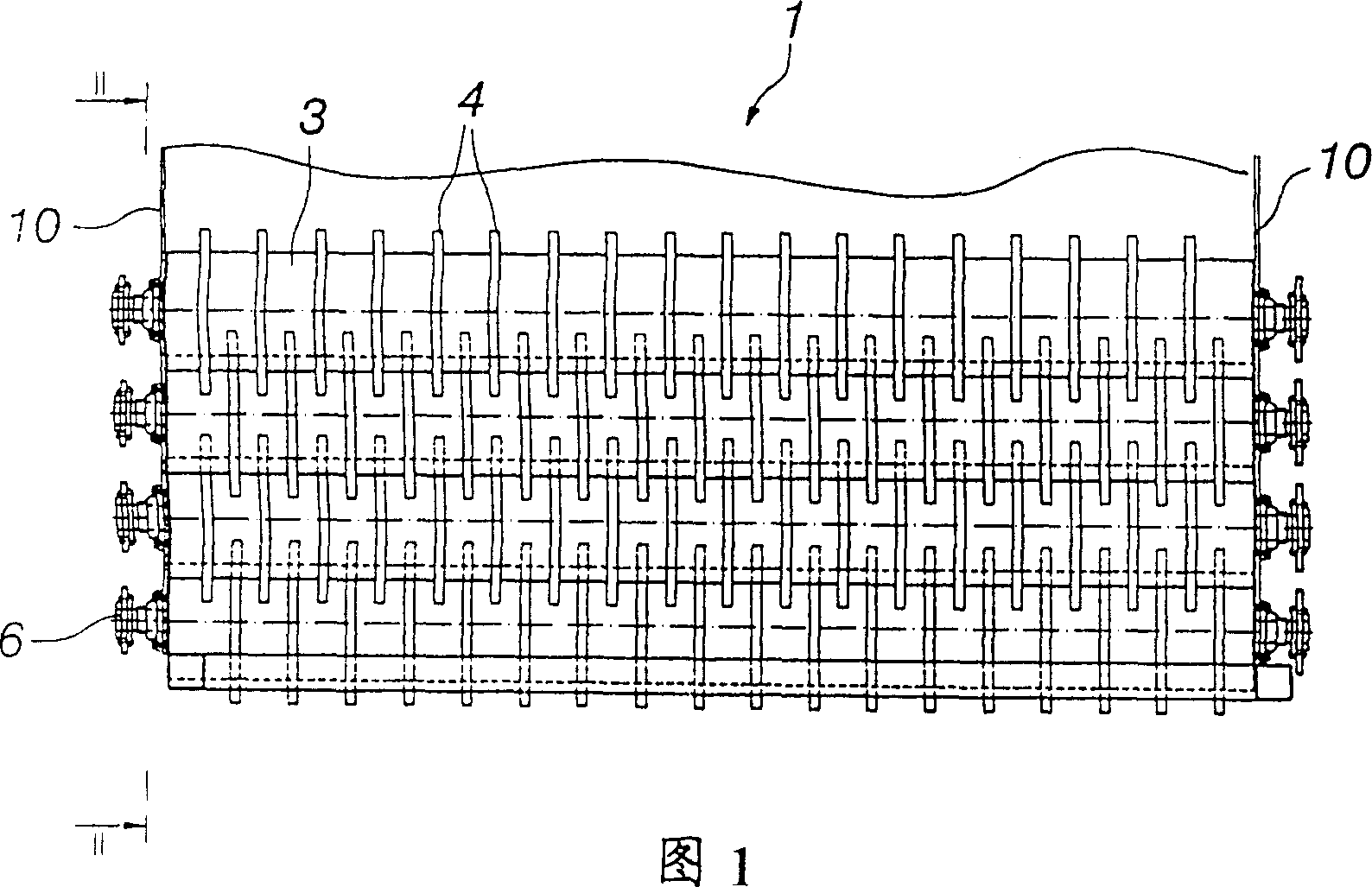

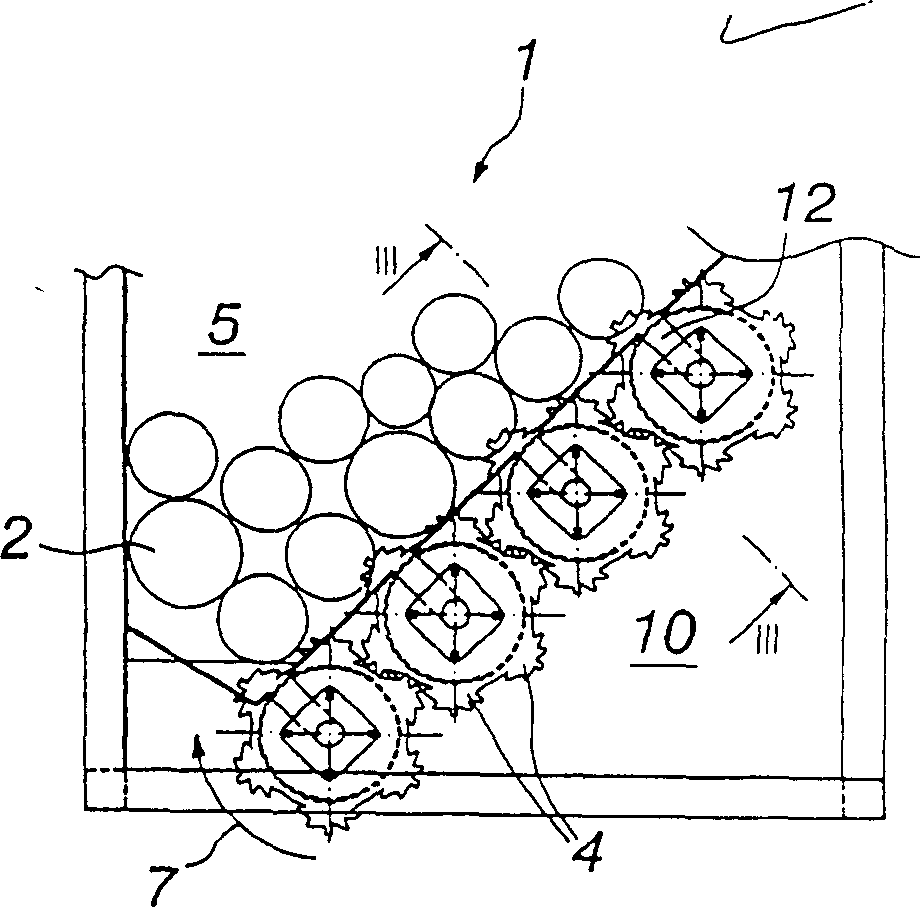

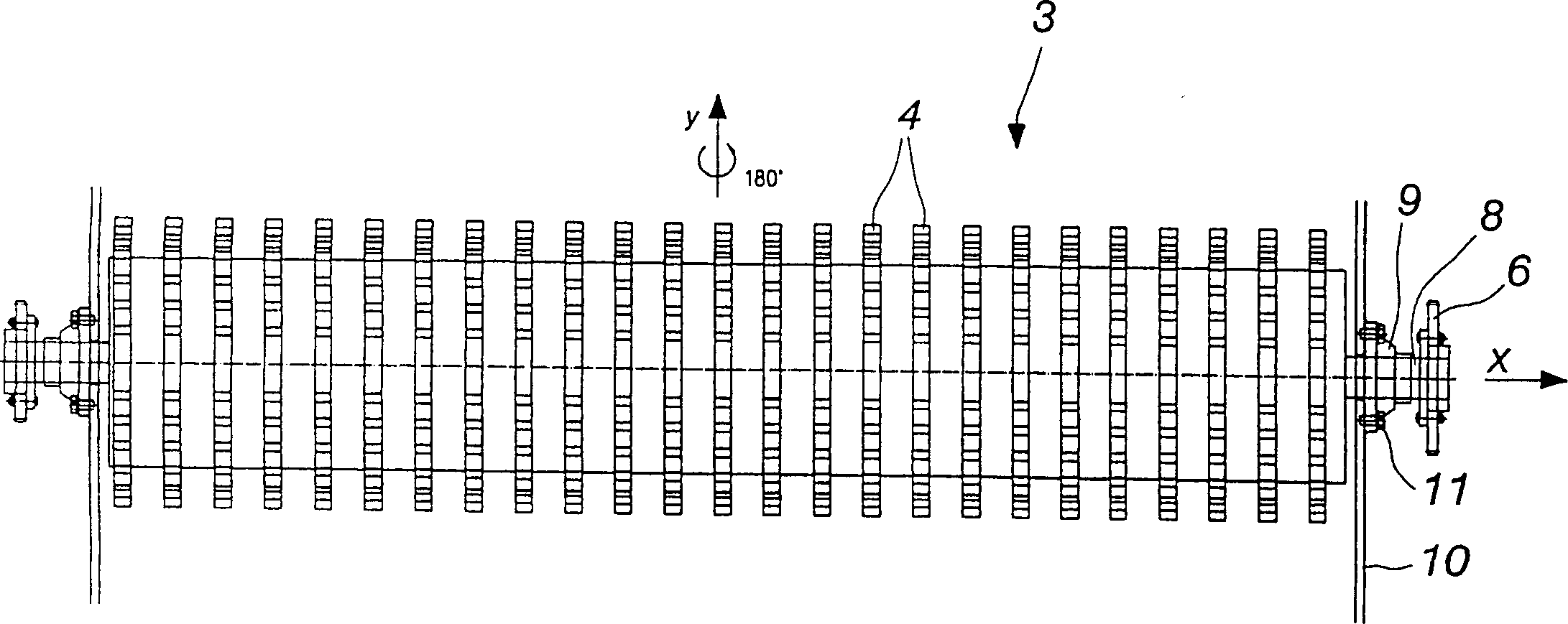

[0014] A debarking mechanism 1 is depicted in the figure for debarking or pre-treatment of trees 2 for final debarking performed separately and for removing at least some of the debarked bark from the timber stream passing through the debarking mechanism.

[0015] The debarking mechanism 1 is provided with a plurality of rotatable debarking shafts 3 extending parallel to the feed direction in which the trees 2 are fed. In the illustrated example, each end of the peeling shaft 3 is provided with a sprocket 6, whereby at least one end of the peeling mechanism 1, the sprocket 6 passes through a sprocket chain (not shown). out) to each other and to the gear of an electric motor not shown.

[0016] Said stripping shaft 3 is provided with a plurality of teeth 4 extending beyond the circumferential surface of said shaft 3, said teeth being suitable for stripping the tree 2 being processed transversely to the length of the tree and simultaneously relative to said stripping shaft 3. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com